Link 2620 User manual

System 2600

2620 Sensor

Interface

Installation and Operating

Manual

Doc # L-2600-1020

Rev. 01

Link Electric & Safety Control Co.

444 McNally Drive

Nashville, TN 37211

Phone: (615) 833-4168

Fax: (615) 834-1984

© 2019

Doc #: L-2600-1020 Page 1 Rev. 01

Table of Contents

1INTRODUCTION .............................................................................................................................. 3

1.1 Features ........................................................................................................................................ 3

1.2 Specifications ............................................................................................................................... 4

2INSTALLATION ............................................................................................................................... 5

2.1 Wiring........................................................................................................................................... 6

2.1.1 Power Wiring ...................................................................................................................... 6

2.1.2 Internal Sensor Connector Wiring ...................................................................................... 7

2.1.3 Front Panel Sensor Connectors........................................................................................... 8

2.1.4 Wiring to the Die Protection Unit....................................................................................... 8

Doc #: L-2600-1020 Page 2 Rev. 01

Table of Figures

Figure 1: 2620 Sensor Interface .................................................................................................................. 3

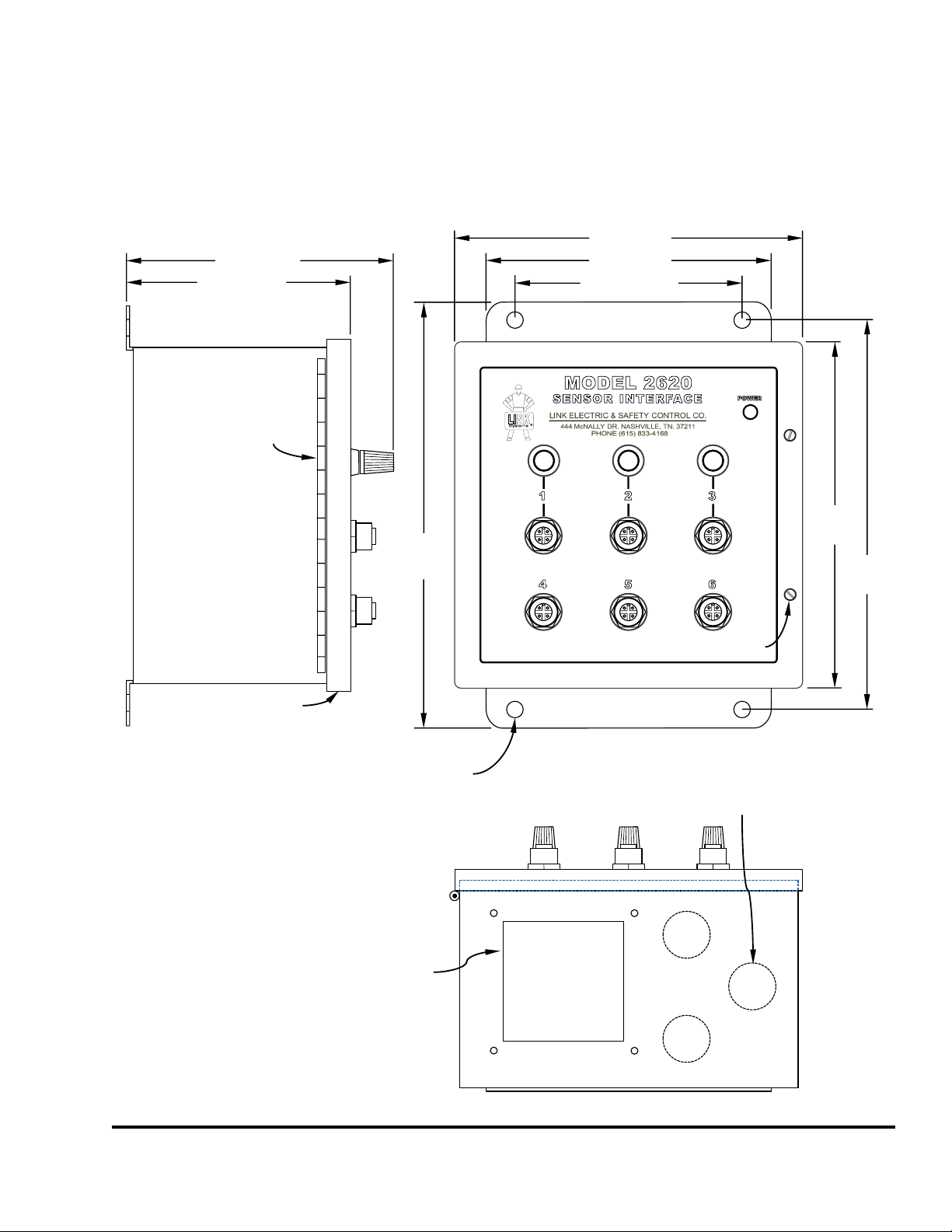

Figure 2: 2620 Sensor Interface Dimensions.............................................................................................. 5

Figure 3: 2620 Sensor Interface Internal Features...................................................................................... 6

Figure 4: Typical Wiring to Internal Sensor Connector ............................................................................. 7

Figure 5: Typical Wiring to M12 Connector .............................................................................................. 8

Figure 6: Outputs Connector....................................................................................................................... 8

Doc #: L-2600-1020 Page 3 Rev. 01

1INTRODUCTION

The 2620 Sensor Interface unit permits

convenient connection of all kinds of sensor types

to die protection logic units such as OmniLink

MPC controls, System 2600 die protection units,

or even third party units. Sensors and probes

installed in or near the die are connected to the

Sensor Interface which also provides sensor

power

.

The Sensor Interface is designed to be located

near the die to facilitate die changes, setup, and

troubleshooting. It permits quick connection of

individual sensors via industry standard M12 4

pin connectors (also known as Micro-DC or

Eurofast connectors) or of all sensors at once via

an optional Quick Connect Receptacle (Link or

customer supplied).

1.1 Features

•Solid state sensors (NPN or PNP), spring probes, and mechanical sensors may be used as inputs to

the Sensor Interface.

•Up to 8 sensors can be powered and passed through to a die protection unit via the internal

connectors (usually through a Link or customer supplied bulk quick connection).

•6 M12 4 pin sensor connectors (also known as Micro-DC or Eurofast connectors) are provided on

the face of the unit for connecting individual sensors to channels 1 - 6.

•3 Banana plug/binding post connectors are provided on the face of the unit for connecting grounding

spring probes or mechanical sensors to channels 1 - 3.

•No configuration is necessary to select sensor type. This Sensor Interface is designed for die

protections units that can select NPN or PNP sensors on their own and so passes the sensor signal

directly through.

•The Sensor Interface is powered from 115 to 230 VAC and provides 24 VDC @ 0.5 Amp total for

powering sensors. Sensor power is available on each of the front panel M12 connectors, the optional

bulkhead connector, and internal terminal strips.

•In cases where 0.5 Amps is not enough power, the Sensor Interface can be powered by an external

24VDC power supply up to 10 amps.

•The enclosure of the Sensor Interface features a removable bulkhead that can be fitted with a quick

connection receptacle so that only one cable must be plugged in from the die. Link has an optional

standard connector (a 19 pin Turck receptacle suitable for up to 16 channels) or, if desired, a

customer supplied connector can be used.

MODEL 2620

SENSOR INTERFACE

POWER

LINK ELECTRIC & SAFETY CONTROL CO.

444 McNALLY DR. NASHVILLE, TN. 37211

PHONE (615) 833-4168

1 2 3

4 5 6

Figure 1: 2620 Sensor Interface

Doc #: L-2600-1020 Page 4 Rev. 01

1.2 Specifications

Size: 6.6” X 6.6” X 4.25” deep (Not counting connections on the front or quick

connect bulkhead connector)

Input Power: 90-264VAC, 47-63Hz, 0.4Amps

OR

24VDC +/- 10%, Up to 10 Amps

Sensor Power: 24 VDC 0.5 Amps total for all sensors from internal supply

24 VDC up to 10 Amps pass-through from external supply

Total Sensor Channels: 8

Front Panel Connections: 3 Banana plug/Binding Post (channels 1 - 3)

6 M12 4-pin (channels 1 - 6)

Internal Connections: Pluggable terminal strips (channels 1 - 8)

NOTE: Unit should be powered by AC power OR DC

power, Not Both!

Doc #: L-2600-1020 Page 5 Rev. 01

2INSTALLATION

The dimensions and mounting footprint of the Sensor Interface are shown below in Figure 2. When

mounted to the press frame or other high shock areas, Link highly recommends using the included

shock mounts, which will add about 0.75 inches (19mm) to the depth of the unit.

6.6” (167)

0.31” (7.9)

diameter

(4 places)

4.25” (108)

5.4” (137)

6.6”

(167)

7.25”

(184)

8”

(203)

4.25” (108)

5.3” (135)

Door

Values in parentheses

are in millimeters

Hinge

Door Screws

(2 places)

2.25” (57)

Square Opening

for Quick Connect

(Plate Provided)

0.875” (22)

diameter

knockout

(3 places)

Figure 2: 2620 Sensor Interface Dimensions

Doc #: L-2600-1020 Page 6 Rev. 01

2.1 Wiring

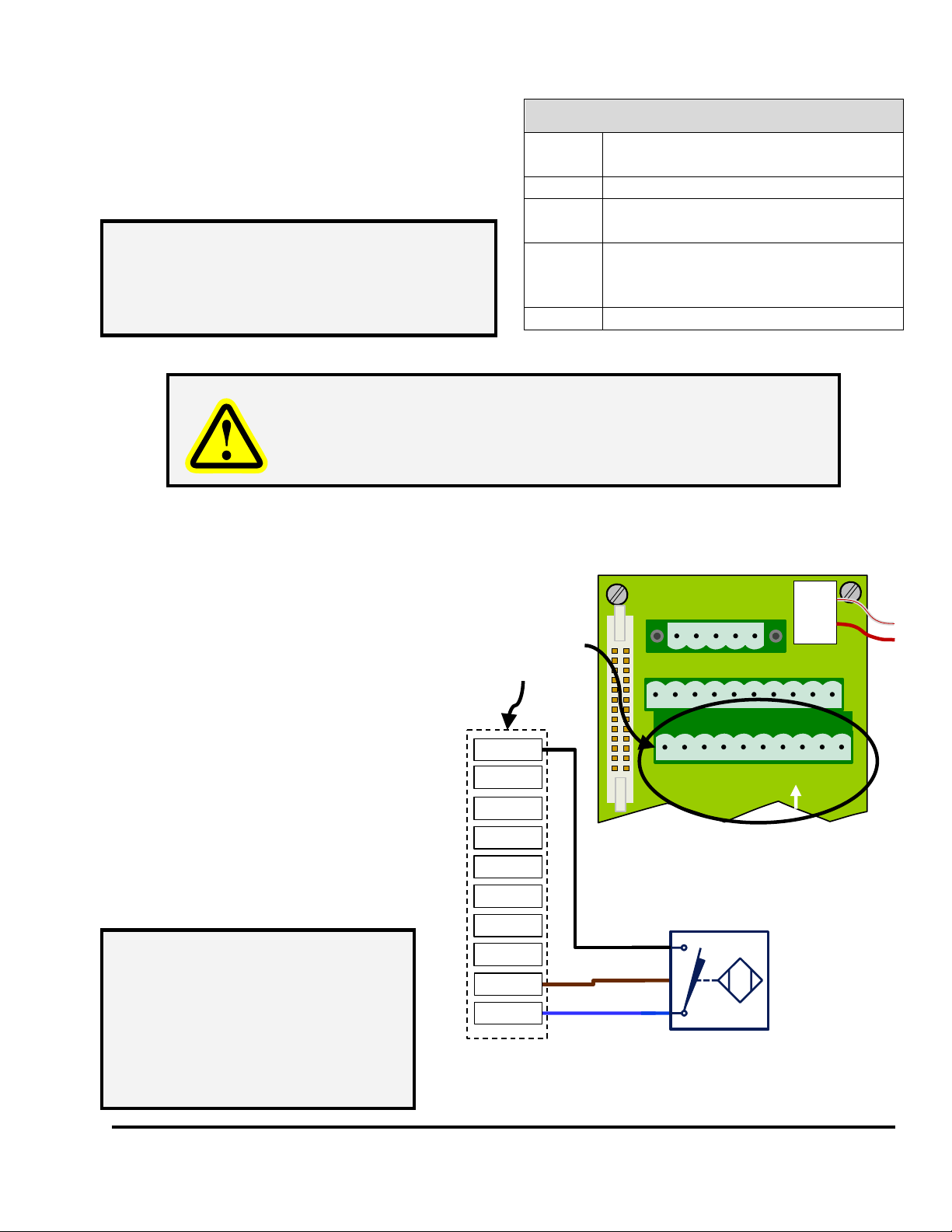

In the following sections, refer to Figure 3below for the locations of particular connectors and other

relevant features.

2.1.1 Power Wiring

WARNING:

National Codes and standards (NEC, VDE, BSI, etc.) and local codes

outline provisions for safely installing electrical equipment.

Installation must comply with specifications regarding wire types,

conductor sizes, branch circuit protection, and disconnect devices.

Failure to do so may result in personal injury and/or equipment

damage.

The Sensor Interface is typically powered by 115VAC, but can be powered from 100 to 240 VAC OR

can pass through an external 24 VDC supply at up to 10 Amps. An external +24 VDC power supply

might be used in cases where unusually high power draw sensors require more than the 0.5 Amps of

current that is available from the internal power supply of the Sensor Interface. Pull power wires with

the appropriate color code in conduit between the Sensor Interface enclosure and the source of power.

Knockouts are provided at the bottom of the enclosure for this purpose.

Power Supply

WARNING

Hazardous Voltage

Contact may cause

Injury or death.

Remove power

Before servicing.

L1

L2

PE

+24

GND

REMOVE JUMPER

IF USING EXTERNAL

+24 VDC SUPPLY

O1 O2 O3 O4 O5 O6 O7 O8 NC GND

TOP ROW: OUT TO DIE PRO. UNIT

I1 I2 I3 I4 I5 I6 I7 I8 +24 GND

BOTTOM ROW: SENSOR CONNECTIONS

O1

O2

O3

O4

O5

O6

O7

O8

NC

GND

I1

I2

I3

I4

I5

I6

I7

I8

+24

GND

TURN THE CORRESPONDING

SWITCH ON FOR CHANNELS

USING BANANA PLUGS OR PIN

2 OF THE M12 CONNECTORS

CONNECTED TO “WHISKER”

SENSORS OR SPRING PROBES

1 2 3 4

Whisker Probe

Switches

Internal

Sensor

Connector

Outputs to

Die Pro. Unit

Connector Power

Connector

Power

Jumper

Figure 3: 2620 Sensor Interface Internal Features

Doc #: L-2600-1020 Page 7 Rev. 01

When using AC power, use the L1, L2 and PE

terminals. When using an external +24 VDC power

supply, use the +24, GND, and PE terminals. The

table at right shows the usage and specifications of

the connections on the power connector.

WARNING:

The Sensor Interface can be powered from EITHER 100-240VAC OR

+24VDC. Never hook up both AC and DC power at the same time.

When using an external +24 VDC supply, make sure the Power

Jumper (see Figure 3) is removed so that the internal +24 VDC supply

is disconnected.

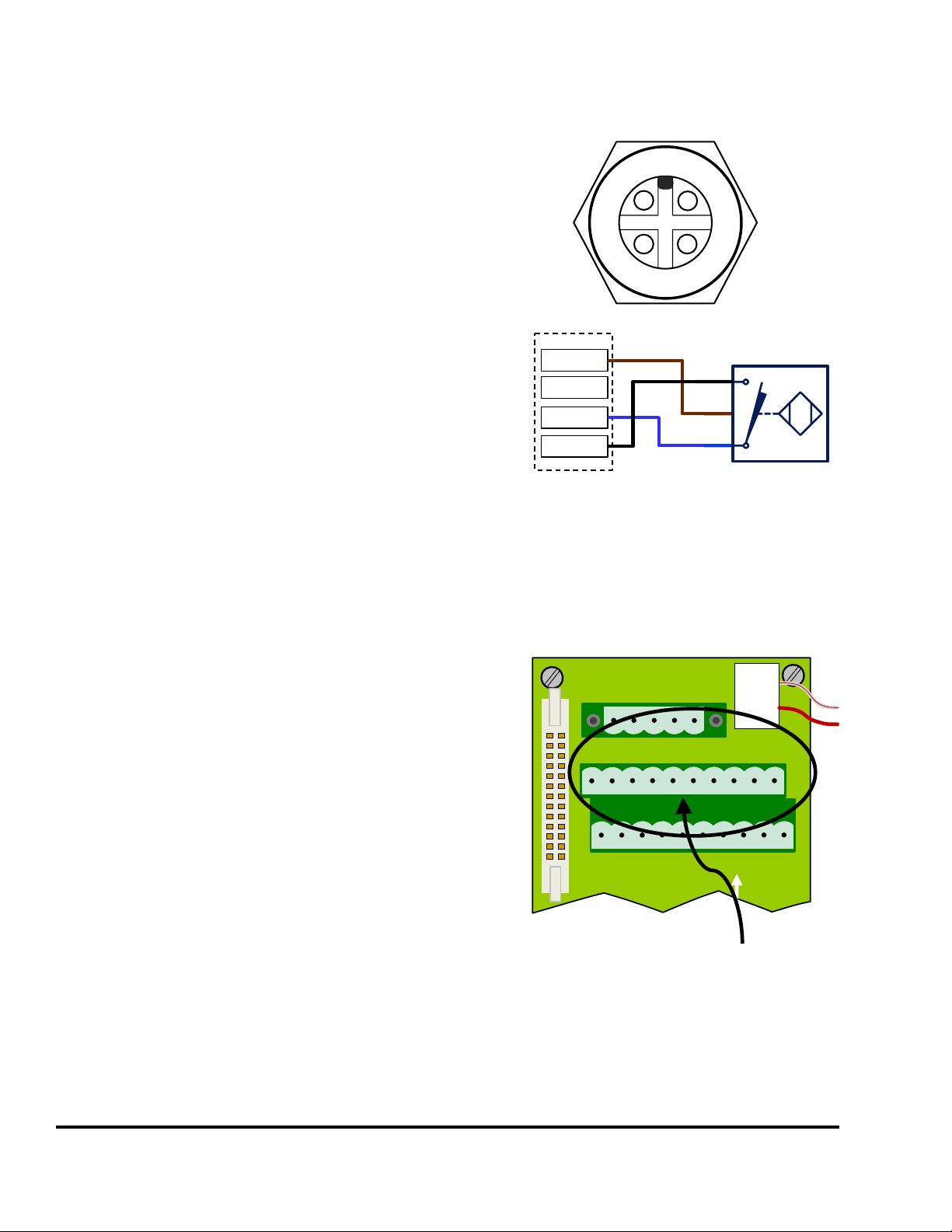

2.1.2 Internal Sensor Connector Wiring

The Internal Sensor Connector (see Figure

3) is primarily used in conjunction with a

Quick Connect bulkhead connector for

mass die termination or if there are some

sensors that are always present on the

machine regardless of what die is

installed. Link offers (Link PN 109090)

an optional quick connect bulkhead

connector (using a Turck CS-19

connector) that is prewired and ready to

plug into the Internal Sensor Connector.

Figure 4 at right shows how a typical

sensor is wired into this connector. The

unit is supplied with a blank plate for

mounting an existing connector if a

connector system is already in use.

Power Connector (See Figure 3)

L1

90 – 264 VAC Line

29 VA (0.4 Amp at 90 VAC)

L2

100 – 240 VAC Neutral

PE

Protective Earth (used with both AC

and DC input power)

+24

+24 VDC Input Power

(Up to 10 Amps can be passed

through)

GND

Ground - +24VDC Return

NOTE: When using an externa +24 VDC

supply, the Power Jumper (see

Figure 3) must be removed. This

disconnects the internal +24 VDC

supply of the Sensor interface.

L1

L2

PE

+24

GND

O1

O2

O3

O4

O5

O6

O7

O8

NC

GND

I1

I2

I3

I4

I5

I6

I7

I8

+24

GND

Internal

Sensor

Connector

1

6

4

5

2

3

7

8

I1

I6

I4

I5

I2

I3

I7

I8

9

10

+24

GND

NPN

BN

BU

NPN

Proximity

Sensor

BK

Figure 4: Typical Wiring to Internal Sensor Connector

NOTE: If a Quick Connect bulk

connector is wired into this

connector but there are

inputs that are not actually

connected in the die, then

the corresponding front

panel connectors are still

available for use.

Doc #: L-2600-1020 Page 8 Rev. 01

2.1.3 Front Panel Sensor Connectors

There are 6 M12 4-pin connectors on the front of Sensor

Interface that allow individual sensor to be conveniently

plugged in. These are wired to match the typical industry

standard 2 or 3 wire DC sensors with molded M12

connectors. M12 connectors are also available (Link PN

108046) that can be wired in the field. Figure 5 at right

shows the pinout and typical connection for the M12

connector.

There are also 3 Banana Plug/Binding Post connectors on the

front of the Sensor Interface that are intended for use with

single wire grounding sensors such as Whisker Probes,

Spring Probes, or other mechanical sensors that are

grounding in nature. Note that Pin 2 on the first 4 of the M12

connectors (labeled WP for “Whisker Probe”) is also a

grounding-only input so that such sensors can be tied in that

way as well. For these sensors, it may be necessary to source

more current through the sensor than is required with solid

state sensors in order to maintain good electrical contact. The grounding inputs have extra pull-ups for

this purpose and even more current can be supplied by switching on the corresponding dip switch for

that channel on the door board of the unit (see “Whisker Probe Switches” in Figure 3).

2.1.4 Wiring to the Die Protection Unit

Figure 6 at right shows a close-up of the outputs connector

that must be wired to the Die Protection Unit. Depending on

the number of channels your Die Protection Unit can handle,

it may not be necessary to use all the outputs. Always

connect the ground (“GND” in the figure at right) on the

outputs connector to ground on the Die Protection Unit.

Then O1 through O8 (or however many are needed) can be

connected to the corresponding Die Protection Unit input.

12

34

1

4

2

3

+24

Inp

WP

GND

NPN

BN

BU

NPN

Proximity

Sensor

BK

M12

Figure 5: Typical Wiring to M12

Connector

L1

L2

PE

+24

GND

O1

O2

O3

O4

O5

O6

O7

O8

NC

GND

I1

I2

I3

I4

I5

I6

I7

I8

+24

GND

Outputs to

Die Pro. Unit

Connector

Figure 6: Outputs Connector

Table of contents

Popular Recording Equipment manuals by other brands

RCS AUDIO-SYSTEMS

RCS AUDIO-SYSTEMS TIF-404 A operating instructions

Lexicon

Lexicon 960L - ADDENDUM LOGIC7 UPMIX ALGORITHM... manual

Actia

Actia PassThru+ XS 2G Getting started

Philips

Philips LFH 9750/00 Service manual

Pioneer

Pioneer DC-777Z operating instructions

HHB

HHB BurnIT CDR-830 operating instructions