6

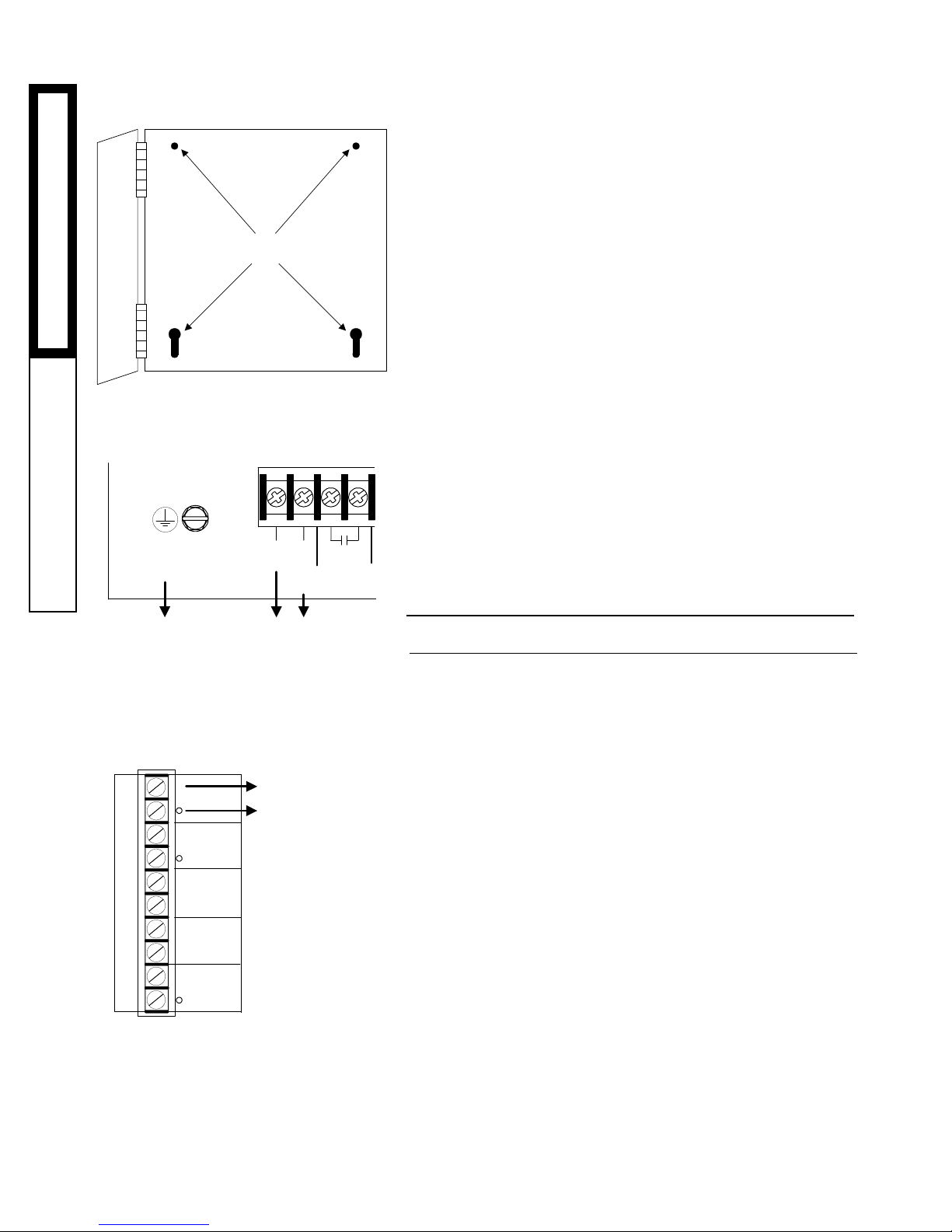

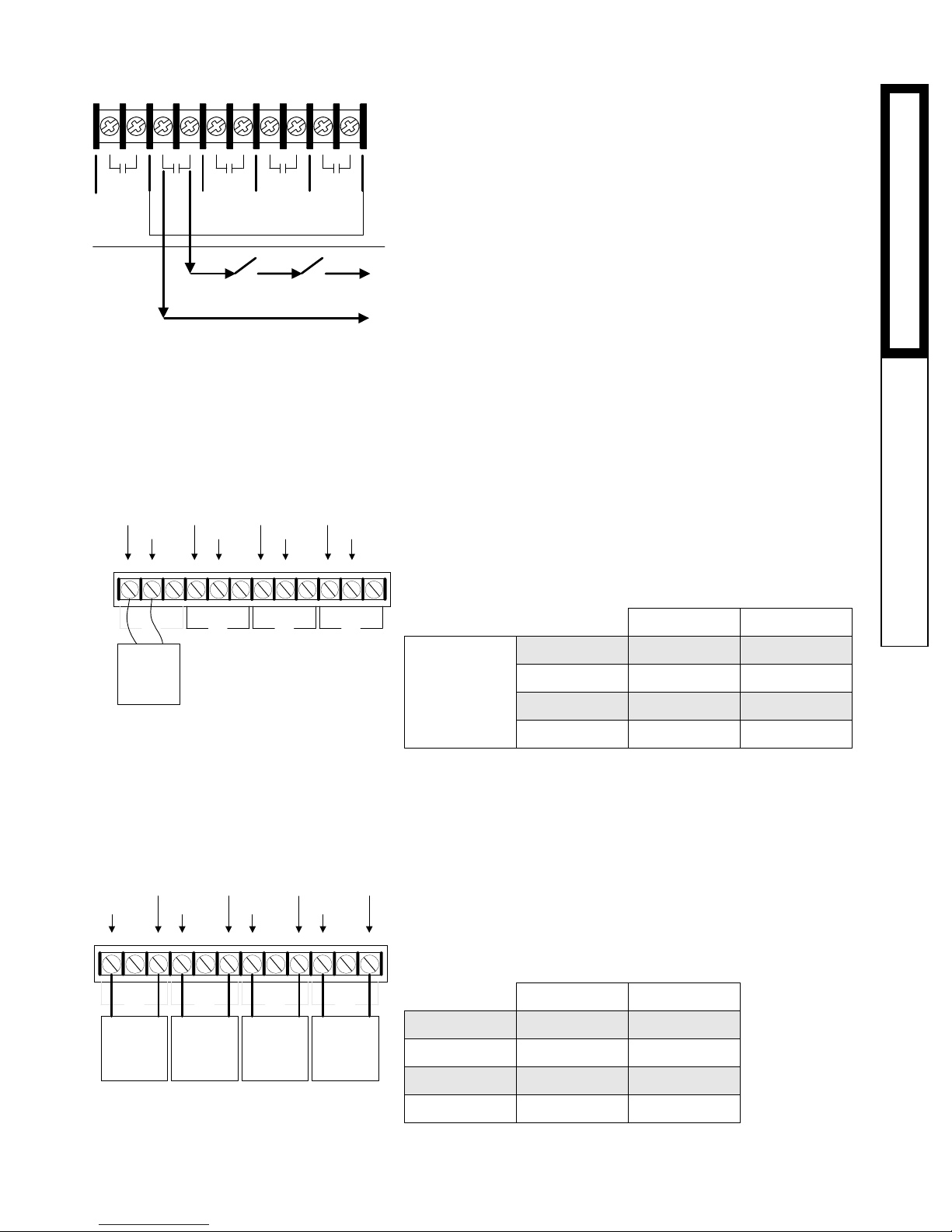

• The System Prove feature is provided to check system component

operation.

• A typical use of this feature is to check for flow before firing any

boiler stages. When there is a call for heat, the System Output

activates the system pump starter. When the pump establishes flow,

a flow switch closes together the SYSTEM PROVE input. Only then

can the Harmony activate boilers and modulate them as required to

hold the temperature set point.

• If the SYSTEM PROVE input is open on a call, the Harmony will

enable only the System Output. All Stage outputs will be off when

the SYSTEM PROVE input is open.

• A factory installed jumper provides the System Prove signal. Do not

remove the jumper unless it will be replaced by a System Prove

signal.

• The System Prove signal must be a dry contact only. No voltage can

be placed across the SYSTEM PROVE - A9, A10 terminals.

• Bring the two wires from the dry contact to the terminals marked

SYSTEM PROVE - A9,A10.

IMPORTANT: DonotremovethefactoryinstalledSystemProve

jumperunless it isreplaced by aSystemProve signal. Ifthe

SYSTEMPROVEinputisnotclosed,theHarmonywillNOT

activatestages.

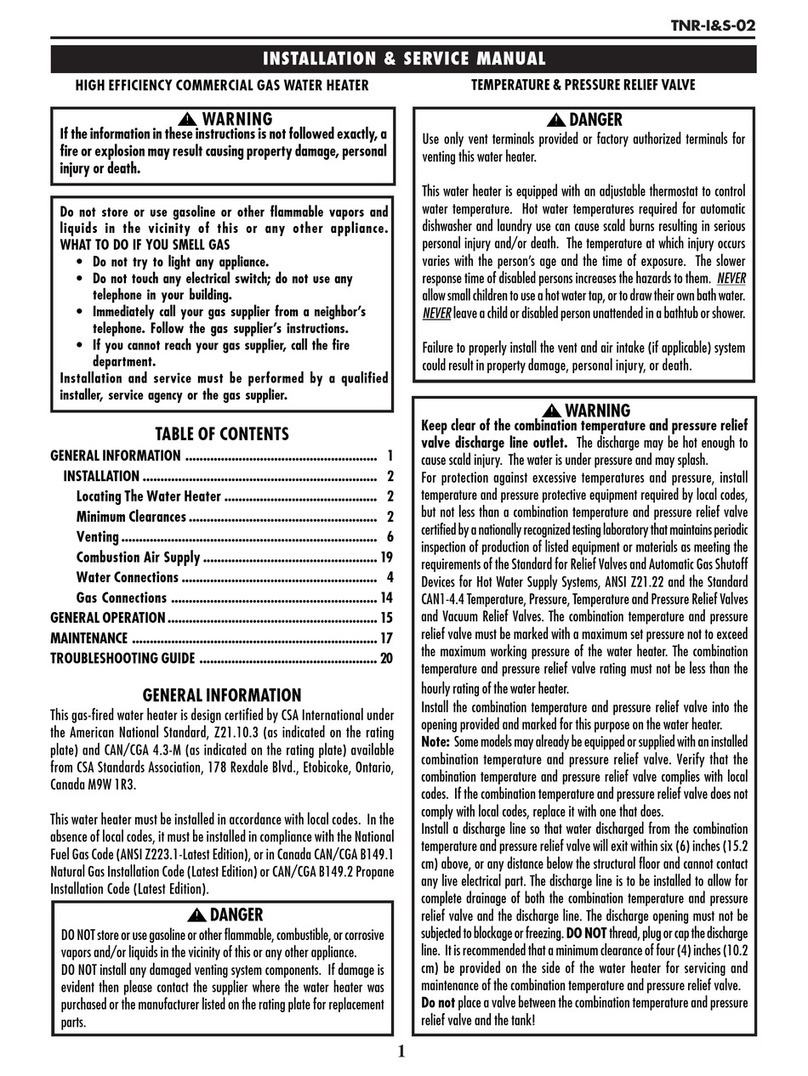

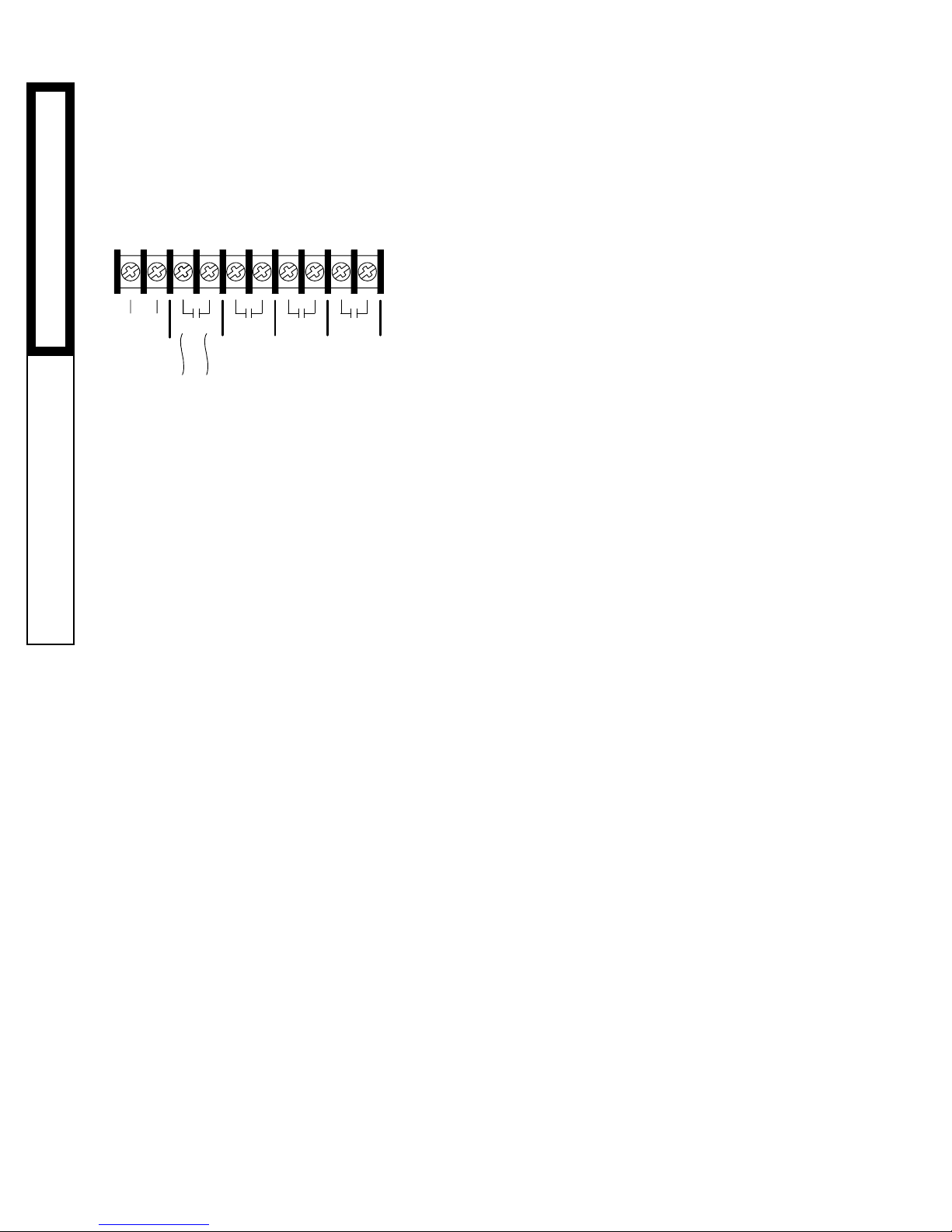

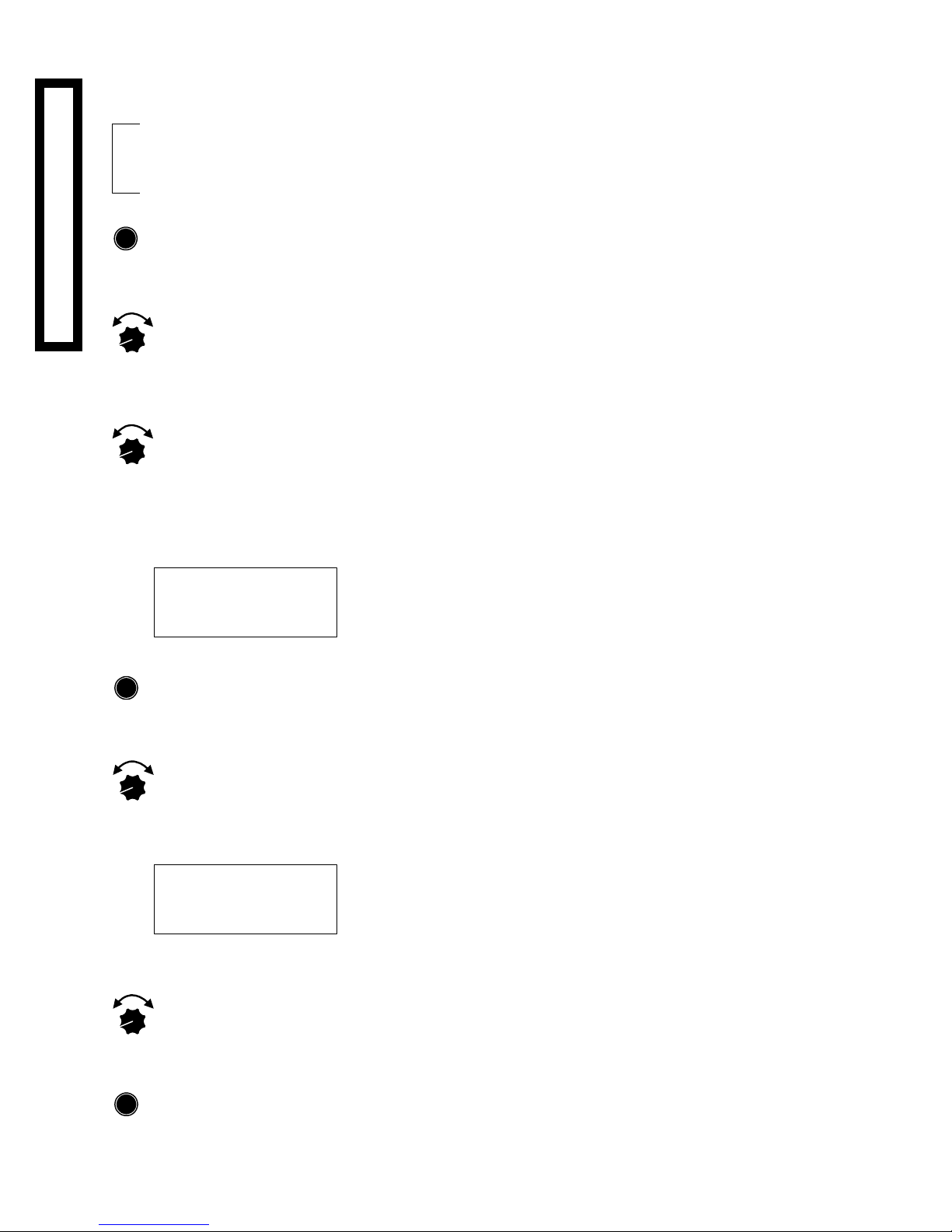

WIRING THE BOILER ACTIVE INPUTS

• A closure across the BOILER ACTIVE terminals informs the Har-

mony that a boiler is running normally. If the BOILERACTIVE

terminals open, the Harmony registers that the Stage has encoun-

tered a safety limit and can not be restarted without a manual reset.

The Harmony will not reactivate or modulate a Stage which is not

Active.

• The Boiler Active signal is not a safety, but use of these inputs will

significantly improve the Harmony's set point control performance in

the event of a Stage encountering a safety limit.

• A pair of BOILER ACTIVE terminals is provided for each stage.

• The Boiler Active signal must be a dry contact closure from the

boiler controlled by that Stage's output. For example, the Boiler

Active signal wired into terminals STAGEA (Terminals B1 and B2)

must come from the unit whose operating limits are connected to

terminals OPERATING LIMIT OUTPUTS A(Terminals 5and 6).

• The BOILER ACTIVE terminals are dry contacts only. No voltage

can be placed across the them.

• Wire the BoilerActive signals to their respective STAGE terminals:

- STAGE A to BoilerActive Input terminals B1&B2

-STAGE B to BoilerActive Input terminals B3&B4

- STAGE C to BoilerActive Input terminals B5&B6

- STAGE D to BoilerActive Input terminals B7&B8

Dry Contact

System Prove

Signal

TEMP

SHUTDOWN

NETWORK

SYSTEM

PROVE

T

+

S

INPUTS

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

WARNING: The SYSTEM PROVE

input can not be used as a safety

limit. All equipment must have its

own certified limit and safety con-

trols as required by local codes.

STAGE

A

STAGE

B

STAGE

C

STAGE

D

Dry Contact

Active Signal

INPUTS

B1

B2

B3

B4

B5

B6

B7

B8

BOILER

ACTVE

WARNING: The BOILER ACTIVE IN-

PUTS can not be used as a safety

limits. All equipment must have its

own certified limit and safety con-

trols as required by local codes.

INSTINST

INSTINST

INSTALLAALLA

ALLAALLA

ALLATIONTION

TIONTION

TION INPUT WIRINGINPUT WIRING

INPUT WIRINGINPUT WIRING

INPUT WIRING