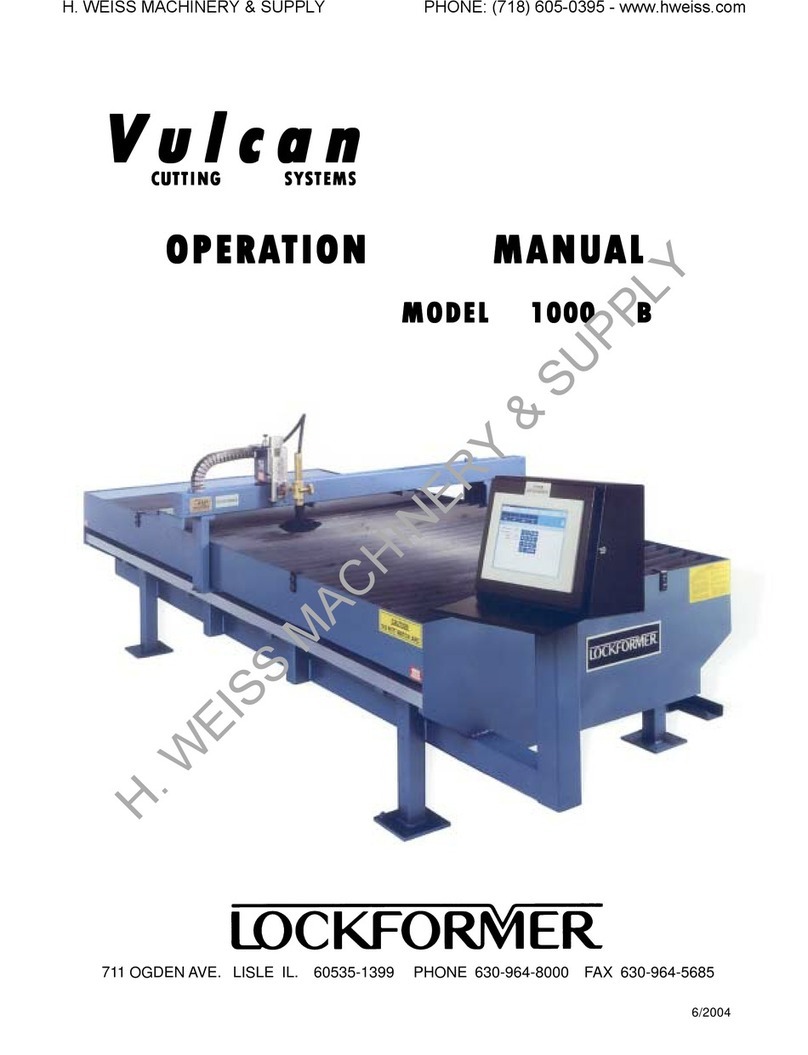

Lockformer Vulcan 2900 User manual

711 OGDENAVE. LISLE IL. 60535-1399 PHONE 630-964-8000 FAX 630-964-5685

REV 08-98

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

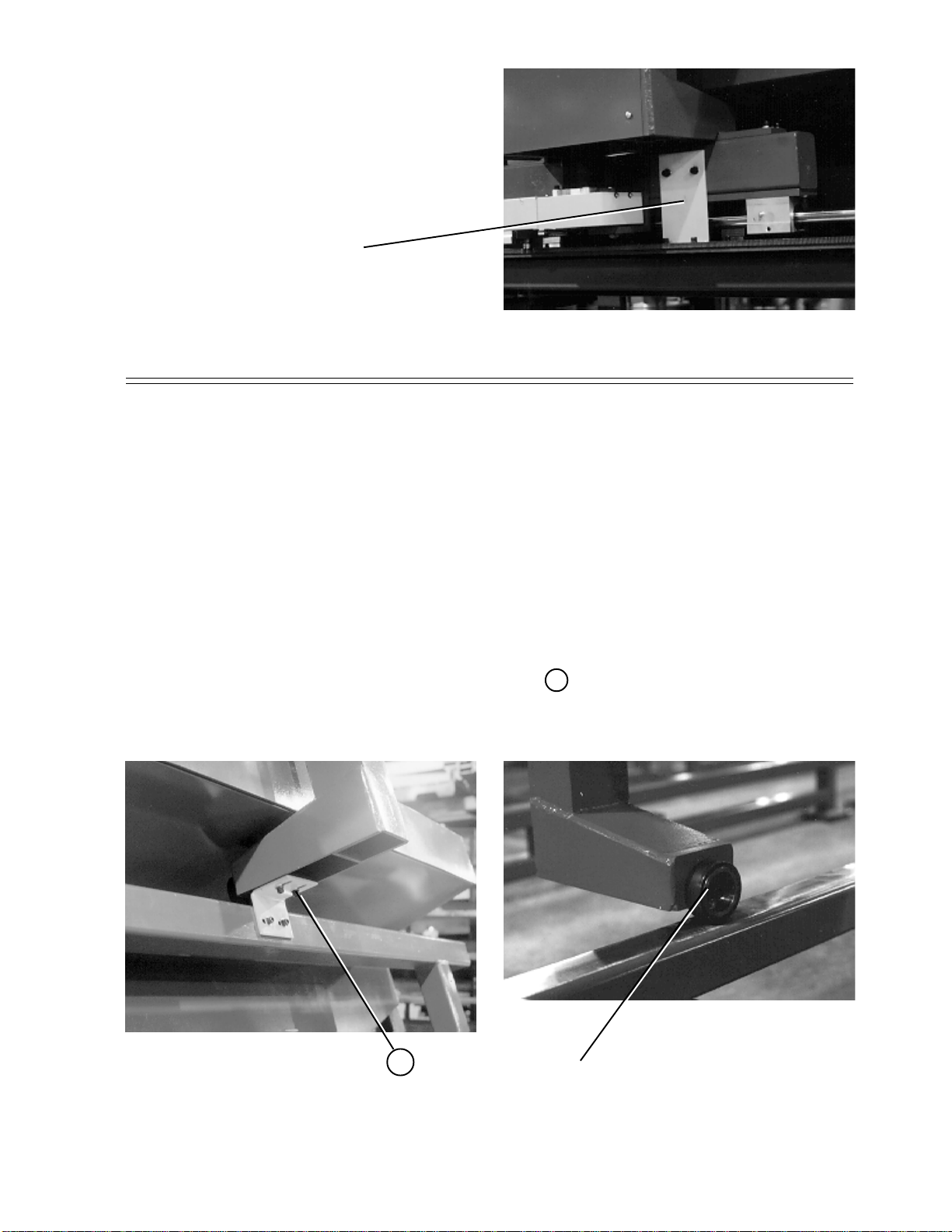

Theunderside ofeachof theinner legsofthe Vulcantable hasa1/2-13 tappedhole.

Fourleveler padshavebeen furnishedwiththe table. BEFOREREMOVINGTHETABLE

FROMTHESHIPPING SKIDScompletelythreadtheadjustmentnutasshowninthe

illustration,thenfullythread alevelerintoeachleg.

DO NOTANCHOR THETABLETOTHE FLOOR. ALockformer installation

technicianwill leveltheequipmentand secureitto thefloor.

SHIPPINGSKID INNERLEGS(4)

BOTTOM VIEW OF TABLE LEG

LEG

LEVELER

ADJUSTMENT

NUT

INSTALLING THE TABLE LEVELERS

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

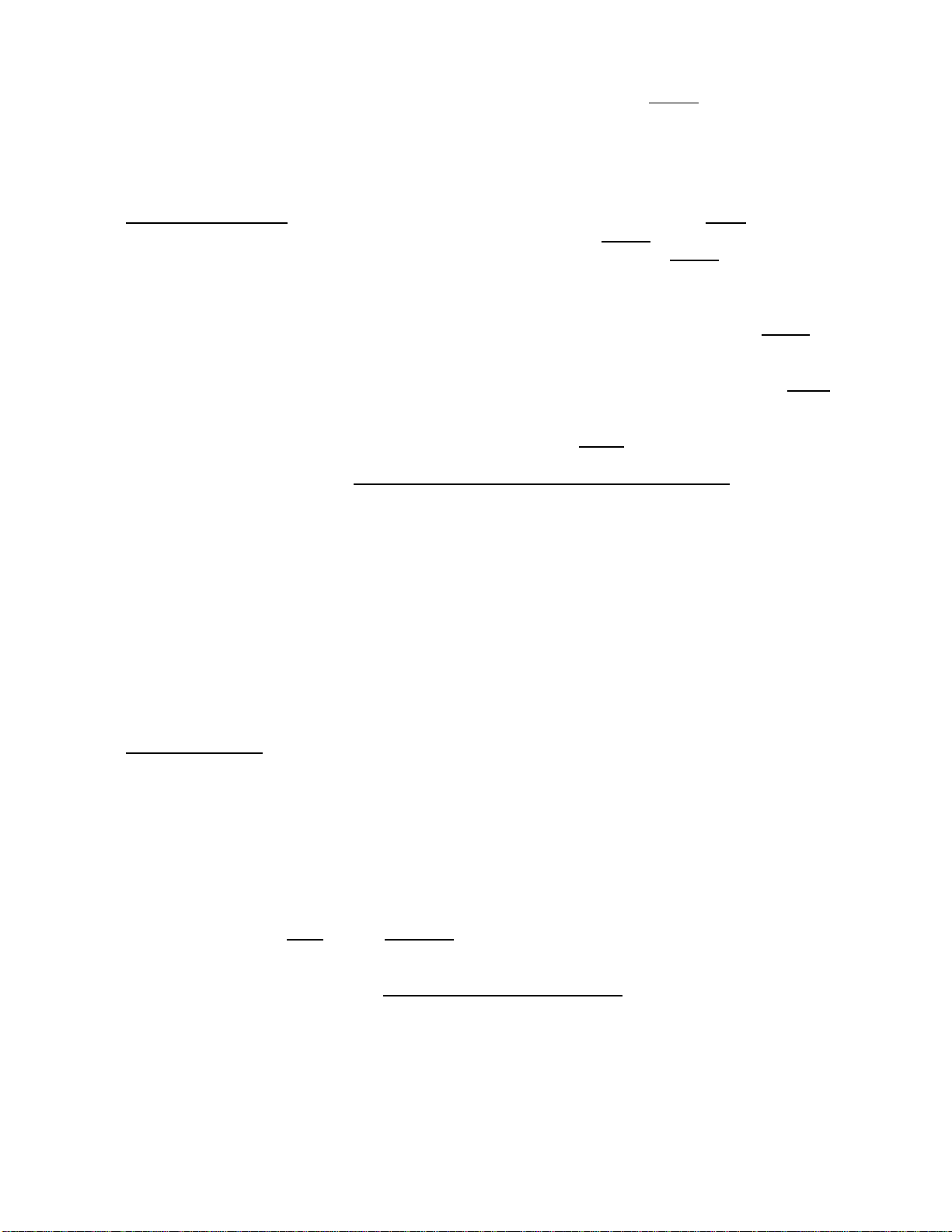

IMPORTANT!

REMOVE THE STEEL ANGLE BRACKETS (YELLOW) SHOWN IN

THE PHOTOS BELOW BEFORE ATTEMPTING TO OPERATE

YOUR VULCAN MACHINE. THESE ITEMS WERE USED TO

SECURE THE MACHINE DURING SHIPPING.

REPLACE THE TWO SOCKET HEAD CAP SCREWS SECURING THE

BRACKETS ON THE CARRIAGE WITH THE SHCS IN THE BAG

ATTACHED TO THE TORCH HEAD (ALLEN WRENCH INCLUDED).

REMOVE THESE BRACKETS

SHIPPING BRACKET REMOVAL

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

REMOVE THESE YELLOW BRACKETS BEFORE

REMOVINGTABLE.

THESE BRACKETS ARE FOUND ON BOTH SIDES OF

THEVULCANMACHINE.

BRACKET REMOVAL CONT.

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

1. Position an appropriate, safe

jacking device and carefully lift the

carriage enough to take the weight

off of the yellow shipping bracket.

2. Remove the bracket by removing

the four mounting screws B .

3. Lower the carriage.

REMOVETHISBRACKET

BEFOREOPERATINGTHIS

MACHINE

PHOTO 1 PHOTO 2

BWHEEL

BRACKET REMOVAL CONT.

WHEEL SIDE OF CARRIAGE

SHIPPING BRACKET REMOVAL

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

SAFETY INFORMATION

Inadditiontothefollowingguidelines,refertoSections1,2,and3ofthismanualforadditionalsafety

information.

The Vulcan Plasma Arc Cutting System can be used with complete safety by its operator and any

persons in the immediate area, but personnel must take precautions against light, heat, radiation,

fumes, and noise produced by the Vulcan while performing plasma cutting operations. Everyone

who works with or near this machine must familiarize themselves with possible hazards and the

simple, effective means explained below to avoid them! Pay close attention to the following

Guidelines and the Vulcan will provide cost efficient service with minimal risk to personnel:

TERM DESCRIPTION

CAUTION: Hazards or unsafe practices which could result in minor personal injury, and

product or property damage.

WARNING: Hazards or unsafe practices which could result in severe personal injury or

death.

DANGER: Immediate hazards which will result in severe personal injury or death.

Thewords"should"and"must"asusedinthismanualshallhavethefollowingmeaning;the

use of should means we strongly suggest that the instruction be followed. The use of must

means that the instruction is mandatory for the safety of equipment and personnel.

INSTANT-ON TORCHES - The machine torch is an instant-on torch. These torches fire (produce

a plasma arc) immediately after torch switch closure or remote switch closure for a machine torch.

Always stand away from the torch as a precaution against accidental torch firing. Be aware of this

hazardous potential; failure to do so can result in serious bodily injury.

EMERGENCY STOP switch shuts off power to all parts of machine except plasma unit. The torch

will stop cutting, but its power will still be active, so throw the main DISCONNECT switch to cut all

power!

CARRIAGEMOVEMENT-ThecarriageonwhichthePlasmaCuttingTorchismountedmoveswith

firm, steady force and can injure anyone in its path. It can travel the entire length of the table (this

is the Y axis). The torch unit also travels across the carriage when cutting (X axis). Keep this path

clear. Stand back from the moveable parts of the machine when it is in operation, or about to be

started. NOTE:Whenused in this manual, the term "machine" will refer to the carriage only. Other

sections of the Vulcan will be described by their specific name and listed separately.

YOU ARE NOT READY TO OPERATE THIS EQUIPMENT

IF YOU HAVE NOT READ AND UNDERSTOOD THE

SAFETY INFORMATION IN THIS MANUAL.

SAFETY FIRST! All Personnel working with or near

the Vulcan must read this section!

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

BURNSAFETY-Intenseultravioletlight,sparks,andhotmetalproducedbyplasmaarccutting will

harm either exposed skin or eyes. Operators and nearby personnel must wear protective clothing

and equipment to avoid hazards.

Eyes Safety - Wear tinted safety goggles, goggles with side shields, or a welding helmet to protect

eyes. Refer to the chart for recommended lens or shield shade;

Arc Current Lens/Shield Shade

Up to 100 Amps Shade No. 8

100-200 Amps Shade No. 10

200-300 Amps Shade No. 12

Over 400 Amps Shade No. 14

Do not use eyewear with broken or pitted lenses or covers. Replace at once.

Post warnings and inform other people in the area not to look directly at the arc unless wearing

glasses, goggles, or a helmet.

The Vulcan Operating Area should be adapted to reduce reflection and transmission of ultraviolet

light. Installprotectivescreensorcurtainstoreduceultraviolettransmissions. Paintwallsandother

surfaces with dark colors to reduce reflection.

SkinSafety-Alwayswearprotectiveclothingincluding,butnotexclusiveto,gauntletgloves,safety

shoes, and head covering.

Flame retardant clothing with cuffless trousers to shield body from sparks and slag is strongly

suggested.

After cutting, sheet edges and the cutting table are dangerously sharp and hot. To avoid cuts and

burns, use heavy gloves to handle pieces during removal.

Do not touch the front of the torch when starting it. After cutting, allow time for the front of the torch

to cool.

Qualified first-aid personnel and facilities should be available at or near any Vulcan site to treat

accidental eye and skin burns at once.

FUME HAZARDS AND PRECAUTIONS - Plasma Arc Cutting vaporizes metals into toxic gases,

soconstantventilationandprecautionsregarding exposuretothe operatororany personsnearthe

Vulcan are absolutely necessary! An appropriate ventilation system, designed to safely withdraw

toxicfumesfromthearea,mustbeinstalledandusedwhenevertheVulcanisoperated. Donotuse

the Vulcan in a confined space unless a safe ventilation system and an operators fresh air supply

is present and working properly! Refer to Section 1, Preliminary Installation for details about

necessary initial ventilation setups.

Be sure to activate the ventilation system before starting the Torch. Periodically check to see that

the vent system continues to remove air efficiently! To ensure that it pulls with its greatest force

duringcutting,alwayscoverthe table top(s)completely,soaircanonly flow throughasmallareato

force gases into the 12" vent hole. If sheets smaller than 5 x 10' are used, cover excess space on

table top(s) with scrap metal.

Donotcutcontainerswithtoxic materials inside or containersthathaveheldtoxicmaterials. Clean

such containers thoroughly before cutting.

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Stock containing or coated with significant percentages of beryllium, cadmium, lead, mercury, or

zinc can all give off poison fumes when burned by plasma arc cutting. Do not cut this stock unless

theoperator,oranyoneelsesubjectedtothefumes,wearsrespiratoryequipmentoranairsupplied

helmet, or the table ventilation system is working efficiently.

Wear a proper breathing mask and use proper ventilation when cutting galvanized metal.

EXTREMECAUTION!Variouschlorinatedsolventsdecomposeandcanturntolethalphosgenegas

whenexposedtoultravioletradiationcaused by plasma cutting. Do not use suchsolventson stock

tobecutbytheVulcan. Askyourvendoraboutsuspectsolventformulas. Do notkeeptheseorany

degreasing agents near the Plasma Arc Cutting System.

FIREHAZARDSANDPRECAUTIONS-Heat,sparksandslagproducedbyplasmacuttingofmetal

cancauseexplosionsorfire. KeepfireextinguisherswithintheimmediateVulcanarea. Donotleave

any combustible matter within 35 ft. (10 meters) of the Vulcan site!

It is strongly recommended that containers used for poisonous or explosive substances never be

plasma cut.

Be sure the Vulcan area ventilation system works properly. Never start the Vulcan as long as air

around it is laden with flammable/explosive agents such as dust, gasoline or other flammable gas,

or combustible liquid vapors. Let the vent system remove such substances first!

Quench freshly cut metal in water or allow metal to cool after cutting, before handling it, or letting

any combustible substances nearby that might be ignited by its heat.

ELECTRICAL HAZARDS AND PRECAUTIONS

Primary Safety Directive - To perform any maintenance or do any work with the machine's

electricalcomponents,always disconnect the main switch to cut power entirely from allpartsorthe

Vulcan, to avoid the dangers of electrocution.

Becauseplasmacuttingrequiresgreater(opencircuit)voltagethanordinarywelding,upto300VDC,

greater precautions against electrocution must be used while cutting.

Input Connections (Refer also to Section 1, Preliminary Machine Installation)

Install a wall-mounted line disconnect switch as close to the plasma unit power supply as possible

and fuse it according to local electrical codes. This switch allows the operator to turn the power

supply off quickly in an emergency situation.

Conform to all national, state, and local electrical codes for primary wiring sizes and types.

Be sure that input conductors are of proper size to carry Plasma Unit’s rated current.

Primary power cable must have a minimum 600 v. rating.

Do not use the system with a damaged power cord. Inspect the primary power cord frequently for

damage or cracking of the cover. EXPOSED WIRING CAN KILL!! If a power cord is damaged,

replace it immediately.

Inspect the torch leads. Replace if frayed or damaged.

Neveroperatetheplasmasystemunlessthepowersupplyunitcoversareinplace. Exposedpower

supply connections present a severe electrical hazard.

Donottouchtheworkpiece,includingthewaste cutoff,whileyoucut. Leave theworkpieceinplace

or on the workbench with the work cable attached while cutting.

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Before changing the torch parts, disconnect the main power or unplug the power supply. After

changing the torch parts and returning the retaining cap to its operating position, plug the power

supply in again.

Never bypass or shortcut the safety interlocks.

Before removing a power supply cover for maintenance, disconnect the main power at the wall

disconnect switch or unplug the power supply. To avoid exposure to severe electrical hazard, wait

five minutes after disconnecting the main power to allow capacitors to discharge.

Wearinsulatedglovesandbootstomaintainproperinsulationagainstelectricalshock. Ifyou must

work in or near a damp area, use extreme caution.

CheckcableoftenforanycrackingorpeelingofcoversandreplacedefectivewiringIMMEDIATELY!

NOTE!To avoid a tripping hazard, it issuggestedthatbrightSafetyTapebe put around the ground

rod and any cable that must lay in a space where people walk.

NOTE! Personal Protection - Keep your body and clothing dry. Do not operate the Vulcan in a wet

or damp environment without proper insulation against ELECTROCUTION! Do not stand, sit, or

otherwise be in any contact with water while operating machine or ELECTROCUTION may result!

Do not operate the Vulcan if any of its electrical cables, torch leads, or the torch itself is damaged.

Do not attempt any maintenance to the Vulcan, including service to torch, plasma unit, or power

supply,withoutfirst disconnectingpowerfrommachineentirelybyshutting offthemaindisconnect!

EXPLOSION PREVENTION - WARNING: The plasma system uses compressed gas. Observe

proper precautions when handling and using compressed gas equipment and cylinders. Refer to

the Index at the end of this section.

When cutting with the plasma system, do not cut in atmospheres containing explosive dust or

vapors. Do not cut pressurized cylinders or any closed container.

Compressed Gas Cylinders -Becertainto takecorrectprecautionswhenhandling and operating

compressed gas equipment and cylinders.

Handle and use any compressed gas cylinder in strict accordance with safety standards such as

publishedbytheCompressed Gas AssociationinArlington,VA.(CGA), American WeldingSociety

in Miami, Fla. (AWS), and the Canadian Standards Association in Ontario, Canada (CSA).

Do not move a cylinder unless its protective valve cover is in place. Do not use a cylinder unless it

is secured in place, upright.

Do not use a cylinder that leaks or is otherwise physically damaged. Do not use hammers or any

other implement to force a stuck valve open. Return cylinders with any such defects to supplier.

Do not lubricate cylinder valve(s) with oil or grease.

Never move or transport a cylinder without the protective valve cover in place.

Do not use a cylinder or its contents for any other purpose than that for which it was designed.

Do not allow a cylinder near electrical hazards such as welding arcs, or expose cylinder to an open

flame or excessive heat, sparks, or slag of any kind, which can cause rupture or explosion.

Hose - Label and color-code all gas hoses in order to clearly identify the type of gas in each hose.

Consult applicable national, state, or local codes.

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Never use an oxygen hose for any gas other than oxygen.

Use the shortest possible lengths of hose to avoid damage, reduce pressure drop, and prevent

possible volume flow restriction. Let the hose lie as straight as possible to prevent kinks when

interconnecting system components. Coil excess hose and place it out of the way to prevent

damage and to eliminate tripping danger.

Checkhoseregularlyforwear,leaks,looseconnections,oranydamagefromheat,flameorsparks.

Immediately replace damaged or unreliable hose!

Pressure Regulators - Maintain all pressure regulators used on the Plasma Unit of the Vulcan in

proper working order to avoid failure and danger to operating personnel. Do not use any regulator

that leaks, creeps excessively or is otherwise damaged. It is strongly recommended that any

malfunctioningequipmentbeservicedonlybytrainedtechnicians,atit’smanufacturer’sdesignated

facility.

Donotlubricateregulator(s)with oilorgreaseanddo notusearegulator for anygasotherthan that

for which it was designed.

NOISE PREVENTION -Theplasmacuttingprocesscangeneratehighlevelsofnoise. Depending

onthearccurrent,materialbeingcut,acoustics,andsizeofthecuttingroom,distancefromthetorch

and other factors, acceptable noise levels as defined by national, state, or local codes may be

exceeded by your plasma system.

GROUNDING - Before operating the plasma system;

InputPower-Besurethepowercordispluggedintoaproperlygroundedoutletorthatthepowercord

ground wire is properly connected to the ground in the disconnect box. If installation of the plasma

system involves connecting a power cord to the power supply, ensure that the power cord ground

wireisproperlyconnected. Conformtonational,state,andlocalstandardwhenfasteningthepower

ground wire to the power supply chassis. CSA standards recommends placing the power cord

groundwireonthestudfirst;thenplacetheotherwiresontopofthepowercordground. Fastenthe

retainingnuttightly.

Make sure that all electrical connections are tight to avoid excessive heating.

Input Power - Connect Ground Lead of power input cable to both electrical system ground in

disconnectbox,andtogroundstudinPlasmaUnitpowersupply. Becertainallgroundlugsarelarge

enough to carry rated current load and make all connections tight to prevent resistance heating.

Output Power - Connect all positive output ground leads to cutting table Star Ground (referred to,

and illustrated in Section 1). Connect Star Ground to reliable Earth Ground. Refer to National

Electrical Code, Grounding Electrode System or other appropriate source for suitable Ground

specifications.

WorkTable-Clamptheworkcablewithgoodmetal-to-metalcontacttotheworkpiece(nottheportion

that will fall away) or to the work table.

Connecttheworktabletoagoodearthground. ConsulttheU.S.NationalElectricalCode,Article250,

Section H Grounding Electrode System, or other appropriate national, state, or local codes.

For additional information, refer to the Index at the end of this section.

ELECTRIC AND MAGNETIC FIELDS (EMF)

Plasma arc cutting and gouging systems create electric and magnetic fields that may interfere with

the correct operation of electronic health support equipment, such as pacemakers or hearing aids.

Anypersonwhowearsapacemakerorhearingaidshouldconsultadoctorbeforeoperatingorbeing

near any plasma system when it is in use. To minimize exposure to EMF: (1) Keep both the work

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

cableandthetorchleadononesideofyourbody. Keepyourbodyfromcominginbetweenthetorch

lead and the work cable. (2) Keep distance of work cable to workpiece as short as possible to

eliminate loop areas. (3) Route torch leads as close as possible to work cable. (4) Do not wrap the

torch lead or work cable around your body. (5) Stay as far away from power source as possible.

SAFETY DEVICES -ThePlasmaUnitsusedonVulcanhavesafety interlocks to prevent danger to

personnel and damage to machine. Do not try to short out or override these interlocks! Check

interlocks and all safety related parts of Plasma Unit frequently and replace them IMMEDIATELY if

they are not working!

The interlocks turn off the power supply when the retaining cap is loosened.

Never bypass or shortcut the safety interlocks on any of the plasma system units.

Do not use the Plasma Unit unless all of its power supply covers are in place; failure to do so will

ENDANGERtheoperatorandotherpersonsnearthemachineanditwillinterferewithcoolingofvital

parts of Unit, which can be damaged as a result.

Be certain that all electrical connections are covered with appropriate insulation material. Cracked

insulation must be replaced!

Each plasma unit is designed to be used only with specific Vulcan torches. Do not substitute other

torcheswhichcouldoverheatandpresentapotentially dangeroussituationtothe operatorandany

personnel in the area.

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

PUBLICATION INDEX

ThePublicationIndexcontainsalistofpublicationsdealingwithplasmaarccuttingequipmentsafety

practices.

1. American National Standards Institute, 1430 Broadway, New York, NY 10018

(212) 354-3300.

ANSI Standard Z41.1, Standard for Men's Safety-Toe Footwear

ANSI Standard Z49.2, Fire Prevention in the Use of Cutting and Welding Processes

ANSI Standard Z88.2, Practices for Respiratory Protections

ANSI Standard Z87.1, Safe Practices for Occupation and Educational Eye and Face

Protection

2. American Welding Society, 550 LeJeune Road, P.O. Box 351020, Miami, FL 33135

(305) 443-9353.

ANSI Standard Z49.1, Safety in Welding and Cutting

AWS Standard A6.0, Welding and Cutting Containers Which Have Held Combustibles

AWS Standard F4.1, Recommended Safe Practices for the Preparation for Welding

and Cutting of Containers and Piping that Have Held Hazardous Substances

3. National Fire Protection Association, 470 Atlantic Avenue, Boston, MA 02210

(617) 770-3000.

NFPA Standard 51, Oxygen - Fuel Gas Systems for Welding and Cutting

NFPA Standard 70-1978, National Electrical Code

NFPA Standard 51B, Cutting and Welding Processes

4. Superintendent of Documents, U.S. Government Printing Office, North Capitol

Street, Washington, D.C. 20402 (202) 783-3238.

NIOSH, Safety and Health in Arc Welding and Gas Welding and Cutting

OSHA, Safety and Health Standards, 29FR 1910

5. Canadian Standards Association Standard Sales, 178 Rexdale Boulevard, Rexdale,

Ontario M9W 1R3, Canada (416) 747-4000.

CSA Standard W117.2, Code for Safety in Welding and Cutting

Canadian Electrical Code Part 1, Safety Standards for Electrical Installations

6. Compressed Gas Association, 1235 Jefferson Highway, Arlington, VA 22202

(703) 979-0900.

CGA Pamphlet P-1, Safe Handling of Compressed Gases in Cylinders

7. National Welding Supply Association, 1900 Arch Street, Philadelphia, PA 19103

(215) 564-3484.

NWSA booklet, Welding Safety Bibliography

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

YOU ARE NOT READY TO OPERATE THIS EQUIPMENT

UNTIL YOU HAVE READ AND UNDERSTOOD THE

SAFETY INFORMATION IN THIS MANUAL.

THIS SAFETY ALERT SYMBOL INDICATED IMPORTANT SAFETY

MESSAGES IN THIS MANUAL. WHEN YOU SEE THIS SYMBOL

CAREFULLY READ THE MESSAGE THAT FOLLOWS AND BE

ALERT TO THE POSSIBILITY OF PERSONAL INJURY OR DEATH.

!

BEFORE ANY MACHINE IS USED BY AN EMPLOYEE OR IS LOANED OR

RENTED,MAKEABSOLUTELYCERTAINTHATTHEOPERATOR(S)PRIORTO

OPERATING:

1. ISINSTRUCTEDINSAFEANDPROPERUSE.

2. REVIEWSANDUNDERSTANDSTHEMANUAL(S)PERTAININGTO

THEMACHINE.

ITISTHEUSER'SRESPONSIBILITYTOUNDERSTANDANDFOLLOWTHE

MANUFACTURER'SINSTRUCTIONSONMACHINEOPERATIONAND

MAINTENANCE,ANDTOOBSERVEALLPERTINENTLAWSAND

REGULATIONS.

WARNING

!

REMEMBER, A CAREFUL OPERATOR IS THE BEST INSURANCE

AGAINST AN ACCIDENT. GIVE COMPLETE AND UNDIVIDED

ATTENTION TO THE JOB AT HAND.

!

WARNING, DO NOT WEAR LOOSE CLOTHING, JEWELRY, OR

UNRESTRAINED HAIR OR BEARD STYLES WHICH MAY CATCH IN

MOVING PARTS.

!

WARNING, THE OPERATOR MUST HAVE AUXILIARY OPERATING

PERSONNEL CLEARLY WITHIN HIS FIELD OF VISION AT ALL TIMES!

!

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

DANGER, COILS MUST NEVER BE CARRIED OVER THE HEADS OF

OTHER EMPLOYEES.

!

WARNING, KEEP LIQUIDS (SOLVENTS, LUBRICANTS, ETC.) AWAY

FROM ELECTRICAL EQUIPMENT.

!

WARNING, YOU MUST NEVER DISCONNECT OR REMOVE ANY

SAFETY DEVICE OR OPERATE ANY MACHINE WHO'S SAFETY DE-

VICES HAVE BEEN DISCONNECTED OR REMOVED.

!

DANGER, DISCONNECT AND LOCK OUT ALL POWER SOURCES

BEFORE INITIATING ANY REPAIRS.

!

!WARNING, IMPROPER OPERATION OF THIS MACHINE MAY

CAUSE DAMAGE TO THE MACHINE AND/OR PERSONAL INJURY TO

THE OPERATOR AND NEARBY PERSONNEL.

WARNING, HYDRAULIC SYSTEMS ARE HIGHLY PRESSURIZED.

ESCAPING HYDRAULIC OIL, EVEN AN INVISIBLE PINHOLE LEAK, CAN

PENETRATE BODY TISSUES CAUSING SERIOUS INJURY. WHEN

LOOKING FOR LEAKS, USE A PIECE OF WOOD OR CARDBOARD.

(NEVER USE THE HANDS OR ANY OTHER PART OF THE BODY)

!

WARNING, DO NOT HANDLE MATERIAL (COIL, SHEET OR

BLANK) WITHOUT WEARING PROTECTIVE GLOVES.

!WARNING, NARROW OR UNSTABLE COILS MUST NOT BE

TRANSPORTED WITHOUT THE AID OF BLOCKING AND/OR SIDE

SUPPORTS

!

WARNING, IF ANY PART OF THIS MACHINE SHOULD BECOME

OVER LUBRICATED AND LUBRICANT SPILLS OVER OR BUILDS UP, IT

SHOULD BE CLEANED UP IMMEDIATELY, SO AS NOT TO HINDER THE

PROPER OPERATION OF THE MACHINE OR ENDANGER OTHER

PERSONNEL.

!

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

WARNING, KEEP THE WORK AREA CLEAR OF OBSTRUCTIONS

AND THE FLOOR CLEAN AND DRY.

!

WARNING, NEVER USE STOOLS, BOXES, CRATES OR SIMILAR

ITEMS AS SUBSTITUTES FOR WORK PLATFORMS, SCAFFOLDING OR

LADDERS.

!

WARNING, DO NOT OPERATE ANY EQUIPMENT WHICH HAS

LOOSE, WORN, OR BROKEN PARTS.

!

WARNING, DO NOT OVERLOAD EQUIPMENT BEYOND IT'S

STATED OR IMPLIED CAPACITIES.

!

WARNING, BEFORE PERFORMING ANY MAINTENANCE ON THIS

MACHINE, BE SURE THAT THE MAIN DISCONNECT SWITCH IS SHUT

OFF AND LOCKED IN PLACE.

!

!WARNING, DO NOT OPERATE ANY EQUIPMENT WITHOUT

GUARDS AND COVERS INSTALLED IN PLACE.

DANGER, YOU MUST NEVER CHECK DIMENSIONS OF

WORKPIECE WHILE EQUIPMENT IS OPERATING.

!

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

12

12

12

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

The Lockformer Company,

711 Ogden Ave., Lisle, Ill. 60532 (630) 964-8000

TABLE OF CONTENTS

Reference Photo

Section 1:

Preliminary Machine Installation

Safety

Uncrating

LocationofMachine

ChecklistforRailSystem

DriveRack

GroundingProcedure/PowerSupply

Ventilation

Fiber Optic Cable Reference

Section 2:

Operation and Procedures

LoadingtheTablewithMaterial

ControlPower-OnProcedure

InitialTorch/HeadSet-UpProcedure

EmergencyStop

PlasmaUnitSet-Up

JobDownload

ExhaustActivation

DryRun

OperationofControlDuringCutting

Releasing a Job to Start a New Job

LostCutRecovery

VulcanDownloadQuickChart

ManualDataInput

ShapeLibrary

VulcanOperationFlowChart

Section 3:

Lockformer Vulcan Maintenance

Safety

InspectionandUpkeep

Lubrication

ReinstallationandAssemblyoftheVulcanTorchHead

TorchHeightAdjustment

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Section 4:

Lockformer Assembly Drawings And Parts Lists

51489Y-DriveMotorAssembly

51491Y-Two-DriveMotorAssembly

51494X - DriveMotor Assembly

51495X - DriveMotor Assembly

51526Rail Assembly - 20 ft. Single Park

51648RailAssembly

51659RailAssembly -20 ft.Double Park

52637TorchLifterAssembly

58470FloatingHeadAssembly

Section 5:

Fiber Optics Information

Specifications

Input/OutputInterface

SystemMalfunctionIsolation

NormalFiberOptic Operation

QuickTest-WillNotDownload

Checkingthe FiberOpticSystem

Checking the Fiber Optic Cable

Bit-DriverSensitivityAdjustment

Bypassingthe FiberOpticSystem

OfficeCablePinConfiguration

Section 6:

Vulcan Troubleshooting

XandYAxisMovement

CuttingErrors

TorchMovement

ComputerBlock

FlashProgram

Section 7:

Additional Information

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Vulcan 2900

REFERENCEPHOTO

"X" AXIS

DRIVEMOTOR

"X"CARRIAGE

("X" AXIS DRIVE)

FLOATINGHEAD

PNEUMATIC

TORCHLIFTER

PLASMA TORCH

"X" BEAM

Y-2EMERGENCY

STOP

"X" AXIS

RACKGEAR

"X" AXIS

SUPPORTROD

CONTROLLER

PRECISION

BEARING

SUPPORTROD

Y-2 RAIL

PROTECTED

CABLETRACK

Y-1 RAIL Y-RAILSPREADER

"Y"AXIS DRIVE

PRECISIONLINEAR

BEARINGS

"X" AXIS GANTRY

WELDMENT

"Y" AXIS

RACKGEAR

X-AXISHOME

SWITCH

X-AXIS HOME

PLATE

Y-AXIS HOME

PLATE

Y-AXIS HOME

SWITCH

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

SECTION 1

PRELIMINARY MACHINE INSTALLATION

1. Safety

2. Uncrating

3. Location of Machine

4. Checklist for Rail System

5. Drive Rack

6. Grounding Procedure / Power Supply

7. Ventilation

8. Fiber Optic Cable Reference

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

ThefollowinginformationoutlinesthefactoryproceduresforpreliminaryinstallationoftheLockformer

Vulcan Cutting Machine. Appropriate Lockformer reference and assembly drawings accompany

this manual as section 4.

1.SAFETY-Voltagesusedonthismachinearepotentiallyhazardous. Therefore,allequipment

must be installed and maintained in accordance with local requirements and National Electrical

Codes. Also see the SAFETY FIRST section of this manual.

2.UNCRATING-Themachine’scratingshouldensurethatallcomponentsarriveingoodorder,

butastheassembliesareuncrated,checkallcontentswiththepackinglistforpossibledamagefrom

shipping. If anything shows up missing, or damaged, notify the carrier in writing at once. It is the

responsibilityofthereceivertofileanyclaimsfordamageagainstthecarrier. Aseachassemblyor

detail is unpacked, it should be placed in a suitable dry area and have its preservative removed by

use of a nontoxic fluid. Avoid the use of trichlorethylene or perchloroethylene, and ensure that the

cleaning area is well ventilated.

3. LOCATION OF MACHINE - The Vulcan needs a floor space where vibration is at an

absolute minimum. Precision operation is necessary for accurate cutting, thus avoid areas where

the transmission of any heavy vibration, (from trucks, factory equipment, etc.) may occur nearby.

Choose a site for the Vulcan near gas and electrical outlets, and if possible, near any related

production lines, for manufacturing efficiency. Material handling is also important, so be sure to

providespaceforstockpilingmaterialandmovingitbyhoist,truck,orothermeans. Adequatelighting

and ventilation must be available for safety reasons, as noted in the safety material.

Machine Grounding - Connect and maintain good electrical grounds to supply ground wire and

machinerail. Donotgroundtoelectricalconduitorpipescarryinggasesor flammableliquids. Use

only recommended sizes of electrical cable. See page 3 for details.

4. CHECKLIST FOR RAIL SYSTEM RAILS - The Machine is factory shipped with all

Rails aligned correctly, but it is recommended that such alignments be rechecked after arrival and

initial placement of machine at its permanent operating site.

To Check the Rails, perform the following steps:

1. Use the jacking screws on the pedestals to level table over each pedestal to within 1/32".

2. Level outboard table Guide Rail to within 1/32".

3. Use the levelling screws to level Guide Rail and Outboard Rail (crossways).

4. Straighten Guide Rail to within .005".

5.NOTE!ThisStepisforDUALTABLESETUPSOnly:CheckRailjoints;Railendsmustbeintight,

positive contact and flush across top and sides of Guide Rail and top of outboard Rail.

6. Check Rail Spacing on X Axis, across carriage; if not 73" +/- 1/32", loosen outboard Rail and

reposition it as required to set this dimension.

7. Recheck Steps 1 through 6.

8. Anchor the table(s) tofloor securelywithlag bolts. NOTE:Suchfasteningcanonlybeperformed

after all alignments of machine are verified; then, customer must use any procedures desired to

secure table, ensuring that Machine and its Rails remain stationary, which is vital.

Page 1

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Table of contents

Other Lockformer Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric 11298 Operator's manual

MAC TOOLS

MAC TOOLS MWTIG owner's manual

Lincoln Electric

Lincoln Electric handy mig Operator's manual

Sealey

Sealey SUPERMIG140.V2 manual

Harbor Freight Tools

Harbor Freight Tools VULCAN PROTIG 200 Owner's manual & safety instructions

Weller

Weller WTSF 80 manual