Lockformer Vulcan 1000B User manual

711 OGDENAVE. LISLE IL. 60535-1399 PHONE 630-964-8000 FAX 630-964-5685

6/2004

MODEL 1000 BMODEL 1000 B

MODEL 1000 BMODEL 1000 B

MODEL 1000 B

OPERAOPERA

OPERAOPERA

OPERATION MANUTION MANU

TION MANUTION MANU

TION MANUALAL

ALAL

AL

VV

VV

Vulcanulcan

ulcanulcan

ulcan

CUTTING SYSTEMSCUTTING SYSTEMS

CUTTING SYSTEMSCUTTING SYSTEMS

CUTTING SYSTEMS

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

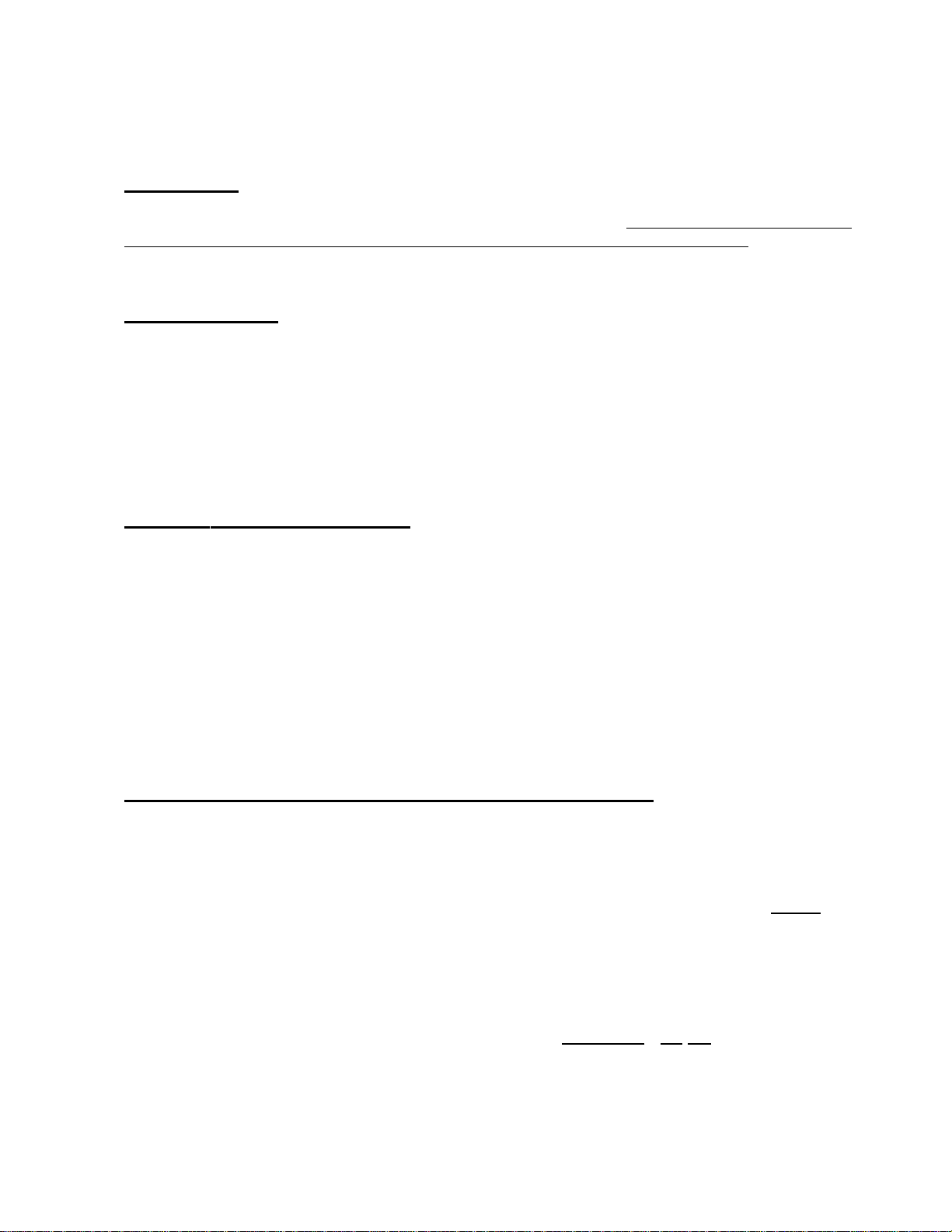

IMPORTANT!

REMOVE YELLOW STEEL ANGLE BRACKETS SHOWN IN

THE PHOTOS BEFORE ATTEMPTING TO OPERATE

YOUR VULCAN MACHINE. THESE BRACKETS WERE USED TO

SECURE THE MACHINE DURING SHIPPING.

SHIPPING BRACKET REMOVAL

DO NOTANCHOR THETABLE TOTHE FLOOR. ALockformer installation

technicianwill leveltheequipmentand secureitto thefloor.

REMOVE THESE BRACKETS

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

SAFETY INFORMATION

YOU ARE NOT READY TO OPERATE THIS EQUIPMENT

UNTIL YOU HAVE READ AND UNDERSTOOD THE

SAFETY INFORMATION IN THIS MANUAL.

Inadditiontothefollowingguidelines,refertoSections1,2,and3ofthismanualforadditionalsafety

information.

The Vulcan Plasma Arc Cutting System can be used with complete safety by it's operator and any

persons in the immediate area, but personnel must take precautions against light, heat, radiation,

fumes, and noise produced while performing plasma cutting operations. By paying close attention

tothefollowingguidelinestheVulcanwillprovidecostefficientservicewithminimalrisktopersonnel.

Everyone who works with or near this machine must familiarize themselves with it's possible

hazards and how to avoid them by following the simple, effective means explained below.

TERM DESCRIPTION

CAUTION: Hazards or unsafe practices which could result in minor personal injury, and

product or property damage.

WARNING: Hazards or unsafe practices which could result in severe personal injury or

death.

DANGER: Immediate hazards which will result in severe personal injury or death.

Thewords"should"and"must"asusedinthismanualshallhavethefollowingmeaning;the

use of should means we strongly suggest that the instruction be followed. The use of must

means that the instruction is mandatory for the safety of equipment and personnel.

INSTANT-ON TORCHES - The torch installed on this machine is an instant-on torch. It will fire

(produce a plasma arc) immediately after the torch switch closure or remote switch closure for a

machine torch. Always stand away from the torch as a precaution against accidental torch firing.

Be aware of this potential hazard. Failure to heed this warning can result in serious bodily injury.

EMERGENCY STOP- This switch shuts off power to all parts of the machine except the plasma

unit. The torch will stop cutting, but its power will still be active, so throw the main DISCONNECT

switch to cut all power!

CARRIAGE MOVEMENT - The carriage upon which the plasma cutting torch is mounted moves

with firm, steady force and can injure anyone in its path. It can travel the entire length of the table

(Y axis). The torch unit also travels across the carriage when cutting (X axis). Keep these paths

clear. Alwaysremainawayfromthemoveablepartsofthemachinewhenitisinoperation,orisabout

to be started. NOTE: When used in this manual, the term "machine" will refer to the carriage only.

Other sections of the Vulcan will be described by their specific name and listed separately.

SAFETY FIRST! All Personnel working with or near

the Vulcan must read this section!

Safety... Page 1

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

BURN SAFETY - Intense ultraviolet light, sparks, and hot metal produced by plasma arc cutting

will harm exposed skin and eyes. Operators and bystanders must wear protective clothing and

equipment to avoid hazards.

EYE SAFETY - Wear appropriate tinted safety goggles with side shields, or a welding helmet to

protect eyes. Refer to the chart for recommended lens or shield shade;

Arc Current Lens/Shield Shade

Up to 100 Amps Shade No. 8

100-200 Amps Shade No. 10

200-300 Amps Shade No. 12

Over 400 Amps Shade No. 14

Do not use eyewear with broken or pitted lenses or covers. Replace them at once.

Postwarningsandinformpeopleintheareanottolookdirectlyatthearcunlessappropriateglasses,

goggles, or a welding helmet is worn.

TheVulcanOperatingAreashouldbeadaptedtoreducethereflectionandtransmissionofultraviolet

light. Installprotectivescreensorcurtainstoreduceultraviolettransmissions. Paintwallsandother

surfaces with dark colors to reduce reflection.

SKIN SAFETY - Always wear protective clothing including, but not exclusive to, gauntlet gloves,

safety shoes, and head covering.

Flame retardant clothing with cuffless trousers to shield body from sparks and slag is strongly

suggested.

Aftercutting,thesheetedgesandthecuttingtablearedangerouslysharpandhot. Toavoidcutsand

burns, use heavy gloves to handle pieces during removal.

Nevertouchthefrontofthetorchwhenstartingit. Aftercuttinghasbeencompleted,allowadequate

time for the front of the torch to cool.

Qualified first-aid personnel and facilities should be available at or near any Vulcan site to treat

accidental eye and skin burns at once.

FUME HAZARDS AND PRECAUTIONS - Plasma Arc Cutting vaporizes metals into toxic gases,

soconstantventilationand precautionsregarding exposureto theoperatororanypersonsnearthe

Vulcan are absolutely necessary! An appropriate ventilation system, designed to safely withdraw

toxicfumesfromthearea,mustbeinstalledandusedwhenevertheVulcanisoperated. Donotuse

the Vulcan in a confined space unless a safe ventilation system and an operator's fresh air supply

ispresentandworkingproperly! RefertoSection1,PreliminaryInstallationfordetailsregardingthe

necessary initial ventilation setups.

Besuretoactivatetheventilationsystembeforestartingthetorch. Checkperiodicallytoconfirmthat

the vent system continues to remove air efficiently! To ensure that it pulls with its greatest force

duringcutting,alwayscoverthetabletop(s)completely,sothataircanonlyflowthroughasmallarea

forcinggasesintothe12"venthole. Ifsheetssmallerthan5x10'areused,coverexcessspaceon

table top(s) with scrap metal.

Donotcut containers with toxicmaterialsinsideorcontainers that have heldtoxicmaterials. Clean

such containers thoroughly before cutting.

Safety... Page 2

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Stock containing or coated with significant percentages of beryllium, cadmium, lead, mercury, or

zinccanallgiveoffpoisonousfumeswhenburnedbyplasmaarccutting. Donotcutthisstockunless

the operator, or anyone else subjected to the fumes, wears appropriate respiratory equipment, an

air supplied helmet, or that the table ventilation system is working efficiently.

ALways wear a proper breathing mask and use proper ventilation when cutting galvanized metal.

EXTREME CAUTION! Various chlorinated solvents decompose and can turn to lethal phosgene

gas when exposed to ultraviolet radiation caused by plasma cutting. Do not use such solvents on

stock to be cut by the Vulcan. Ask your vendor about suspect solvent formulas. Do not keep these

or any degreasing agents near the plasma arc cutting system.

FIREHAZARDSANDPRECAUTIONS-Heat,sparksandslagproducedbyplasmacuttingofmetal

cancauseexplosionsorfire. KeepfireextinguisherswithintheimmediateVulcanarea. Donotleave

any combustible matter within 35 ft. (10 meters) of the Vulcan site!

It is strongly recommended that containers used for poisonous or explosive substances never be

plasma cut.

Be sure that the Vulcan area ventilation system works properly. Never start the Vulcan as long as

airarounditisladenwithflammable/explosiveagentssuchasdust,gasolineorotherflammablegas,

or combustible liquid vapors. Let the vent system remove such substances first!

Quench freshly cut metal in water or allow metal to cool after cutting before handling it, or allowing

it to contact combustible substances nearby that might be ignited by its heat.

ELECTRICAL HAZARDS AND PRECAUTIONS

Primary Safety Directive - To perform maintenance or work with the machine's electrical

components, always disconnect the main switch to disable power entirely from all parts of the

Vulcan, to avoid the dangers of electrocution.

Becauseplasmacuttingrequiresgreater(opencircuit)voltagethanordinarywelding,upto300VDC,

extreme protection precautions against electrocution must be used while cutting.

Input Connections (Refer also to Section 1, Preliminary Machine Installation)

Install a wall-mounted line disconnect switch as close to the plasma unit power supply as possible

and fuse it according to local electrical codes. This switch allows the operator to turn the power

supply off quickly in an emergency situation.

Conform to all national, state, and local electrical codes for primary wiring sizes and types.

Be sure that input conductors are of proper size to carry Plasma Unit’s rated current.

Primary power cable must have a minimum 600 v. rating.

Do not use the system with a damaged power cord. Inspect the primary power cord frequently for

damage or cracking of the cover. EXPOSED WIRING CAN KILL!! If a power cord is damaged,

replace it immediately.

Inspect the torch leads. Replace if frayed or damaged.

Neveroperatetheplasmasystemunlessthepowersupplyunitcoversareinplace. Exposedpower

supply connections present a severe electrical hazard.

Donot touch the workpiece, including the waste cutoff, while cutting. Leavethe workpiece in place

until after all cutting is complete.

Safety... Page 3

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Before changing the torch parts, disconnect the main power or unplug the power supply. After

changing the torch parts and returning the retaining cap to its operating position, plug the power

supply in again.

Never bypass or shortcut the safety interlocks.

Before removing a power supply cover for maintenance, disconnect the main power at the wall

disconnectswitchorunplugthepowersupply. Toavoidexposuretosevereelectricalhazards,wait

five minutes after disconnecting the main power to allow capacitors to discharge.

Wearinsulatedglovesandbootsto maintain proper insulation against electrical shock. If you must

work in or near a damp area, use extreme caution.

CheckcableoftenforanycrackingorpeelingofcoversandreplacedefectivewiringIMMEDIATELY!

NOTE!To avoid a tripping hazard, it issuggested that brightSafety Tape be putaround the ground

rod and any cable that must lay in a space where people walk.

NOTE! Personal Protection - Keep your body and clothing dry. Do not operate the Vulcan in a wet

or damp environment without proper insulation against ELECTROCUTION! Do not stand, sit, or

otherwise be in any contact with water while operating machine or ELECTROCUTION may result!

Do not operate the Vulcan if any of its electrical cables, torch leads, or the torch itself is damaged.

Do not attempt any maintenance to the Vulcan, including service to torch, plasma unit, or power

supply,without firstdisconnecting powerfrommachineentirelyby shuttingoffthemaindisconnect!

EXPLOSION PREVENTION - WARNING: The plasma system uses compressed gas. Observe

proper precautions when handling and using compressed gas equipment and cylinders. Refer to

the Publication Index at the rear of this section.

When cutting with the plasma system, do not cut in atmospheres containing explosive dust or

vapors. Do not cut pressurized cylinders or any closed container.

Compressed Gas Cylinders -Be certain totakecorrect precautionswhenhandlingand operating

compressed gas equipment and cylinders.

Handle and use compressed gas cylinders in strict accordance with safety standards such as

publishedbythe CompressedGasAssociationin Arlington,VA.(CGA),American WeldingSociety

in Miami, Fla. (AWS), and the Canadian Standards Association in Ontario, Canada (CSA).

Do not move a cylinder unless its protective valve cover is in place. Do not use a cylinder unless it

is secured in place, upright.

Do not use a cylinder that leaks or is otherwise physically damaged. Do not use hammers or any

other implement to force a stuck valve open. Return cylinders with any such defects to supplier.

Never lubricate cylinder valve(s) with oil or grease.

Never move or transport a cylinder without it's protective valve cover in place.

Do not use a cylinder or its contents for any other purpose than that for which it was designed.

Do not place a cylinder near electrical hazards such as welding arcs, or expose it to an open flame

or excessive heat, sparks, or slag of any kind, which can cause it to rupture or explode.

Hose -Label andcolor-codeall gashosesin ordertoclearly identifythetype ofgaspresent ineach

hose. Consult applicable national, state, or local codes for detailed information.

Never use an oxygen hose for any gas other than oxygen.

Safety... Page 4

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Use the shortest possible lengths of hose to avoid damage, reduce pressure drop, and prevent

possible volume flow restriction. Let the hose lie as straight as possible to prevent kinks when

interconnecting system components. Coil excess hose and place it out of the way to prevent

damage and reduce tripping danger.

Check hose regularly for wear, leaks, loose connections, or damage from heat, flames or sparks.

Immediately replace damaged or unreliable hose!

Pressure Regulators - Maintain all pressure regulators used on the Plasma Unit of the Vulcan in

proper working order to avoid failure and danger to operating personnel. Do not use any regulator

that leaks, creeps excessively, or is otherwise damaged. It is strongly recommended that any

malfunctioningequipmentbeservicedonlybytrainedtechnicians,atit’smanufacturer’sdesignated

facility.

NEVERlubricateregulator(s)withoilorgreaseanddonotusearegulatorforanygasotherthanthat

for which it was designed.

NOISE PREVENTION -Theplasmacuttingprocesscangeneratehighlevelsofnoise. Depending

upon the arc current, material being cut, acoustics, and size of the cutting room, distance from the

torch, and other factors, acceptable noise levels as defined by national, state, or local codes may

be exceeded by your plasma system.

GROUNDING - Before operating the plasma system:

InputPower-Besurethepowercordispluggedintoaproperlygroundedoutletorthatthepowercord

ground wire is properly connected to the ground in the disconnect box. If installation of the plasma

system involves connecting a power cord to the power supply, ensure that the power cord ground

wireisproperlyconnected. Conformtonational,state,andlocalstandardwhenfasteningthepower

ground wire to the power supply chassis. CSA standards recommends placing the power cord

groundwireonthestudfirst;thenplacetheotherwiresontopof thepowercordground. Fastenthe

retainingnuttightly.

Make sure that all electrical connections are tight to avoid excessive heating.

Input Power - Connect ground lead of power input cable to both electrical system ground in

disconnectbox,andtogroundstudinPlasmaUnitpowersupply. Becertainallgroundlugsarelarge

enough to carry rated current load and make all connections tight to prevent resistance heating.

Output Power - Connect all positive output ground leads to cutting table Star Ground (referred to,

and illustrated in Section 1). Connect Star Ground to reliable Earth Ground. Refer to National

Electrical Code, Grounding Electrode System or other appropriate source for suitable Ground

specifications.

WorkTable - Clamptheworkcable withgoodmetal-to-metalcontact totheworkpiece(not thedrop

off portion) or to the work table itself.

Connecttheworktabletoagoodearthground. ConsulttheU.S.NationalElectricalCode,Article250,

Section H Grounding Electrode System, or other appropriate national, state, or local codes.

For additional information, refer to the index at the rear of this section.

ELECTRIC AND MAGNETIC FIELDS (EMF)

Plasma arc cutting systems create electric and magnetic fields that may interfere with the correct

operationofelectronichealthsupportequipment,suchaspacemakersorhearingaids. Anyonewho

wearsapacemakerorhearingaidshouldconsultadoctorbeforeoperatingorbeingnearanyplasma

systemwhenitisinuse. TominimizeexposuretoEMF: (1)Keep boththe workcableandthetorch

leadon onesideofyour body. Keepyourbody fromcominginbetween thetorchlead andthework

cable. (2) Keep the distance of work cable to the table as short as possible to eliminate loop areas.

(3)Routetorchleadsascloseaspossibletoworkcable. (4)Donotwrapthetorchleadorworkcable

around your body. (5) Stay as far away from power source as possible.

Safety... Page 5

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

SAFETY DEVICES - The plasma unit used on the Vulcan have safety interlocks to prevent danger

topersonnelanddamagetomachine. Neverattempttoshortoutoroverridetheseinterlocks! Check

theinterlocksandallsafetyrelatedpartsoftheplasmaunitfrequentlyandreplacethemIMMEDIATELY

if they are not working!

The interlocks disconnect the power supply when the retaining cap is loosened.

Never bypass or shortcut the safety interlocks on any of the plasma system units.

Do not use the plasma unit unless all of its power supply covers are in place; failure to do so will

ENDANGERtheoperatorandbystandersnearthemachineand willinterferewiththecoolingofthe

vital parts of unit, which may be damaged as a result.

Be certain that all electrical connections are covered with appropriate insulation material. Cracked

insulation must be replaced!

Each plasma unit is designed to be used only with specific Vulcan torches. Do not substitute other

torches which may overheat and present a potentially dangerous situation to the operator and any

personnel in the area.

Safety... Page 6

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

PUBLICATION INDEX

ThePublicationIndexcontainsalistofpublicationsdealingwithplasmaarccuttingequipmentsafety

practices.

1. American National Standards Institute, 1430 Broadway, New York, NY 10018

(212) 354-3300.

ANSI Standard Z41.1, Standard for Men's Safety-Toe Footwear

ANSI Standard Z49.2, Fire Prevention in the Use of Cutting and Welding Processes

ANSI Standard Z88.2, Practices for Respiratory Protections

ANSI Standard Z87.1, Safe Practices for Occupation and Educational Eye and Face

Protection

2. American Welding Society, 550 LeJeune Road, P.O. Box 351020, Miami, FL 33135

(305) 443-9353.

ANSI Standard Z49.1, Safety in Welding and Cutting

AWS Standard A6.0, Welding and Cutting Containers Which Have Held Combustibles

AWS Standard F4.1, Recommended Safe Practices for the Preparation for Welding

and Cutting of Containers and Piping that Have Held Hazardous Substances

3. National Fire Protection Association, 470 Atlantic Avenue, Boston, MA 02210

(617) 770-3000.

NFPA Standard 51, Oxygen - Fuel Gas Systems for Welding and Cutting

NFPA Standard 70-1978, National Electrical Code

NFPA Standard 51B, Cutting and Welding Processes

4. Superintendent of Documents, U.S. Government Printing Office, North Capitol

Street, Washington, D.C. 20402 (202) 783-3238.

NIOSH, Safety and Health in Arc Welding and Gas Welding and Cutting

OSHA, Safety and Health Standards, 29FR 1910

5. Canadian Standards Association Standard Sales, 178 Rexdale Boulevard, Rexdale,

Ontario M9W 1R3, Canada (416) 747-4000.

CSA Standard W117.2, Code for Safety in Welding and Cutting

Canadian Electrical Code Part 1, Safety Standards for Electrical Installations

6. Compressed Gas Association, 1235 Jefferson Highway, Arlington, VA 22202

(703) 979-0900.

CGA Pamphlet P-1, Safe Handling of Compressed Gases in Cylinders

7. National Welding Supply Association, 1900 Arch Street, Philadelphia, PA 19103

(215) 564-3484.

NWSA booklet, Welding Safety Bibliography

Safety... Page 7

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

YOU ARE NOT READY TO OPERATE THIS EQUIPMENT

UNTIL YOU HAVE READ AND UNDERSTOOD THE

SAFETY INFORMATION IN THIS MANUAL.

THIS SAFETY ALERT SYMBOL INDICATED IMPORTANT SAFETY

MESSAGES IN THIS MANUAL. WHEN YOU SEE THIS SYMBOL

CAREFULLY READ THE MESSAGE THAT FOLLOWS AND BE

ALERT TO THE POSSIBILITY OF PERSONAL INJURY OR DEATH.

!

BEFORE ANY MACHINE IS USED BY AN EMPLOYEE OR IS LOANED OR

RENTED,MAKEABSOLUTELYCERTAINTHATTHEOPERATOR(S)PRIORTO

OPERATING:

1. ISINSTRUCTEDINSAFEANDPROPERUSE.

2. REVIEWSANDUNDERSTANDSTHEMANUAL(S)PERTAININGTO

THEMACHINE.

ITISTHEUSER'SRESPONSIBILITYTOUNDERSTANDANDFOLLOWTHE

MANUFACTURER'SINSTRUCTIONSONMACHINEOPERATIONAND

MAINTENANCE,ANDTOOBSERVEALLPERTINENTLAWSAND

REGULATIONS.

WARNING

!

REMEMBER, A CAREFUL OPERATOR IS THE BEST INSURANCE

AGAINST AN ACCIDENT. GIVE COMPLETE AND UNDIVIDED

ATTENTION TO THE JOB AT HAND.

!

WARNING, DO NOT WEAR LOOSE CLOTHING, JEWELRY, OR

UNRESTRAINED HAIR OR BEARD STYLES WHICH MAY CATCH IN

MOVING PARTS.

!

WARNING, THE OPERATOR MUST HAVE AUXILIARY OPERATING

PERSONNEL CLEARLY WITHIN HIS FIELD OF VISION AT ALL TIMES!

!

Safety... Page 8

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

DANGER, COILS MUST NEVER BE CARRIED OVER THE HEADS OF

OTHER EMPLOYEES.

!

WARNING, KEEP LIQUIDS (SOLVENTS, LUBRICANTS, ETC.) AWAY

FROM ELECTRICAL EQUIPMENT.

!

WARNING, YOU MUST NEVER DISCONNECT OR REMOVE ANY

SAFETY DEVICE OR OPERATE ANY MACHINE WHO'S SAFETY

DEVICES HAVE BEEN DISCONNECTED OR REMOVED.

!

DANGER, DISCONNECT AND LOCK OUT ALL POWER SOURCES

BEFORE INITIATING ANY REPAIRS.

!

WARNING, HYDRAULIC SYSTEMS ARE HIGHLY PRESSURIZED.

ESCAPING HYDRAULIC OIL, EVEN AN INVISIBLE PINHOLE LEAK, CAN

PENETRATE BODY TISSUES CAUSING SERIOUS INJURY. WHEN

LOOKING FOR LEAKS, USE A PIECE OF WOOD OR CARDBOARD.

(NEVER USE THE HANDS OR ANY OTHER PART OF THE BODY)

!

!WARNING, NARROW OR UNSTABLE COILS MUST NOT BE

TRANSPORTED WITHOUT THE AID OF BLOCKING AND/OR SIDE

SUPPORTS

WARNING, IF ANY PART OF THIS MACHINE SHOULD BECOME

OVER LUBRICATED AND LUBRICANT SPILLS OVER OR BUILDS UP, IT

SHOULD BE CLEANED UP IMMEDIATELY, SO AS NOT TO HINDER THE

PROPER OPERATION OF THE MACHINE OR ENDANGER OTHER

PERSONNEL.

!

Safety... Page 9

WARNING, DO NOT HANDLE MATERIAL (COIL, SHEET OR

BLANK) WITHOUT WEARING PROTECTIVE GLOVES.

!

!WARNING, IMPROPER OPERATION OF THIS MACHINE MAY

CAUSE DAMAGE TO THE MACHINE AND/OR PERSONAL INJURY TO

THE OPERATOR AND NEARBY PERSONNEL.

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

WARNING, KEEP THE WORK AREA CLEAR OF OBSTRUCTIONS

AND THE FLOOR CLEAN AND DRY.

!

WARNING, NEVER USE STOOLS, BOXES, CRATES OR SIMILAR

ITEMS AS SUBSTITUTES FOR WORK PLATFORMS, SCAFFOLDING

OR LADDERS.

!

WARNING, DO NOT OPERATE ANY EQUIPMENT WHICH HAS

LOOSE, WORN, OR BROKEN PARTS.

!

WARNING, DO NOT OVERLOAD EQUIPMENT BEYOND IT'S

STATED OR IMPLIED CAPACITIES.

!

WARNING, BEFORE PERFORMING ANY MAINTENANCE ON

THIS MACHINE, BE SURE THAT THE MAIN DISCONNECT SWITCH

IS SHUT OFF AND LOCKED IN PLACE.

!

!WARNING, DO NOT OPERATE ANY EQUIPMENT WITHOUT

GUARDS AND COVERS INSTALLED IN PLACE.

DANGER, YOU MUST NEVER CHECK DIMENSIONS OF

WORKPIECE WHILE EQUIPMENT IS OPERATING.

!

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

12

12

12

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Safety... Page 10

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

The Lockformer Company

711 Ogden Ave., Lisle, IL. 60532 (630) 964-8000

TABLE OF CONTENTS

Reference Photos

Section 1. Preliminary Machine Installation

Section 2. Operation and Procedures

Section 3. Maintenance

Section 4. Lockformer Assembly Drawings And Parts Lists

Section 5. Troubleshooting

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

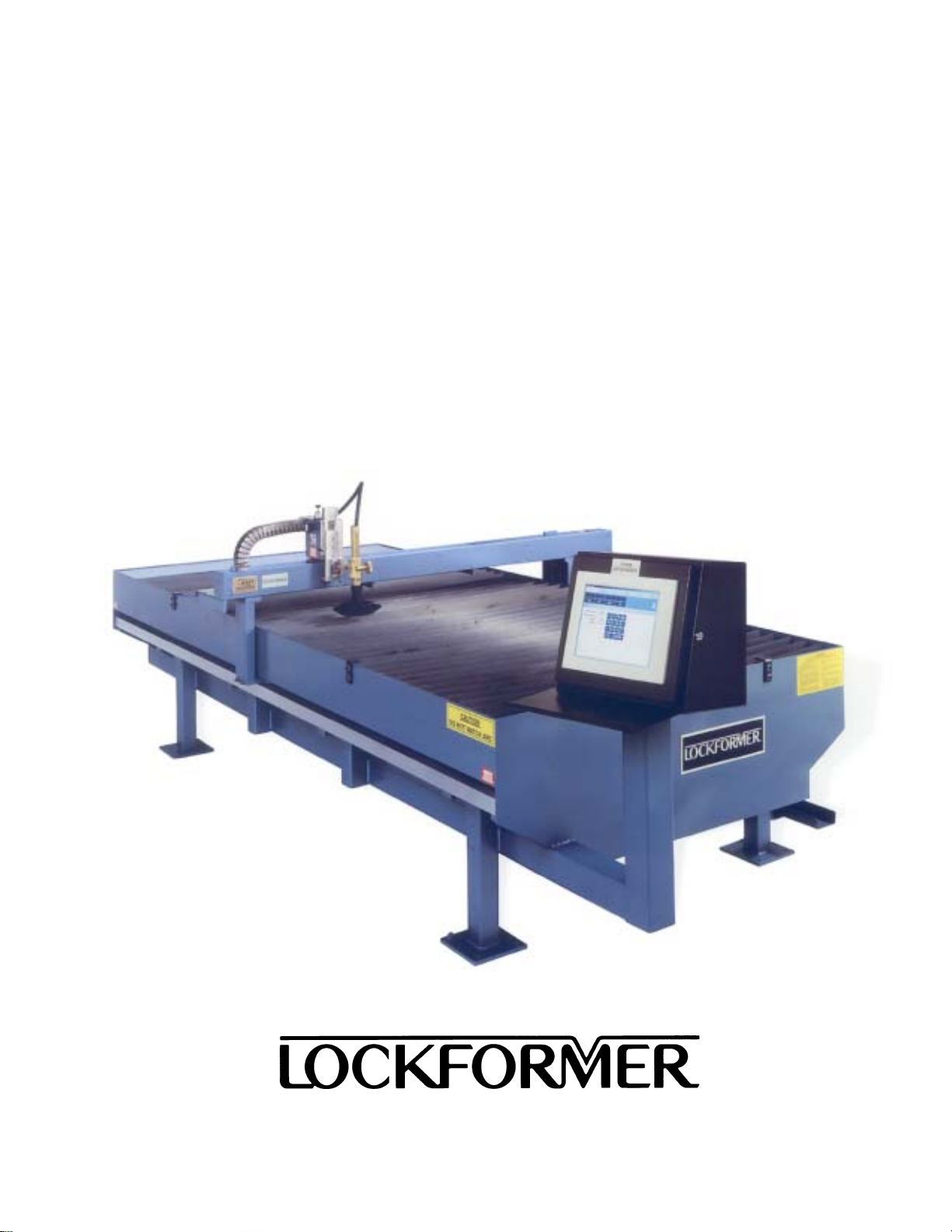

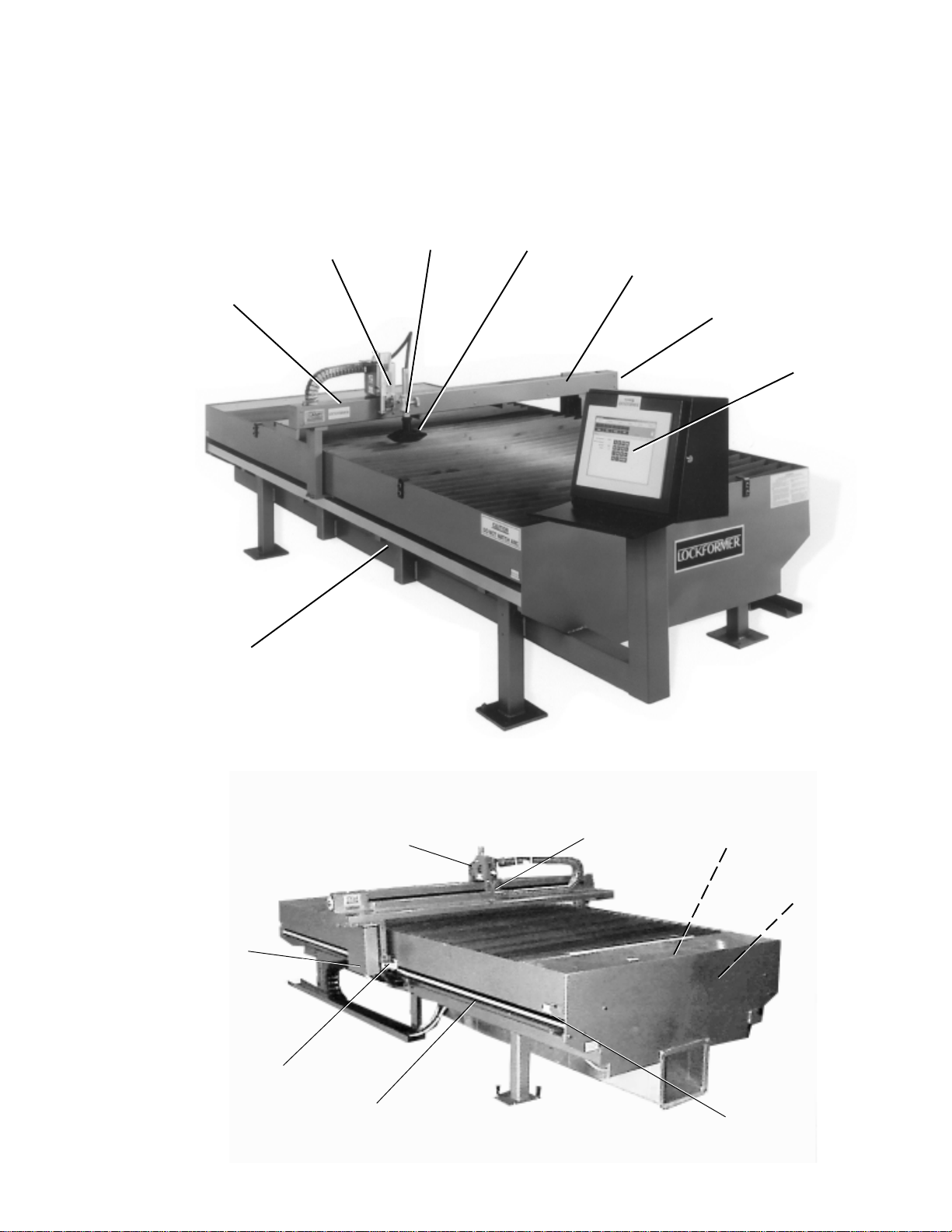

Vulcan 1000B

REFERENCE PHOTOS

"X" AXIS

DRIVEMOTOR

X-AXIS

HOMESWITCH

"X"CARRIAGE

FLOATING

HEAD

PNEUMATIC

TORCHLIFTER

PLASMA

TORCH

"X" BEAM EMERGENCY

STOP

TOUCHSCREEN

MONITOR / P.C.

"Y" AXIS

SUPPORTROD

X-AXIS

HOMEPLATE

Y-AXIS

SUPPORT TUBE

"Y" AXIS

HOME

SWITCH

"Y" AXIS

HOMEPLATE

"Y" AXIS

DRIVEMOTOR

(INSIDE)

DRIVE

SYSTEM

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

SECTION 1

PRELIMINARY MACHINE INSTALLATION

1. Safety

2. Uncrating

3. Location of Machine

4. Incoming Power Supply for Plasma Unit

5. Grounding Procedure / Power Supply

6. Ventilation

7. 200 Foot Cable Category 5E Cable Set Up Procedure

8. 5.7 / 5.8 Touch Screen Networking Procedures (3) Pages

9. Optional Control Positions Drawing Number AA55773

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

ThefollowinginformationoutlinesthefactoryproceduresforpreliminaryinstallationoftheLockformer

Vulcan Cutting Machine. Appropriate Lockformer reference and assembly drawings accompany

this manual. See section 4.

1. SAFETY

Voltagesusedonthismachinearepotentiallyhazardous. Therefore,allequipmentmustbeinstalled

andmaintainedinaccordancewithlocal requirements and National Electrical Codes. Also see the

SAFETY FIRST section of this manual.

2. UNCRATING

Themachine’scratingshouldensurethatallcomponentsarriveingoodorder,butastheassemblies

areuncrated,checkallcontentswiththepackinglistforpossibledamagefromshipping. Ifanything

shows up missing, or damaged, notify the carrier in writing at once. It is the responsibility of the

receiver to file any claims for damage against the carrier. As each assembly or detail is unpacked,

itshouldbeplacedinasuitabledryareaandhaveitspreservativeremovedbyuseofanontoxicfluid.

Avoid the use of trichlorethylene or perchloroethylene, and ensure that the cleaning area is well

ventilated.

3. LOCATION OF MACHINE

The Vulcan needs a floor space where vibration is at an absolute minimum. Precision operation is

necessary for accurate cutting, thus avoid areas where the transmission of any heavy vibration,

(from trucks, factory equipment, etc.) may occur nearby.

Choose a site for the Vulcan near gas and electrical outlets, and if possible, near any related

production lines, for manufacturing efficiency. Material handling is also important, so be sure to

providespaceforstockpilingmaterialandmovingitbyhoist,truck,orothermeans. Adequatelighting

and ventilation must be available for safety reasons, as noted in the safety material.

DO NOTANCHOR THETABLE TOTHE FLOOR. ALockformer installation

technicianwill leveltheequipmentand secureitto thefloor.

4. INCOMING POWER SUPPLYFOR PLASMA UNIT

The proper cable setup procedures are as follows:

1. Locate the Plasma Unit (consult Lockformer Service Department).

2. Use as short a power cord as is practical to connect the machine to its power supply. Donot use

a cable that is too short - use one that leaves some slack so it cannot stretch or break during use.

Do not coil the cables. Follow all applicable local, state, and national codes.

3.RouteACpowerwirestokeepthemawayfromanyauxiliarypower;thisincludessolenoids,control

boxes, etc.

4. Connect the Vulcan to an AC power source for its use exclusively. Do not operate any other

machinery from the same power line as the Vulcan!

Preliminary Installation... Page 1

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

STAR

GROUND

LUG

NOTE:

THE GROUNDING

LOCATION IS SHOWN

WITH THE TOOL

BOX REMOVED

PHOTO 1

5. GROUNDING PROCEDURE / POWER SUPPLY

AVulcananditsperipheralequipmentmust beproperlygroundedforsafe,efficientoperationofthis

system,whichrequirescarefulroutingandconnectionofgroundwires. StarGroundisthetermused

heretodescribethemethodoffocusingallofthesystem’sgroundwiresbydirectingthemalltosame

centraltiepointtoanearthground. RefertoaccompanyingLockformerassemblydrawingstoassist

inthecorrectarrangement ofelectrical connectionsfor grounding. Figure#1,whichappearsatthe

endofthissection,isaStarGroundassemblydrawing,showingsuggestedpositioningforgrounding

wires.

Set up the grounding as follows:

a.Usethesystem’sworktable as the Star Ground tie point. Position the Star Ground lugasshown

infigure#1,nearplasmasupplyandincloseproximitytolocationofgroundrod. NOTE! Thisground

rod must be installed according to the National Electrical Code Standards. See the Safety First

section.

b.Install acoppergroundrod intothefloor (atleast 8 ft.longand 1/2"indiameter) incloseproximity

totheSTARGround,directlybeneathitif possible. Seefigure1forrecommendedlocationoptions.

NOTE! To avoid tripping on cable, it is suggested that bright safety tape be put around ground rod

and any cable that must be the space where people walk.

c.Connectthestargroundtothegroundrodwithastrandedwire(minimum2AWG) Thiswirecannot

be more than 4 feet long. Be sure each end of the wire is tightly secured to ground and rod,

respectively.

d. Connect the green wire secured to machine gusset, to the Star Ground lug.

e.Cleanany surfaces, to which eitherendofa ground wire will beconnected,ofanyrust or grease,

toensurethatallgroundconnectionsmakethenecessarycontactwiththecomponent; thenconnect

all grounding wires, making sure all connections are tight. Use wire (minimum of 8 AWG) for

grounding straps.

CAUTION

Do not ground to electrical conduit or pipes carrying gases or flammable liquids.

Use only recommended sizes of electrical cable.

NOTE: Supply power to machine through a shielded main power line. Do not use any type of

extension cord.

The Vulcan Plasma Unit has been prewired for voltage ordered.

Preliminary Installation... Page 2

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Figure 1

STAR

GROUND

LUG

PLASMA ARC

POWER SUPPLY

CONTROLLER

GROUND

ROD

LOCATION

OPTION1

GROUND

ROD

LOCATION

OPTION2

EMERGENCY STOP

EMERGENCY STOP

Preliminary Installation... Page 3

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

EXHAUST OPENING

PHOTO 2

1 FOOT LONG

CAT 5E CABLE 200 FOOT LONG

CAT 5E CABLE

CROSSOVER

COUPLING

ALLJOBDATAISSTORED

ONTHE"V"DRIVE

OFFICE SHOP

CONTROLLER

V DRIVE

CDRIVE

6. VENTILATION (see SAFETY, FIRST foreword for additional information!)

To remove the toxic gases that are generated when metal is vaporized, a suction system with

minimum. 3000-3500 cfm. exhaust draw must be installed on the cutting table through the opening

provided at the bottom on the end of table.

7. CAT 5E CABLE SET UP PROCEDURE

Run a Category 5 Cable enclosed in 1" diameter conduit to the rear of the control console.

WARNING Do not pull on the cable ends. The cable ends are not covered under the warranty, If

brokenduringinstallation.

Preliminary Installation... Page 4

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

8. 5.7/5.8 TOUCH SCREEN NETWORKING PROCEDURES

Vulcan 5.7/5.8 TouchScreen Networking Procedures

Note: These configurations assume that the Vulcan Shop Computer and the Vulcan TouchScreen

Computer are not being networked to a company-wide network. The company’s networking

personnel must configure any networking to a company-wide network.

These configurations assume that the Vulcan Shop Computer serves as the Vulcan data

repository.

These procedures apply to Windows version XP Professional or XP Home Edition operating

systems.

>Before beginning verify the following:

1. TheNICs(networkinterfacecards)areinstalledandthecrossovercable

connectedbetweentheVulcanShopComputerandtheVulcanTouchScreen

Computer.

2. AkeyboardandamouseisconnectedtotheTouchScreenusingthesplitter

cable is contained in the LCD Monitor box.

3. Theblack protectionblockisconnected toprinterport1.

4. ThefollowingsoftwarehasbeeninstalledontheTouchScreencomputer.

A. VulcanSoftware

B. VS Control Program

C. .NETFramework

5. TheVulcanShopComputerispoweredonandtheVulcansoftwarehasbeen

loaded.

From the Vulcan TouchScreen Computer

To Set Computer Name and Workgroup Name

1. SelectStartand highlightMY COMPUTER fromtheselectionpop-up window.

Rightclick themouseon MY COMPUTER andchoose showonthe desktop.

Thiswillplaceaniconfor MY COMPUTER on yourdesktop.

2. Right click on the MY COMPUTER icon located on the desktop and choose

properties.TheSystempropertieswindowwillnowappear.

3. ChoosetheComputerNametab.

4. ClicktheChangebuttonnextto”renamethiscomputer"or"joinadomain."

TheComputerNamechangesWindownowappears.

5. Inthecomputernamebox,typeVulcan-ts1.

6. Intheworkgroupnamebox,typeVULCAN.

7. ChooseOKfromtheWelcometotheVulcanworkgroupwindowandOKfromthe

prompttorestartcomputerwindow.

8. Restart yourcomputer byselecting Start, Shutdown, and Restart.

Preliminary Installation... Page 5

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Table of contents

Other Lockformer Welding System manuals

Popular Welding System manuals by other brands

EWM

EWM GT 1000 SKK95 3M operating instructions

TOP GUN WELDING

TOP GUN WELDING TGWTIG195DCPULSE user manual

Lincoln Electric

Lincoln Electric 10630 Operator's manual

Lincoln Electric

Lincoln Electric DUAL VANTAGE 800-I Operator's manual

Miller Electric

Miller Electric Big Blue 400 PX owner's manual

Miller

Miller Big Blue 600 Air Pak owner's manual

WORMS

WORMS Robin Subaru MIxte 4500/3.2 Instructions for use

RedHotDot

RedHotDot HOT MIG-19 user manual

Miller

Miller Syncrowave 200 owner's manual

Thermal Dynamics

Thermal Dynamics DRAG-GUN 38 instruction manual

Miller Electric

Miller Electric 280 NT owner's manual

Saf-Fro

Saf-Fro DVU P400 Instruction for operation and maintenance