SAFETY PRECAUTIONS

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

▶

SAFETY PRECAUTIONS

Before replacing the blades, turn the tractor engine off, pull the parking brake, disengage the power

take off, rise the mower using the tractor lift, and install supports to prevent accidental dropping of the

machine.

MOWING

Clear the mowing area of debris BEFORE mowing, especially objects that may be thrown and cause

harm. Dry lawn cuts easier, requires less power and is likely to bunch and plug the mower. If the lawn is

taller than about 8", consider mowing twice proper adjustments.

Do not operate the mower if all the safety requirements are not in place.

Lower mower and start the PTO. Lower to the ground and increase the PTO rpm.

Wear work clothes or other comfortable apparel. Avoid baggy clothes or clothes with long sleeves to

prevent being grabbed by turning or mowing components.

Move forward at slow speed. Inspect the work and consider marking mowing height adjustments by

moving the washers on top of the wheels.

Safety operation

-Do not place your hands, inside the machine when it is running.

-Do not use the mower to transport people or objects when it is running or during transport.

-When rising the mower, slow down PTO speed 20% of normal and only raise as much as is

needed to have the proper clearance. Increases the life of the PTO.

-Mower clogged. Remove material. If it is too wet, wait for grass or mud to dry.

-Do not remove safety cover & safety equipment. If you want to remove or clean it, turn the

tractor engine off first.

-Keep hands, feet and clothing away from attachment when mower is running.

-Do not use the mower to transport a load.

-When the mower is running and working, stay at a safe distance from mower.

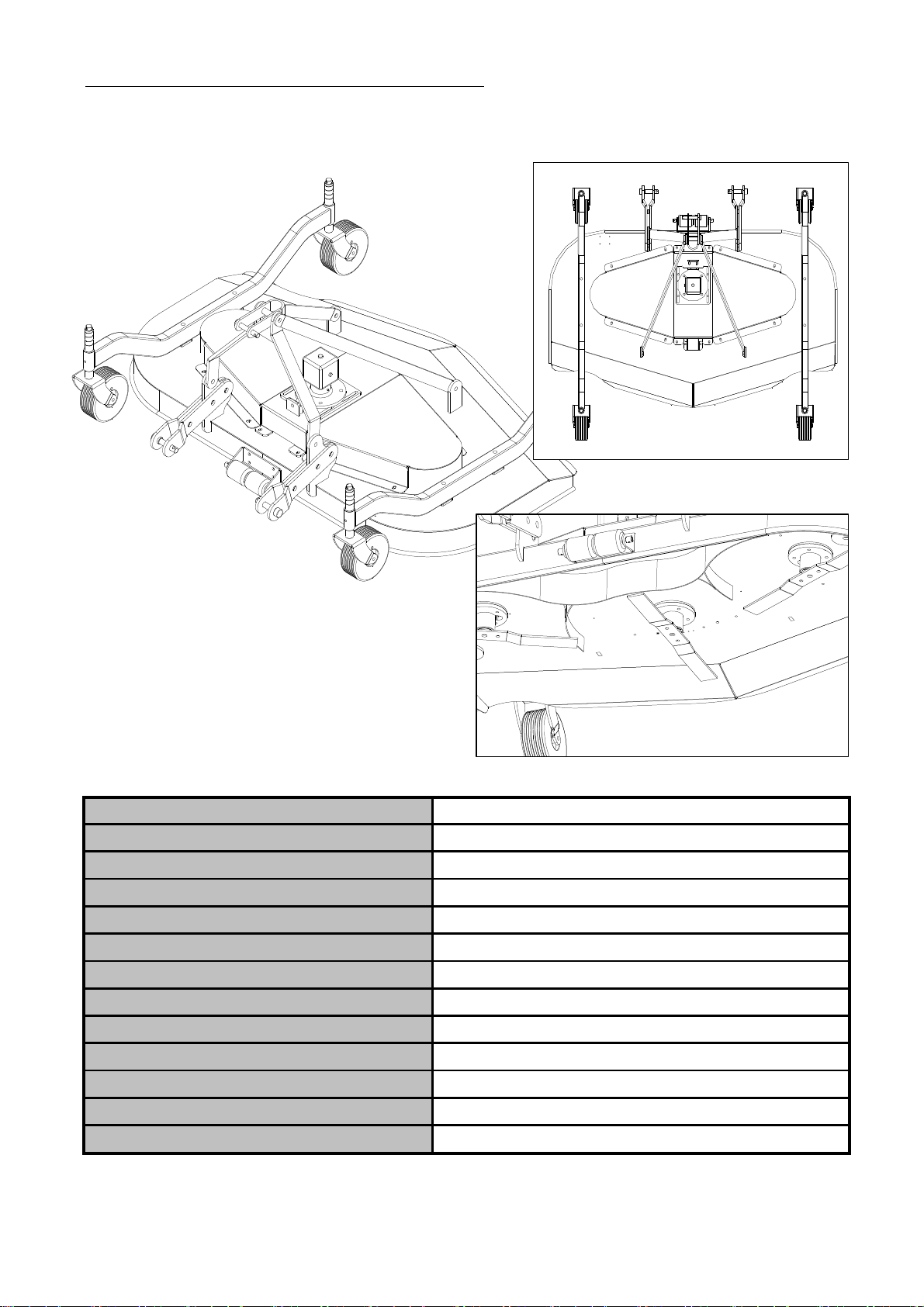

INSPECTION ITEMS

-Make sure that the tractor drawbar does not interfere with either hooking up the mower or running

the PTO.The tractor top link needs to be easily adjustable in length. Position the mower behind

tractor on a level surface. Make sure all lift

ins and related l

nch

ins are in

lace.

Do not clean, lubricate, repair or adjust any components when the engine is running or the equipment is

For height adjustment, stop the PTO completely, cut off the engine, remove the lynch pins in the wheel

Belt tension :

-Maintain to be just tight enough to prevent slipping.

-To adjust, turn bolt in front of the gearbox. Belts that too height will lead to premature failure and

may cause a safety hazard.

GENERAL NORMS.

Before starting, running or servicing the machine, do not drink alcoholic beverages, take drugs or any

other substances which ma

effect the o

erator or service

erson's abilit

.

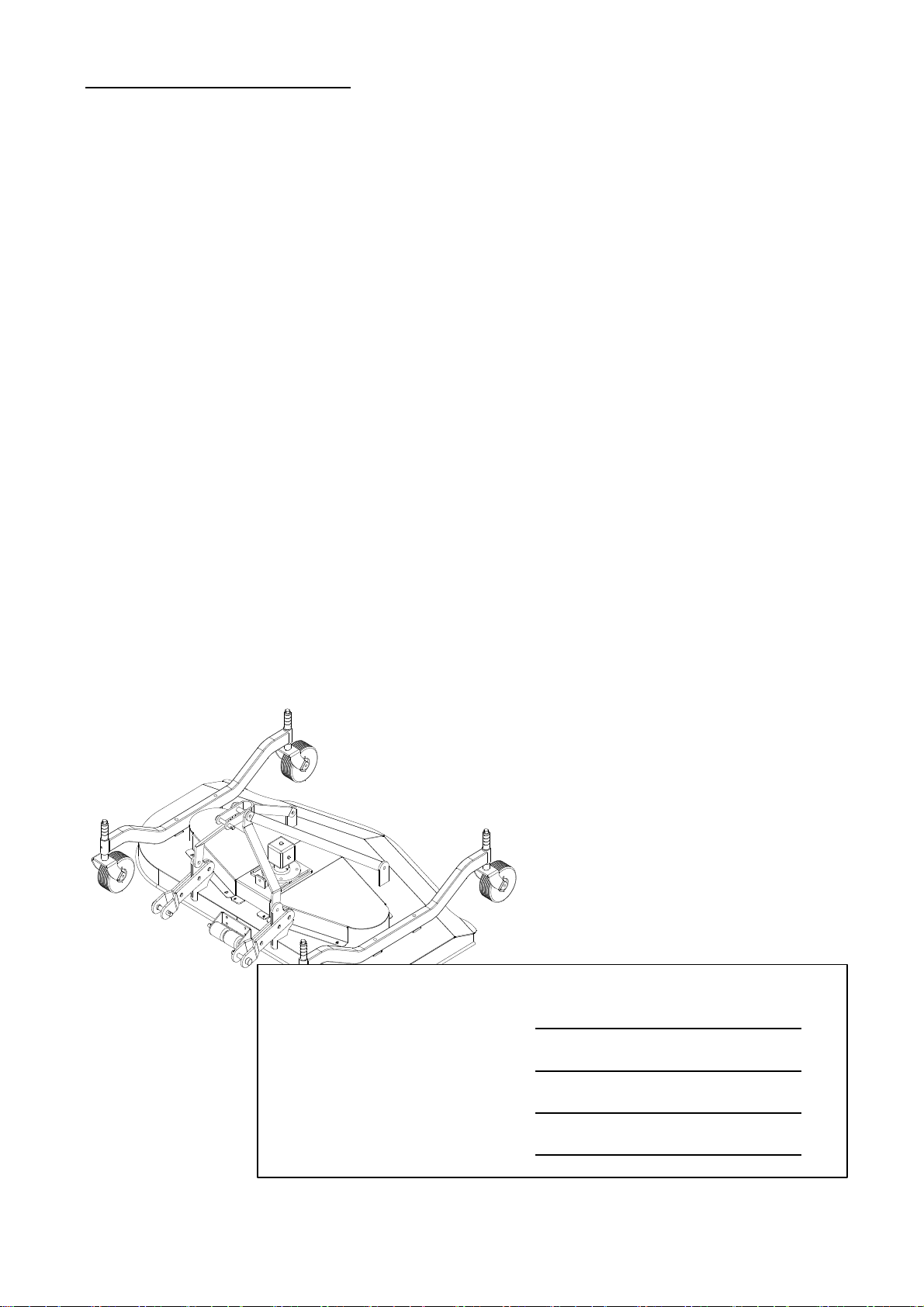

Hooking up to the tractor

-Nobody is standing between the tractor and the mower.

-Make sure that the engine is off, the power take off disengaged and the handbrake engaged when

carr

in

out when connectin

the mower to the tractor.

-Make sure that the tractor PTO shaft and the mower input shaft are connected.

Proper operating, service and adjustment is the key to machine performance and long life. Inspect

frequently for loose bolts, proper belt tension, blade sharpness , ect.

All hardware & guides in place and tight, especially that the blade bolts are tight.

5