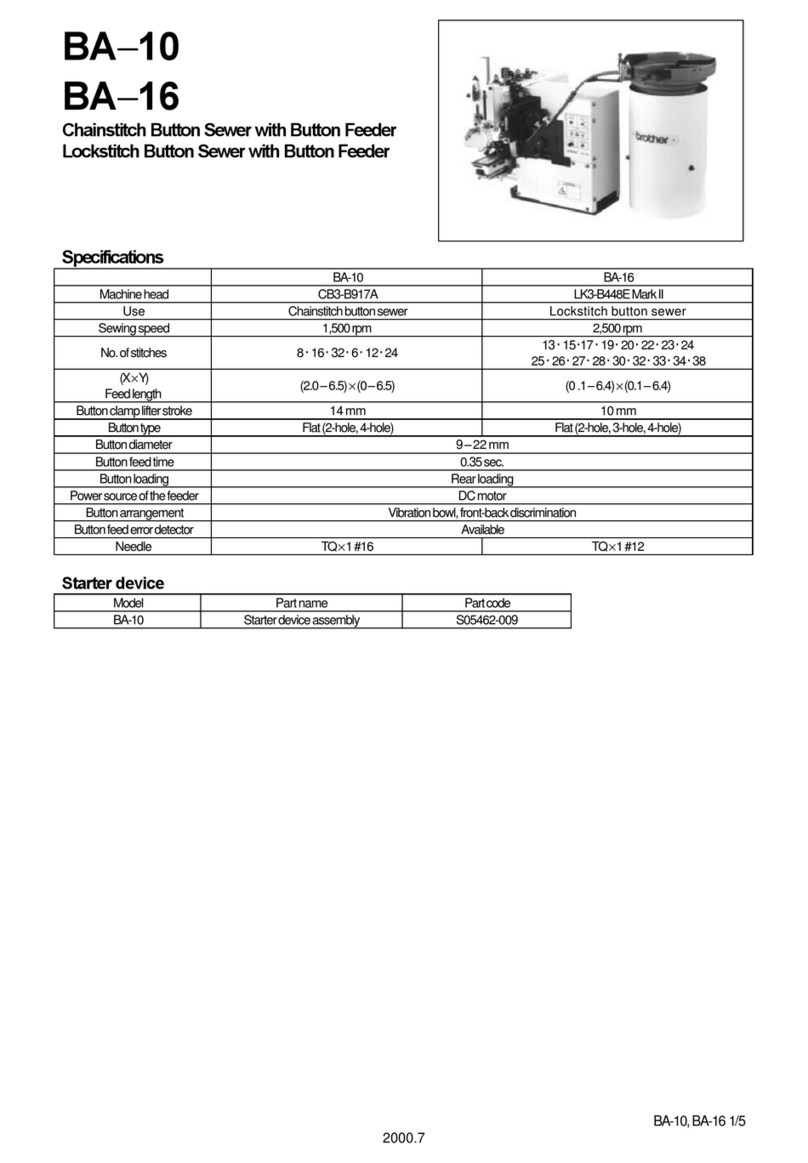

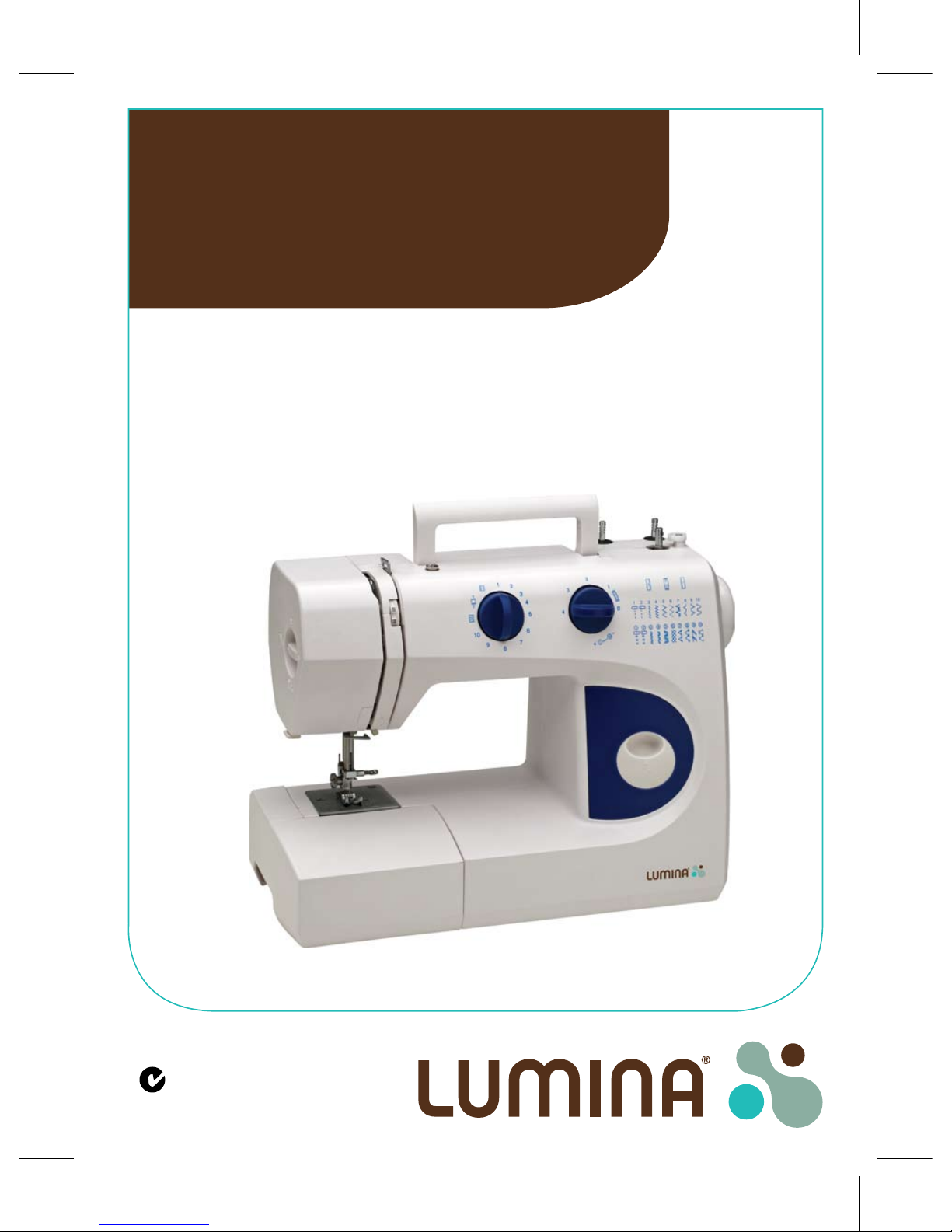

Lumina ESM008 User manual

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

the household series

sewing machine

Date: 25.09.2007

Version: 02

Page: Front (of 40 pages)

model number: ESM008

after sales support

tel: 1300 366 144

N11013 Q04532

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

II

Date: 25.09.2007

Version: 02

Page: II (of 40 pages)

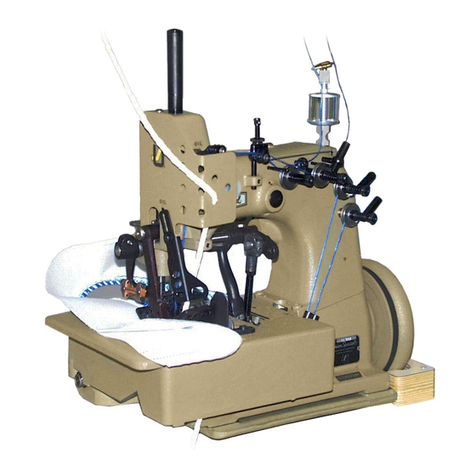

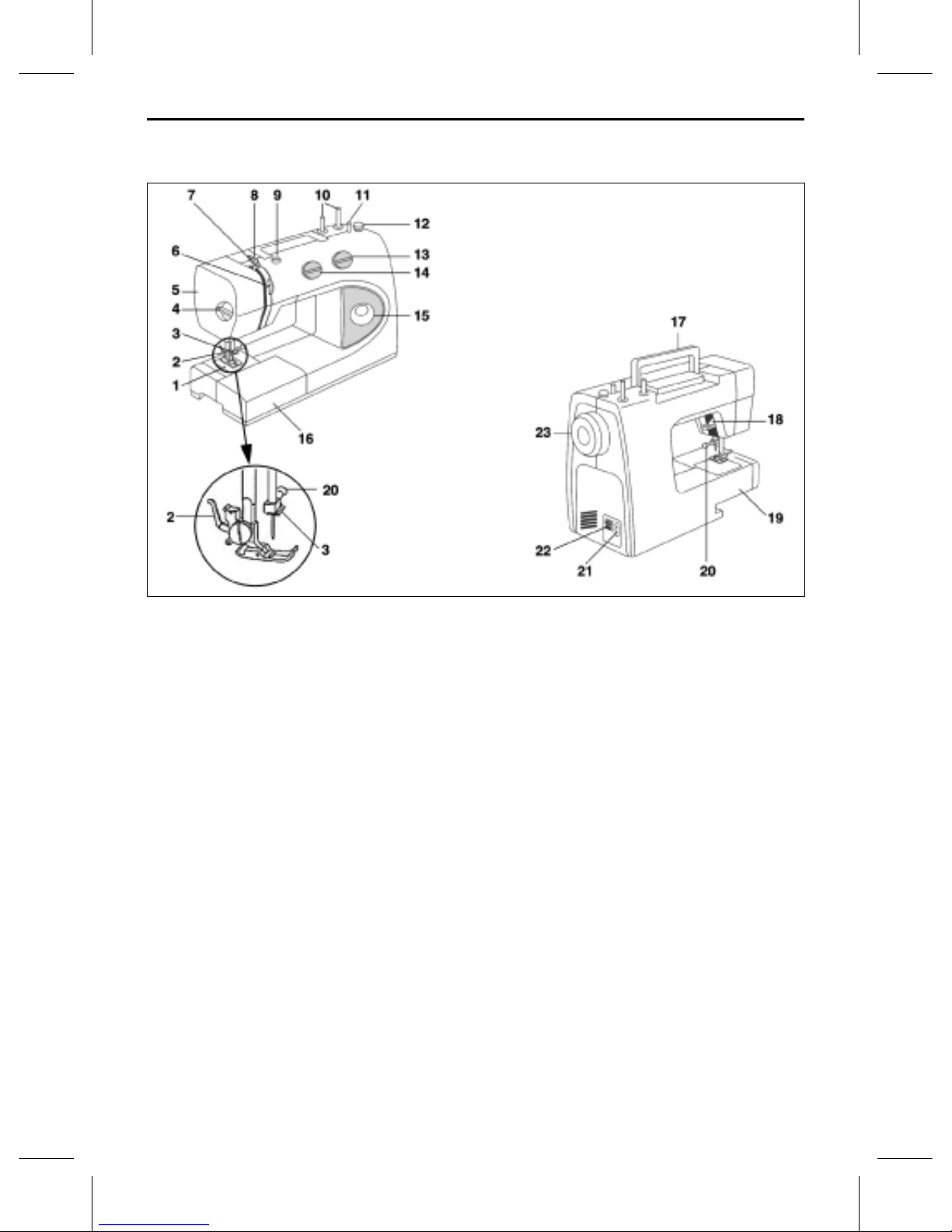

PARTS DESCRIPTION

1. Needle plate

2. Sewing foot retainer lever

3. Thread hook

4. Rotary switch sewing foot pressure

5. Upper cover

6. Thread tension adjusting wheel

7. Thread take-up lever

8. Thread tensioner

9. Winding tension disc

10. Thread spool holder

11. Bobbin supporting arm

12. Bobbin winder

13. Stitch length rotary switch

14. Stitch pattern rotary switch

15. Reverse sew button

16. Extension table

(with accessories case)

17. Carrying handle

18. Sewing foot lever

19. Free arm table

20. Needle clamp screw

21. Foot pedal socket

22. On/off switch for the light

23. Hand wheel

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

III

Date: 25.09.2007

Version: 02

Page: III (of 40 pages)

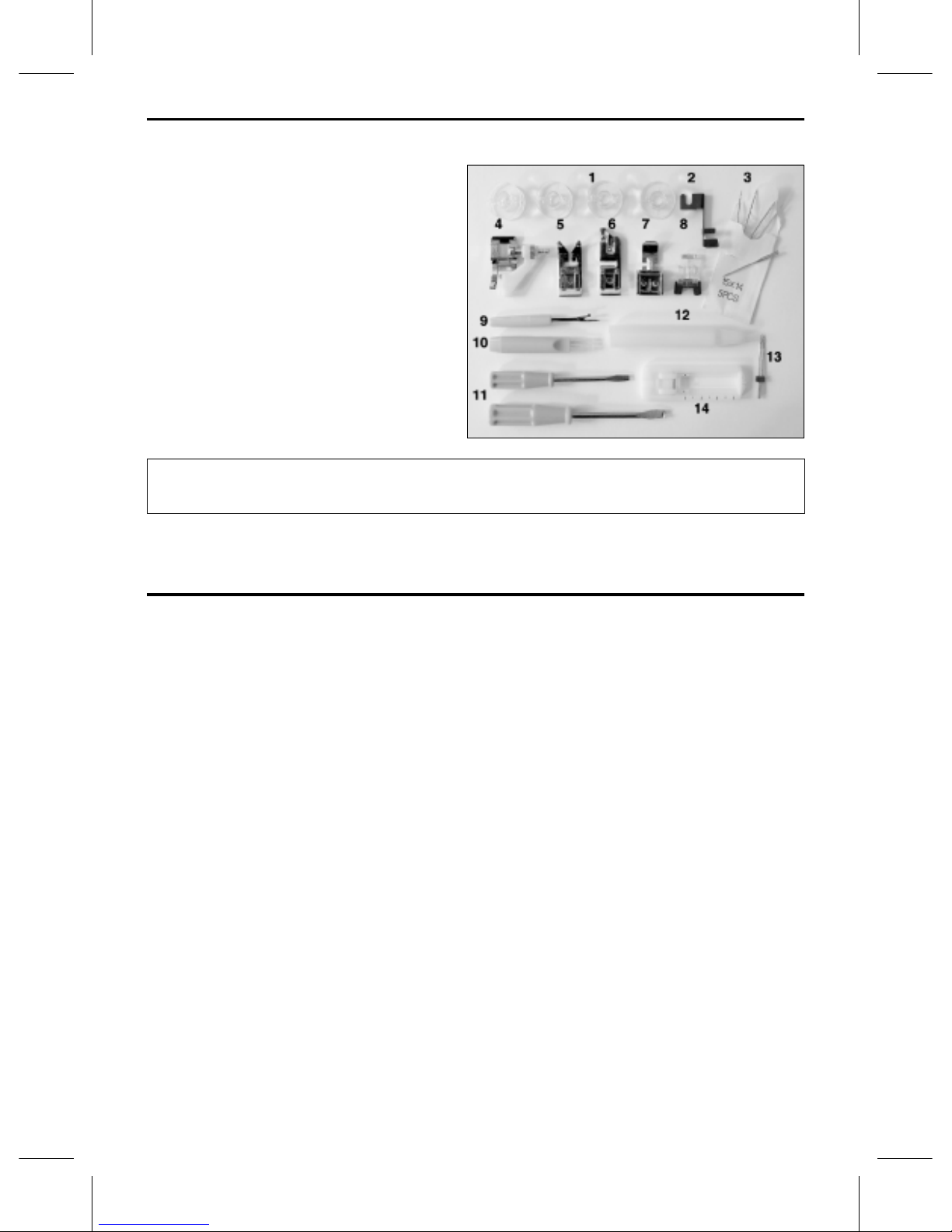

ACCESSORIES

1. Bobbins (4 items)

2. Guide rail

3. Needle assortment

4. Blind stitch foot

5. Zig-zag foot (standard foot)

6. Seaming foot

7. Zipper foot

8. Button sewing foot

9. Cutting device

(to be found in the brush’s handle)

10. Brush

11. Screwdriver (2 items)

12. Small squirt oiler

13. Double needle

14. Buttonhole foot

15. Power cable with foot pedal (not displayed)

16. Covering cap (not displayed)

Please check the accessories with regard to completeness.

TECHNICAL DATA

Lumina ESM-008 sewing machine:

Rated voltage 220-240 V ˜50 Hz, rated input 85 W, motor 70 W, TÜV-GS, CE, protection class II.

Lamp:E14, max. 15 W.

Foot pedal MODEL HKT7:

Rated voltage 200-240 V ˜50 Hz, 0.5 A, CE, protection class II.

The Lumina ESM-008 sewing machine may only be used with the MODEL HKT7 foot pedal.

NOTE: The zig-zag foot is fixed to the machine on the sewing foot retainer. The small accessories are

arranged in a folding compartment in the extension table.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

1

Date: 25.09.2007

Version: 02

Page: 1 (of 40 pages)

PARTS DESCRIPTION ...................................... II

ACCESSORIES ................................................. III

TECHNICAL DATA ........................................... III

SAFETY WARNINGS ......................................... 2

Getting to know your sewing machine ........ 2

Intended use ................................................. 2

Before starting ............................................. 2

Safety warnings ........................................... 2

Environment protection ............................... 4

Packaging ....................................................... 4

Disposing of the appliance ............................. 4

OPERATION ....................................................... 5

Installing and connecting ............................ 5

Preparing the sewing operation .................. 5

Function of the foot pedal .............................. 5

Extension table ............................................... 5

Sewing machine light ..................................... 6

Change the sewing foot .................................. 7

Changing the needle ....................................... 7

Overview needle and thread ........................... 8

Using the thread spool holder ........................ 8

Removing and inserting of the bobbin case ... 9

Winding ........................................................ 10

Inserting the thread into the bobbin case .... 11

Threading the upper thread ......................... 12

Taking up the lower thread .......................... 13

Adjusting the tension of the upper thread .. 14

Stitch pattern rotary switch ......................... 14

Stitch length rotary switch .......................... 15

Reverse sew button ....................................... 15

Lowering the feeder ..................................... 16

Rotary switch for adjusting

the sewing foot pressure .............................. 16

Starting the sewing work .......................... 17

Straight stitch .............................................. 17

Altering the sewing direction ....................... 17

Using the markings on the needle plate ...... 18

Sewing a right angle .................................... 18

Sewing techniques ..................................... 19

Overview over the stitches

and sewing techniques ................................. 19

Zig-zag stitch ................................................ 20

Whip stitch ................................................... 20

Triple zig-zag stitch....................................... 20

Triple straight stitch .................................... 20

Sewing on buttons (zig-zag foot) ................. 21

Sewing on buttons (button sewing foot) ...... 22

Sewing a buttonhole ..................................... 23

Sewing in zippers ......................................... 24

Blind stitch using guide rail ........................ 25

Blind stitch using blind stitch foot .............. 26

Seaming ........................................................ 27

Sewing with double needles ......................... 27

Embroidery stitches ................................... 28

Arch stitch .................................................... 28

Elastic crotch seam ....................................... 28

Grid stitch .................................................... 28

Elastic stitch with two stitches .................... 29

Applique ....................................................... 29

Closed overlock stitch ................................... 29

MAINTENANCE AND CARE ............................ 31

Removing the case and its parts ................ 31

Cleaning the feeder .................................... 32

Oiling the parts beneath the upper cover .. 32

Trouble shooting ........................................ 33

TABLE OF CONTENTS

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

2

Date: 25.09.2007

Version: 02

Page: 2 (of 40 pages)

SAFETY WARNINGS

Getting to know your sewing machine

Your Lumina ESM008 sewing machine is a top-quality modern appliance enabling you to perform

numerous sewing operations. Among other things, these include:

• 24 different sewing programmes

• Inserting zippers by means of the zipper foot

• Sewing buttonholes

• Sewing on buttons

• Seaming with a special seaming foot

• Sewing with free arm

Intended use

Only the functions described in these Operating lnstructions may be carried out with this sewing

machine. Any other use is considered as not intended use.

Before starting...

Before putting your sewing machine into operation, please observe the following points:

• The appliance is solely designed for private use.

• Prior to initial operation read these Operating lnstructions thoroughly and in particular observe the

safety warnings in the next paragraph.

• If possible, keep the Operating lnstructions ready at hand near the appliance.

• If you hand on the appliance to other persons, please also include these Operating Instructions.

• Only use accessories recommended by the manufacturer, listed in this manual.

Safety warnings

The following symbols are used in these Operating lnstructions for identifying safety warnings

Danger!

This symbol identifies dangers that may result in severe injuries.

Attention!

This symbol identifies dangers that may result in injuries and material damages.

NOTE: These Operating lnstructions only describe how to operate your sewing machine. The sewing

know-how as well as the corresponding technical terms are considered as a prerequisite.

The numbers used in the text refer to the main figure on the fold-out on the inner side of the front.

There are, however, some exceptions. In such cases the text contains a corresponding note. Letters

refer to parts marked in the adjacent drawing.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

3

Date: 25.09.2007

Version: 02

Page: 3 (of 40 pages)

SAFETY WARNINGS

It is necessary that you strictly adhere to the following safety warnings:

Danger! For protection against electric shock

• The appliance operates with dangerous voltage. Never leave the sewing machine

unattended if it is energised.

• After using the sewing machine, when leaving or before cleaning it, immediately

disconnect the power plug.

• The appliance must not be contacted with dripping water or splash water, or with

other liquids.

• Only connect the appliance to a properly installed and fused 220-240 V socket.

• Prevent liquids from entering into the appliance. However, if it happens, immediately

disconnect the power plug and refer to our service centre, see warranty card.

• Always disconnect the power plug before changing a light bulb. Use light bulbs of

the same type (I5 W, E14) only.

• Do not make modifications to this appliance.

Attention! For protection against burns, fire hazards, electric shock, or personal

injuries

Installation

• The sewing machine must not be operated out of doors.

• Install appliance on horizontal surface only.

• The sewing machine must not be operated in places where propellant products

(sprays) or oxygen are used.

• Do not use appliance in humid places. Maintain a minimum distance of one meter to

sources of humidity, like washbasins or similar.

• Do not expose appliance to heat. Also observe a sufficient distance to heating devices

or similar. This also applies to the power cable.

• The power cable has to be uncoiled completely. Pay attention that the power cable

does present a trip hazard.

• When using an adaptor plug or an extension cord, observe that they comply with

legal requirements.

During operation

• This sewing machine is not intended for use as a toy. Increased caution is advisable

if the sewing machine is used by children or near children.

• Do not use the appliance if it shows visible damages on the casing or the power cable.

Repairs on the appliance are to be carried out by the service centre only. If the power

supply cord of this appliance is damaged, it has to be substituted by our service

centre, in order to prevent dangers.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

4

Date: 25.09.2007

Version: 02

Page: 4 (of 40 pages)

SAFETY WARNINGS

• When operating the sewing machine, do not block the vents, and keep the vents and

foot pedal clear of lints, dust and fabric residues.

• Do not insert or let objects fall into openings on the sewing machine.

• For switching off the machine, set on/off switch for the light to ‘0’’ and disconnect

the power plug.

• For disconnection from the mains supply, always pull on the plug, not on the cable.

• Keep away fingers from all moving parts. Particular caution is advisable in the area

of the sewing needle. Always pay attention to the upward and downward motion of

the needle, if it is activated.

• Use original needle plates only. An incorrect needle plate can result in breaking the

needle. Do not use bent needles.

• During sewing, do not pull or drag the fabric. This can result in breaking the

needle.

• When carrying out operations in the area of the needle, like for example threading,

changing the needle, threading the bobbin, changing the sewing foot, or similar

operations, switch off sewing machine.

• In order to prevent an uncontrolled activation of the sewing machine, do not place

objects on the foot pedal. The foot pedal or the motor can fuse!

During maintenance

• Always disconnect the power plug, if the casing is opened for cleaning purposes or

for carrying out other service adjustments described in this manual.

• For cleaning the casing, only use neutral soaps and cleaning agents. Benzine, diluter

and abrasive powder can damage the casing and the machine and therefore should

never be used.

PROTECTING THE ENVIRONMENT

Packaging

Please keep the packaging; when transporting the appliance it will be well protected in the original

packaging.

If you do throw the packaging away, please dispose of it in an environmentally friendly manner.

Disposing of the appliance

When the appliance reaches the end of its service life, please contact your local waste

disposal authority; they will be able to tell you how to dispose of it properly.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

5

Date: 25.09.2007

Version: 02

Page: 5 (of 40 pages)

SAFETY WARNINGS

Wiring instructions

This product is supplied with a fitted re-wireable plug. If the plug becomes damaged in any way it may

be necessary to re-wire the plug or replace it.

For a CLASS II appliance (Double Insulated), not requiring an earth connection.

Fit a 13 amp plug conforming to BS 1363. Ensure that the plug is fitted with a 3 amp fuse.

Rewire the plug in accordance with the following instructions:

• Blue or Black : Neutral

• Brown or Red : Live

- Ensure that the Blue or Black wire is connected to the Neutral pin and the Brown or Red wire is

connected to the Live pin.

- Ensure that the copper wire at the end of the Blue or Black wire and Brown or Red wires are

screwed securely to the correct pin connections.

- Ensure that the plug cable anchor is secure.

- Replace the plug cover.

The electrical cable which acts as a sheath to the two connecting wires must lead into the plug. Do not

allow the Blue/Black wire or Brown/Red wire to be exposed outside the plug.

IF YOU ARE IN ANY DOUBT WHEN RE-WIRING A PLUG CONSULT A QUALIFIED ELECTRICIAN.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

6

Date: 25.09.2007

Version: 02

Page: 6 (of 40 pages)

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

7

Date: 25.09.2007

Version: 02

Page: 7 (of 40 pages)

OPERATION

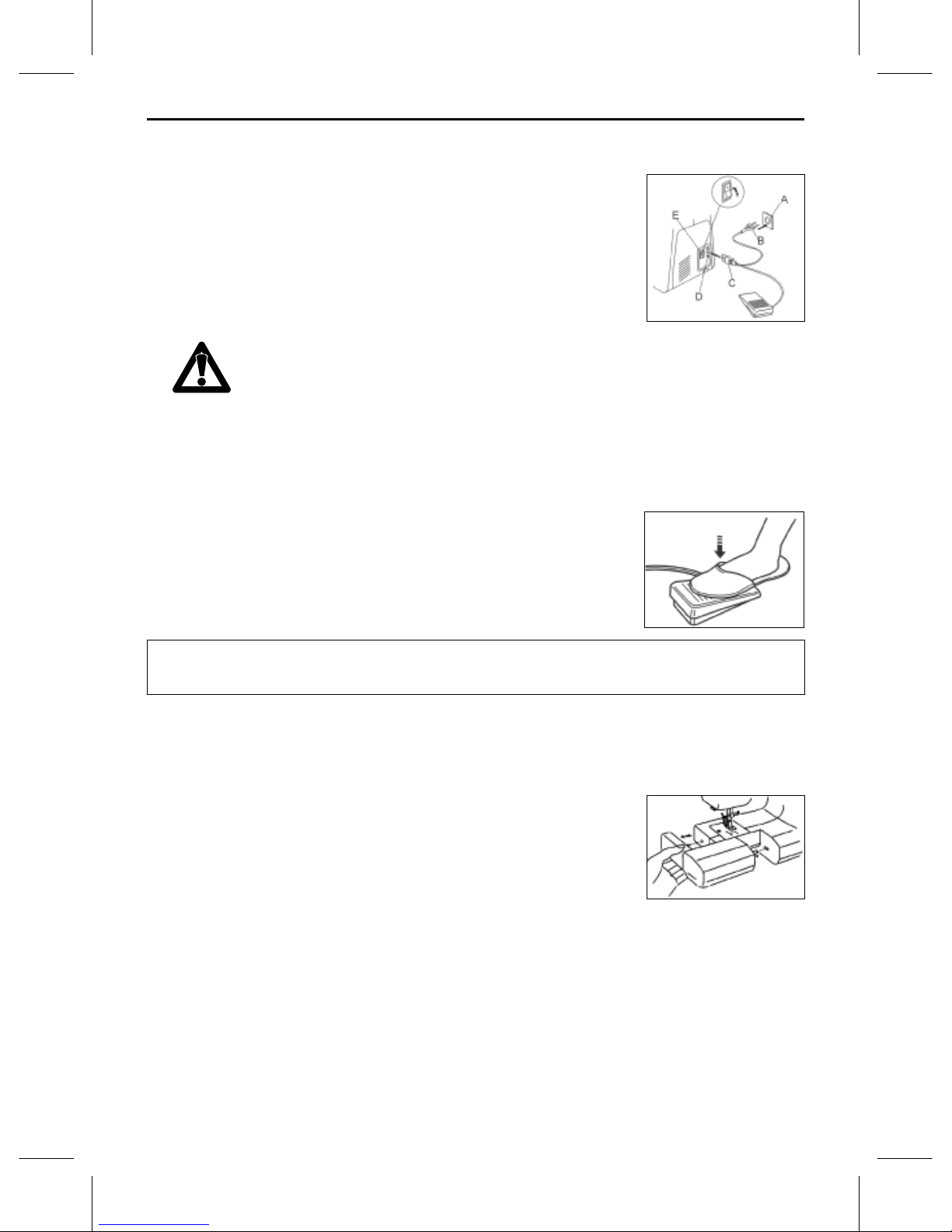

Installing and connecting

1. Place the sewing machine on a stable even table, providing a sufficient

degree of freedom for your legs and the foot pedal. If you place the

sewing machine on a coated surface, place a non-slip mat underneath

the machine.

(A) Mains socket

(B) Power plug

(C) Plug of the foot pedal cable

(D) Socket on the sewing machine

(E) On/off switch for the light

Attention! Fire hazard!

Check whether the voltage and frequency identified on the nameplate comply with the

voltage and frequency of your power supply system. The nameplate is placed on the

back side of the sewing machine.

2. Insert the pug of the foot pedal cable (C) - the plug between foot pedal and power plug - into the

corresponding socket (D) on the sewing machine.

3. Connect the power plug (B) to a mains socket (A).

4. Operate the on/off switch for the light (E) in order to activate the sewing machine light.

Preparing the sewing operation

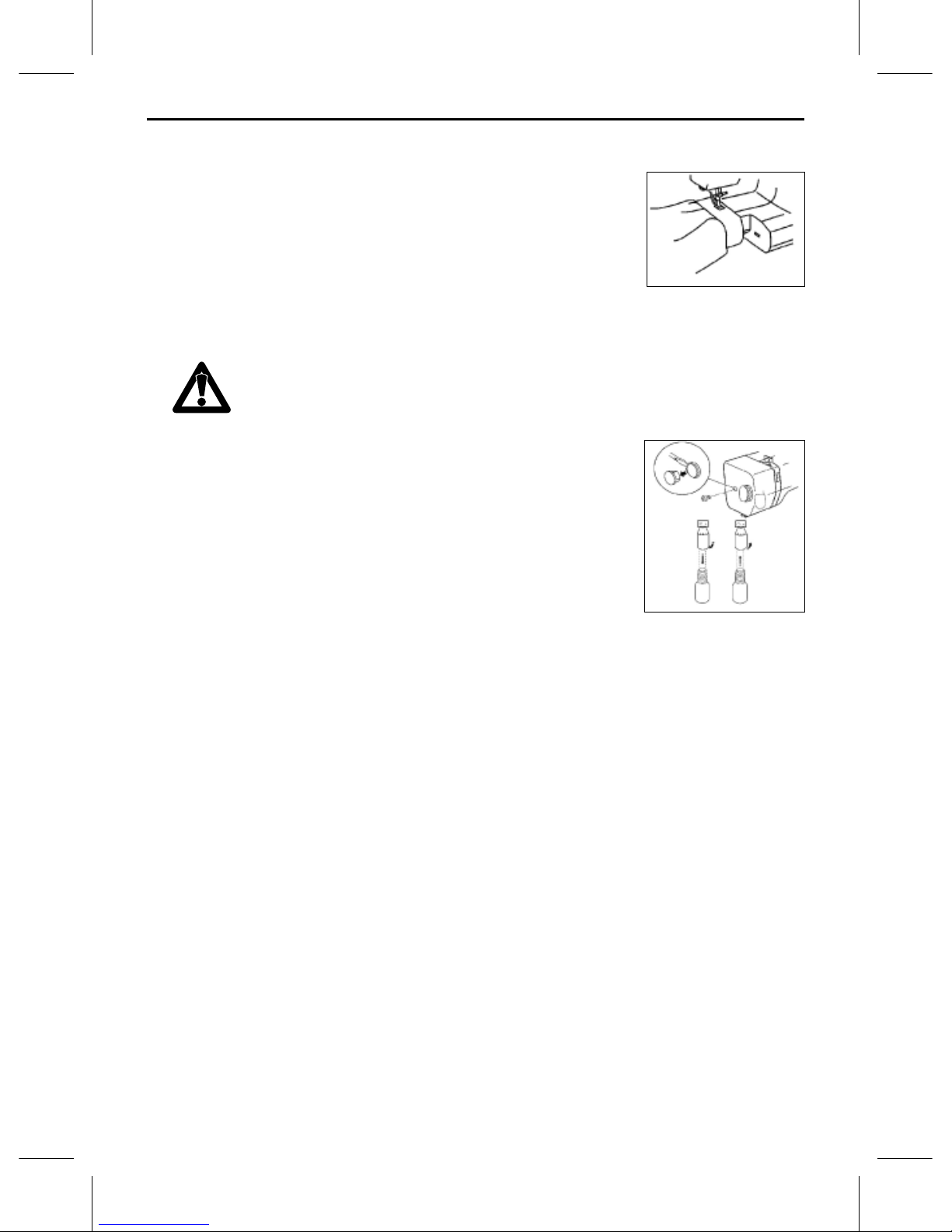

Function of the foot pedal

1. You can define the sewing speed by means of the foot pedal. The more the

foot pedal is pressed downwards, the more the sewing speed increases.

2. By letting go of the foot pedal, the machine is stopped.

Extension table

The extension table increases the working area during sewing operations and can simply be removed.

The use of the free arm enables sewing of places that are difficult to access.

Removing the extension table

1. Remove the extension table as described in the figure.

2. In order to reinstall the extension table, connect it to the sewing machine

again (quilting with sewing table).

NOTE: Before carrying out initial operation of the sewing machine, practise using the foot pedal

without a thread.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

8

Date: 25.09.2007

Version: 02

Page: 8 (of 40 pages)

OPERATION

Advantages and application of free arm sewing

• Preventing a fabric accumulation in front of the sewing needle when

sewing pockets, seams and sleeves, waist cut outs and other rounded

sewing parts.

• Repairing places on knee and elbow, as well as children’s wear.

Sewing machine light

The sewing machine light is placed on the top end of the upper cover (5).

Attention! Danger of electric shock!

Before changing the light bulb, use the on/off switch to switch off the light and disconnect

the power plug. If the sewing machine has been activated before, the light bulb is hot.

There is burn hazard. Wait several minutes, in order to let the light bulb cool off.

1. Remove the screw covering on the left side on the sewing machine.

2. Remove the screw.

3. Remove the upper cover (5).

4. For removing, turn the light bulb to the left.

5. Insert the new light bulb and turn it to the right.

6. Replace the cover and screw it tight.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

9

Date: 25.09.2007

Version: 02

Page: 9 (of 40 pages)

OPERATION

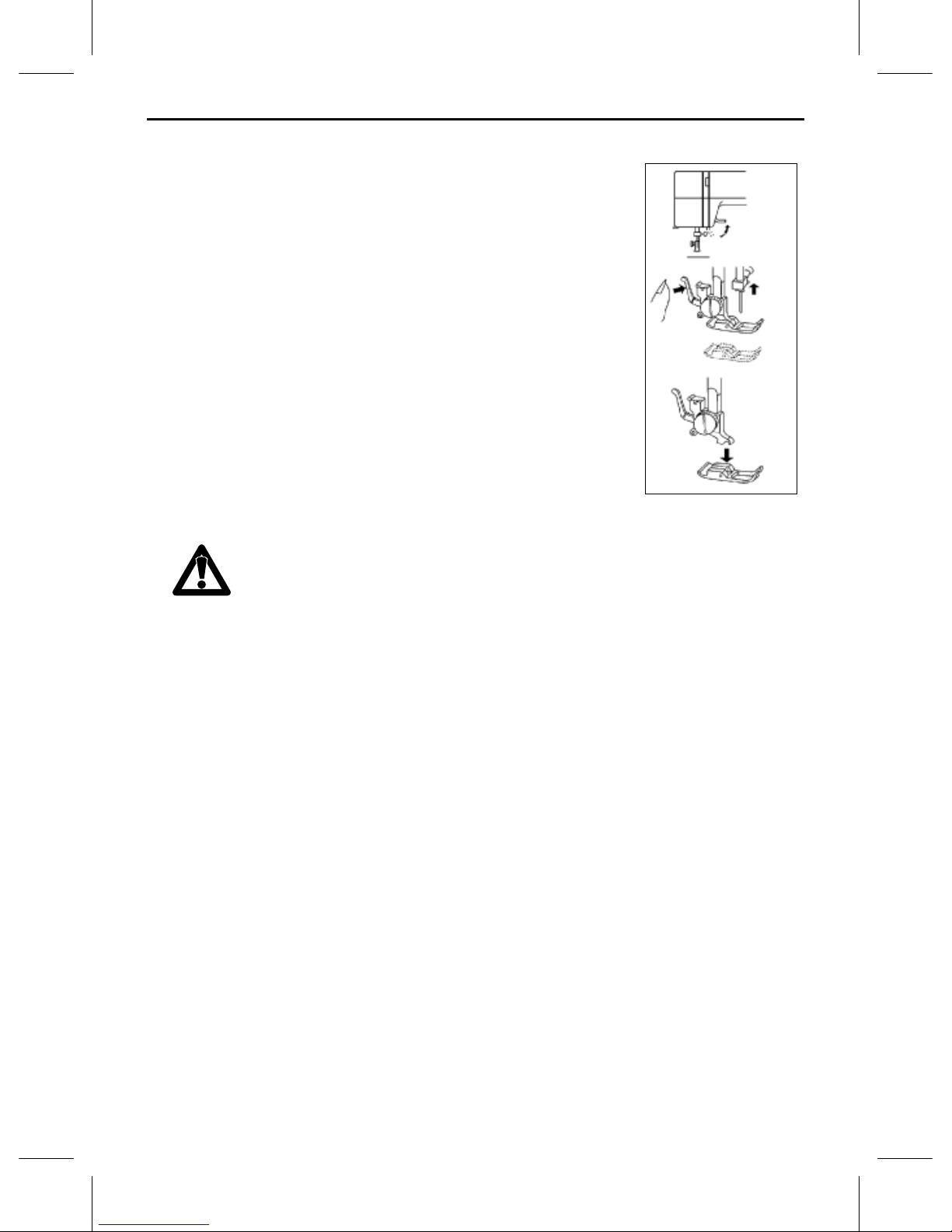

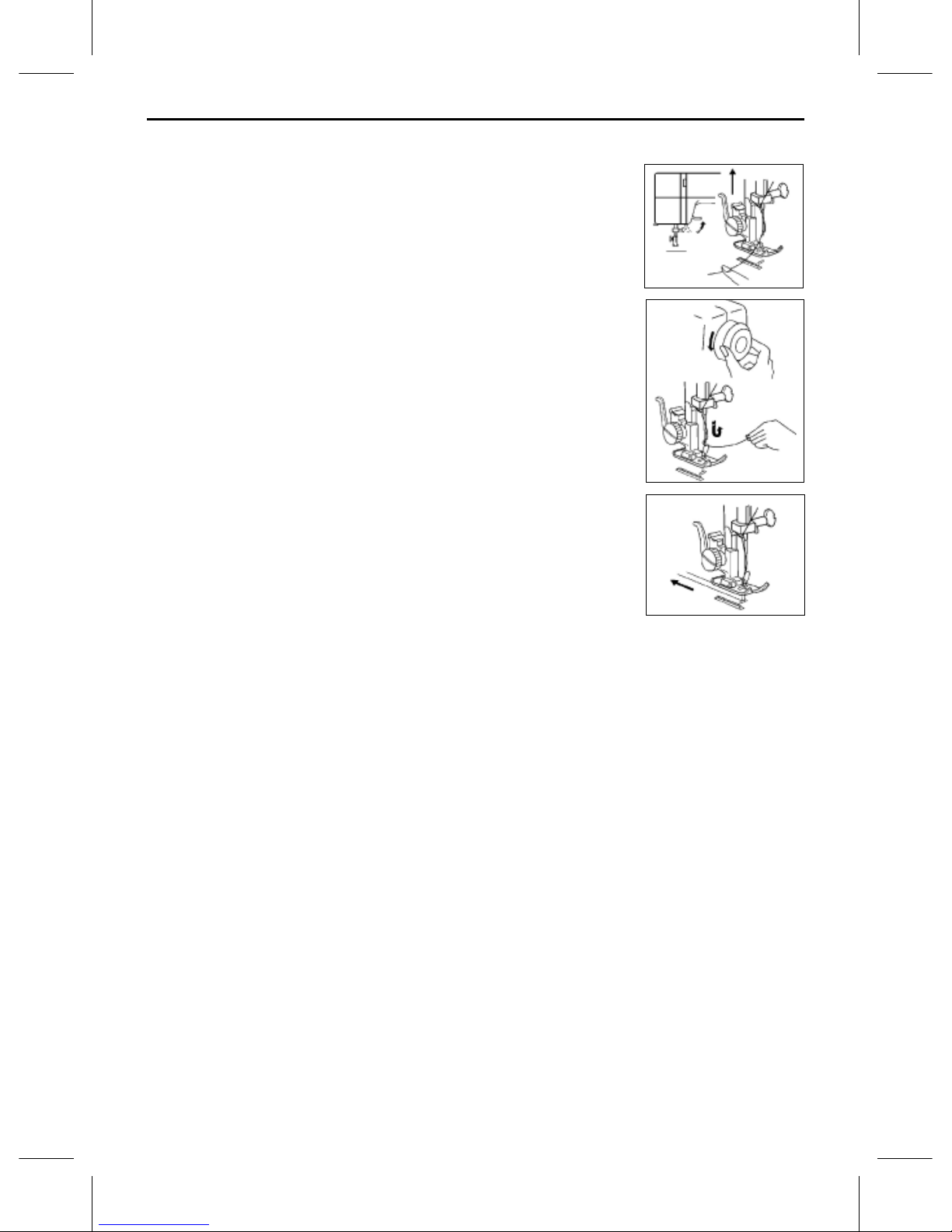

Change the sewing foot

1. Disconnect the power plug.

2. Place the needle in the highest position by moving the hand wheel (23)

towards yourself.

3. Lift the sewing foot by means of the sewing foot lever (18).

4. Release the foot by lifting the sewing foot retainer lever (2) on the back

side of the sewing foot lever.

5. Place the desired sewing foot on the needle plate, so that the bar of the

sewing foot is positioned directly beneath the sewing foot retainer.

6. Press the sewing foot retainer lever (2) and lower the sewing foot lever

(18). Like this, the sewing foot is connected and fixed to the sewing foot

retainer.

Changing the needle

1. Disconnect the power plug.

2. Place the needle in the highest position by moving the hand wheel (23)

towards yourself.

3. Lower the sewing foot by means of the sewing foot lever (18).

4. Loosen the needle clamp screw (20) by turning anticlockwise.

5. Remove the used needle from the needle retainer.

6. Replace the new needle, so that the flat side points to the back. When

inserting the needle, it has to be pushed into the needle retainer as far

as possible.

7. Afterwards tighten the needle clamp screw (20).

Attention! Risk of injury!

Check in regular intervals whether the needle is still straight and sharp. A bent needle

can break and cause injuries! Knots and skipped stitches in Jersey fabrics, finely woven

silk or silk fabrics are often caused by damaged needles.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

10

Date: 25.09.2007

Version: 02

Page: 10 (of 40 pages)

OPERATION

Overview needle and thread

No. 60 (#7)

No. 70 (#l0)

Finely woven silk

Crepe fabrics

70-80 100-140

No. 80 (#12)

No. 80-90 (#12-14)

Natural silk

Cotton

50-60

40-50

80-100

60-70

No. 90-100 (#14-16)

No. 90-100 (#14-18)

Wool

Denims

30-40

30

50-60

45-50

Sewing of elastic fabrics no. 70 (#l0) Jersey fabric 70-80 100-140

Using the thread spool holder

The thread spool holders (10) serve for taking up thread spools.

1. Before sewing, remove the thread spool holders (10) from the casing of

the sewing machine.

2. Insert the thread spool holders (10) into the casing before putting the

sewing machine away.

(A) Upper thread

(B) Opening in the thread spool holder

NOTE: If the thread that is used often, winds itself round the thread spool holder or is knotted, you

can guide the thread through the opening in the thread spool holder (B) (see figure above). In doing

this, the opening is positioned in the direction of the thread spool.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

11

Date: 25.09.2007

Version: 02

Page: 11 (of 40 pages)

OPERATION

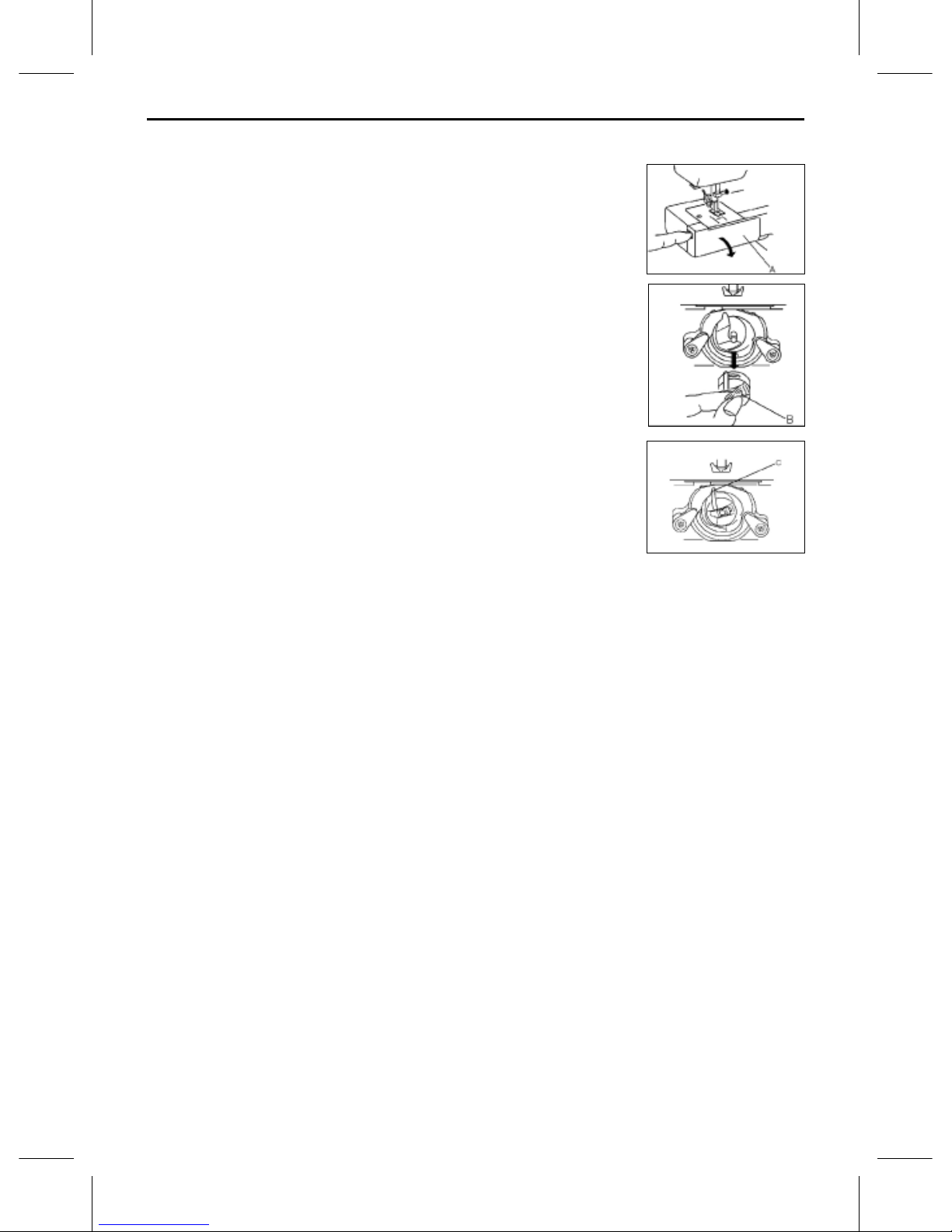

Removing and inserting of the bobbin case

1. Disconnect the power plug.

2. Open the free arm lid (A).

3. Place the needle in the highest position by moving the hand wheel (23)

towards yourself.

4. Grip the bobbin case bar (B) and pull the bobbin case out of the casing.

5. When reinserting, make sure that the bobbin case finger (C) engages

firmly into the cut-out above in the casing.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

12

Date: 25.09.2007

Version: 02

Page: 12 (of 40 pages)

OPERATION

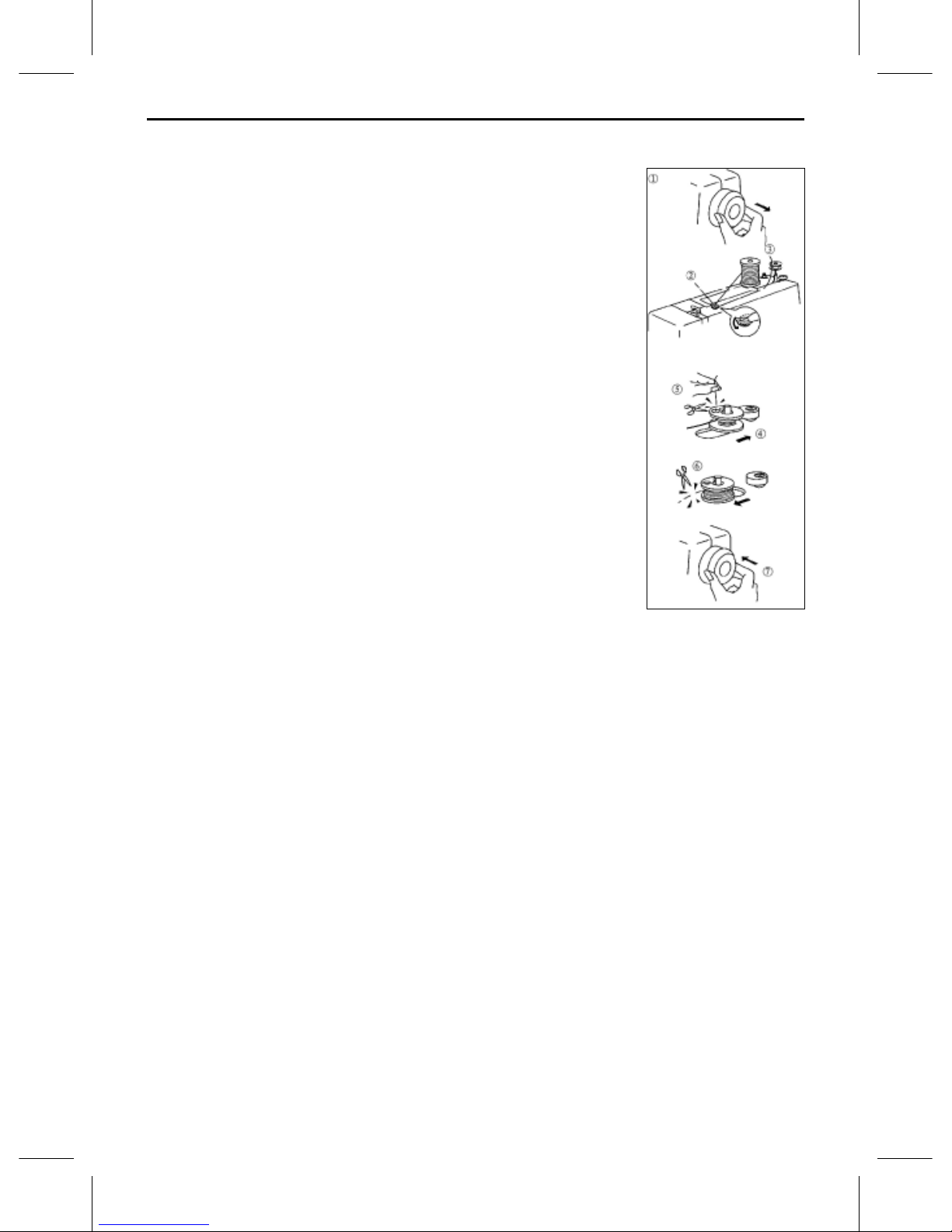

Winding

The numbering on the figure corresponds to the following work steps:

1. Pull the hand wheel (23) outwards, in order to break contact. Now the

needle does not move anymore if you turn the hand wheel.

2. Guide the thread from the thread spool through the winding tension

disc (9).

3. Guide the thread from the inside through one of the small openings of

the bobbin and place the bobbin onto the bobbin supporting arm (11).

4. Press the bobbin to the right against the bobbin case (12).

5. Hold the thread end tight, and slightly press the foot pedal.

Stop after the thread has wound itself several times round the bobbin.

Cut off the surmounting thread end directly in front of the bobbin.

Again press the foot pedal and wind the thread until the bobbin is

filled.

The machine will stop automatically.

6. Now press the bobbin supporting arm (11) to the left and cut off the

thread.

7. Push the hand wheel (23) to the inside (into starting position), in order

to reactivate contact.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

13

Date: 25.09.2007

Version: 02

Page: 13 (of 40 pages)

OPERATION

Inserting the thread into the bobbin case

1. Disconnect the power plug.

2. Place the needle in the highest position by moving the hand wheel (23)

towards yourself.

3. Remove the bobbin case, see Page 11.

4. Insert the bobbin into the bobbin case.

In doing this, make sure that the thread is guided in the direction of the

arrowhead (clockwise).

5. Insert the thread into the slot of the bobbin case.

6. Then pull the thread through the bobbin tension spring to the outlet

opening. Let approx. 10 cm of the thread hang out of the bobbin.

7. Reinsert the bobbin case.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

14

Date: 25.09.2007

Version: 02

Page: 14 (of 40 pages)

OPERATION

Threading the upper thread

Disconnect the power plug.

Lift the sewing foot by means of the sewing foot lever (18) and move

the hand wheel (23) towards yourself, in order to place the thread

take-up lever (7) into the highest position.

Place a thread spool on the thread spool holder (10).

Lead the thread through the back side of the thread spool.

The numbering on the figure corresponds to the following work steps:

1. Guide the thread through the thread tensioner (8).

2. Pull the thread from the right upward around the thread tensioning

disc.

3. Pull the thread tight and guide it through the opening of the thread

take-up lever (7) from the right.

4. Guide the thread downwards and through the thread hook (3).

5. Guide the thread further downwards and through the next thread guide

hook.

6. Thread the needle from the front to the back.

NOTE:

The thread run is clarified by numbers on the machine.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

15

Date: 25.09.2007

Version: 02

Page: 15 (of 40 pages)

OPERATION

Taking up the lower thread

1. Lift the sewing foot by means of the sewing foot lever (18) and loosely

hold the end of the upper thread in your left hand.

2. Move the hand wheel (23) towards yourself until the thread take-up

lever (7) is placed in its highest position. The needle must have been

moving downward before.

3. Pull at the upper thread, in order to take up the lower thread.

4. Pull out both threads about 5 cm, and guide both threads underneath

the sewing foot towards the back.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

16

Date: 25.09.2007

Version: 02

Page: 16 (of 40 pages)

OPERATION

Adjusting the tension of the upper thread

When sewing with straight stitch, the upper and lower threads are

connected to each other between the fabric parts.

1. Select the appropriate tension for the thread tensioning disc by means

of the thread tension adjusting wheel (10).

(A) Newly adjusted value

The lower the numerical value, the lower the tension of the upper thread.

To lower the tension of the upper thread, turn the adjusting wheel as

indicated in the figure on the right.

The higher the numerical value, the higher the tension of the upper thread.

To increase the tension of the upper thread, turn the adjusting wheel as

indicated in the figure on the right.

Tension of the upper thread with regard to zig-zag stitch:

In order to achieve good results when sewing with zig-zag stitches, the

tension of the upper thread should be lower than when sewing with

straight stitch. The upper thread should be visible on the back side of

the sewing part.

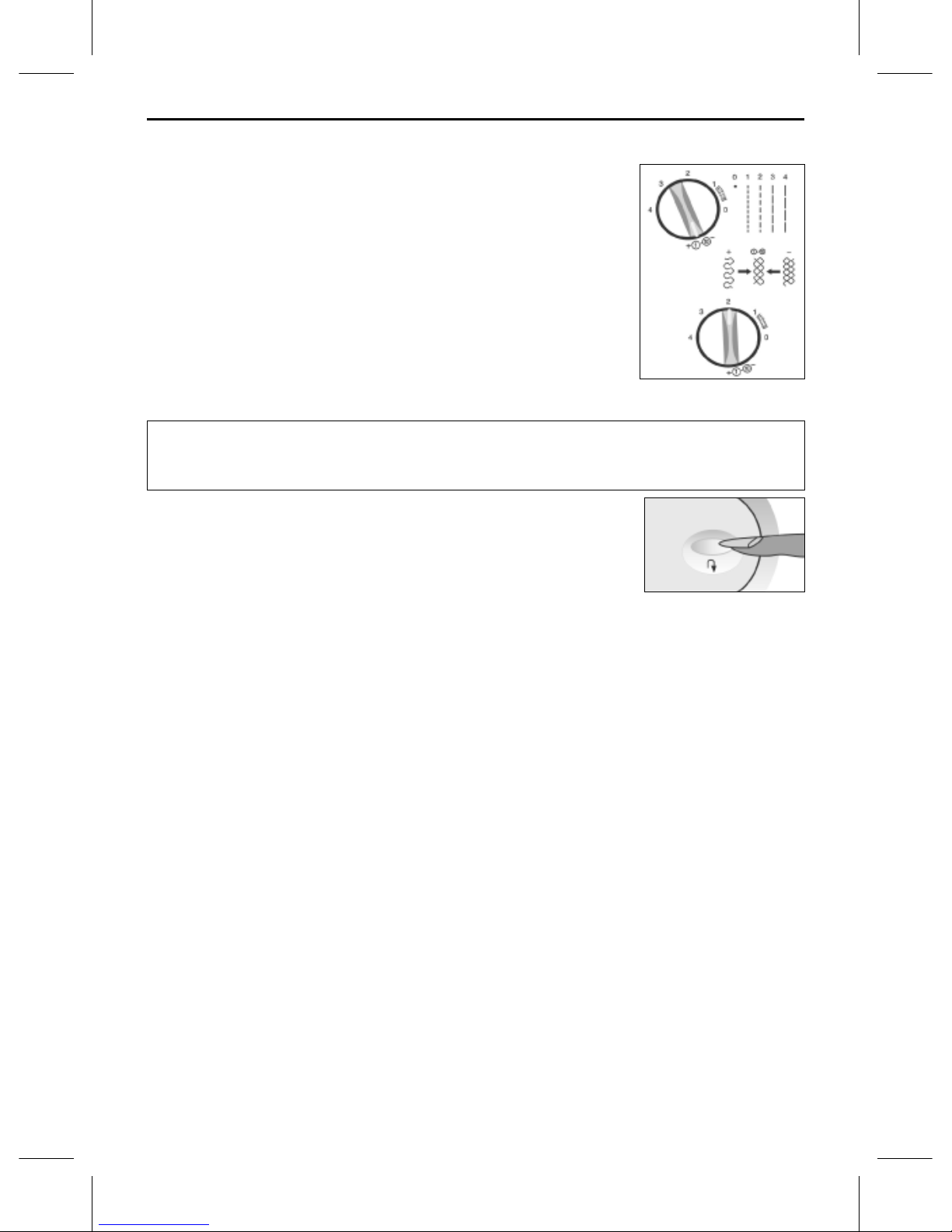

Stitch pattern rotary switch

1. Move the needle out of the fabric.

2. Select the desired stitch pattern by means of the adjusting wheel (14).

3. For the elastic stitches (lower row), select the desired number by means

of the stitch pattern rotary switch (14).

By means of the stitch length rotary switch (13; see below), you adjust

the lower stitch pattern row by positions 1-10.

Buttonholes are sewed with the symbols (A), see page 25.

Client: ALDI Australia

Project: Lumina ESM 008

Language: EN

Barcode: 930 5026 10 000 3 00151

17

Date: 25.09.2007

Version: 02

Page: 17 (of 40 pages)

OPERATION

Stitch length rotary switch

Dependent on the selected stitch, it is possible that you have to alter the

stitch length in order to achieve an optimum result.

1. Adjust the desired stitch length by means of the stitch length rotary

switch (13).

The higher the number, the longer the stitch.

Setting the value between 0 and 1 is qualified for sewing buttonholes.

The range between 0.5 to 4 is qualified for sewing zig-zag stitches.

For sewing with an elastic stitch, the adjustment 1-10 is selected.

How can the quality of the elastic stitch be improved?

If this adjustment does not provide a satisfactory result when sewing

with an elastic stitch, you can alter the stitch density by means of the

stitch length rotary switch (13):

• "-" denser stitches

• "+" wider stitches.

Reverse sew button

1. Press the reverse sew button downward if you only want to sew

backwards.

NOTE:

The length of the stitch seamlessly changes with regard to an adjustment of the rotary switch between

0 and 1, and therefore should be adjusted correspondingly.

Table of contents