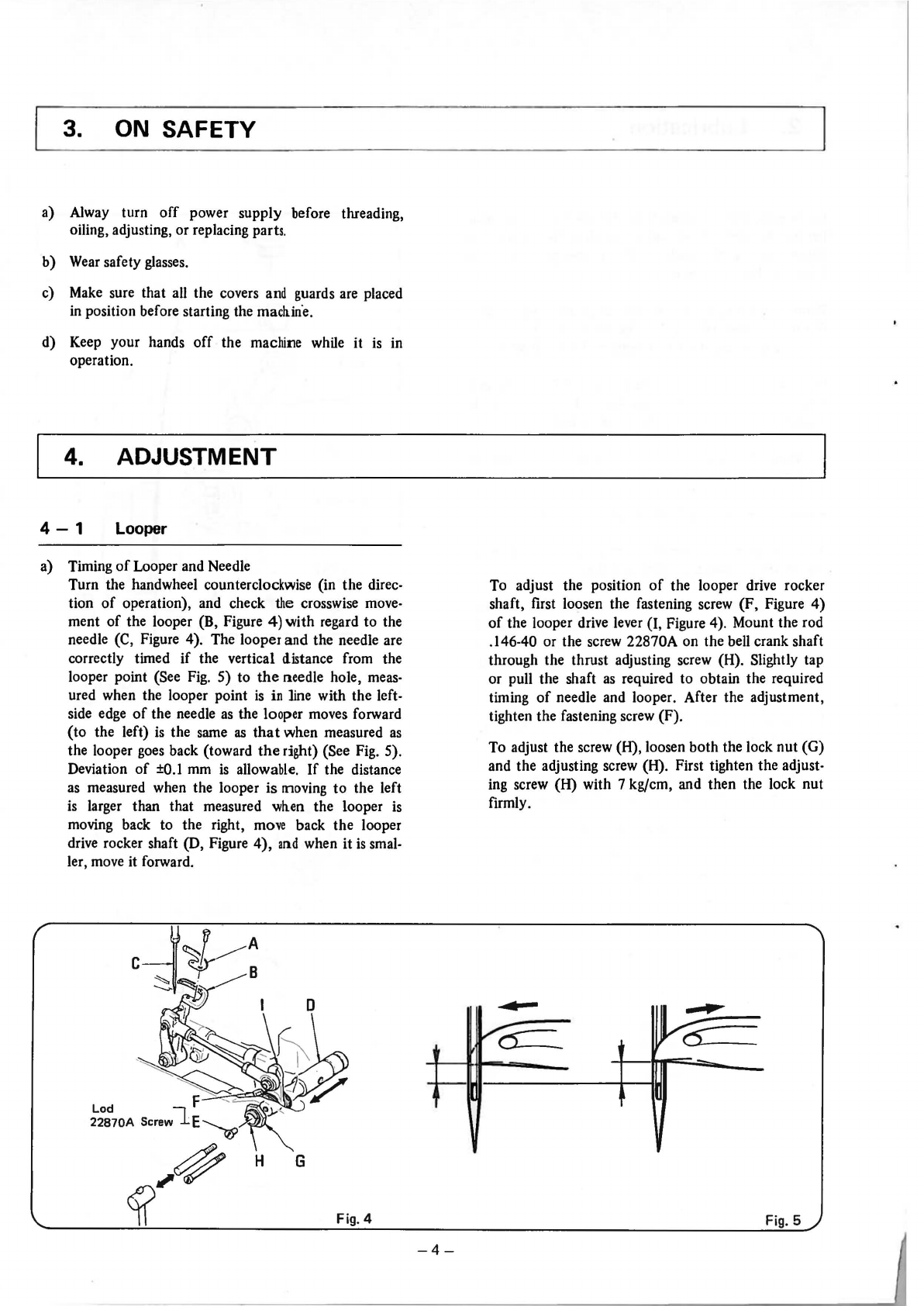

4-4

Change

of

Stitch Length (Figure 13 refers)

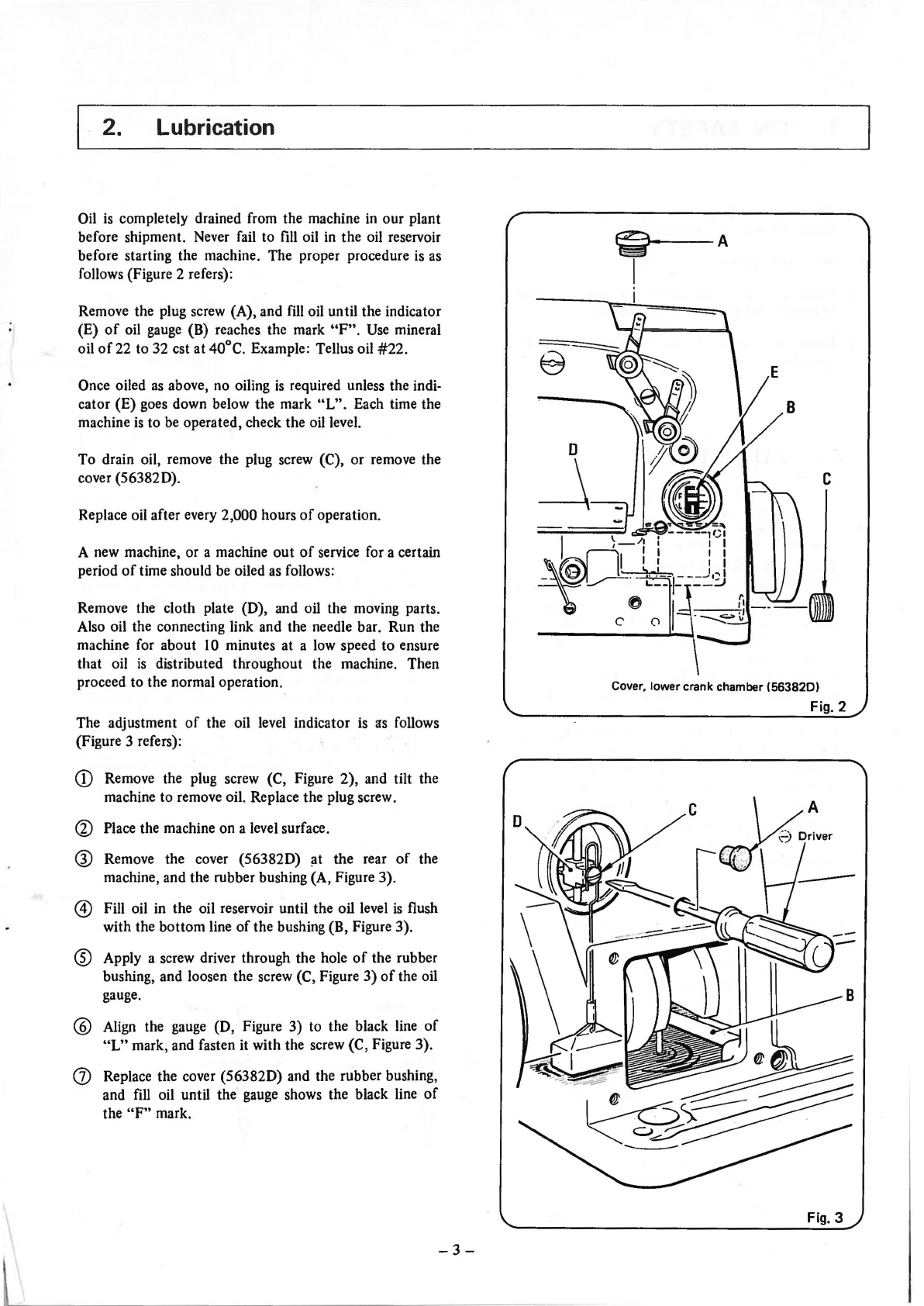

Your machine is adjusted to the stitch length

of

7

mm

in

our plant before shipment. You can change the stitch

length

in

the following procedure when necessary:

Loosen the nut (B)

of

the feed regulating stud, and turn

the screw (D) on the dial. Turning

it

to the right will

make the stitch smaller (S), and turning it to the left

larger (L). Tighten the nut (B) only by half and turn

the pulley by hand to produce a length

of

seam to con-

firm whether the desired stitch length is obtained or not.

After the adjustment, tighten the nut (B) firmly.

Note: Nut (B) has left-hand threads.

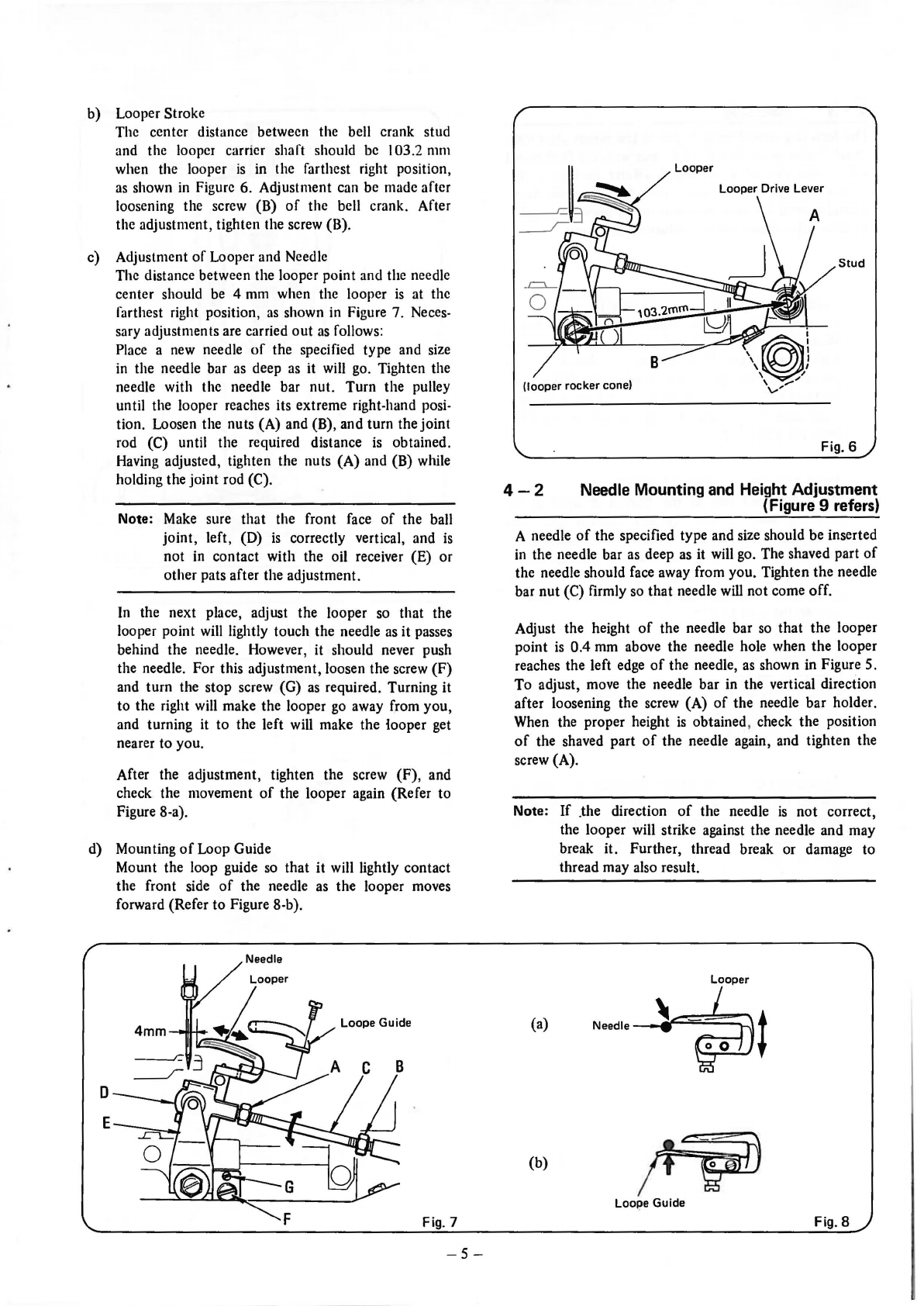

4-5

Needle Guard (Figure 14 refers)

the upper edge

of

the needdle hole must be even with

the lower surface

of

the needle guard

{B)

when the

needle (A)

is

in

the lowest position

in

.its travel. To adjust,

loosen the screw (C) and move the needle guard (B)

in

the vertical direction.

Make

necessary adjustment

so

that the clearance between the needle (A) and the

needle guard (B)

is

0 to 0.1 mm,

as

shown in Figure 14.

Be

careful that the needle (A) will not contact the needle

guard (B).

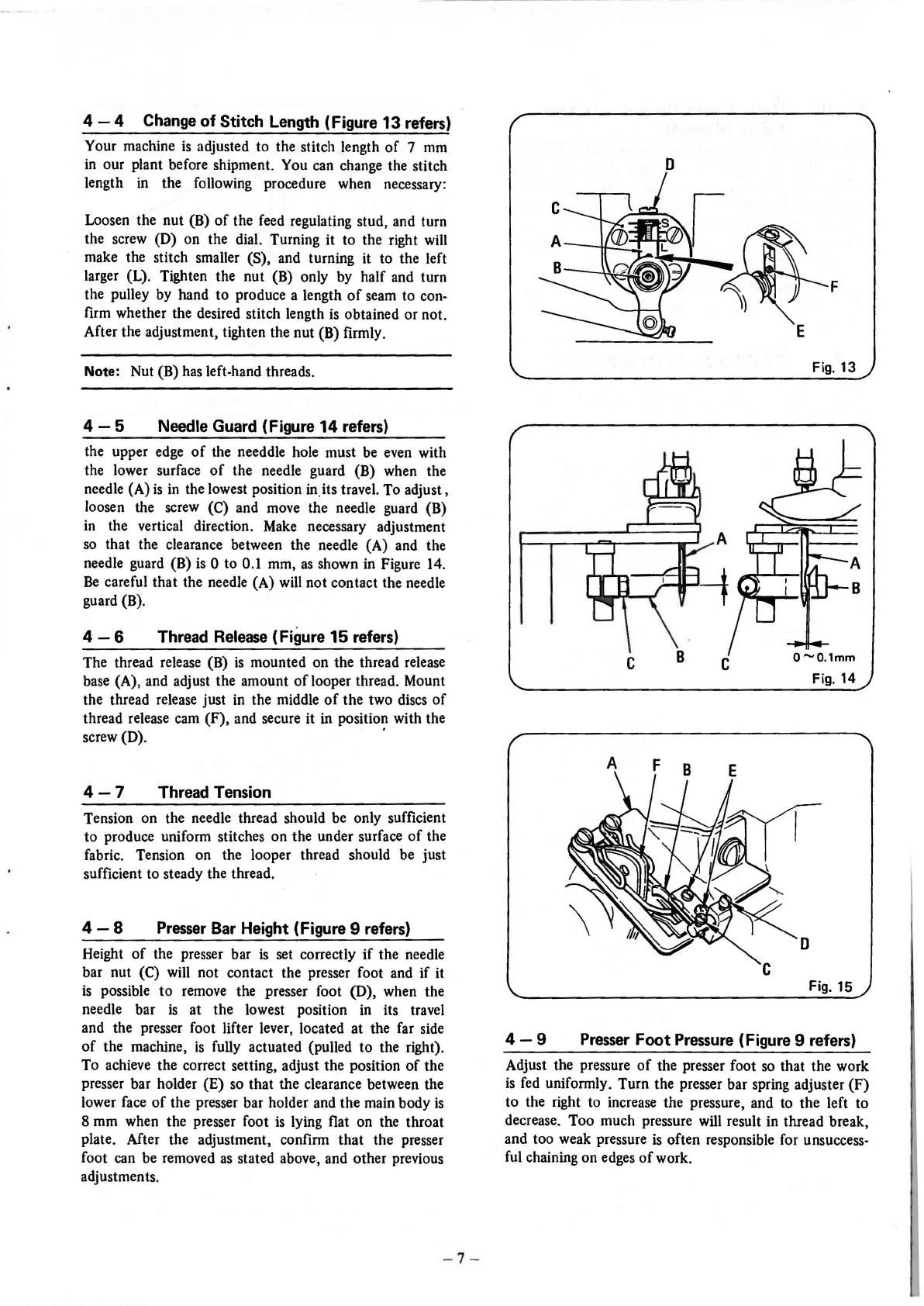

4-6

Thread

Release

(Figure

15

refers)

The thread release (B)

is

mounted on the thread release

base (A), and adjust the amount

of

looper thread. Mount

the thread release just in the middle

of

the two discs

of

thread release cam (F), and secure it in position with the

screw (D). ·

4-7

Thread Tension

Tension on the needle thread should be only sufficient

to produce uniform stitches on the under surface

of

the

fabric. Tension on the looper thread should be just

sufficient to steady the thread.

4-8

Presser

Bar Height (Figure 9 refers}

Height

of

the presser bar

is

set correctly

if

the needle

bar nut (C) will not contact the presser foot and

if

it

is

possible

to

remove the presser foot (D), when the

needle bar is at the lowest position in its travel

and the presser foot lifter lever, located at the far side

of

the machine,

is

fully actuated (pulled to the right).

To achieve the correct setting, adjust the position

of

the

presser bar holder {E) so that the clearance between the

lower face

of

the presser bar holder and the main body

is

8 mm when the presser foot

is

lying flat on the throat

plate. After the adjustment, confirm

that

the presser

foot can be removed

as

stated above., and other previous

adjustments.

- 7 -

D

F

Fig.

13

Fig.

14

A F

D

Fig.

15

4-9

Presser

Foot

Pressure

(Figure 9 refers)

Adjust the pressure

of

the presser foot

so

that the work

is

fed uniformly. Turn the presser bar spring adjuster

(F)

to the right to increase the pressure, and to the left to

decrease. Too much pressure will result in thread break,

and too weak pressure

is

often responsible for unsuccess-

ful chaining on edges

of

work.

From the library of: Superior Sewing Machine & Supply LLC