Table of Contents 3

© Lutz-Jesco GmbH 2018

Subject to technical changes.

181112

BA-10407-02-V08

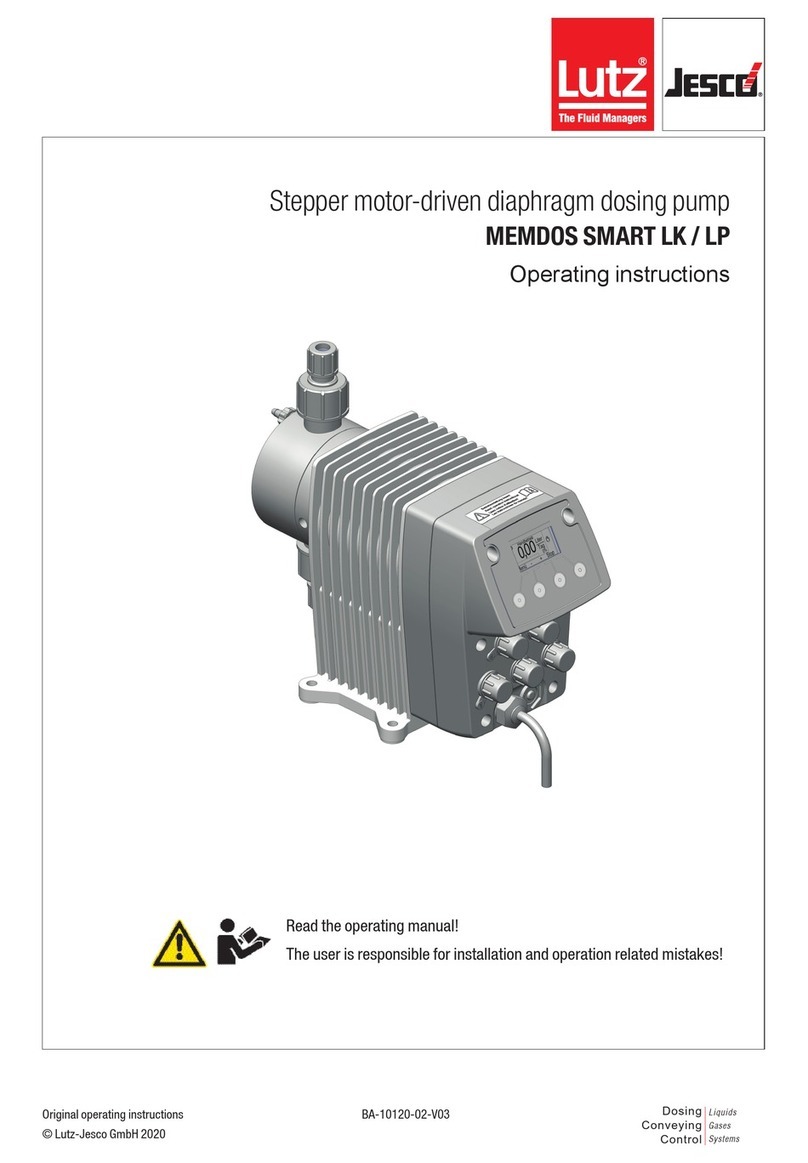

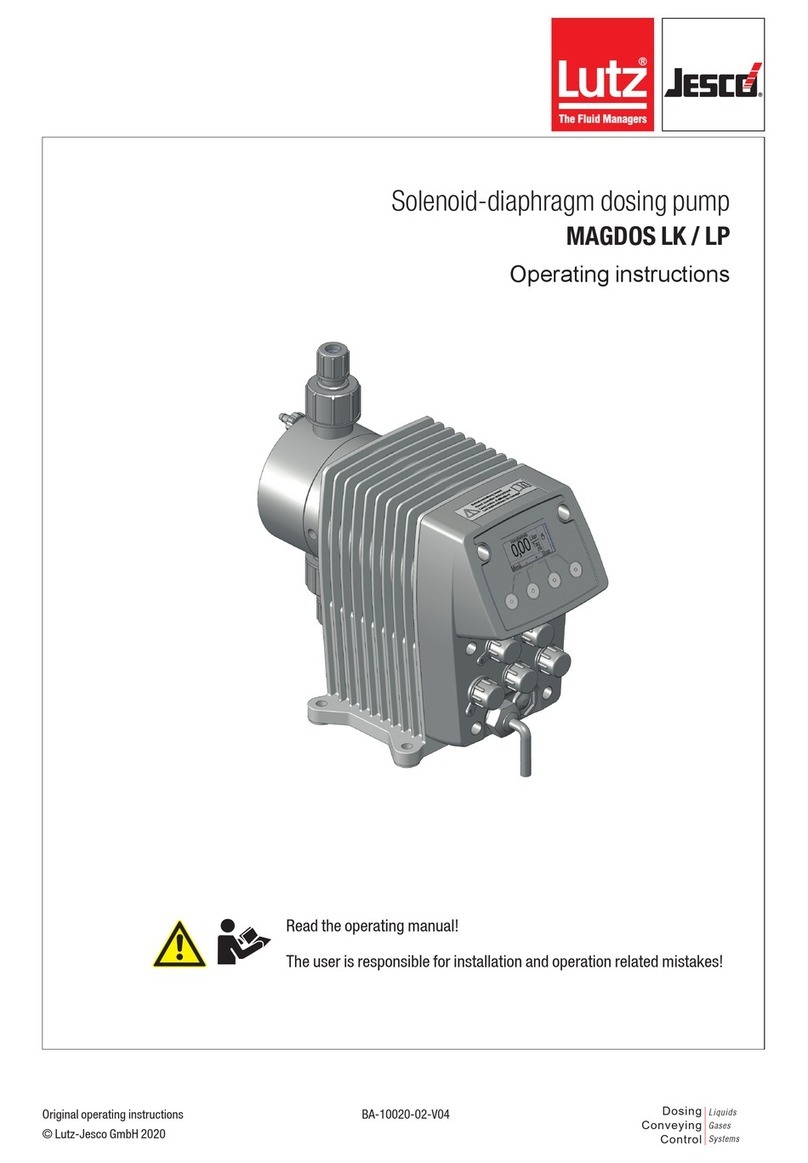

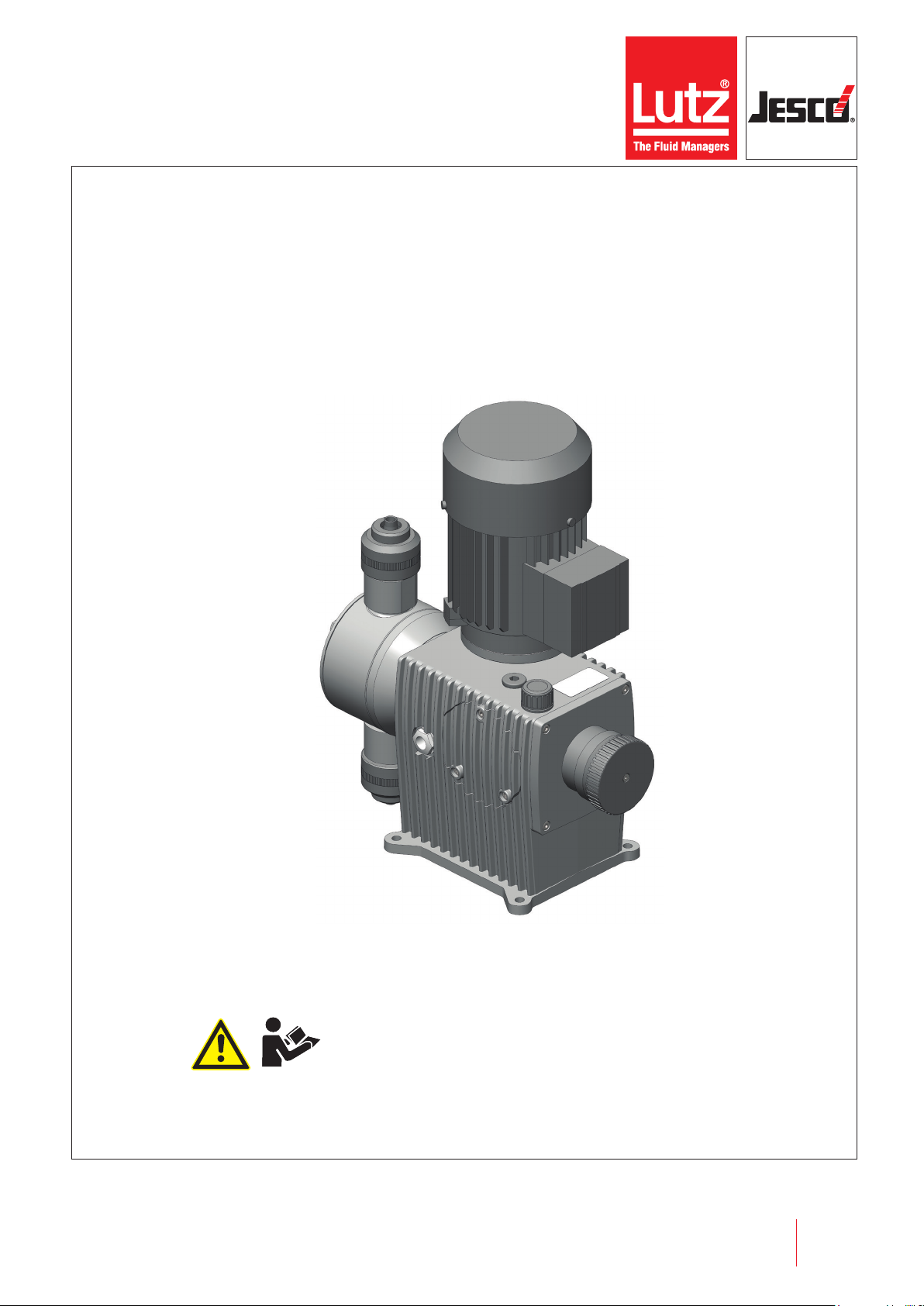

Motor-driven diaphragm dosing pump MEMDOS LB Operating instructions

Table of Contents

1 Notes for the Reader ..........................................................4

1.1 General non-discrimination..........................................................4

1.2 Explanation of the signal words ....................................................4

1.3 Explanation of the warning signs ..................................................4

1.4 Identification of warnings.............................................................4

1.5 Identification of action instructions...............................................4

2 Safety .................................................................................5

2.1 General warnings.........................................................................5

2.2 Warnings for use within explosive-risk zones................................6

2.3 Hazards due to non-compliance with the safety instructions .........6

2.4 Working in a safety-conscious manner .........................................6

2.5 Personal protective equipment.....................................................6

2.6 Personnel qualification.................................................................7

3 Intended use ......................................................................8

3.1 Notes on product warranty ...........................................................8

3.2 Intended purpose.........................................................................8

3.3 Principles ....................................................................................8

3.4 Prohibited dosing media...............................................................8

3.5 Use in explosion risk areas...........................................................8

3.6 Ex label of dosing pump and motor...............................................8

3.7 Foreseeable misuse.....................................................................9

4 Product description .........................................................10

4.1 Properties..................................................................................10

4.2 Scope of delivery .......................................................................10

4.3 Structure of the dosing pump .....................................................10

4.4 Function description ..................................................................10

4.5 Rating plate ...............................................................................11

5 Technical data..................................................................12

5.1 Delivery capacity data................................................................12

5.2 Operating conditions and limits ..................................................13

5.3 Other data .................................................................................13

5.4 Motor data.................................................................................14

5.5 Electrical servomotors ...............................................................18

6 Dimensions ......................................................................19

6.1 MEMDOS LB 4 - 80, 150 ............................................................19

6.2 MEMDOS LB 110, 160 - 1010 ....................................................20

6.3 MEMDOS LB 4 - 80, 150 with electrical servomotor ....................21

6.4 MEMDOS LB 110, 160 - 1010 with electrical servomotor ............21

7 Installing the Dosing Pump..............................................22

7.1 Set up information .....................................................................22

7.2 Installation on a wall console......................................................22

8 Hydraulic installations.....................................................23

8.1 Design of the system..................................................................23

8.2 System piping............................................................................24

8.3 Suction and pressure valves.......................................................24

8.4 Connecting a leakage drain........................................................24

8.5 Hydraulic accessories ................................................................25

9 Electrical installation.......................................................27

9.1 Drive motor connection..............................................................27

9.2 Connection of electric servomotor ..............................................28

10 Control..............................................................................28

11 Operation..........................................................................29

11.1 Commissioning the dosing pump .............................................29

11.2 Commissioning the electric servomotor....................................30

11.3 Decommissioning the dosing pump..........................................30

11.4 Shutting down in an emergency ...............................................30

11.5 Storage ...................................................................................30

11.6 Transportation .........................................................................30

11.7 Disposal of old equipment........................................................30

12 Maintenance ....................................................................31

12.1 Maintenance intervals..............................................................31

12.2 Change the oil..........................................................................32

12.3 Tighten up dosing head bolts....................................................33

12.4 Diaphragm replacement ..........................................................33

12.5 Clean suction and pressure valves............................................34

13 Troubleshooting ...............................................................35

13.1 Type of fault .............................................................................35

14 Spare parts.......................................................................37

14.1 Diaphragm spare parts kits ......................................................37

14.2 Dosing head spare parts kits including valves...........................37

15 Delivery characteristic curves.........................................38

16 EU Declaration of Conformity...........................................40

17 Declaration of no objection..............................................41

18 Warranty claim.................................................................42

19 Index.................................................................................43