97D - 108 Meteor® Snowblower

This Blower is ideal for tractors 100 - 120 HP Cat #2 3PH.

Attaching the Meteor® Blower for the first time.

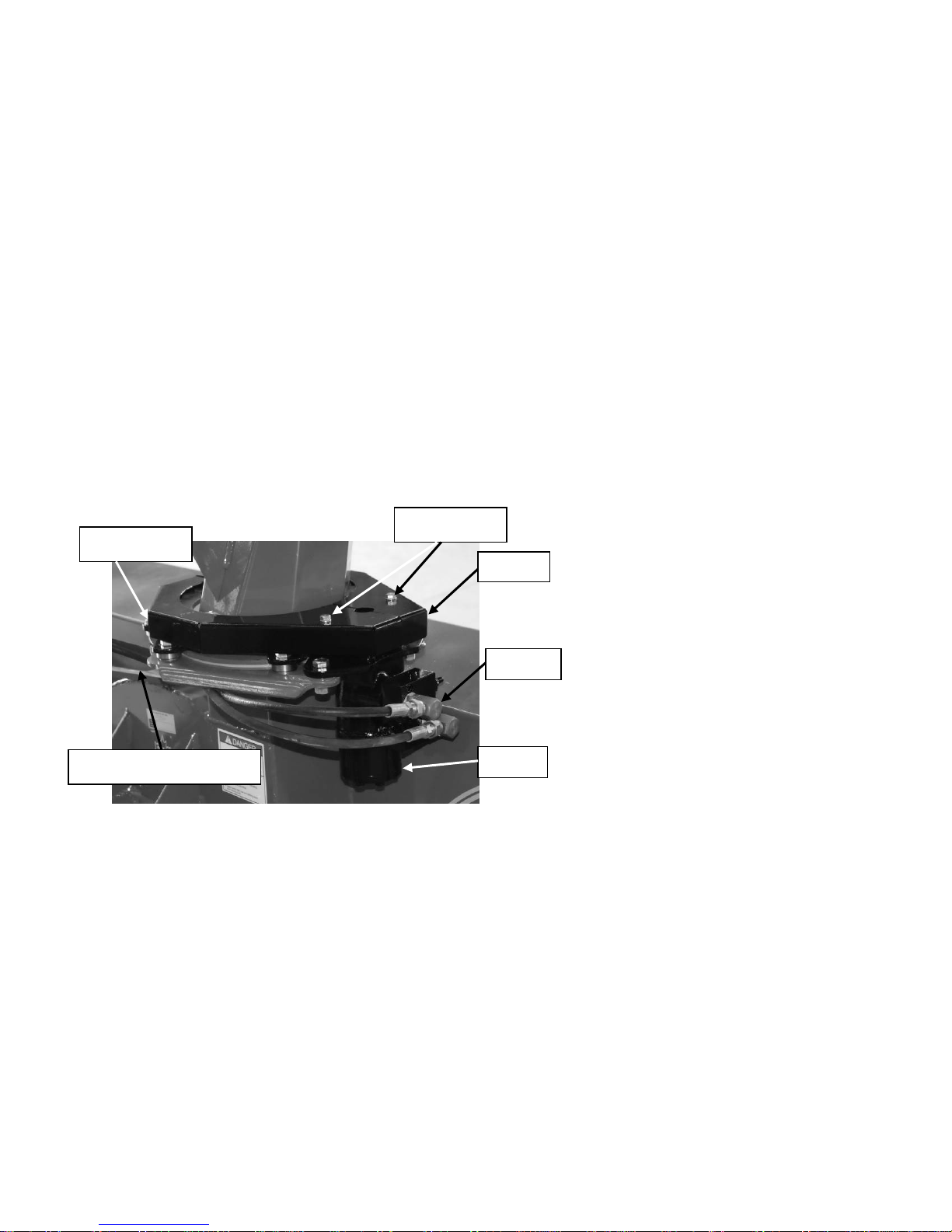

Set the blower on a level surface and back the tractor up to it. Place the lower 3PH arms

of the tractor between the lower hitch plates on the blower and insert the hitch pins that

came with the blower, secure these with the Lynch Pins. Next swing the top link into

place and adjust the length so the top link pin can be inserted. You will have to supply the

top link pin. With the top link set at this length the blower will be flat or parallel to the

ground.

Do not fasten the PTO shaft to the tractor.

1. Slowly lift the blower until the gearbox shaft is at the same height as the PTO

output on the tractor.

2. Push (or collapse the telescopic part of the PTO completely). If you cannot

collapse it far enough to slide get it on the tractor then it has to be shortened.

3. Measure the amount that the shaft is too long. Remove it from the blower and pull

it apart.

4. Take a hacksaw and cut ½ of the measurement from each end, cut both the plastic

tube and the metal core.

5. Use a file to remove the burrs from the cut parts, wipe any filings from the

surfaces and slide the shaft together to be sure that it slides freely.

6. Make sure the plastic shield is free to rotate on the shaft before installing on the

machine.

7. Reinstall the PTO on the blower and fasten it to the tractor pushing the spring-

loaded pin in and sliding the yoke onto the tractor spline until the pin snaps into

place.

8. Next lift the 3PH arms to the highest point, determine the overlap on the PTO

shaft. It should be at least 3” if it is too short then the PTO will jam rather then

collapse. This will put severe strain on the shaft and gearbox.

9. It may come apart and this will allow a spinning PTO to become an

uncontrolled weapon and could severely injure or kill someone!

10. After it has been determined that the PTO is OK and will not jam or come apart,

make sure any bystanders are well away from the machine.

11. Lower the blower to ground level, engage the PTO and slowly start the blower.

Make sure that everything is turning freely.

12. Slowly increase the speed until you have reached 540 RPM on the PTO or (1000

RPM with the 1000 RPM PTO option). This is the speed that this blower was

designed for. If it turns faster the fan could be going dangerously fast. If it turns

slower it will not perform very well as the snow will not get blown very far.

Snowblower performance will vary greatly due to ambient temperature and type

of snow.