M-PT MV-RAD User manual

M-PT Matjeschk-PowerTools GmbH & Co. KG mail@m-pt.de Tel.: +49 (0) 35 796 / 9760

Am Saegewerk 11 www.m-pt.de Subject to technical modifications!

01920 Ralbitz-Rosenthal Status 07/2022

User Manual

MV-RAD

MV-RAD

Page 2

1. Introduction

Electric torque drivers of the MV-RAD series represent high quality tools designed for

tightening, detaching and inspection of bolted connections. Users should carefully read this

manual before starting to work. As this document has to be considered as an integral part

of the equipment, it should remain available in its surroundings until the end of its lifetime.

In case of any supplementary questions, do not hesitate and consult our factory service.

Patent right and copyright must be respected. Distribution, reproduction and transmission

to third parties are not admissible.

2. Table of Contents

1. Introduction________________________________________________________________________ 2

2. Table of Contents __________________________________________________________________ 2

3. Manufacturer_______________________________________________________________________ 4

4. EU Declaration of Conformity ____________________________________________________ 4

5. Safety Notes _______________________________________________________________________ 5

5.1. General Remarks _______________________________________________________________ 5

5.2. Surroundings___________________________________________________________________ 5

5.3. Electrical Safety ________________________________________________________________ 5

5.4. Safety of Personnel ____________________________________________________________ 5

5.5. Absence of Damages___________________________________________________________ 5

6. Scope of delivery___________________________________________________________________ 5

7. Product Identification ______________________________________________________________ 6

8. Specification _______________________________________________________________________ 6

9. Detailed Description________________________________________________________________ 6

9.1. Start-up________________________________________________________________________ 6

9.2. Initial Steps ____________________________________________________________________ 6

9.3. Switching ON __________________________________________________________________ 7

9.4. Main Screen____________________________________________________________________ 7

9.5. General Procedure _____________________________________________________________ 7

9.6. Setting the Torque _____________________________________________________________ 7

9.7. Units ___________________________________________________________________________ 7

9.8. Adjustment of Follow-up Rotary Angle _________________________________________ 8

9.9. Preselections___________________________________________________________________ 8

9.10. Advanced Menu______________________________________________________________ 9

9.11. Limits __________________________________________________________________________ 9

9.12. Bolt Counter ________________________________________________________________ 10

9.13. Adjustment Lock____________________________________________________________ 10

9.14. Point Calibration ____________________________________________________________ 11

9.15. Languages __________________________________________________________________ 11

9.16. Prove Program ______________________________________________________________ 11

9.17. Bolt Documentation System_________________________________________________ 12

9.18. Set Date and Time __________________________________________________________ 12

9.19. Identification of a Operator__________________________________________________ 13

9.20. Total and Maintenance Counter _____________________________________________ 13

9.21. Device Information __________________________________________________________ 13

9.22. Diagnosis ___________________________________________________________________ 13

9.23. Key Lock____________________________________________________________________ 13

10. Support for Reaction Arm _______________________________________________________ 14

11. PC-Software MV-RAD-Datalogger _______________________________________________ 15

11.1. Add the electric torque driver as Bluetooth-Device under Windows____________ 15

11.2. Software Installation in Windows ______________________________________________ 15

11.3. Software Set-up_______________________________________________________________ 15

MV-RAD

Page 3

11.4. Read-out of Data______________________________________________________________ 15

11.5. Saving and Print of Data ______________________________________________________ 15

11.6. Synchronization of the Clock __________________________________________________ 15

12. Trouble-Shooting _______________________________________________________________ 16

12.1. Message “Voltage Fault” ______________________________________________________ 16

12.2. Message “Sensor Fault” _____________________________________________________ 16

12.3. Message “Insert SD Card” ___________________________________________________ 16

12.4. Instead of letters, the display shows merely lines_____________________________ 16

12.5. Incorrect Date and Time_____________________________________________________ 16

12.6. Adjustment of Minimum or Maximum Torque Impossible_____________________ 16

12.7. No Reaction to Key Commands _____________________________________________ 16

12.8. No Reaction to Start Button _________________________________________________ 16

12.9. In left-handed rotation, bolts are not detached ______________________________ 16

12.10. Error Message after Completion of Bolting___________________________________ 16

13. Accessories _____________________________________________________________________ 17

13.1. Tool Suspension ______________________________________________________________ 17

13.2. Extension Pieces ____________________________________________________________ 17

13.3. Sockets and Securing Pins __________________________________________________ 17

14.Disclaimer_______________________________________________________________________ 17

15. Maintenance / Service___________________________________________________________ 17

15.1. General Remarks ______________________________________________________________ 17

15.2. Visual Inspection ____________________________________________________________ 17

15.3. Service Intervals ____________________________________________________________ 17

15.4. Spare Equipment____________________________________________________________ 18

15.5. Calibration __________________________________________________________________ 18

15.6. Manufacturer’s Address _____________________________________________________ 18

16. Product Overview _______________________________________________________________ 19

MV-RAD

Page 4

3. Manufacturer

M-PT Matjeschk-PowerTools GmbH & Co. KG

Am Saegewerk 11

01920 Ralbitz-Rosenthal

Germany

Phone: +49 (0) 35796 / 9760

E-Mail: mail@m-pt.de

4. EU Declaration of Conformity

We M-PT Matjeschk-PowerTools GmbH & Co. KG

Am Saegewerk 11

01920 Ralbitz-Rosenthal, Germany

Declare under our sole responsibility that the product

Product Name: Electric Torque Wrench

Series: MV-RAD

is in conformity with the provision of the following EU standards and directives:

- DIN EN 55014-1:2018-08

- DIN EN 55014-2:2016-01

- DIN EN IEC 61000-3-2:2019-12

- DIN EN 61000-3-3:2020-07

- DIN EN 62841-1:2016-07

- DIN EN 62841-2-2:2015-05

acc. to directives 2006/42/EG, Appendix II A

2014/53/EG.

Ralbitz-Rosenthal, 29.04.2021

MV-RAD

Page 5

5. Safety Notes

5.1. General Remarks

•Safety of personnel and trouble-free operation can only be warranted with original

M-PT components installed. This relates to all elements of the device, accessories

and spare parts. M-PT does not assume any responsibility and rejects all

corresponding claims in the case of unauthorized installation of foreign parts.

5.2. Surroundings

•The working zone must be clean and sufficiently illuminated.

•The equipment is not appropriate for environment requiring ATEX instrumentation,

i.e. the presence of corresponding liquid, gas or dust in proximity of the working

zone is strictly forbidden. Sparks could give rise to fire hazard.

•Local legislation and regulations for prevention of accidents must be observed.

5.3. Electrical Safety

•The connector of the tool must match the socket in place. Manipulations are not

admissible.

•The tool has not been designed for applications in wet environment (rain, extreme

moisture etc.).

•With respect to the cable, generally known rules must be followed (prevention of

excessive stress, heat, abrasion or damage caused by sharp edges or moving

machine components).

•For outdoor applications, also extension cables –whenever used- must meet the

same requirements.

•If operation in humid environment cannot be avoided, a fault current circuit breaker

is imperative.

5.4. Safety of Personnel

•Persons not participating in the procedure in question should be kept away, in order

not interfere in the work.

•Tools should be stored protected from unauthorized access.

•The tool should not be left to persons, unconscious of possible danger, or not

knowing this manual.

•Protective equipment is required.

5.5. Absence of Damages

•Before starting to work, the entire equipment must be inspected.

•In case of any damages, first repair must be performed –by qualified specialists and

by means of original spare parts.

•This is particularly valid in the case of defective switches.

•At the end of the work or before exchanging components, the device must be

disconnected from mains.

6. Scope of delivery

•Electric torque driver, ready-to-use

•Reaction arm with retaining ring

•User manual with EU declaration of conformity

•Calibration certificate

•Storage case

MV-RAD

Page 6

7. Product Identification

The type plate with tool designation and serial number is illustrated below.

8. Specification

See type plate and test certificate.

9. Detailed Description

9.1. Start-up

•The instrument is delivered ready-to-use.

•Components and accessories to be added should not impair function and safety of

the tool.

•Mains voltage and frequency are specified on the type plate.

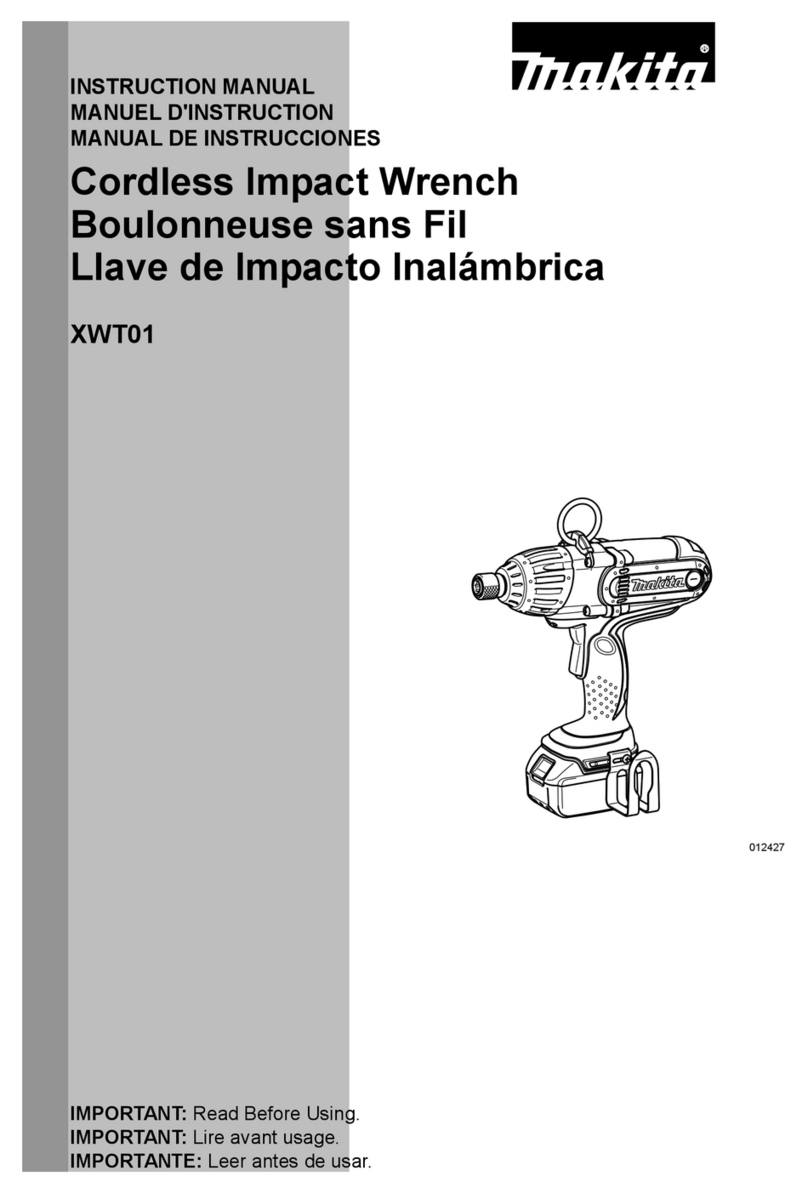

9.2. Initial Steps

1. First the reaction arm (2) has to be plugged onto the toothed wheel work (1), as

illustrated.

2. In order to secure the reaction arm, insert the locking ring (3) into the

corresponding groove of the gearing.

3. The socket (4) has to be shifted onto the integrated square drive bolt. Only sockets

with standard square opening, acc. to DIN 3121 should be used.

4. Secure the assembly by pin (5).

5. The pin itself has to be secured as well (from falling out), by means of retaining ring

(6).

6. The device can be connected to the mains.

1

2

3

4

5

6

MV-RAD

Page 7

9.3. Switching ON

After initialization, the screen displays time and date together with the file

currently open. If date and time require adjustment, refer to chapter 9.18.

The screen has to be confirmed by pressing key M.

Note that the screen appears only in the case of bolt documentation system

enabled.

9.4. Main Screen

•Upper left: Current sense of rotation

•Upper right: Model (“34” designates the MV-RAD 34 series.)

•Center line: Current set value of torque

•Lower line: Set value for angle of rotation

•The last result still remains on the display for 10 sec. after completion

of the bolting process.

•In the case of bolting failure, the color of displayed

values changes to red. The fault can be

acknowledged by any key.

9.5. General Procedure

•Settings have to be entered by keys (M),

(↑) and (↓) (1).

•Sense of rotation is determined by selector switch

(2).

•Initiate rotation by start button (3).

9.6. Setting the Torque

•The last torque in use is shown immediately after switching ON.

•Default value is 0 Nm.

•The sense of rotation is displayed at the upper left corner (as explained above).

•The device type appears at the upper right corner.

•Adjustment of torque is enabled by key M.

•The torque value display changes to yellow.

•Increase or decrease the value by keys ↑and ↓.

•To speed up adjustment, press and keep pressed the corresponding key (↑resp. ↓).

•To confirm the setting, press Mone more time.

•The torque value from now on is shown in white.

9.7. Units

•The torque unit can be chosen in the Settings option of the Advanced Menu and

then selecting the unit desired.

•The following possibilities are available:

·Newtonmeter –Nm

·Foot-pound –ft/lbs

·In 100 steps (for fine tuning, consult factory service).

•Recalibration after change of units is not necessary.

•For working in step mode, a torque table is available, consult factory service.

1

2

3

MV-RAD

Page 8

9.8. Adjustment of Follow-up Rotary Angle

•A follow-up rotary angle can only be adjusted, if this feature has been enabled in the

Advanced Menu (Extended), as explained in section 9.10.

•Set-up takes place in the main screen, as illustrated below:

•First the torque itself is adjusted after pressing key M. This procedure has already

been explained in section 9.6.

•After confirmation of the torque value (by key M), adjust the angle by keys ↑und ↓.

•Press Mone more time to confirm the angle setting.

•Note that the angle can only be adjusted within the range between 10° and 360°.

•As soon as the torque exceeds the maximum torque of the tool, the unit

automatically switches OFF (refert to specification, section 8).

9.9. Preselections

•Up to 10 preselections defined by the user can be stored.

•For standardized HV connections, preselections are stored as well, but cannot be

modified. (HV relates to high-strength prestressed bolts).

•Press Mfor a longer time, to open main menu.

•Press Magain, to gain access to the menu of preselections (Preset).

•Choose between user defined Customerpreset and default HV preselections.

•The following parameters are shown:

·Order number of preselection

·Name

·Torque (see point 9.6)

·Follow-up Rotary Angle (point 9.8)

·Limits for final torque (point 9.11)

·Bolt Counter (point 0)

·Program type selected (Normal or prove program, refer to point 9.16)

•Call up the preselection desired by means of ↑and ↓.

•Pressing key Mopens a menu with the following options:

•„Accept“: The displayed preselection is accepted as the

current setting for the bolting process.

•„Overwrite“: Data of the displayed preselection are modified,

i.e. overwritten by the current settings.

•„Cancel“: Return to displayed preselection.

MV-RAD

Page 9

•„Back “: Return to Preselection menu.

•Press „Back“ again to return to the main screen.

•HV preselections however are fixed and cannot be modified. They are displayed in

conformity with the torque range available for the model concerned.

•Default tightening torques for HV bolts relate to the modified torque method acc. to

DIN EN 1993-1-8 for k-class K1.

9.10. Advanced Menu

•Access to Advanced Menu (Extendet) requires password entry. The default code is

„17580“.

•If this code is intended to be modified, open “Password”, accessible in the main

menu.

•In the Advanced Menu, the following options are provided:

·Advanced functions:

▪Activation of follow-up rotary angle (refer to point 9.8)

▪Activation of limits (point 9.11)

▪Activation of Bolt Counter (point 9.12)

▪Point calibration (point 9.14)

▪Selection of units (point 9.7)

▪Language (point 9.15)

·System Release (consult factory service)

·Bolt Documentation System (point 9.17)

·Lock Advanced Menu

9.11. Limits

•Before specifying limits themselves, activate this function in the Advanced Menu:

•Limits can be defined to each final tightening torque.

•For pure torque tightening, limits can be assigned to angles. This angle is counted

up from minimum torque of the device.

•For torque-rotary angle tightening however, limits apply to the final torque.

•These limits can be entered in the main screen, after completion of setting for

torque and follow-up angle:

•Limits have to be confirmed by key M.

•During storage of the preselection, limits are saved as well (refer

to point 9.9).

MV-RAD

Page 10

•In the course of the process, infraction of limits is clearly visible on the screen.

•The tool can be unlocked again by pressing any key.

9.12. Bolt Counter

•The bolt counter is enabled or disabled in the Advances Menu as well.

•Setting takes place again in the main screen:

•Once enabled, set the counter to any value between 1 and 999.

•The counter reacts to all successful bolting procedures carried out in right-handed

rotation.

•After arrival at the selected number, the tool automatically is locked. To restart

operation, proceed as follows:

·Choose a new number or

·Disable the counter

•If during an activated run the tool is disconnected from the mains, it restarts from

the current position after switching ON (i.e. the progress is stored in non-volatile

memory).

•To avoid double counting of bolts tightened already beforehand (by erroneously

selecting a corresponding bolt a second time), it is recommended to use the counter

together with the limit function (point 9.11), and e.g. to set for torque tightening the

lower test angle to 10°.

9.13. Adjustment Lock

•The adjustment lock is enabled or disabled in the Adavaced Menu as well.

•If the adjustment lock is activated, the torque can not be changed.

•Only the saved presets (point 9.9) can be selected.

MV-RAD

Page 11

9.14. Point Calibration

•The precision of the tool for particular bolt cases can be increased by point

calibration.

•For reference measurement of the real torque, a measuring device (e.g. the Smart

Socket™ described in section 16.7) is necessary.

•The torque desired is set up in the main screen.

•The point calibration can be stored in form of a preselection (section 9.9).

•Activate the calibration procedure in Advanced Menu, option „Point Calibr.”

•The screen shows „Perform 1. Bolt“

•The first bolting has to be carried out.

•Enter the result in the display.

•To select the second bolting procedure, press ↓.

•Peform the second procedure, and enter the result again.

•Complete the calibration by pressing ↓and then M.

9.15. Languages

•In the Advanced Menu, choose between the following five languages:

·German

·English

·Spanish

·French

·Dutch

•After confirmation of the language, the device automatically performs restart.

9.16. Prove Program

•The Prove Program is not included in the standard delivery, it is available upon

request. It has been developed for verification of tightened bolt connections.

•This feature can be enabled by option “Prog. selection”, as shown below:

•After Prove Program enabled, the display shows in an alternating sequence the

word „Prove“ and the torque selected.

•The Prove Program establishes the selected torque in a slow rise.

•If the real torque of the bolt is lower then the test torque, the tool further tightens

the bolt until the desired value is reached.

•After completion, the follow-up angle appears on the screen.

MV-RAD

Page 12

•If in the Advanced Menu, limits have been activated (point 9.11), the tool performs an

assessment of the follow-up angle.

•In the case of follow-up angle outside tolerance,

the value is shown in red, the limit concerned is

mentioned as well „Upp. Lim.“resp. „Low. Lim.“.

•Acknowledge the fault by pressing any key.

•Otherwise the value is shown in green.

•Note that the speed of the tool in test mode is lowered (compared

to normal operation).

•Even for tight bolt connection, the elastic deformation of the

reaction arm gives rise to a displayed follow-up angle of ca. 1 to 3°.

The exact value has to be determined before starting the test routine, and to be

taken into account for evaluation.

9.17. Bolt Documentation System

•The Bolt Documentation System as well is not part of the standard delivery content.

•After purchasing and installation of the software, the Advanced Menu features the

submenu „Documentation“

•Quick access is also possible by pressing both arrow keys simultaneously.

•The following commands are contained in the documentation menu:

·View Log File: Inspect data of all boltings completed.

·Choose Log File: A new file can be created.

·Date/Time: The current time and date can be set, acc. to instructions in

section 9.18.

·Settings: Entry of a user identification (see also point 9.19), and data transfer

to PC can be activated/disabled.

·Program used: The decision between normal and prove program is made in

this sub-menu (section 9.16).

•The following data are saved within the files:

·Current number: A number is assigned to each bolting

disposing of a torque above the minimum tool torque.

·Process number: Assigned to each bolt successfully

tightened in right-handed rotation.

·Date and time

·Set and real torque

·Selected torque unit

·Set and real rotating angle

·Final torque for rotating angle tightening

·Limits selected (see point 9.11)

·Total angle and bolting time

·Mains voltage and frequency

·Program type (normal or prove program)

·User (see section 9.19)

•A new file can be created by “Choose Log File”.

•Store this file (“Save”) to activate it.

•Pressing key Mfor a longer time erases the

entry.

•When storing an empty entry, the last file

automatically continues to be used further.

9.18. Set Date and Time

•Date and time within the system are displayed and used only with documentation

feature enabled.

MV-RAD

Page 13

•Before setting date and time, enter password to open the Advanced Menu (point

9.10).

•The clock can be synchronized by software included in the delivery (point 11).

9.19. Identification of a Operator

•Activation/disabling of user ID takes place under ‘Settings’ in the documentation

menu.

•Once enabled, the system during start-up requests for entry of an ID (eight

characters), to be included in the documentation as well.

9.20. Total and Maintenance Counter

•Total and Maintenance Counter are located in the Statistics Menu.

•The first value relates to the entity of bolting procedures performed by the present

tool, the latter number to the procedures carried out after the last maintenance.

•Both counters are subdivided into:

·0 –20 % of maximum torque

·21 –80 %

·81 –100 %

·0 –100 % of maximum torque (this is the total value)

•When 20,000 boltings are reached, the message „Scedule the Maintenance“informs

the user, that the next maintenance routine is required.

9.21. Device Information

•The following information is available here:

·Version no. of software

·Serial no. of tool

·Phone number of factory service and website of manufacturer

9.22. Diagnosis

•The option „Diagnosis“ is not intended for the user himself, but is required

sometimes for consultation of factory service by phone.

9.23. Key Lock

•Simultaneous pressing of Mand ↑keys for 3 sec. activates key lock.

•Repeat the same procedure to unlock the keys again.

•With key lock enabled, the display cannot be modified. The tool itself however goes

on working as usual.

MV-RAD

Page 14

10. Support for Reaction Arm

Height of Reaction Arm:

Support for Reaction Arm:

Danger of Squeezing:

MV-RAD

Page 15

11. PC-Software MV-RAD-Datalogger

11.1. Add the electric torque driver as Bluetooth-Device under Windows

1. Install the Bluetooth-Stick included in the delivery.

2. Activate data connection at the tool itself. The feature “Data transfer” is available in

the Settings submenu of the Documentation menu described beforehand.

3. In the Start menu of the PC, select function „Devices and Printers“.

4. Command „Add Device“.

5. Select the serial number of the tool (e.g. MV-RAD-M123456).

6. Command „Next“.

7. After successful implementation, click on „Close“.

8. In window „Devices and Printers“, mark the serial number of the tool by a right click.

9. Select „Properties“ menu.

10. Select „Hardware“ tab.

11. The relevant COM port (e.g. „COM11“) can be found in the name designation of the

Bluetooth connection.

12. Close all windows.

11.2. Software Installation in Windows

13. The installation routine is initiated by start of „setup.exe”.

14. Licence conditions have to be confirmed.

15. Command „Next“

16. Select the folder desired for storage, click on „Next“.

17. Click on „Next“.

18. After completion, click on „Close“.

19. The data connection at the device is finished by „Back“.

11.3. Software Set-up

1. Open „MV-RAD-Datalogger“ software by a link on the desktop.

2. Under „Select Port“, designate the COM port determined in section 11.1 (e.g. „COM11“).

11.4. Read-out of Data

•Activate data connection at the tool itself. The feature “Data transfer” is available in

the Settings submenu of the Documentation menu described beforehand.

•Click on „Load data“.

•During first selection of the tool, a particular designation must be assigned e.g. an

inventory number or a distinct name.

•Confirm by command „Save“.

•While loading a new file, a particular designation must be assigned, e.g. plant or

order number.

•Confirm by command „Save“.

•Progress of the loading process is visualized at the left lower corner of the screen.

The speed amounts to ca. 3 records/sec.

•After completion, tool and file can be selected at the upper left corner of the screen.

•Together with the name of tool and file, a table with recorded data is displayed.

11.5. Saving and Print of Data

•To create a printout, select the Print option in the tab ‚Menu‘.

•When storing a file in form of a .pdf, first in the print menu a pdf-printer has to be

selected (the installation CD contains a corresponding element).

•To store in form of .csv or .xlsx files, select the Export option in the tab ‚Menu‘, and

then the suffix desired.

11.6. Synchronization of the Clock

•Activate data connection at the tool itself. The feature “Data transfer” is available in

the Settings submenu of the Documentation menu described beforehand.

•In the tab ‚Menu‘, select option ‚Synchronize Clock‘.

MV-RAD

Page 16

12. Trouble-Shooting

If a particular problem cannot be solved on the basis of the instructions listed below,

consult factory service immediately. Improvised repair is not recommended.

12.1. Message “Voltage Fault”

The mains voltage is obviously out of tolerance (nominal value ± 25V), refer to point 8.

12.2. Message “Sensor Fault”

Impulse transmitter is defective.

12.3. Message “Insert SD Card”

The SD card has not been recognized.

12.4. Instead of letters, the display shows merely lines

The SD card has not been recognized.

12.5. Incorrect Date and Time

The battery is empty (if the problem is not due to transport to another time zone).

12.6. Adjustment of Minimum or Maximum Torque Impossible

Possible reasons:

•Incorrect calibration

•Internal memory corrupted, consult factory service

12.7. No Reaction to Key Commands

If the problem cannot be solved by restart, the membrane keyboard is defective.

12.8. No Reaction to Start Button

Possible reasons:

•Torque set to 0 Nm.

•Bolt Counter activated and set to 0.

•Bolt Counter activated, preselected number reached, all boltings complete.

•Button itself defective.

12.9. In left-handed rotation, bolts are not detached

Possible reasons:

•Torque required exceeds maximum torque of the tool.

•Selector switch Left/Right is defective.

12.10. Error Message after Completion of Bolting

Possible reasons:

•Limits have been enabled, but not correctly adjusted.

•Bolt excessively tightened (e.g. a connection already fixed is tightened once more).

•The tool during rotary angle bolting has reached its maximum torque. In

corresponding cases, the instrument automatically is switched OFF to protect

internal components. Simultaneously an error message appears.

•The start button has been released before the tool is disabled.

MV-RAD

Page 17

13. Accessories

13.1. Tool Suspension

In order to simplify work and avoid unprofessional

constructions, stable suspensions, to be attached to the

gearings, are available for all tool models. Consult factory

service.

13.2. Extension Pieces

Extension pieces in different lengths are

available for all models, to grant access also to

recessed positions or in narrow places.

13.3. Sockets and Securing Pins

Sockets and reaction arms must mutually match. To

obtain a convenient configuration, consult factory

service.

14. Disclaimer

This manual has carefully been prepared. In the case of supplementary questions, do not

hesitate and consult factory service. The manufacturer does not assume any responsibility

for technical or typographic mistakes; technical specifications and corresponding

instructions are subject to change without notice. The manufacturer is not responsible for

direct or indirect consequential damages in connection with equipment, services or use of

the product. No warranty is given for the content of this document.

The warranty exclusively relates to defects in material and workmanship and becomes null

and void in the case of misuse, abuse, neglect and improper use. It is strictly forbidden to

manipulate components or to perform repair by means of parts not approved by the

manufacturer in writing. Improper use or misapplications shall be construed to include

excess of any specification of the equipment.

15. Maintenance / Service

15.1. General Remarks

•Safety and correct function of the tool can only be ensured by regular maintenance.

•Procedures like mounting, new adjustment, modifications, functional upgrading and

repair are reserved to M-PT factory service, if no other authorization is given in

writing.

•Installation of original M-PT spare parts is mandatory, foreign parts are not

admissible. This includes all internal components and accessories.

15.2. Visual Inspection

Visual inspection is required in regular intervals and refers to following criteria:

•Absence of external damage

•Function of movable parts

•Damages of shaft, drive and reaction arm

15.3. Service Intervals

•The convenient service interval depends on frequency of use.

•For permanent bolting at an intensity of up to 80% of maximum torque,

maintenance after 20,000 procedures is recommended.

•An individual maintenance conception matching the requirements of the application

can be discussed with our factory service.

MV-RAD

Page 18

15.4. Spare Equipment

•If during repair or maintenance, a spare tool is reqiured, rental equipment is available

any time.

15.5. Calibration

•The period of validity of the factory calibration amounts to 1 year, frequency of use

is not taken into consideration.

15.6. Manufacturer’s Address

M-PT Matjeschk-PowerTools GmbH & Co. KG

Am Saegewerk 11

01920 Ralbitz-Rosenthal, Germany

Phone: +49 (0) 35796 / 9760

E-Mail: mail@m-pt.de

MV-RAD

Page 19

16. Product Overview

16.1. Electronic Torque Wrench E-RAD BLU

•Torques from 135 to 16.500Nm

•Hightest speed for electronic tools

•Comprehensive documentation

•Accuracy +3,0%

16.2. Electric Torque Wrench MV-RAD (MED)

•Torques from 65 to 11.000Nm

•Repeatability +3,0%

•Comprehensive documentation

•Torque Check function for maintenance work

•Special programs possible

16.3. Battery Torque Wrench MB-RAD, B-RAD, QX

•Torques from 30 to 7.000Nm

•Continuously adjustable

•In pistol shape and flat angle version

•Repeatability starting from +2,8%

16.4. Pneumatic Torque Wrench RAD

•Torques from 35 to 15.000Nm

•Continuous torque build-up

•High speed model

•Lightweight construction

•ATEX certification optionally

•Repeatability +5,0%

16.5. Hydraulic Torque Wrench IBT, MFC, LOW

•Torques from 110 to 71.000Nm

•With torsion retaining ratchet

•Equipped with 360°x180°-ball and socket joint

16.6. Hydraulic High-Pressure Equipment

•Pressure up to 2.000 bar

•Supply quantity up to 8.2 l/min

•For simultaneous operation of 2 torque tools

16.7. Torque Measurement by SMART SOCKET

•Torques from 100 to 16.200Nm

•Accuracy +1,0%

•Graphical display of torque results

•Incl. software for data recording

16.8. Rental Equipment

•An extensive selection of tools is also available in our rental park.

Table of contents

Other M-PT Power Tools manuals