15 16

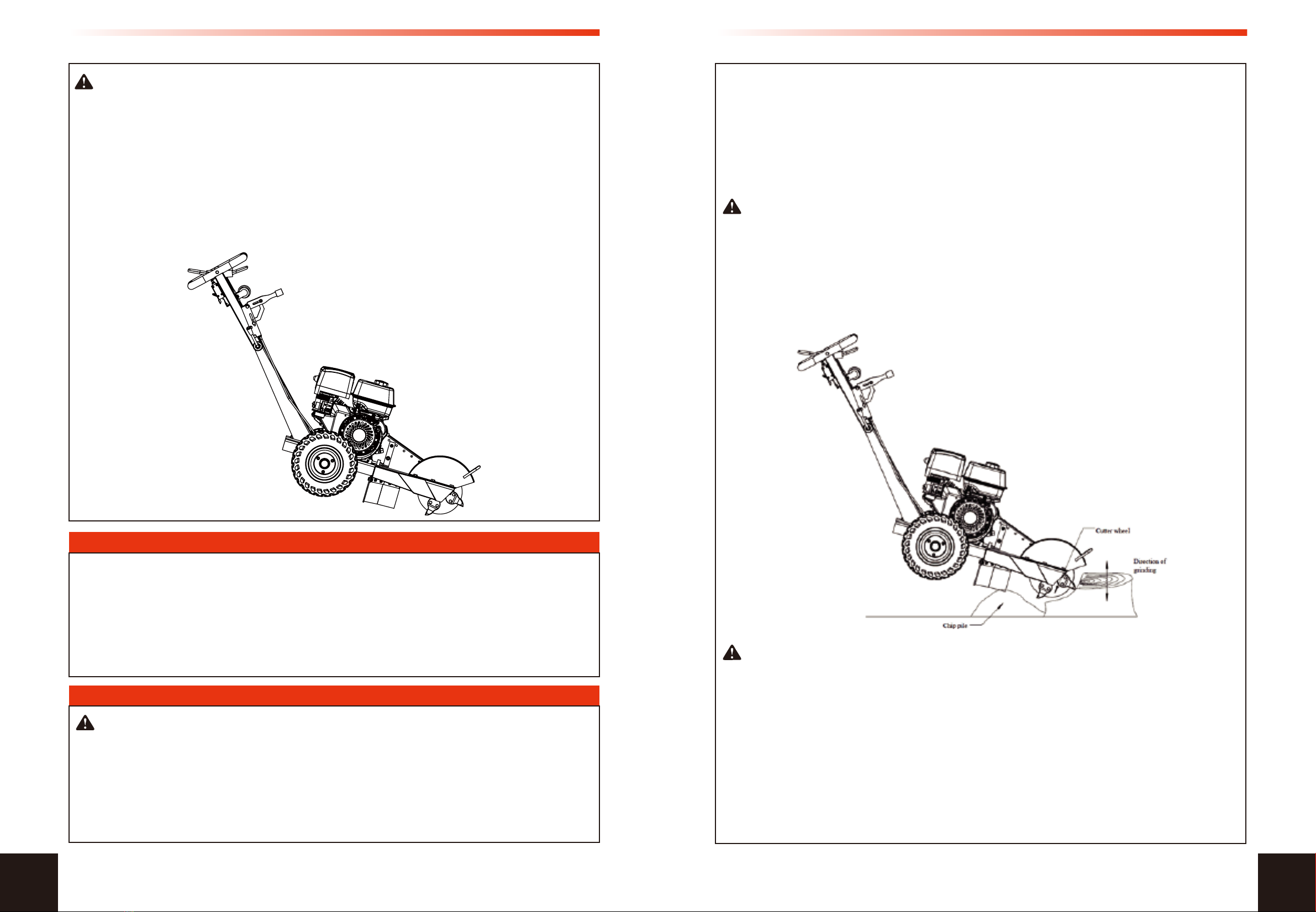

ALWAYS shut off the engine, make sure the engine is cool, and disconnect the spark plug before clean-

ing, adjusting, or servicing the grinder. Make sure all guards and shields are replaced before using.

Perform periodic maintenance as directed in this manual to keep the

grinder in safe working condition.

Read and follow these safety rules whenever you will be servicing the

grinder:

● Turn off grinder. Always turn off grinder and remove spark plug

or spark plug wire before working on the engine or grinder to prevent

accidental starting.

● Replace guards/shields. Make sure all guards and shields are

replaced after servicing the grinder.

● Burns. Muffler will be hot even after unit is stopped. Allow unit to

cool before servicing.

● Repair. Major service, including the installation or replacement of

parts, should be performed only by a qualified electrical service

technician.

● Replacement parts. If a part needs replacement, only use

factory approved repair parts. Replacement parts that do not meet

specifications may result in a safety hazard or poor operation of the

grinder and will void the warranty.

Perform engine maintenance as specified in the engine owner's

manual.

Engine maintenance items include:

● Oil and oil filter changing

● Air filter check/replacement

● Spark plug cleaning and replacement

● Fuel filter check/replacement

● Fuel tank cleaning.

Inspect the fuel system and check for leaks on a regular basis.

Look for: signs of leaks or deterioration, chafed or spongy fuel hose,

loose connections, loose or missing fuel hose clamps, damaged

gasoline tank, or defective gasoline shut-off valve.

Perform regular

Maintenance

Follow Safety Rules

Perform Engine

Maintenance

Inspect Fuel System /

Check for Leaks

Remove spark plug, in order to ensure the grinder cannot be started

in a storage location or y untrained persons or children.

Remove Spark Plug

The grinder should be started regularly. At least every 4 weeks, start

the engine and let it run for 10 to 15 minutes.

Monthly exercising of the grinder will dry out any moisture that has

accumulated, lubricate cylinders, and clean out old gas in the carbu-

retor. Moisture, old gas, and dry mechanical parts cause deterioration

in stored engines.

Start Grinder Every 4

Weeks

If you will not be able to start the grinder regularly, you must prepare

the engine for long term storage to prevent gum deposits from

forming and causing malfunction of the engine.

Prepare engine for long term storage by:

● Removing all gasoline from the tank and carburetor

OR

● Adding fuel stabilizer to the gasoline (following manufacturer's

instructions)

Fuel stabilizer steps:

1. Ensure gas tank is full.

2. Add fuel stabilizer to fuel tank.

3. Run engine at least 10 minutes after adding stabilizer to allow it to

enter the fuel system.

4. Shut off engine.

5. Disconnect spark plug wire and remove spark plug.

6. Add one teaspoon oil through spark plug hole.

7. Place rag over spark plug hole and turn starter (or pull the recoil)

a few times to lubricate the combustion chamber.

8. Replace spark plug, but do not reconnect the spark plug wire.

Gasoline is highly flammable and explosive. Drain the fuel into an

approved container OUTDOORS and far away from open flame.

NEVER store an engine with fuel in the tank indoors or in poorly

ventilated spaces where fuel vapor can come in contact with

● Static electric sparks.

● Sparks from electric wiring, batteries, or running engines.

● Sources of heat (such as a hot engine or exhaust).

● Open flames, including pilot lights.

Prepare Engine for Long

Term (Seasonal) Storage

if needed

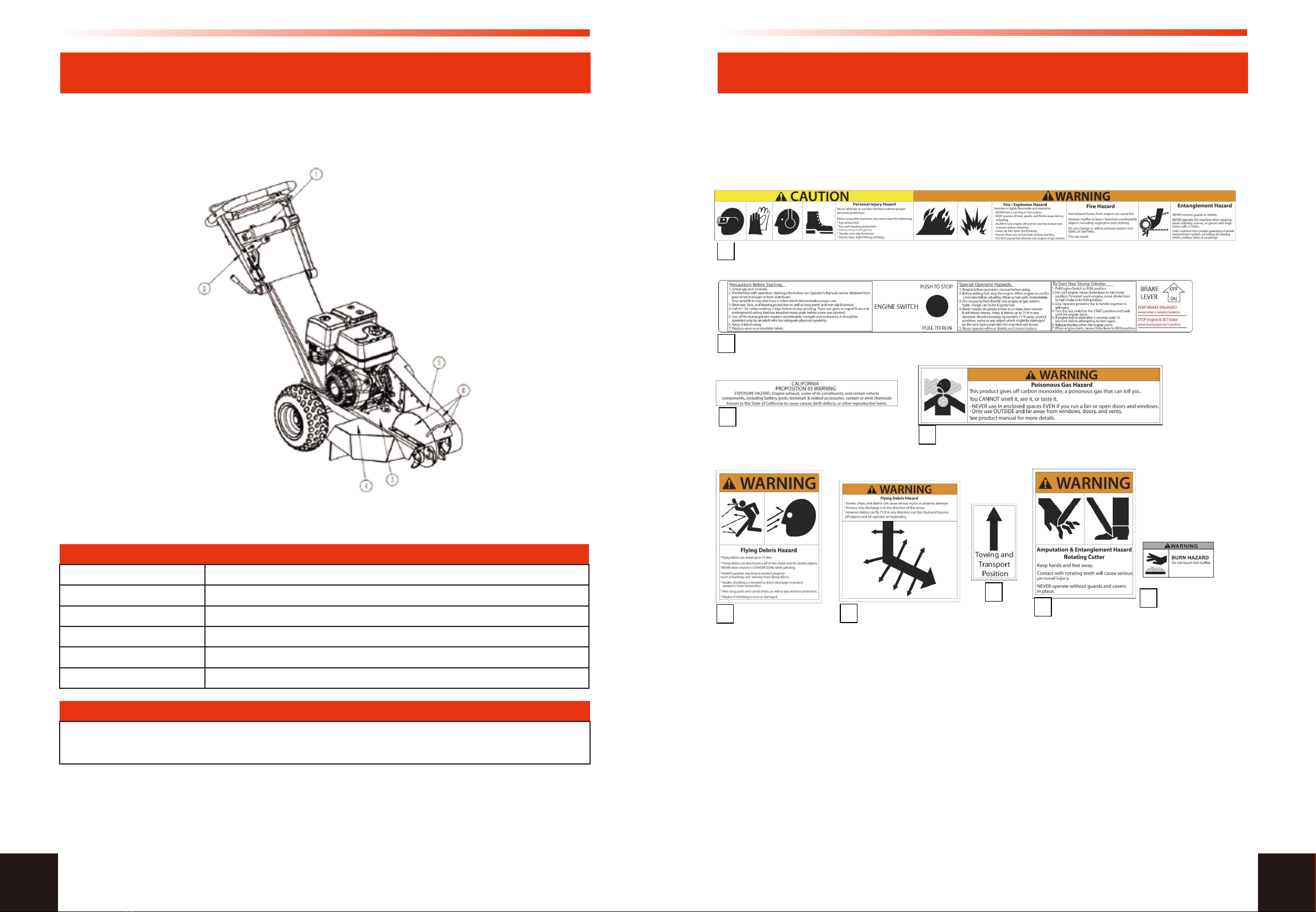

WARNING: Gasoline fire / explosion hazard

WARNING

MAINTENANCE