PRO STORMER PSMD001 User manual

CORDLESS Mini Grinder

PSMD001

Please do not press the locking knob while the machine is running to

avoid damage to the machine or safety accident

warning:read all safety warnings and all instructions. Failure to follow

the warnings and instructions may result in electric shock, fire and/or

serious injury.

Safety instructions

save all warnings and instructions for future reference.

1) Work area safety

a)

b)

c)

2) Electrical safety

a)

b)

c)

d)

keep work area clean and well lit. Cluttered or dark areas invite accidents.

do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets

Will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled

Cords increase the risk of electric shock.

- 01 -

When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal

injury.

Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, nonskid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of these

devices can reduce dust-related hazards.

e)

3) Personal safety

a)

b)

c)

d)

e)

f)

g)

- 02 -

4) Battery tool use and care

a)

b)

c)

d)

e)

DESCRIPTION

Ensure the switch is in the off position before inserting battery pack.

Inserting the battery pack into power tools that have the switch on invites

accidents.

Recharge only with the charger specified by the manufacturer. A charger

that is suitable for one type of battery pack.

Use power tools only with specifically designated battery packs. Use of

any other battery packs may create a risk of injury and fire.

When battery pack is not in use, keep it away from other metal objects like

paper clips, coins, keys, nails, screw, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery

terminals together may cause burns or fire.

Under abusive conditions, liquid may be ejected from the battery; avoid

contact, if contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may

cause irritation or burns.

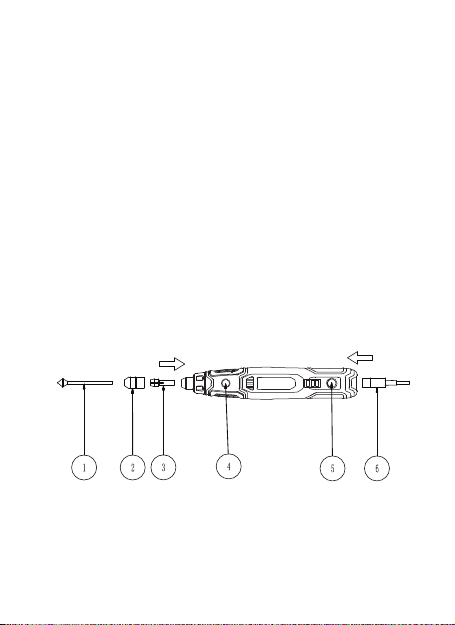

1. Accessory

2. Locking Collar

3. Collet

4. Locking Knob

5. On/Off Switch

6. MicroUSB

- 03 -

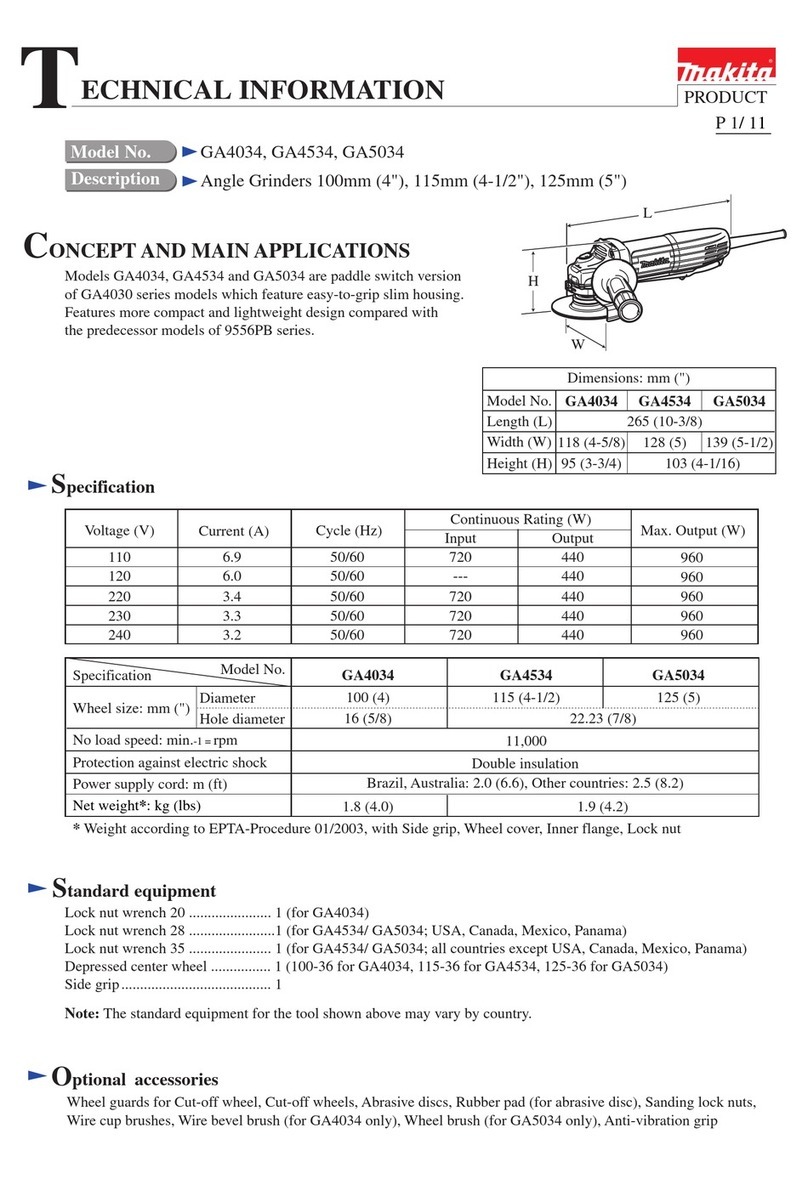

Technical data

Voltage rating: 3.7V DC

Battery type:3.7V Li-on / 0.6Ah

Charging voltage: 5V DC (USB)

Charging time: 2hr

No-speed: 5000/10000/15000 min

Collet size: ø2.3mm/ø3.2mm

Changing the parts

1.

2.

3.

4.

5.

Waring!

1.

2.

3.

4.

5.

6.

CHARGING THE TOOL

Connect the power supply (DC5V 500mA to 2000mA), Insert Micro USB into

the machine.

Turn the device off and ensure that the rotating part is stopped!

Push and hold the locking knob then turn the chuck until the button is fully

pushed in!

When the rotating part is clicked in, turn the locking knob down and pull

the parts/bit out from the tool.

Insert the new accessories into the chuck then fix the screw on while

pushing the locking knob

Finally, release the locking knob

Before using the tool, ensure that it is ready and safe to use!

Do not use in wet condition and enviroment!

Never use the tool near to flammable gas or liquids.

Do not force to operate the device when it slows down or stops turn it off

and finish the work process.

Wear glasses while using the tool.

Do not touch the drill/grinding tip during operation(even if it is in low speed),

because it can cause injury!

- 04 -

-1

Model: KM3.7A

Red light=charging Green light=Charging completed

Charger will automatically stop charging the battery when charging is

completed. It is ok to leave tool on charger continually

NOTE! A battery pack that has been unused for a while or never been

charged must be charged before reuse or first use.

CAUTION! Do not charge a battery for a second time in close succession.

There is a danger of overcharging the battery pack.

Switching on and off / Setting the speed range

Switching on / Setting the speed range:

Set the On / Off switch

Press the speed control between 1 and 3

Press switch 2 seconds, the tool will turn off

Accessories

Polishing wheels: Use to polish work-pieces made of metal and plastic.

Use one of the provided mandrels to assemble.

Diamond bits: For fine detail work, engraving, carving, touch-up and

finishing. Use on wood, jade, ceramic, glass, hardened steel, semi precious

stones and other hard materials. Bits are covered with diamond particles.

Grinding stones: Use for surface treatment of metal parts, cast-metal parts,

welding seams and for the removal of rust. Different shapes are available.

Cutting-off wheels: Use to cut work-pieces made of metal, plastic, wood or

stone. Use one of the provided mandrels to assemble. The cutting-off wheel

only cuts with the outer edge.

- 05 -

Dressing Stone: Use for cleaning and whetting grinding stones, if their

surface has become irregular or dirty.

Drum Band: Use to grind or smooth workpieces made of wood or glass

fiber material. Use with the provided grinding drum.

Mandrels: Shafts with screw or threaded head, which are designed for

retaining grinding and polishing wheels.

Drill bits: Use for drilling holes in work-pieces made of plastic, wood or

metal.

Cleaning, maintenance

Always pull out the mains power plug before starting any cleaning work.

Cleaning

●

●

●

Maintenance

There are no parts inside the equipment which require additional maintenance.

nvironmental Protection

Keep all safety devices, air vents and the motor housing free of dirt and

dust as far as possible.

Wipe the equipment with a clean cloth or blow it with compressed air at

low pressure.

We recommend that you clean the device immediately each time you

have finished using it.

Clean the equipment regularly with a moist cloth and some soft soap. Do

not use cleaning agents or solvents; these could attack the plastic parts

of the equipment. Ensure that no water can seep into the device.

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your Local Authority or retailer for recycling advice

- 06 -

Table of contents

Popular Grinder manuals by other brands

Central Machinery

Central Machinery 94186 Assembly and operating instructions

Makita

Makita GA4034 technical information

BITEHARDER

BITEHARDER 12 VOLT CARBIDE GRINDER instructions

Würth

Würth EWS 8-115 Light Original operating instructions

STI

STI Prep/Master 2807 operating manual

Oregon

Oregon 510A owner's manual

Flex

Flex L 8-11 115 Original operating instructions

Atlas Copco

Atlas Copco LSF39 S180E Safety information

Proxxon

Proxxon TSG 250/E manual

Desoutter

Desoutter KC912D3 manual

Milwaukee

Milwaukee angle grinder Operator's manual

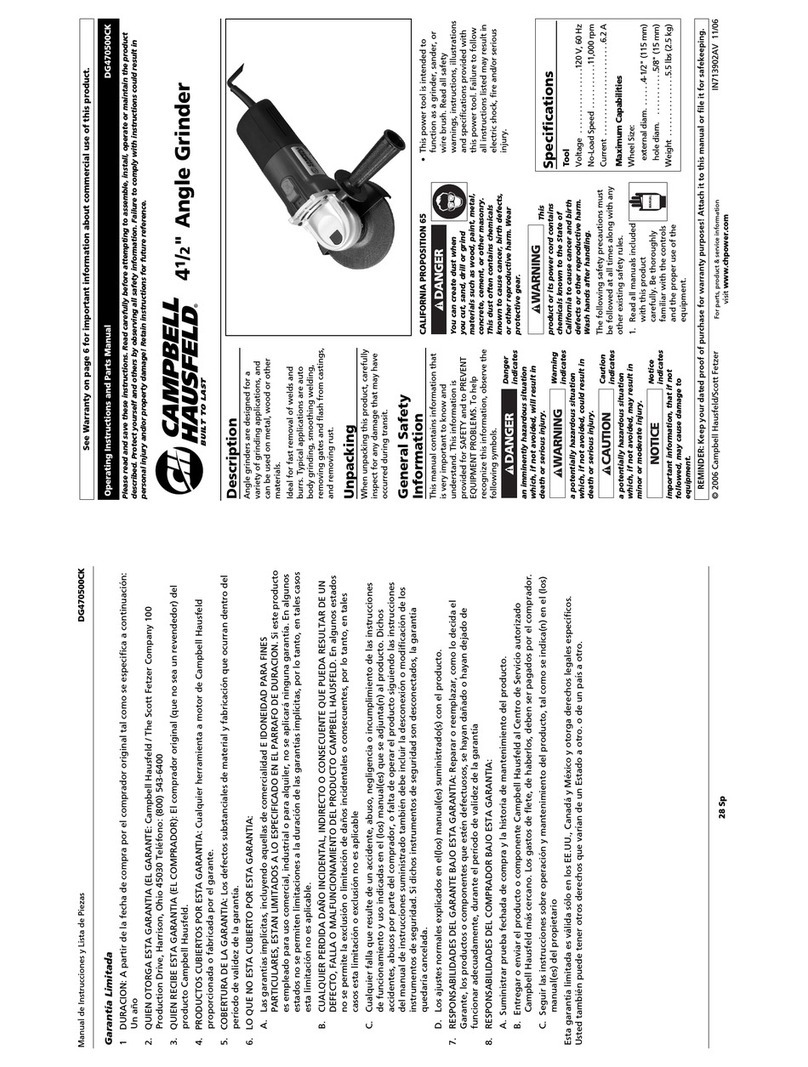

Campbell Hausfeld

Campbell Hausfeld DG470500CK Operating instructions and parts manual