4

Trouble shooting:

No. Trouble Cause Trouble shooting

1

When you Turn Air Valve to the

“Open” position and press Push

Button down, but the Extractor Unit

won’t start operation.

You might stand upside down the

body inclines (when it in the no uid

condition), if the body had the uid,

it might incline 45° shake several

times, and then pressed the button,

heard " click " the sound means

normal.

Please to press the blue color

button that is on the "cover

housing", if you hear the sound

in " click " obviously, means in

the normal condition. If there’s no

voice, it means abnormally.

2

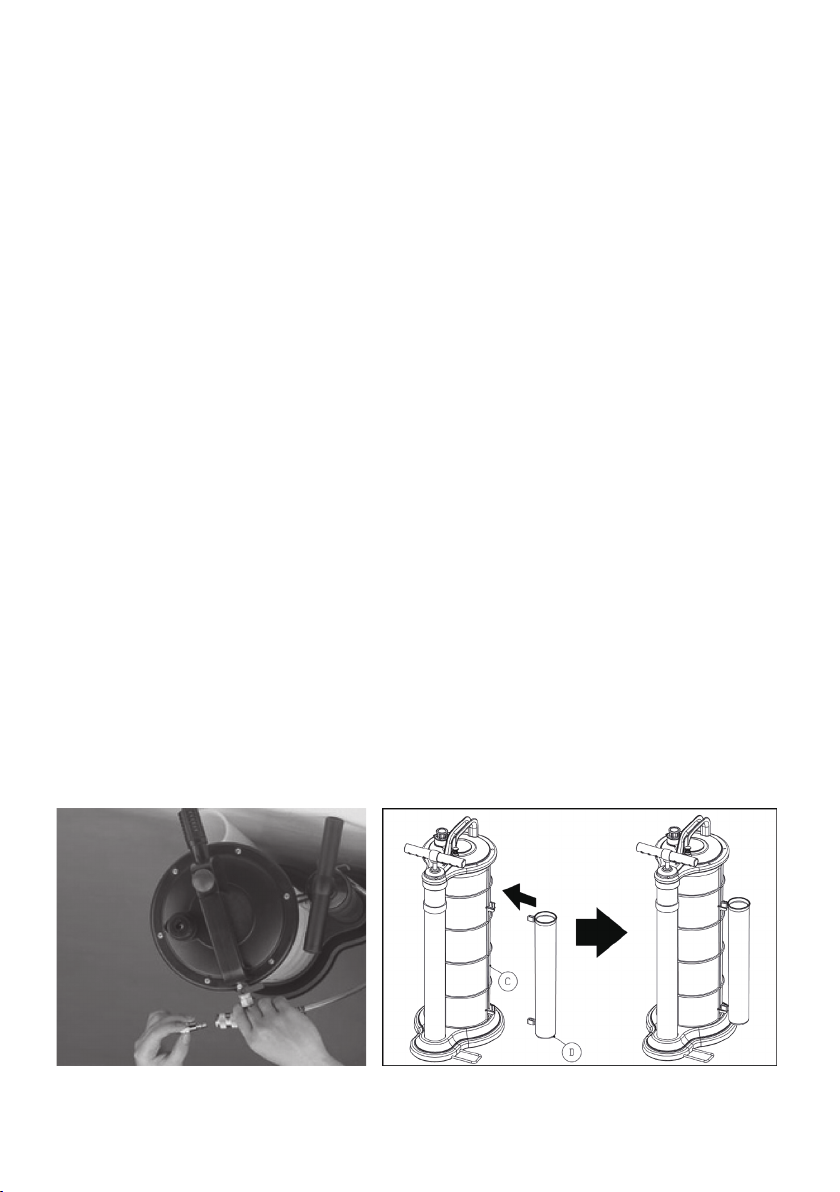

When you Turn Air Valve to the

“Open” position and press Push

Button down, but the Extractor Unit

won’t start operation.

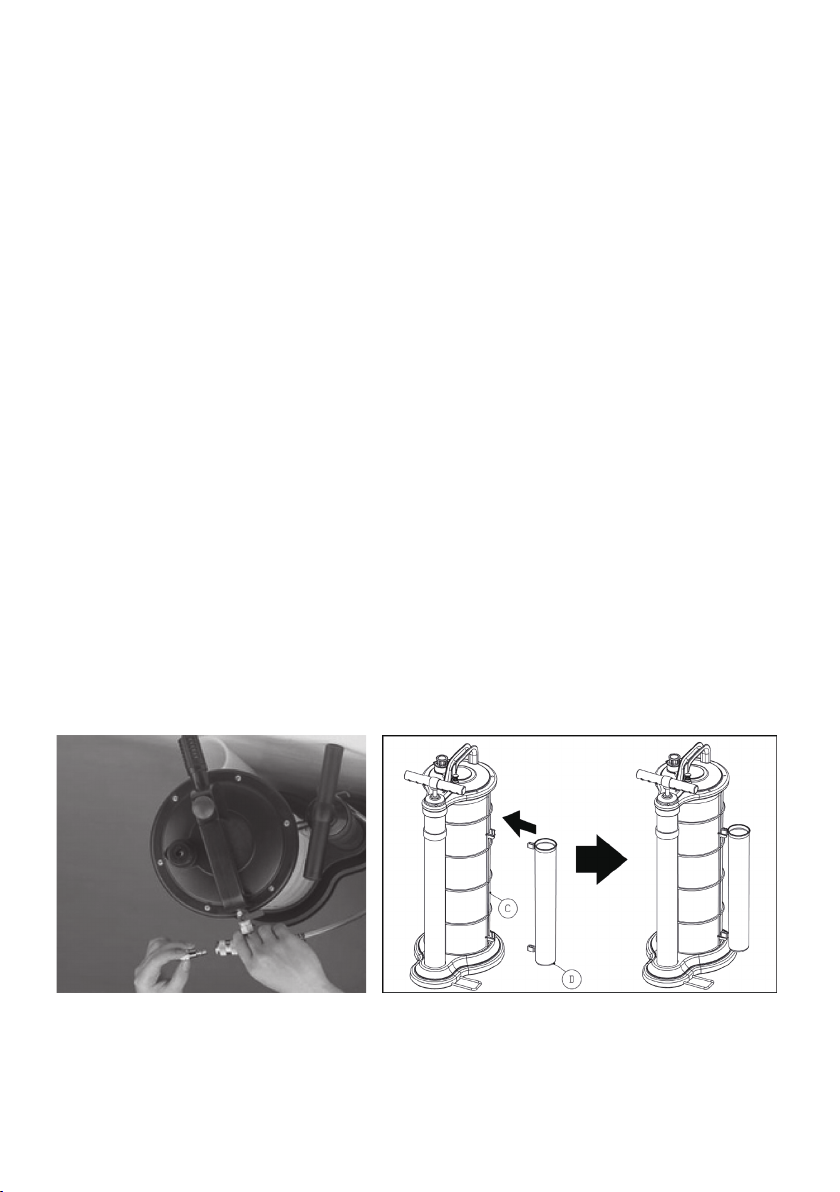

During Using, it should stain with

some lube make the internal part

more slippery. The correct place to

ll lube follow as: make the quick

coupler out rst, pump the oil in

and then jointed the quick coupler,

when the Compressor air come

in, the lube will follow air into the

internal of the Extractor unit.

3

When the uid inside the extractor

tank reaches “Full” position,

the Extractor Unit won’t shut off

Automatically.

Please to close the air valve and

stop the action, then dispose of

the uid in accordance to the laws,

use trouble shooting in step 1 and

step 2.

4When the Extractor Unit work on, but

it can’t suck the uid any more

To check the tube whether has

inserted the location rmly or

slip? to inspect the uid is empty

or not? to check the uid inside

the extractor tank reaches “Full”

position or not?