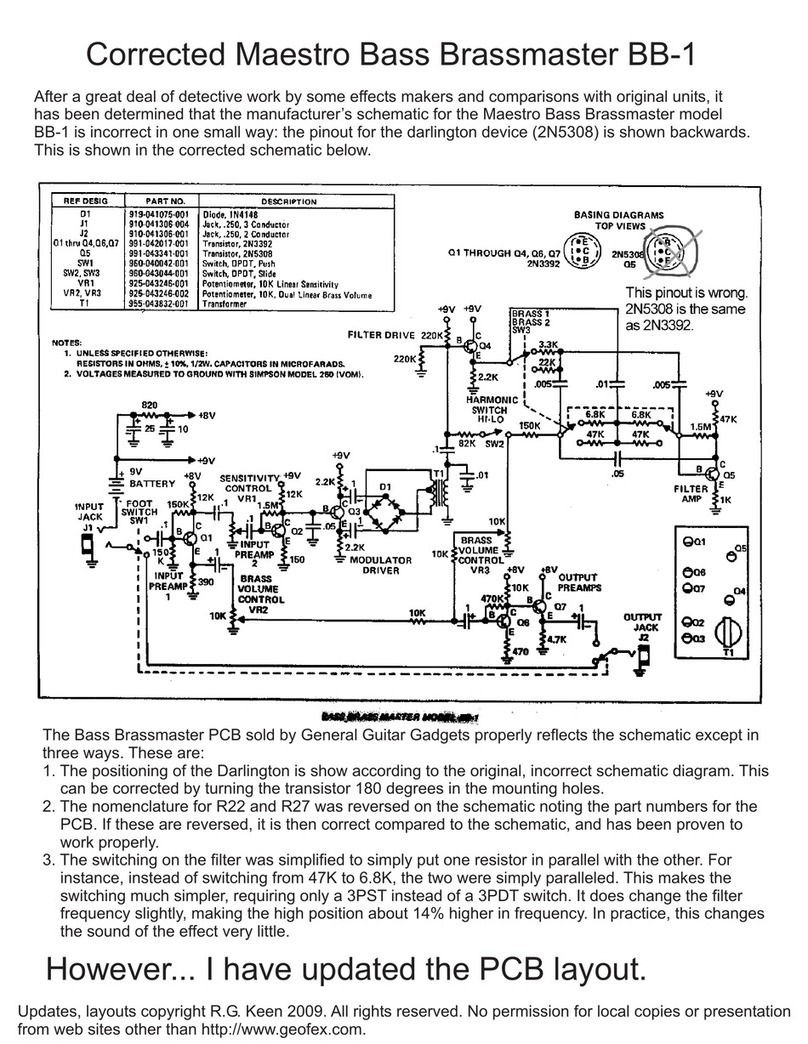

a) Visually inspect unit for broken wires,

damaged components, loose connections and other

obvious defects.

b) Make certain unit is connected and operated

according to Owners Manual or instruction label

located on bottom of unit. If possible, check

associated equipment such as cables, battery or

amplifier used with the unit.

c) Connect 9volt dc power source to battery

clip and turn DRIVE and VOLUME pots to

maximum output level.

d) Apply a200 millivolt peak-to-peak sine wave

at afrequency of 500 Hz to AXE jack J2 and observe

dc voltage levels and ac signal levels as shown on

the schematic diagram using an oscilloscope.

NOTE

Ahigh impedance voltmeter (1 megohm

per volt or higher) may be used to

measure dc voltage levels. Note that voltage

levels and waveforms displayed on the

schematic diagram are not absolute values

as readings may vary between units.

e) Once the problem is localized, check the

suspected part by direct substitution if possible.

Otherwise use avoltmeter or oscilloscope to deter-

mine the malfunctioning part.

NOTE

All replacement parts may be obtained

from Moog Music, Inc. However, many

standard electronic parts may be obtained

locally in less time than is required to

receive them from Norlin. When purchasing

replacement parts locally, check the parts

list for proper value, tolerance and rating.

REASSEMBLY

a) Reassemble Maestro Fuzz in reverse order of

disassembly referring to the exploded view (Figure 1

)

and noting the following additions.

b) Finger tighten nuts (13) securing printed

circuit board assembly (15) to housing assembly (26)

to allow printed circuit board assembly to fit into

slots of end caps (10). After both end caps are

installed, tighten nuts (13).

c) Connect three pin connector (24) to printed

circuit board assembly (15) making certain black

wire (pin 1) is on left side of connector at bottom of

printed circuit board.

d) Slip dial assemblies (4 and 5) on rotary pot

shafts (left dial assembly (4) marked “L” between

“9” and “0” and right dial assembly (5) marked “R”

between “9” and “0”) and turn each dial assembly

full counterclockwise and then clockwise.

e) Turn right dial assembly full counterclockwise.

Holding dial assembly steady at “0,” insert small

screwdriver in hole at center of dial assembly and

turn pot shaft full counterclockwise, then approxi-

mately five degrees clockwise to relieve strain on pot

shaft. Tighten setscrew (3).

f) Turn left dial assembly full clockwise. Holding

dial assembly steady at “0,” insert small screwdriver

in hole at center of dial assembly and turn pot shaft

full clockwise, then five degrees counterclockwise to

relieve strain on pot shaft. Tighten setscrew (3).

g) Rotate both dial assemblies making certain

their range is from “0” to “9.”

REPLACEMENT PART LISTS

ORDERING

The following lists specify parts available from

Moog Music, Inc., Customer Service Department,

2500 Walden Avenue, Buffalo, New York 14225,

(716) 681-7242. Please specify the unit name, model,

serial number, part description, electrical reference

designator if applicable and part number when ordering.

3