5

2Installation

2.1 External air intake and fume exhaust

For proper operation, the thermo-stove must be positioned in a place where the air necessary for

combustion can flow. Air inflow must take place directly through permanent openings (according to UNI

10683) applied on outside-facing walls having the following features:

Be made in such a way that they can not be obstructed, either from the inside or the outside;

Be protected with grid, wire mesh or suitable guard, provided that it does not reduce the minimum

cross-section of 100 cm.

The minimum volume of the room must not be less than 30 mᶾ.

Air flow can also come from rooms adjacent the installation room, provided that the former are equipped

with an external air intake and NOT used as bedroom and bathroom or, do not present fire hazards, as

storage areas, garages and warehouses for combustible materials may be. Fitting operations must strictly

comply with the provisions of current regulations.

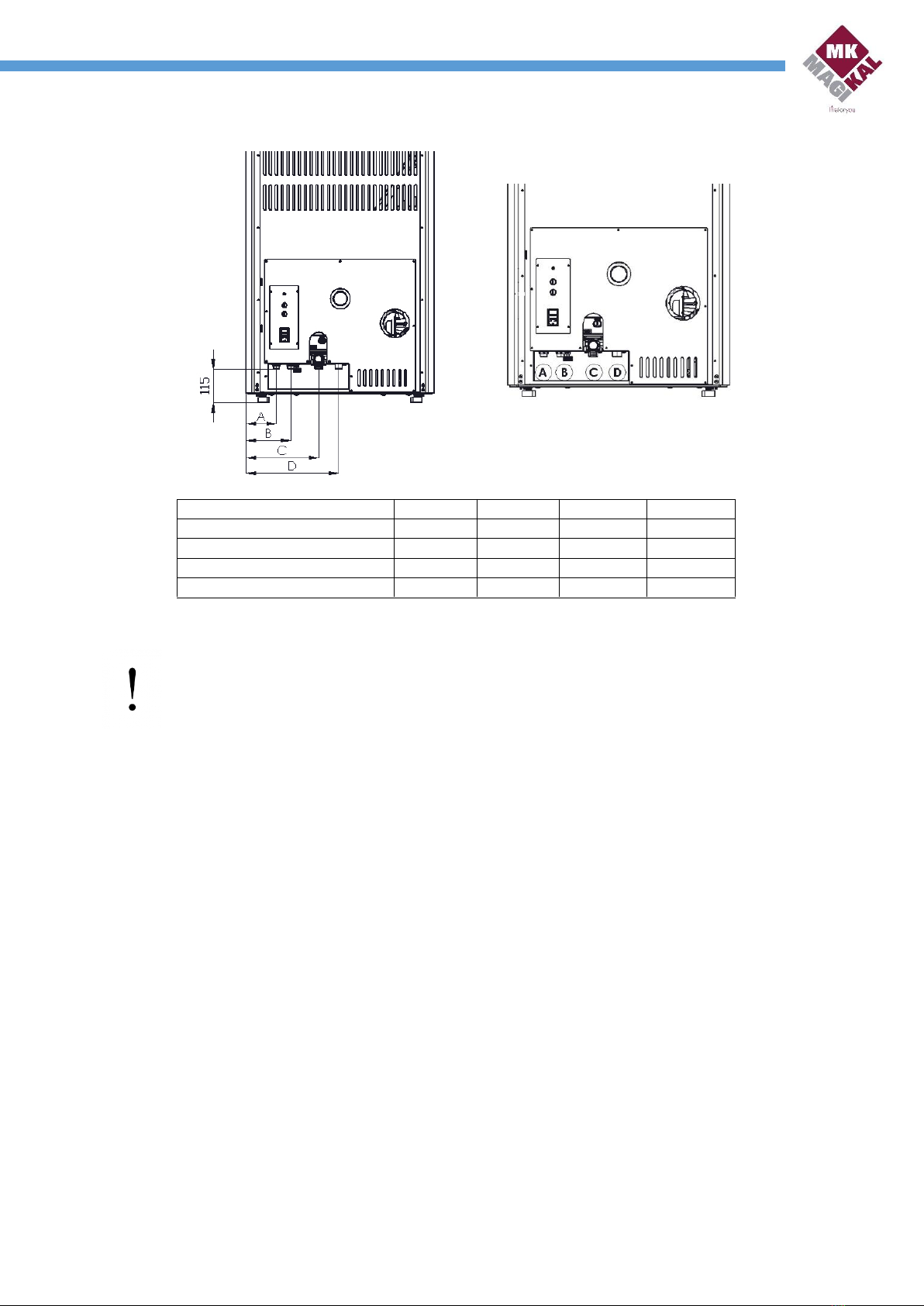

The combustion air inlet of the stove must be made with a Ø50 pipe provided by the customer and fitted in

the rear part.

Installation in bedroom, bathrooms or shower is not permitted, as well as any area in which another

heating appliance without independent inflow (fireplaces, stove, etc.) is already installed

2.2 Flue and smoke pipe

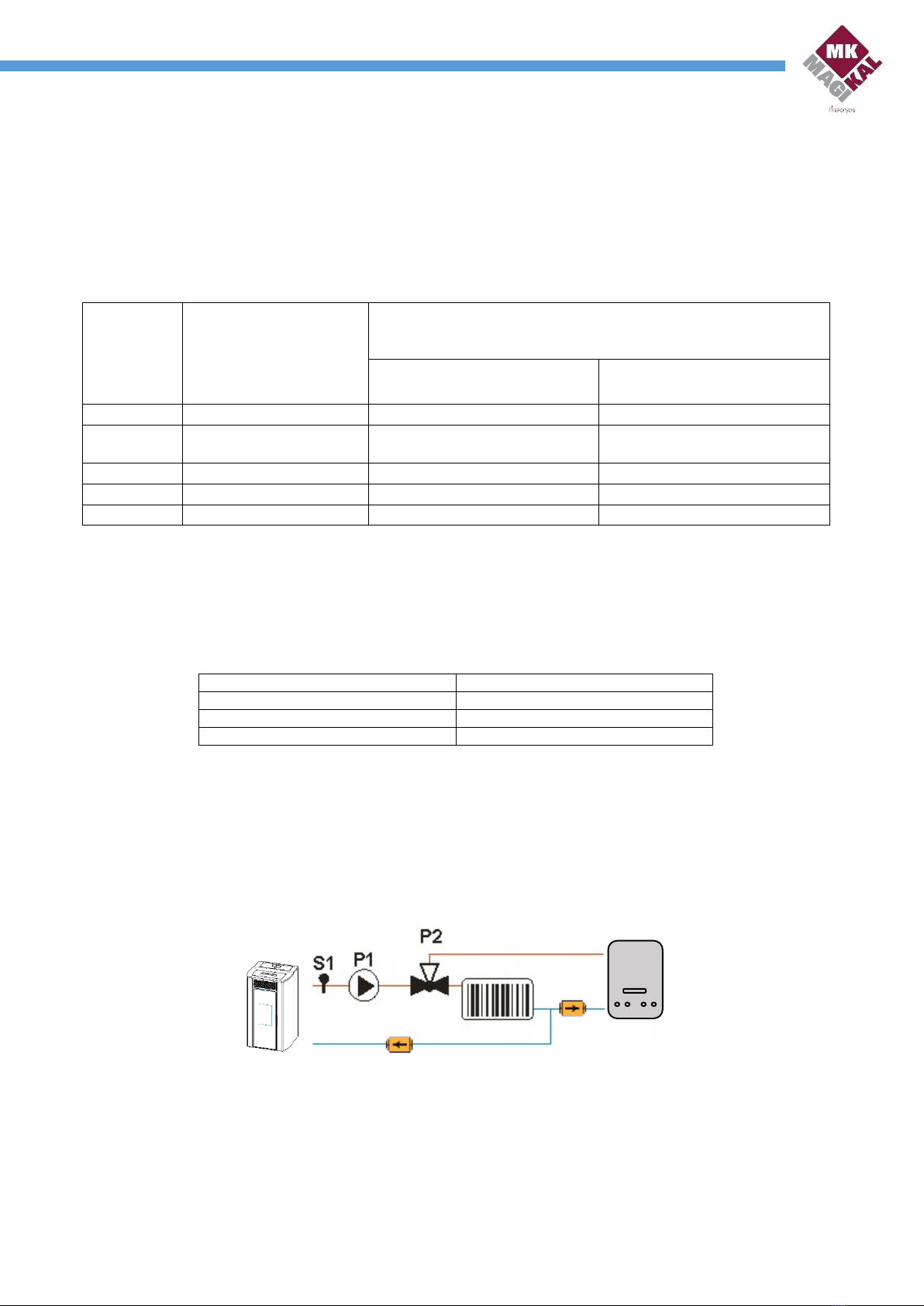

The discharge of combustion by-products must be through the rooftop and take place in 3 different ways:

Using an external flue duct, which must have a minimum internal diameter of 80mm and using

only insulated pipes (double-walled) in stainless steel fixed to the wall (Fig. 8).

By means of a flue, which must have internal dimensions not exceeding 200x200mm; otherwise,

or in case of bad conditions (e.g., cracks, poor insulation, etc), we recommend inserting inside the

barrel a stainless steel pipe of adequate diameter that develops along its entire length up to the

chimney pot (Fig. 9).

By means of a flue or smoke pipe connection which, for proper functioning, immediately

downstream the stove must feature a vertical section of at least 1500mm of height and minimum

horizontal sections having a total width not exceeding 4000mm with an upward slope of no less

than 3% (Fig.10). Moreover, for each 90° bend, we recommend extending the vertical section by 1

m and for each horizontal section, extending the vertical by 2 m. In the case of vertical

developments greater than 7 meters, it is necessary to use pipes with a 100mm internal diameter.

50 Ø.