Magna-Matic Corporation - W4599 County Road IW - Waldo WI 53093 USA - Phone: (920) 564-2366 - FAX: (920) 564-2368 - Toll Free USA & Canada 1-800-328-1110

http://

www.magna-matic.com - email: [email protected] © Copyright 2023 All rights reservedQuick Setup Guide WARNING WHEN USING ELECTRIC TOOLS, BASIC SAFETY

PRECAUTIONS SHOULD ALWAYS BE FOLLOWED

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, AND PERSONAL INJURY.

CAUTION TURN OFF AND UNPLUG

BEFORE SERVICING

Page 3

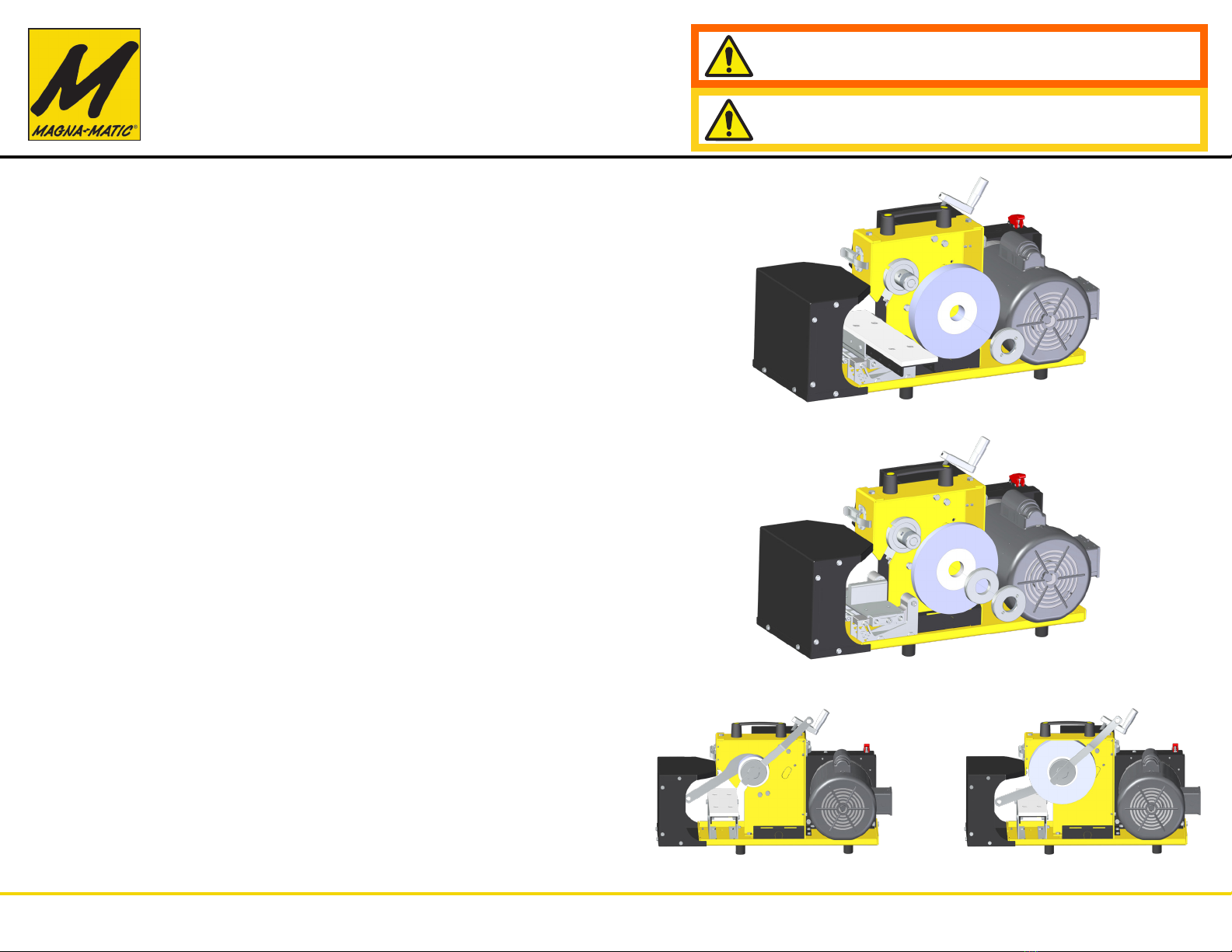

SHARPENING A CONVENTIONAL LAWN MOWER BLADE

Be sure to wear protective clothing while handling and sharpening lawn mower blades. Wear

safety glasses and protective gloves. Always de-burr the underside of the blade, prior to

sharpening the blade.

BLADE & SHARPENER PREPARATION

1. Clean the blade to its base material, using the MAG-12008 blade cleaner, or alternate

cleaning process. Inspect the blade for fractures. (never weld mower blades)

2. Check the straightness with the gauge rod of the MAG-1000 blade balancer

(never straighten bent blades)

3. Obtain a balance reading from the MAG-1000 to indicate the light end of the lawn mower

blade. Once the light end is sharpened, that end is complete. The heavy end is used

to remove material for balance. See MAG-1000 instructions for more details on blade

balancing. (never weld mower blades)

4. Adjust the cutting edge angle to 30 degrees.

CONVENTIONAL BLADE SHARPENING

1. Switch the ON/OFF switch to ON position

2. Place the conventional blade on the worktable, you should push and pull the blade

across the grinding wheel. Notice approach the grinding wheel as shown below. Stay

perpindicular to the

rotation of the wheel.

3. Keep firm downward

pressure on the top

of the blade so that

contact is maintained

with the worktable. This

is important because

the angle is referenced

off the worktable and

underside of the blade.

4. The force into the

grinding wheel should

be substantial resulting

in a continuous stream

of sparks and a deep

smooth grinding sound.

5. The grinding process

should be continuous

without interruption until

finished.

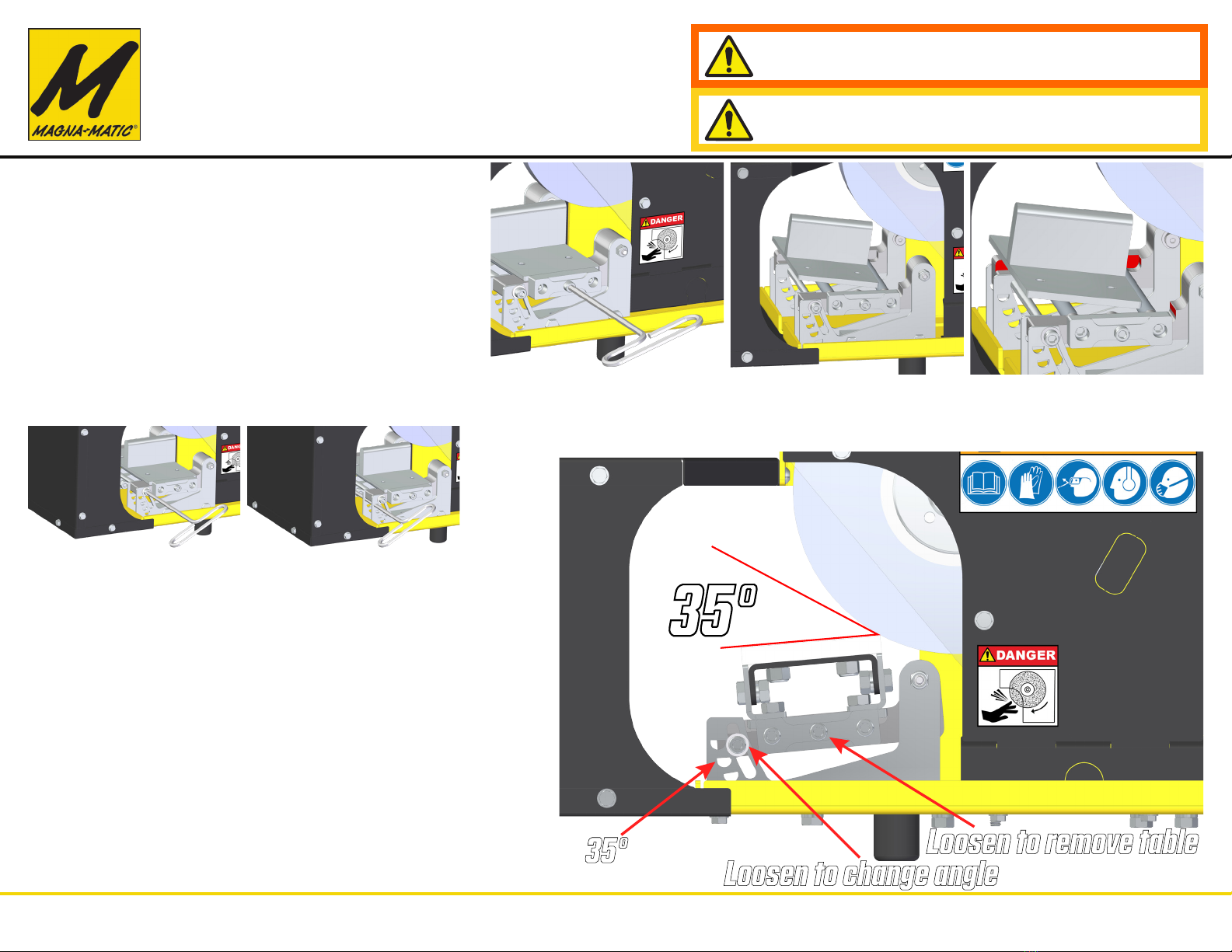

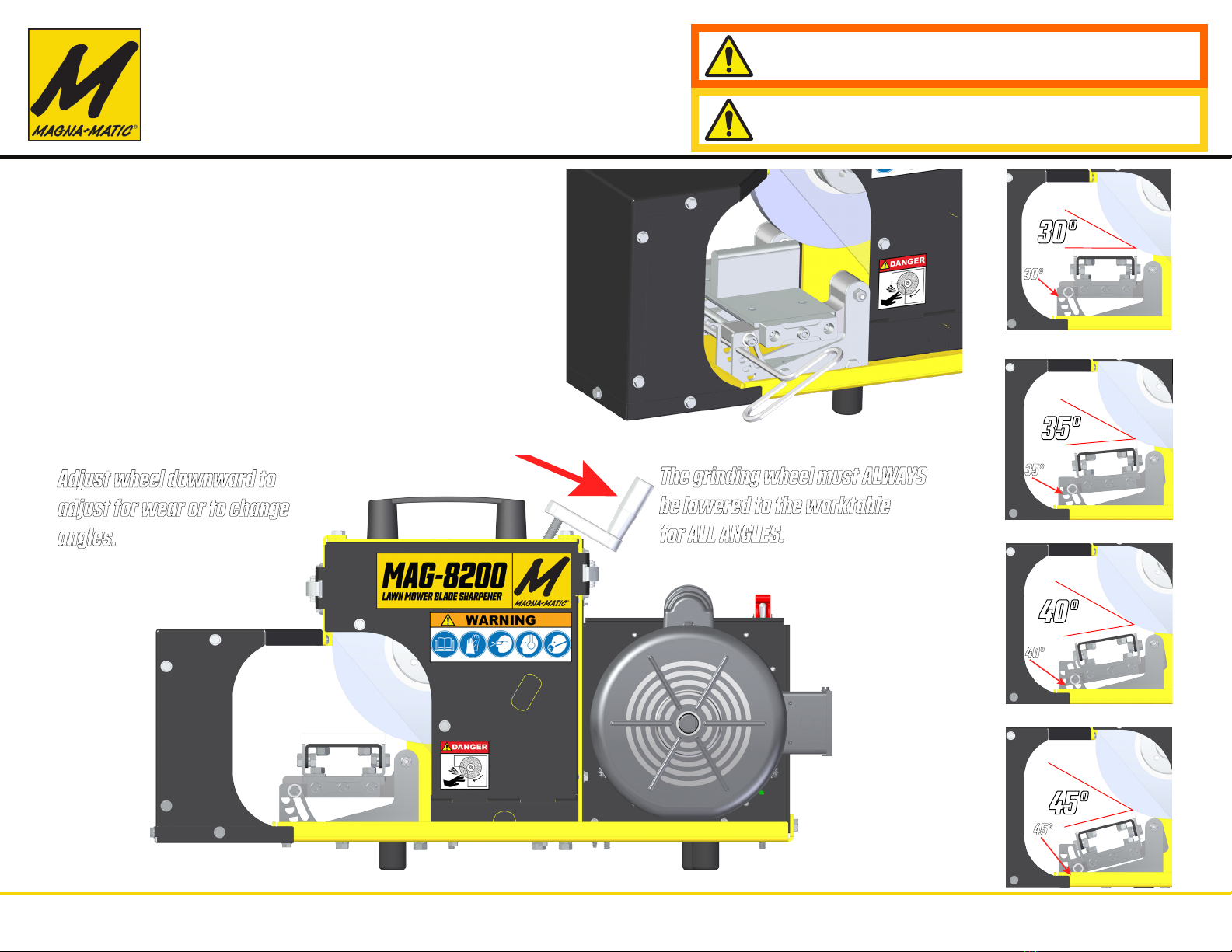

ADJUSTING THE EDGE ANGLE

30 Degree Reference Point - When the grinding wheel is lowered to the worktable (almost cutting

the work table corner) you will produce a 30 degree angle on the lawn mower blade. As the grinding

wheel wears and reduces in diameter, continue to lower the grinding wheel to almost touch the work-

table (1/32” space) to maintain a consistent 30 degree edge angle on a blade. As the wheel wears

into an angled shape it will lower deeper into the worktable. Regardless if the grinding wheel is new

or almost used up - you will always want to be as close as the wheel can get to the plastic worktable

(without grinding the plastic) to maintain 30 degrees. If you grind into the plastic worktable you have

now changed this angle reference point.

If you have worn out - or accidently ground the plastic worktable - please note there are two pieces

to the worktable. There is an onboard replacement under the top surface. Simply take the four bolts

out and swap the two surfaces. Two worktables must always be installed to keep the 30 degree angle

reference point.

The edge angle can be varied plus or minus the 30 degree reference point via the

adjusting crank.

Raising the grinding wheel will result in a lesser than 30 degree angle

(a more shallow angle.)

Lowering the grinding wheel into the work table (grinding into the work table) will result in a greater

than 30 degree angle (a steeper angle.) Note: you will be creating a new angle reference point. To

make this steeper angle reference point you will grind into the plastic worktable.

ANGLE DETERMINATION

(when sharpener is set to 30 degrees)

If the grinding wheel only grinds the TRAILING EDGE the angle is greater than 30 degrees.

If the grinding wheel only grinds the LEADING EDGE the angle is less than 30 degrees.

HINT: The cutting edge-angle is 30

degrees - when the cutting edge face

width is twice the thickness of the blade.

Cutting Diameter

Cutting Edge

Lift

30°

Cutting Edge

Cutting Tip

Cutting Tip

DANGER WARNING

Keep constant pressure downward

maintain flat contact with blade underside and worktable

Slide the blade back

and forth across the grinding wheel

Apply pressure into the

grinding wheel

MAG-8200 Sharpener

Overhead-View

Right-Handed

Blade

Left-Handed

Blade