3

to mind when you start using your machine, you will see for yourself that your new

washer dryer can give a convincing and state of the art reply to all of them.

This machine has been designed to adapt the washing

process to all types of fabric and to treat your washing in the

most delicate way possible. In any case, we would advise

you to take certain basic precaution:

Mend any tears in items before washing them.

Sew back on any buttons that are loose.

Close any zips.

Do not machine wash items without hems.

Empty the pockets of jackets, shirts and trousers and

turn them inside out.

Button up any bag-like items that could hold water

(pillow cases for example).

Large items like sheets and table cloths should be put in

loosely and not folded.

Turn shirts inside out.

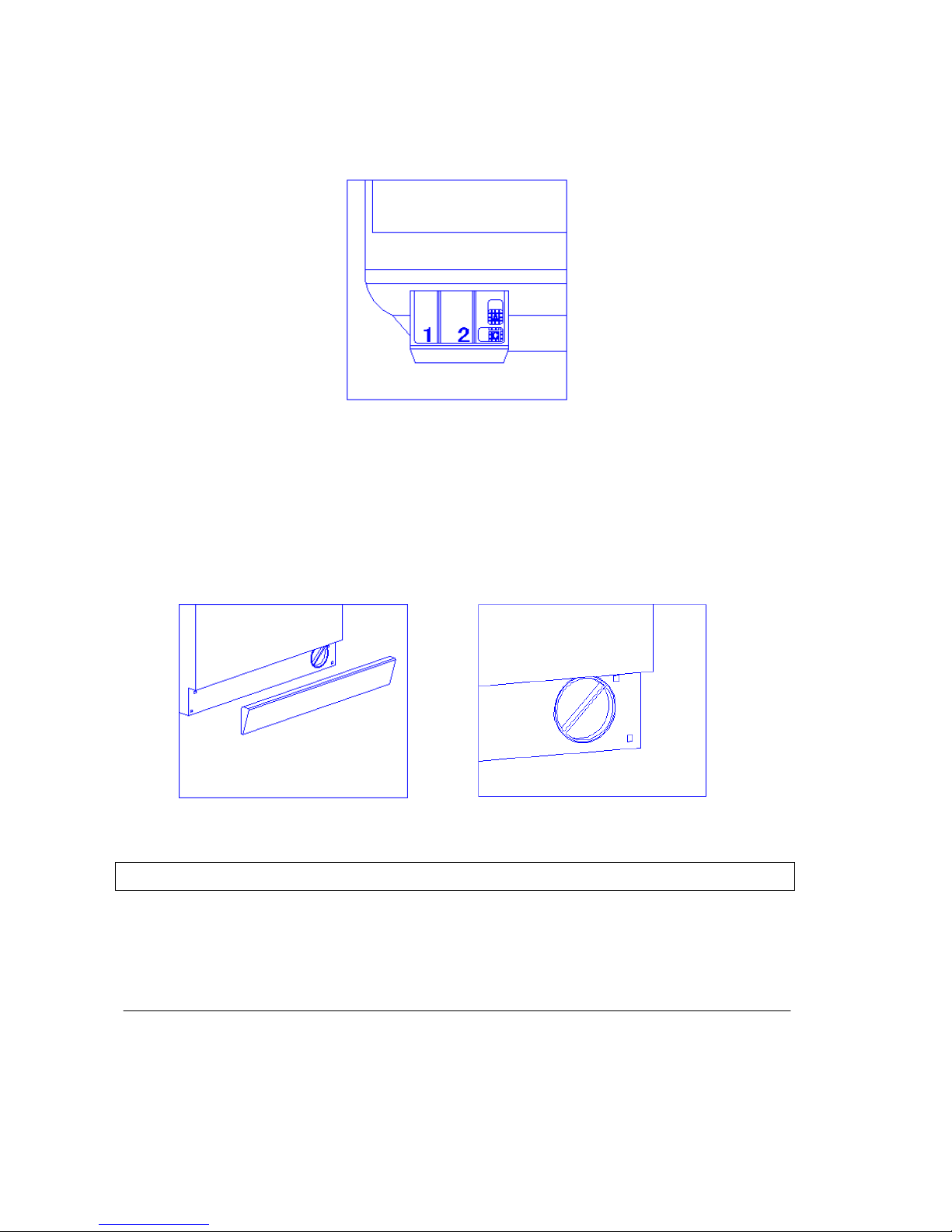

Apart from the performance of

the machine, a successful wash

also depends on the quality of the detergent used.

There are numerous excellent brands on the market.

For your machine to work best, we suggest you use

non-foam detergents that are specifically for

automatic washer dryer. If you are washing synthetics or

woolens, you should use detergents made specially for

them.

Above all, avoid using dry cleaning solvents such as

trichloroethylene or similar products.

It depends, In some areas the water is vary hard and it

leaves calcium deposits on both the heating element of the

washer dryer and on the washing itself. Which over time

damage both. In such case, it is a good idea to mix a water

softener, or decalcifier, in with your detergent to dissolve the

calcium.

Your machine, has a solution to every

problem

Every time you have particularly dirty items to wash, when

you think it would help them to have a longer wash with

more detergent.

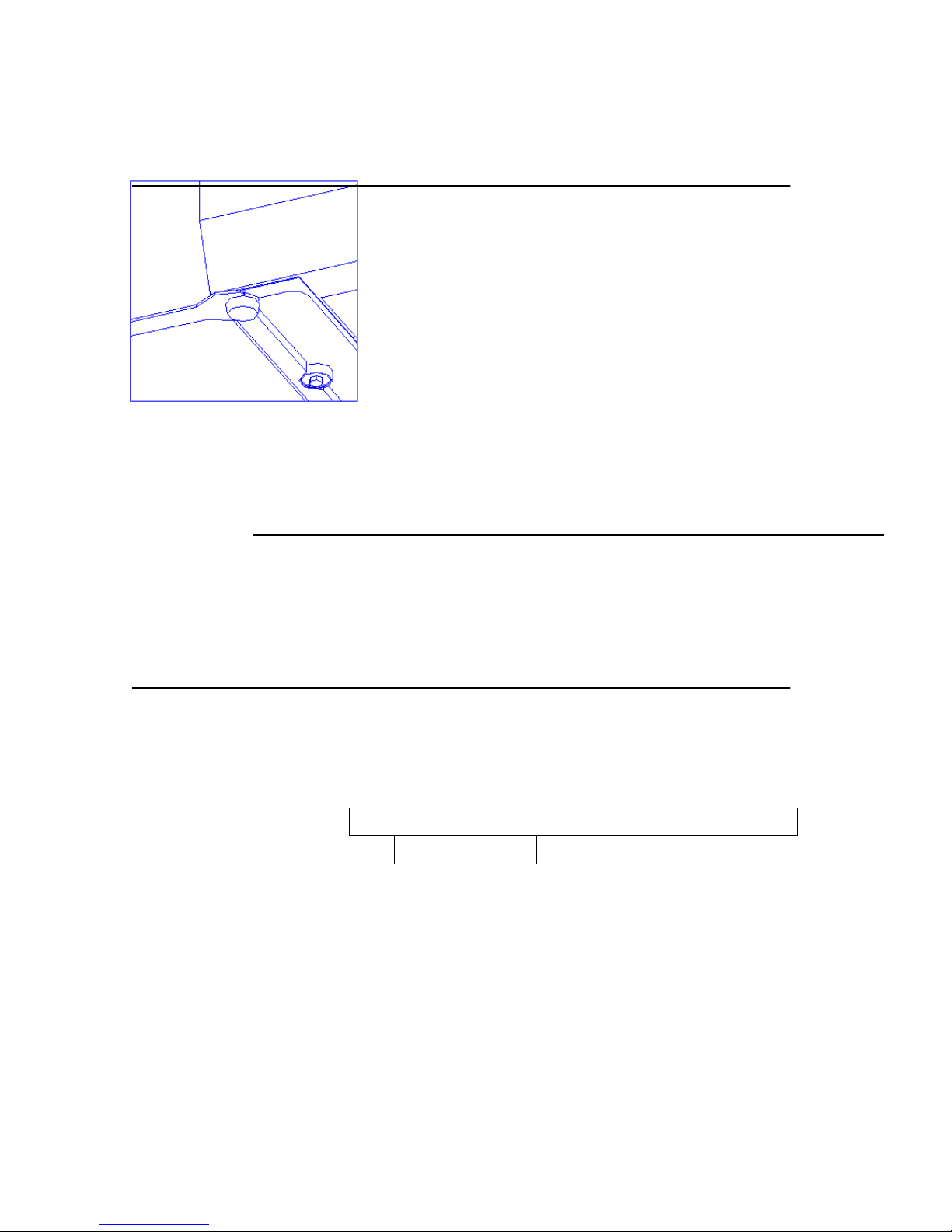

The most important thing is for it to be perfectly level. This

is why it has adjustable feet (fig.1) so as to eliminate any

imperfections in the floor.