Manning AirScan IR-F9 Manual

405BarclayBoulevard

Lincolnshire, Illinois 60069

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

ha_manning@honeywell.com

www.honeywellanalytics.com

www.manningsytems.com

18908 AirScan-iR-comm 05/2016 REVD

MOUN T ENCLOSURE THI S END UP. DO NOT BLOCK PERFORATED VENT HOLES.

AirScan

Contents

Serialnumber:

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

2

Section

Title

Page

1 SensorDescription

System Specifications and Sensor Specifications

4

2

Installation

A

Locating the Sensor

5

Figu

re

1:

Mo

u

n

ting

Dimens

io

ns

fo

r

the

AirScan

TM

iR

5

B

Wiring

6

Fig

u

re

2:

Wiring

Diag

ram

fo

r

AirSc

an

TM

iR

6

3

Operation

A

Start-up Procedure

7

Figure 3: Required LED Status at Start-up

7

B

Pushbutton Operation, LED Indicators, Adjustment Pots and Test Points

8

Figure 4: Board ComponentLayout

8

Figure 5: LED Layout

8

LED Indicators and BlinkSequence

9

Figure 6: LED Blink Sequence

9

Figure 7: LED Indicator Summary

10

Normal RunModes

10

4/20 mA Loop Test Mode

10

Calibration Mode

10

Fault Indicator Error Sequences

11

C

Modes of Operation

12

Normal RunModes

12

4/20 mA Loop Modes

13

Calibration / Programming Modes

14

D

Calibration

15

Figure 8: Board ComponentLayout

15

4/20 mA Output Calibration

17

Zero Calibration

17

Figure 9: Board ComponentLayout

18

Span Calibration

18

E

Diagnostic Procedures

19

Simple Zero Test

19

4/20 mA Output Loop Integrity Check

19

F

Troubleshooting

21

Electrical Interference

21

F

igur

e

10:

T

r

oublesh

ootin

g

th

e

A

i

rS

ca

n

TM

iR

21

Sensor On-Board Diagnostic System

21

Erroron4/20mAOutput

22

Sensor Output at 0 mA

22

Sensor Output at .5 mA

22

Gas Concentration Indicated with No Refrigerant Present

22

IR Source Failure

22

4

Maintenance

23

5

Replacement Parts

23

6

Limited Warranty

24

Introduction

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm.

3

This manual has been prepared to help in the use and installation of the Manning Systems

AirScan

TM

iR

(Infrared Refrigerants) Sensor.

This manual

will

convey

the operating

principles of the sensor, ensure proper installation, and demonstrate start-up and routine

maintenance procedures.

This manual must be carefully followed by all individuals who have or will have the

responsibility

for using or servicing the

AirScan

TM

iR Sensor.

Warranties

made

by

Manning Systems, Inc. with respect to this equipment will be voided if the equipment is

not used and serviced in accordance with the instructions in this manual. If indoubt

about a procedure, please contact Manning Systems, Inc. before proceeding.

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm.

4

1

Sensor Description

Gasdetectionbytheinfraredmethodisbasedonthe

principle that most gases absorb infrared energy at a

characteristic frequency. In this instrument, a broad

band infrared source emits energy which is then band-

pass filtered to produce a narrow range of frequencies

characteristic of the refrigerants’ (CFC/HCFC/HFC)

absorption spectra. Any refrigerant in the gas sample cell

selectively absorbs energy reaching the detector. This

reductioninenergyisdetected,amplified and sent tothe

signal processing portion of the system.

Cable Recommendation:

Three conductor, stranded,

shieldedcablewithdrainwire,allenclosedinavinyl

jacket. For cable runs up to 200 feet use, #18 AWG

(Belden #8770 orequivalent). For cable runs up to 1,000

feet, use #16 AWG (Belden #8618 or equivalent).

Unit Enclosure:

NEMA 4, gasketed, molded fiberglass

reinforced polyester. Non-painted, non-rusting

construction appropriate forfoodareas. UL 508 listed,

CSA certified for use with industrial control equipment.

TM

The

Manning Systems AirScan

TM

iR

Sensor line

is

a

three-

wire,4/20mA sensorfortwo bandsof refrigerants

NOTE:

The standard AirScan

classified areas only.

iR is foruse innon-

available in a range of 0–3,000 ppm, but can be adjusted

for lower ranges, if required. The low-band or R-404a

infrared sensor reacts to R-123, R-134a, R-404a and R-507.

The

high-band

or

R-22

AirScan

TM

iR

sensor reacts

to

R-22.

Itssolid,high-massmetalbenchprovidesstructuraland

thermal stability, greater immunity to vibration, as well as

superior

EMI/RFI

shielding

of

the

detector

and

source.

Internal compensation for environmental changes allows

the sensor to automatically adapt to fluctuating

temperature and humidity conditions. The unit exhibits

extremely high reliability with no moving parts.

Sens

o

r

Spec

ific

ation

s

Type:

CFC/HCFC/HFCselectiveinfraredgassensor/

transmitter AirScan

TM

iR

Method of Detection:

Dual channel infrared energy

absorption (N.D.I.R. Non-dispersive Infrared)

Gases Monitored:

Low-Band (R-404a, R-507, R-134a,

and R-123), High-Band (R-22)

Range Available:

0–3,000 ppm (can berescaled to 0–

1,000ppm,or0–500 ppm ifrequired)

TM

Every

two

s

e

conds

SensorCheck

TM

techno

l

o

gy

mo

nito

rs

SensorCheck

Features:

Dual channel functionality test,

the

AirScan

TM

iR

source

and ensures

that

the

dual

channels are functioning properly. A notification signal

willbetransmittedifanyofseveralperformance

parameters is not met.

Monitoring equipment must be configured to indicate a

fault if the signal is less than 1.5 mA. All signals over

20mAmustbeconsideredahighgasconcentration.

Manning Systems infrared sensors are normally long-

lived (5 years plus), unless physically damaged or wetted

with water or other liquid.

System Specifications

Electrical Power:

24 Volts DC regulated, 1.0 amp.

Output:

Linear 4/20 mA output into a load resistor of

500 ohmsmaximum

Cable Length to Sensor:

1,000 feet maximum

source strength evaluation, incoming voltage monitor,

IR source integrity check, operating temperature monitor,

“zero” down drift monitor, and internal circuitry check.

Accuracy:

± 3% of full scale

Repeatability:

±1%offullscale

Cross Sensitivity:

Not affected by moisture, food odors,

floor cleaners, temperature changes, etc.

Operating Humidity:

0–100% RH (condensing)

Operating Temperatures:

–20° F to +140° F

Storage Temperature:

–20° Fto +140° F

Gas Sampling:

Diffusionmethod with no moving parts

Sampling Frequency:

Real time continuous monitoring

ofallpoints

Response Time:

T

90

in10 seconds with full-scale target

calibrationgas @ .75 liters/min. flow rate

Weight:

4.4lbs.

Dimensions:

9.59" high x 7.71" wide x 4.52" deep

2 Installation

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

5

3.68”

MOUNT ENCLOSURE THIS END U P. DONOT B LOCK PERFORATED VEN T HOLES.

AirScan

A

Locating the Sensor

Because each sensor can only “report” what it is

seeing at the moment,

it is very important that the

sensor be located where leaks are most likely to

occur.

CFC/ HCFC/HFC vapor is heavier than

ambientair, so in a roomwith no airmovement it will

tend to settle. For quickest detection, mount the

sensoraboutonetotwofeetfromthe floor,closeto

the potential leak source.

Ifthe primaryapplicationis thefastestpossible leak

detection, mount the sensor near the potential leak

sources. In doing this, be aware that the indicated

concentration may not be representative of personnel

exposureand easyaccessforthe required calibration

and maintenance could be compromised.

General Mounting Considerations:

•

Must be easily accessible for calibration and

maintenance.

•

Always

mount the sensor vertically.

•

Mountthesensorclosetothepotentialleak

source for fastest possible leak detection.

•

If personnel protection is the primary

application, mount in the “breathing zone.”

•

Protect sensor from water, excessive humidity,

and wash-down.

•

To prevent electrical interference, keep sensor

and wire runs away from mercury vapor lights,

variable speed drives, and radio repeaters.

•

Protect sensor from physical damage (fork lifts,

etc.).

•

Do not mount the sensor overa door in a

refrigerated area.

•

Forhighlycriticallocationsmorethanone

sensorshouldbeinstalledineachroom.

Very Important:

•

Sensor

must

be mounted vertically

•

Never

mount sensorflat on a ceiling

•

Enter enclosure

only

through existing hole in

bottom of enclosure

•

Always

make a drip loop in the conduit

•

Never

mountsensoronavibratingsurface.

Mount sensor enclosures through the flange holes as

shown in Figure 1, and

always

mount vertically.

Penthouses:

Multi-Coil(defrostonecoilatatime)–

Inthis case the best location is usually in the center of

thepenthousefourorfivefeetabovethegrate.

Single Coil (or when all coils defrost at the same time) –

In this case high moisture conditions can occur and the

sensorshouldbemountedonefootabovethe grate.

TM

•

Take air movement and ventilation patterns into

Engine Rooms:

TheAirScan

iRsensorshouldbe

account.

Figure1: Mounting Dimensionsforthe AirScan

TM

iRSensor

mounted in a cool part of the room, if possible. Keep

thesensorawayfromhotairexhaustingfromelectric

motors or other machinery.

7.71”

1”

9.59”

9.19”

4.52”

5.01”

FRONT VIEW

SIDE VIEW

TOP VIEW

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

6

2

Installation

continued

Output (white)

+24 VDC(red)

SIG

+24

GND

SHLD

JP1

DC ground (black)

Shield (bare)

TEST +

TEST -

Ceiling

Hung Evaporators:

When

mounting AirScan

TM

iR

sensorsnear evaporators,mount the sensornohigher

than two feet below the top of the evaporator coil.

Do not

mount in high air flow (1,200 feet/minute

maximum).

Never

mount the sensor on evaporators as

vibration can damage the sensor.

Other Locations:

When

mounting AirScan

TM

iR

sensors

inlocationssuchasrooftopairunits,ductwork,attic

spaces, makeup air intakes, etc., contact Manning Systems

for application assistance and recommendations.

B

Wiring

Electrical wiring must comply with all applicable codes.

Plantequipmentthatmaybeinvolvedandoperatingcon-

ditions should be discussed with local operating personnel

todetermine ifanyspecialneedsshouldbeconsidered.

Groundtheshieldatthemaincontrolpanel.Connect

the shield wire in the sensor terminal block labeled

shield

. Tape all exposed shield wire at the sensor to

insulate it from the enclosure.

All penetrations into a refrigerated room should be

sealed to prevent condensate from forming in the

conduit and dripping into the sensor enclosure.

Make drip loops for cables going into sensor housings

(see Figure 1). Follow the special mounting instructions

ontheenclosure(…

This EndUp).

Electrical Power:

24 VDC regulated, 1.0 amp.

Output:

Circuitboardmounted sensorprovidesalinear

4/20 mA output. Monitoring equipment may have a

maximum input impedance of 500 ohms.

Contact Manning Systems for specific wiring

TM

Nearly all start-up problems are due to improper wiring

instructions when usingAirScan

TM

iR sensors withan

or monitor configuration. Please follow these guidelines

AirAlert

96d readout unit.

carefully.

Always use three conductor, insulated, stranded,

shielded coppercable. Use

only

three conductor cable,

not

two cables of two conductor wire (see Figure 2).

CableRecommendation:

Use#18/3(Belden#8770)

for cable runs up to 200 feet. Use #16/3 (Belden

#8618)forcablerunsupto1,000feet.Useonlythe

existing punchedholesforconnectionsto the sensor.

TM

If

th

e

Ai

rS

c

a

n

TM

iR

is

to

be

us

ed

with

the

AirAlert

TM

96d,

Monitoring:

The AirScan

iR Refrigerant Sensor may be

please call Manning Systems for specific wiring instructions.

Donotpullsensorwiringwith ACpower cables.

Thiswill

cause electricalinterference.Be sure there are no breaks

or splices in sensor wiring runs. If cable runs cannot be

made without a splice,all connections must be soldered.

Solderingshouldbedoneusingarosinfluxtotiethe

connecting ends of sensor wires to ensure a positive and

long-lastingcontact.

monitored by any Manning Systems Readout/Alarmunit

or other appropriately configured system. Monitoring

equipmentmust be configuredto indicate a fault if the

signal isbelow1.5mA. Allsignalsabove 20mA mustbe

consideredahighgasconcentration.Afailedsensorwill

output a 0.5 mA signal.

Figure 2: Wiring Diagram for the AirScan

TM

iR Sensor

White

connectsto signalinputof

monitoring equipment

Red

connects to 24 VDC power supply

positive side

Black

connects to 24 VDC ground side

Bare wire wrap

connects to case ground

at monitoring equipment (earth ground)

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

7

3

Operation

The AirScanTMiR has several modes of operation,

including two normal run modes, two 4/20 mA loop

check modes and five calibration modes. These will be

explained inOperation, Section C, Modes of Operation.

Modes are entered by properly activating pushbuttons

located on the circuit board, shown in Figure 4.

Sensor operation status is indicated by the blink

pattern of seven LEDs located in a vertical row on the

right side of the sensor circuit board (see Figure 4).

LED status is differentiated by color and duration/

pattern of blink(s). LED Indicators and Blink

Sequences are shown in Figure 6, followed by an

explanation of blink patterns.

A

Start-Up Procedure

Before applying power, make a final check of all wiring

for continuity, shorts, grounds, etc. It is usually best to

disconnect external alarms and other equipment from the

sensor until the initial start-up procedures are completed.

Check the power supply voltage to the sensor with a

digital volt meter set to VDC. Place the black lead on

sensor terminal GND and the red lead on +24 (see

Figure 4, Note 1). Voltage should be between 21 and 28

IMPORTANT:

The AirScanTMiR sensor is factory

calibrated and should require minimal adjustments after

installation.

CARB Compliance: To ensure continued compliance

with CARB performance guidelines, calibrate the unit

in the environment in which it will be used. Frequency

of calibration can improve accuracy; Honeywell

Analytics recommends calibration every 6 months.

Environmental factors such as temperature, humidity,

and pressure can affect accuracy. Consider these factors

when establishing a maintenance program .

Allow the sensor to operate for 12 hours with the

enclosure sealed prior to testing the sensors. This will

give the sensor time to reach thermal equilibrium to the

external and internal temperatures while in operation.

Because sensors are normally located at a distance from

the main unit, the test time required and accuracy of the

response checks will be improved if two people perform

the start-up procedures and use radio contact.

Start-Up Test:

1)

One person exposes each sensor to a small amount

of the gas that is being monitored.

VDC. If voltage is outside this range, check power supply 2) The second person stays at the control unit to

and wiring.

After power-up, ensure the LEDs below are operational

as follows (see Figure3):

•Green “Power” LED continuous ON

•Both Fault LED’s areOFF

•Green “source” LED is blinking once every

2 seconds

NOTE: Forcold/humidadverseenvironmentalconditions

the “ATMOS” LED may be turning on and off periodic-

ally. In addition, the “system” LED may be blinking or

continuous ON, also described in later sections.

determine that each sensor, when exposed to the

gas fumes, is connected to the proper input and

responds, causing appropriate alarm functions.

Figure3: Required LED Status at Start-up

LED

WITH OUTPUT

FILTERING

WITHOUT OUTPUT

FILTERING

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

OFF

FAULT

R

OFF

OFF

mA FAULT

R

OFF

OFF

SOURCE

G

ATMOS

G

ON PERIODICALLY

ON PERIODICALLY

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

8

3

Operation

continued

B

Pushbutton Operation,

LED Indicators,

Adjustment Pots and

Test Points

The

AirScan

TM

iR has

two

internal

pushbuttons, and

two

adjustment pots that are utilized for navigation of test

functions, calibrations, and operating modes. In addition,

apairoftestpointsisalsoprovidedthatassistinthe

connection to standard meter leads for use in the

upcoming calibration and diagnostic procedures (see

Figure 4).

Figure 4: Board Component Layout

•

“Zero” adjustment pot – adjusts output calibration

ofthe4mA nominalrestingpoint

•

“Span”adjustmentpot–adjuststhe20mA

concentration level or unit span/sensitivity.

•

PushbuttonS1– used to initiate the auto-zero

function, program the 4 mA output calibration,

and initiate the 4/20 mA loop test.

•

Pushbutton S2 – used to program the span setting.

•

Test(+) and Test(–) for connection to a DC Volt

meter(see Figure 4, Note 2).

IMPORTANT:

The pushbutton(s) must be pressed the

correct numberof times and at thecorrect rate.

•

When a multi-press sequence must be performed,

ICSP Programming Port

Serial Port

the button must be pressed rapidly and evenly,

Zero Adjust

Span Adjust

Note 1:

Checking

voltage to sensor

at +24 and GND

24

VDC

ZERO

SPAN

JP3

S1

S2

Pushbutton S1

Pushbutton S2

Draw

Chamber

Rx LED

Tx LED

JP2

lifting one’s finger completely from the actuator

foreach consecutivepress.

•

Forpressandholdactivations,one’sfingermust

always be applying a down pressure without

disruption for the specified time in order to

activate the desired mode.

•

See complete details of each operation in other

parts of the manual.

The

AirScan

TM

iR

also

has

a

group

of

LED’s

(see

Figure

5)

thatblink in specificsequences(seeFigure 6on next

Black

-Red

+

JP1

SIG

+24

GND

SHLD

POWER

SYSTEM

CALIBRATE

FAULT

mA FAULT

IR SOURCE

ATMOS

ACTIVE

page) to indicate sensor operation and programming

modes. A summary of sensor operation and

programming modes with corresponding LED blink

sequencesis shownin Figure7 onpage 10.

Note 2:

Reading

signalatTEST+

and TEST-

TEST +

TEST -

Figure 5: LED Layout

40-200

mVDC

POWER

Black

-

Red

+

Tubing to

calibration point

SYSTEM

CALIBRATE

FAULT

mA FAULT

IRSOURCE

ATMOS

ACTIVE

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

9

3

Operation

continued

LED Indicators and Blink Sequence

Figure6: LED BlinkSequence

SEQUENCE

1 sec. 2 sec. 3 sec.

SOURCE BLINK

SLOW BLINK

MEDIUM DOUBLE BLINK

FAST BLINK

CONTINUOUS ON

Green Power LED

•

Continuous ON when power is applied

Yellow System LED

•

Continuous ON during normal filtered output run

mode – “dead band” from 4 to 4.6 mA

•

Slow blink during normal non-filtered output run

mode

•

Fast blink indicating unit lost calibration data

•

OFF during 4/20 mA loop check

Yellow Calibrate LED

•

Continuous momentary ON for auto-zero mode

activation

•

Slow blink for 4 mA output calibration mode

•

Mediumdoubleblinkindicates4/20mAloop

check .5 mA (low)

•

Fast blink for “span” calibration mode and

4/20 mA loop check 22 mA (high)

Red Fault LED (all scenarios produce a .5 mA output)

•

Continuous ON indicates a failed source, low

signal, or circuit failure

•

Slow blink indicates the power supply DC 24V

inputvoltageistoolow.

•

Medium double blink indicates sensor is outside

the operating temperature range.

•

Fastblinkindicatesthesignal drifted below4mA

and needsto be re-calibrated, onlyinnon-filtered

output run mode (no dead-band).

Red mA Fault LED attempts to output .5 mA fault signal

•

Fast blink indicates4/20mAloopfailure or load

resistance too high

Green Source LED

•

Oneblinkevery2secondsindicateswhensource

is energized and also that the source is not short

circuited.

Green ATMOS LED

•

Continuous ON indicates ATMOS circuitry is active

or adjusting the enclosure’s internal environmental

conditionsforthesensortofunctionreliably.

NOTES:

•

Ifthe SourceLEDisn’t blinking,

do not

proceed

untiltheconditioniscorrected.

•

If a Fault LED is lighted, immediately refer to

Fault IndicatorError Sequences (page 11) to

determine potential problem. Do not attempt

calibration if a Fault is indicated.

•

All status LED’s are subordinate to Fault

indicators.

•

If an LED is indicated as OFF, it must actually be

OFF for proper sensor operation.

•

IfanLEDstatusisN/A(notapplicable),thatLED

indication may vary depending on other

operational factors.

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

10

3

Operation

continued

G

Y

R

Figure 7: LED Indicator Summary

See LED indicators and blink sequence descriptions on page 9.

= Initiated by button press

= GreenLED

= YellowLED

= RedLED

Normal RunMode 4/20 mA Loop Test Mode

NOTE1:

Dead-bandfrom 4mAto4.6mA

NOTE2:

Nodead-bandfrom 0to26mA

NOTE 3:

Environmental compensation energized for cold temperatures

NOTE1:

Erroronoutput willresult infast blink on redmAFAULTLED.

Calibration Mode

LED

ZERO FUNCTION

INITIATED

1

DURING SPAN

CALIBRATION

DURING 4 mA

OUTPUT CALIBRATION

FACTORY CALIBRATION

LOST

2

POWER

G

SYSTEM

Y

N/A

CALIBRATE

Y

N/A

FAULT

R

OFF

OFF

N/A

N/A

mA FAULT

R

OFF

OFF

OFF

N/A

SOURCE

G

N/A

N/A

N/A

N/A

ATMOS

G

N/A

N/A

N/A

N/A

NOTE 1:

Indicates that “Zero” function is initiated and pushbutton S1 can be released. Yellow Calibrate LED will be off after pushbutton is released.

NOTE 2:

Indicates unit lost the factory calibration data. Contact Manning Systems.

LED

4/20 mA LOOP TEST

(22 mA HIGH)

1

4/20mA LOOPTEST

(.5 mA LOW)

1

POWER

G

SYSTEM

Y

OFF

OFF

CALIBRATE

Y

FAULT

R

N/A

N/A

mA FAULT

R

N/A

N/A

SOURCE

G

N/A

N/A

ATMOS

G

N/A

N/A

LED

WITH OUTPUT

FILTERING

1

WITHOUT OUTPUT

FILTERING

2

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

OFF

FAULT

R

OFF

OFF

mA FAULT

R

OFF

OFF

SOURCE

G

ATMOS

G

ON PERIODICALLY

3

ON PERIODICALLY

3

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

11

3

Operation

continued

G

Y

R

Figure7:LEDIndicatorSummary,continued

See LED indicators and blink sequence descriptions on page 9.

Fault Indicator Error Sequences

= Initiated by button press

= GreenLED

= YellowLED

= RedLED

LED

LOST FACTORY

CALIBRATION

1

FAILED 4/20 mA

OUTPUT

2

LOW SIGNAL OR

FAILED SOURCEORCIRCUIT

POWER SUPPLY

VOLTAGE TOO LOW

OPERATING TEMPERATURE

RANGE EXCEEDED

POWER

G

SYSTEM

Y

N/A

N/A

N/A

N/A

CALIBRATE

Y

N/A

N/A

N/A

N/A

N/A

FAULT

R

N/A

N/A

mA FAULT

R

N/A

N/A

N/A

N/A

SOURCE

G

N/A

N/A

N/A

N/A

N/A

ATMOS

G

N/A

N/A

N/A

N/A

N/A

NOTE 1:

Indicates Normal Run Mode wthout output filtering where unit lost factory calibration data. Contact Manning Systems for technical support.

NOTE 2:

Indicates failed 4/20 mA output signal. Load resistance is too high.

LED

READING DRIFTED

BELOW 4mA

1

SHORTED

SOURCE

POWER

G

SYSTEM

Y

N/A

N/A

CALIBRATE

Y

N/A

N/A

FAULT

R

mA FAULT

R

N/A

N/A

SOURCE

G

N/A

OFF

ATMOS

G

N/A

N/A

NOTE 1:

Indicates the gas reading drifted below 4 mA and needs to be

re-calibrated only in non-filtered output run mode (nodead-band).

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

12

3

Operation

continued

C

Modes of Operation

The

AirScan

TM

iR has various

modes

of

operation and

calibration:

•

Normal run mode with output filtering

•

Normal run mode without output filtering

•

4/20 mA loopcheck

•

4/20mAcalibrationtoanexternalPLCor

read-out panel

•

Neutral gas resting point or “zero” calibration

mode

•

Span calibration modes

NormalRunModes

Normal runmodewith outputfiltering

Thismode outputs asignalfrom4to 27mAwitha

“dead band” from 4 to 4.6 mA. This “dead band” masks

small environmental anomalies that could facilitate

output signal fluctuations or transients around the 4 mA

resting point when the unit is not sensing target gas.

Start:

If the “system” LED is blinking slowly, press and

holdbothS1andS2simultaneouslyfor1secondor

more until the “system” LED is continuous ON, then

release both buttons. If the “system” LED is blinking

fast, thismodecannotbe engagedand the factoryneeds

to be contacted. See the followingexample.

Normal runmodewithoutoutput filtering

This mode outputs a signal that nominally rests at 4 mA

andcanrange continuouslyfrom0to 27mA.Anysubtle

changes in sensor response will be sent to the mA loop

output. This mode is entered automatically when the

calibrationmodes are activated. Some users may wish

to see the subtle anomalies in the signal near the

nominal 4 mA restarea.

Start:

Ifthe “system” LEDis continuous ON, press and

hold both S1 and S2 simultaneously for 1 second or

more until the “system” LED is blinking slowly then

releasebothbuttons to enterthis mode. Ifthe “system”

LEDis blinkingfastthis modeis always engagedand

canonly be exited by fully calibratingthe unit.See the

following example.

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

ATMOS

G

N/A

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

13

3

Operation

continued

4/20mA LoopTest

{22 mA full-scale and .5 mA fault check}

Start:

Press S1 5 times within a two to three second

period of time. The yellow “system” LED will turn off

andthe yellow“calibrate”LEDwillblinkfast.Seethe

following example. Output should be 21 to 22.5mA.

22 mA Full Scale Output Test

ToproceedtothenextstepinthemAtest,pressand

hold S1 for 1 secondor more until the yellow “calibrate”

LED is a medium double blink. See the following

example.Theoutputshouldbe between.4and.6mA.

.5mA Fault OutputTest

LED

SEQUENCE

POWER

G

SYSTEM

Y

OFF

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

N/A

SOURCE

G

N/A

ATMOS

G

N/A

Exit:

Press and hold S1 for 1 second or more until the

yellow “system” LED resumes the state beforethe mA

test was initiated and theyellow “calibrate” LED turns

off.

LED

SEQUENCE

POWER

G

SYSTEM

Y

OFF

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

N/A

SOURCE

G

N/A

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

14

3

Operation

continued

Calibration/Programming Modes:

Refer to

Calibration, Section D

before proceeding.

Auto “ZERO” Program Function

Start:

PressandholdS1for1secondoruntiltheyellow

“calibrate”LEDturnscontinuousON.ReleaseS1andthe

yellow “calibrate” LED will turn off. This indicates the unit

“zero” is now programmed to a neutral or 4 mA resting

state for

0 ppm of target gas.

LED

SEQUENCE

POWER

G

SYSTEM

Y

N/A

CALIBRATE

Y

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

N/A

ATMOS

G

N/A

“Span” Calibration/Programming Mode

Start:

Press and hold S2 for 1 second or until the yellow

“system” LED blinks slowly and the yellow “calibrate”

LED blinks fast. Once in this mode the “span” pot can be

adjusted to determine the 20 mA full-scale concentration.

Exit:

To program the “span” setting and exit this mode,

press and hold S2 for 1 second or until the yellow

“system” LEDresumesthe state beforethe calibration

mode was initiated and the yellow “calibrate” LED turns

off.

4 mA Output Calibration/Programming Mode

Start:

Press and hold S1 for 7 seconds or until the yellow

“system” LED turns continuous ON and the yellow

“calibrate LED blinks slowly. See the following example.

Once in this mode the “zero” pot can be adjusted to

calibrate the 4 mA output to a PLC, SCADA system,

panel, etc.

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

OFF

SOURCE

G

N/A

ATMOS

G

N/A

Exit:

Toprogramthe4mAcalibrationpointandexit

thismode,pressandholdS1for1secondoruntilthe

yellow “system” LED resumes the state before the

calibration mode was initiated and the yellow “calibrate”

LED turnsoff.

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

N/A

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

15

3

Operation

continued

JP3

S1

ZERO

D

Calibration

Before calibrating the unit, ensure the startup procedure

was followed and unit was powered on for a minimum

of 12 hours (with the enclosure door closed) in the

operating environment.

IMPORTANT NOTE:

For environments where the ambient

temperature is less than 10° F, during the calibration

procedure, the door must be closed as far as possible.

This will ensure the sensor temperature will not drop

belowtheminimumoperatingtemperaturewhichcould

adversely affect the programmed calibration parameters.

There are only two adjustment pots and two pushbuttons

on the main board that are used for programming the

calibration parameters. See

Section B, Pushbutton

Operation, LED Indicators, Adjustment Pots and Test

Points.

UseSectionBtofamiliarizeyourselfwiththe

pushbuttonsS1,S2,adjustmentpots“zero”,“span”,

Test(+), Test(–) and their locations on the main board

(see Figure8).

Figure 8: Board Component Layout

In addition, the LED indicators and blink pattern

meaningsarealsosummarizedinthissection.The

calibration procedure will require use and knowledge of

the following tools within the sensor:

•

“Zero” adjustment pot – adjusts output calibration

ofthe4mAnominalrestingpoint

•

“Span” adjustment pot – adjusts the 20mA

concentration level or unit span/sensitivity

•

Pushbutton S1 – used to initiate the auto-zero

function and program the 4 mA outputcalibration

•

Pushbutton S2 – used to program the spansetting

Inaddition,thereare fourLED’susedinthecalibration

procedure. Yellow “system” and “calibrate”, and red

“fault” and “mAfault”LED’s locatedonthemainboard

areutilizedasstatusindicatorsduring thecalibration

procedure and as diagnostic and trouble indicators.

Non-calibrated Sensor or Loss of Factory Calibration

IMPORTANT:

Uponpowerup,iftheyellow“system”

LEDisshowingafastblinkpattern,theunithasn’tbeen

calibrated yet or has lost the factory calibration and

ICSP ProgrammingPort

Serial Port

requires a

full

calibrationbeforeit can reliably read the

Zero Adjust

Span Adjust

Pushbutton S1

Pushbutton S2

Rx LED

Tx LED

target gas. See the following example. Should thisoccur,

please contact Manning Systems for assistance!

JP2

SPAN S2

Draw

Chamber

POWER

SYSTEM

CALIBRATE

JP1

TEST +

TEST -

SIG

+24

GND

SHLD

FAULT

mA FAULT

IR SOURCE

ATMOS

ACTIVE

Tubing to

calibration point

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

N/A

FAULT

R

N/A

mA FAULT

R

N/A

SOURCE

G

N/A

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

16

3

Operation

continued

Before continuing with the calibration procedure,

determine which of the two Normal output modes is

best for the control scheme. Filtered output holds a

stable4mAsignal withinadead-bandrange whilethe

non-filtered output allows the signal to be seen without

any output limitations.

After this output mode choice is made, continue

through Steps 1–3of the Calibration Procedure. As a

firststep,the4mAoutputismatchedtothesignal

input device being used as a controlpanel. Afterthis is

accomplished, Step 2 (Zero Calibration) and Step 3

(SpanCalibration)canbecompletedinthatorder.

Filtered Output Mode

Each unit is equipped with a filtered output or “dead

band” output mode which locks the output at 4 mA for

signal readings of 4 to 4.6 mA. This masks surrounding

abruptadverseenvironmentaltransients thatwould

cause asmallshort-termanomalyonthe 4mA resting

point fora near0 ppm reading ofthe target gas. Inthis

mode,theyellow“system”LEDwillbeON.Seethe

following example.

Non-Filtered Output Mode (no signal deadband)

Start:

Press and hold both the “zero” (S1) and “span”

(S2)buttonssimultaneouslyforonesecondoruntil the

“system” LED begins to blink slowly. See example

below.

Thismodewillallowanyanomaliestobetransmitted

from 0 to 27 mA on the output. This mode is also used

in the upcoming Simple Zero Test procedure.

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

ATMOS

G

N/A

Exit:

To revert back to “dead band” mode, repeat the

same button press procedure above. This button press

sequence will toggle between modes (filtered to non-

filtered).

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

17

3

Operation

continued

STEP 1

4-20 mA Output Calibration

This procedure calibratesthe 4/20mAoutput to matcha

PLCinputconverterorvariousdevicesthatinterpretthe

4/20 mA signal output to ensure the 4mAoutput rests at

a true 4 mA even with minor mismatches in load

resistance, long feed wiring, or adverse environmental

conditions.

Start:

Set meter to mV DC and place meter leads on

Test(+) and Test(–) respectively (see Figure 9).

•

Press and hold the “zero” button (S1) for 5 seconds

oruntilthe “calibrate”LEDis blinkingslowly and

the“system”LEDiscontinuousON.Makesurethe

“mA Fault” LED is OFF.

•

Adjustthezeropotentiometeruntiltheoutput

reads 3.99 to 4.01 mA (39.9 to 40.1 mV). This sets

the 4 mA resting point. Make small adjustments and

wait for the output to change because adjustment

response is delayed between source pulses.

4mAoutputprogrammingcalibrationmode

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

OFF

SOURCE

G

N/A

ATMOS

G

N/A

Exit:

Press and hold the “zero” button (S1) for one

secondormoreuntilthe“calibrate”LEDturnsoff.

The“system”LEDwillresumethepreviousstate,either

“filtered” or “non-filtered” output mode. This indicates the

parameters are now programmed into memory.

STEP 2

Zero Calibration

This procedure sets the internal reference that is

indicativeof0ppmoftargetgas.

ItMUSTbeperformed

before proceeding or every other setting will be offset

and inaccurate.

The “zero” can be initiated at any time as

long as a neutral gas is flowing through the calibration

port or the surrounding air is known to be FREE of any

target gasdownto1ppm.

Start:

Apply

pure nitrogen

(N

2

) into the calibration port at

a rate of .6 liter/min. for at least 3 minutes (OR until out-

putsignaliswithin±.02mAofsignaldeviation/change).

•

Press and hold the “zero” button (S1) for approxi-

mately1secondoruntiltheyellow“calibrate”LED

is continuous ON.

•

When yellow calibration LED is continuous ON,

release the “zero” button. The “calibrate” LED will

turn off and the unit will be zeroed. See example

below.

“Zero”programmingcalibration mode

LED

SEQUENCE

POWER

G

SYSTEM

Y

N/A

CALIBRATE

Y

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

N/A

ATMOS

G

N/A

Exit:

System will automatically resume previous mode,

either“normal”or“no dead band” mode.This indicates

the parameters are now programmed into memory.

Placemulti-meterleadsonTest(+)andTest(–)and

ensuretheoutputissteadilyresting between3.9to

4.1 mA (see Figure 9 on next page). If this isn’t the

case, initiatetheauto“zero”procedureonceagain.

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

18

3

Operation

continued

JP3

S1

ZERO

40-200

mVDC

Black Red

-

+

Figure 9: Board Component Layout

ICSP Programming Port

Serial Port

Pressandholdthe“span”button(S2)for1secondor

more until the yellow “calibrate” LED blinks fast andthe

Zero Adjust

Span Adjust

Pushbutton S1

Pushbutton S2

Rx LED

Tx LED

yellow “system” LED is blinking slowly. See the

following example.

JP2

Note 1:

Checking

voltage to sensor

at +24 and GND

VDC

SPAN S2

Black

-

Red

+

Draw

Chamber

POWER

SYSTEM

CALIBRATE

Note 2:

Reading

signal at TEST+

and TEST-

STEP 3

Span Calibration

JP1

TEST +

TEST -

SIG

+24

GND

SHLD

FAULT

mA FAULT

IR SOURCE

ATMOS

ACTIVE

Tubing to

calibration point

Ensure the output rests between3.9and 4.1 mA (39.0

to 41.0 mV). If this is not the case, perform the “zero”

procedure again.

Once the output is within the required range with

nitrogen flowing, apply

full-scale

target gas into the

calibrationport at a rate of .6 liters/min for 3 minutes

immediately following the nitrogen flow.

If the signal is 26 mA or greater, adjust the “span”

potentiometer counter-clockwise until the signal is near

This procedure sets the “span” or concentration level

that would depict a 20 mA reading for full-scale target

gasonthe4/20mAoutput.Thelowerthetargetgas

concentrationis fora span of 20mA, the more sensitive

orresponsivetheunitwould be tolower ppmreadings.

NOTE:

Thisprocedureshouldonlybeperformedifthe

zero and4/20mAproceduresaresuccessfullycompleted.

Start:

SetmetertomVDC, placemeterleadson

Test(+) and Test(–) respectively (see Figure 9).

Apply

pure nitrogen

(N

2

) into the calibration port at

arate of.6 Liter/min. forat least 3minutes (OR until

output signal has stabilized to within ± .02 mA of signal

deviation/change). If N

2

is currently flowing from previous

“zero” calibration, disregard the additional flow time.

20mA.

Becausethere is a slight delay inpotentiometer

movement, make small adjustments and wait for the

output to change because adjustment response is

delayed between source pulses.

Wait until theoutput signal hasstabilizedto within±.02

mA of signal deviation/change. Adjust the “span”

potentiometer again until the output reads around 20 mA.

Exit:

Press and hold the “span” button (S2) for one

second or more until the yellow “calibrate” LED turns

off. The yellow “system” LED will resume the previous

state, either “filtered” or “non-filtered” output mode.

This indicates the parameters are now programmed into

memory.

24

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

N/A

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

19

3

Operation

continued

E

Diagnostic Procedures

Simple ZeroTest

Thistestwillensuretheunitiscalibratedforatrue

“zero” and duly represents an absence of target gas in

this condition.

Start:

Set meter to mV DC, place meter leads on

Test(+) and Test(–) respectively (see Figure 9).

•

Apply

pure nitrogen

(N

2

) into the calibration port

atarateof.6Liter/min.foratleast3minutes.

Check the status of the yellow “system” LED.

IfthisLEDiscontinuousON,placetheunitin

non-filtered output run mode by pressing both the

“zero” (S1) and “span” (S2) buttons

simultaneouslyfor1secondoruntilthe “system”

LED begins to blink slowly. See example below.

•

Wait until output signal has stabilized to within

±.02mAofsignal deviation/change.

•

Outputshouldreadbetween3.9and4.1mA

(39.0 to 41.0 mV).

If this is not the case, proceed to the next step.

•

Follow the “zero”procedure above to re-zero the

unit

•

Follow the“simplezerotest”procedure toensure

theunitisrestingattheoptimum4mApoint.

Simple “Zero” test – NO “Dead-band” mode 0 to 26 mA

Exit:

Pressandholdboththe“zero”(S1)and“span”

(S2)buttons simultaneouslyfor1secondormoreuntil

“system”LEDis continuousON.Unitshouldbe ready

for long-term operation.

4/20 mA Output Loop Integrity Check

22 mA High Signal Test

STEP 1

Start:

Set meter to mV DC, place meter leads on

Test(+) and Test(–) respectively (see Figure 9).

•

Press the “zero” (S1) button 5 times. The yellow

“calibrate” LED will blink fast and the yellow

“system” LED will turn off. The output should be

21 to 22.5 mA (210 to 225 mV).

Ifaproblemexistsontheoutputsignalline,orthe

output load is not within the specified range, the “mA

fault”LEDwill blinkeitherbeforeoruponactivationof

this test. In some cases the 22 mA high signal output

will cause incorrect output load resistance values to

surface because of the demand on high resistances to

produce high currents.

Low power supply voltages can also be something to

investigateifthiserrorsurfacesonlywhenthe22mA

high test is initiated.

During 4/20 mA loop test (22 mA high)

LED

SEQUENCE

POWER

G

SYSTEM

Y

OFF

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

N/A

SOURCE

G

N/A

ATMOS

G

N/A

LED

SEQUENCE

POWER

G

SYSTEM

Y

CALIBRATE

Y

OFF

FAULT

R

OFF

mA FAULT

R

OFF

SOURCE

G

ATMOS

G

N/A

Manning AirScan-iR Refrigerant Sensor

18908 AirScan-iR-comm

20

3

Operation

continued

During 4/20 mA loop test (22 mA high) w/ Error on output

LED

SEQUENCE

POWER

G

SYSTEM

Y

OFF

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

SOURCE

G

N/A

ATMOS

G

N/A

.5 mA Low Signal Output Test for

Fault Conditions

NOTE:

The unit must be in the 4/20 mA loop (22 mA

high) test to proceed with this test.

STEP 2

Start:

Press and hold the “zero” (S1) button for at least

one second or until the yellow “calibrate” LED shows

medium double blink. The yellow “system” LED will

remain off and the output should change to .4 to .6 mA

(4to6mV).

Ifaproblemexistsontheoutputsignalline,orthe

output load is not within the specified range, the “mA

fault”LEDwill blinkeitherbeforeoruponactivationof

this test.

If an error surfaces during this test only, the possibility

ofcross-talkcanexist onthe signalline. This is caused

by resistive shorts to power or other voltage sources

thatcanraisethe.5mA target currentontheline.

Moistureintheconnectorcancausestrayvoltageto

migrate fromthe 24VDC pinover to the 4/20 mAsignal

line. Check connectors or refer to the troubleshooting

sectionorerrorcode analysis sectionforassistance.

During 4/20 mA loop test (.5 mA low)

LED

SEQUENCE

POWER

G

SYSTEM

Y

OFF

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

N/A

SOURCE

G

N/A

ATMOS

G

N/A

During 4/20 mA loop test (.5 mA low) with Error

LED

SEQUENCE

POWER

G

SYSTEM

Y

OFF

CALIBRATE

Y

FAULT

R

N/A

mA FAULT

R

SOURCE

G

N/A

ATMOS

G

N/A

STEP 3

Exit:

Pressandholdthe“zero”(S1)buttonforatleast

one second or until the yellow“calibrate LED turns off.

The yellow “system” LED will resume the previous state,

either “filtered” or “non-filtered” output mode.

NOTE:

Inaddition totestproceduresinitiatedmanually,

every 2

seconds

SensorCheck

TM

technology monitors several

performance

parameters

of

the

AirScan

TM

iR.

A

notification

of.5mAontheoutputsignalistransmittedif anyof

theseparametersisnotmet.

Table of contents

Other Manning Accessories manuals

Popular Accessories manuals by other brands

MTS Sensors

MTS Sensors Level Plus M Series Replacement guide

Byron

Byron BY103 Installation and operation instruction

turck

turck RU600U Series Instructions for use

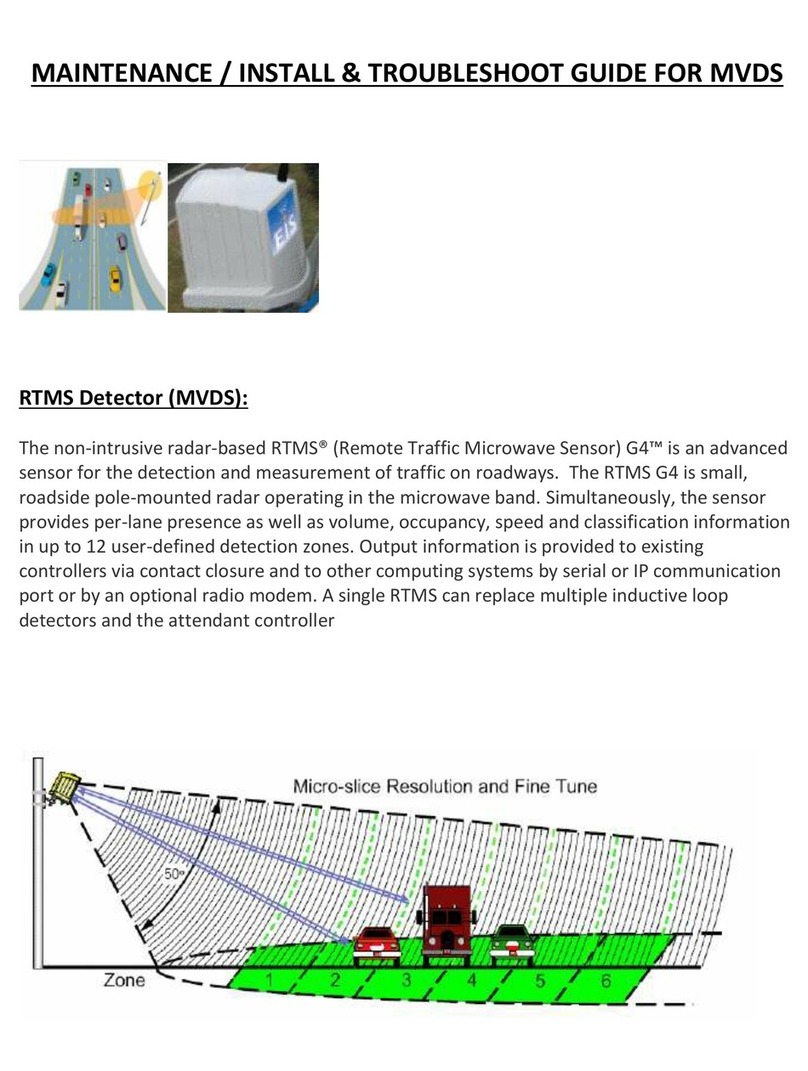

Image Sensing Systems

Image Sensing Systems RTMS G4 Installation, operation, maintenance, & troubleshooting

Kogan

Kogan SMARTERHOME KARMDF200BA user guide

Omron

Omron ZFX-C10 COMMUNICATION user manual