Maplin A67HY User manual

Thisproduct

hos

been

corefully

engineered

ond

monufoctured

togive

you

dependoble

operotion'.

Prior

touse,pleose

ensure

thotyoureod

ondundersiond

ollwoirings,

coutions

ondinitructions

included

in thisinstruction.

monuol,

ond those

published

by youru-"hi"l"

bottery

monufocturer

ondmonufoclurer

ofonydevice

intendedtobe'used

withthis

unit.

Pleoseretoin

ihismonuol

for

s.IN.I POWER

STATION

WITH

AIR

CO'IIPRESSOR

ORDER

CODE:A67HY

FEATUR,ES:

. 600

AMP

BATTERY

JUMPER

. 260

PSIAIR

COMPRESSOR

O

2OO

WATTPOWER

INVERTOR

O

I2 VOI-TPOWER

STATION

. WORKTIGHT

IMPORTANT:

future

reference. I

CONTRO[S:

l. Rubberized

Hondle

2. Air Compressor

On/Off Switch

3. Air

Compressor

Gouge

4. Heovy

DutyBooster

Clomps

5. l2V Socket

6. LED

WorkLight

OnlOff Swilch

7. Voltmeter

8. Bottery

StotusButton

9. 5 LED

WorkLight

10. lnvertor

On/Off Switch

I l. AC

Outlet

12. AirHose

Comportment

13.

Jumpstorfer

On/OffSwitch

14. Air

CoolingFon

IMPORTANT

SAFEGUARDS:

o Toprotect

ogoinst

electricol

hozords

or shock,

woter

orsources

of moisture. do notexposechorger,

odoptors,

or unitto

,YIAPIIN

ETECTRONICS

[TD. o Jumpstortvehicles

inwell

ventiloted

oreos

only.

o Monitor

thepressure

gouge

during

us9..g9

coreful

nottoover-inflote

obiects.

r lhis device

contoins.

seoled,,non-sp-illoble

leodocid botteries

ond must

be disposed

of

properly

ot the,end

ofthe

product's

life.

Contoct

yourlocol

outhority

for

odvice

ontlieproper

disposol,/recycli

ngprocedure.

o lfthe

u.nitis

domoged

bydropping

orother

heovy

impocts,

seekprofessionol

guidonce

from

o quotttted

engtneer

betore

usingogoin.

WORK LIGHT:

. !jrp.!V turnthe

worklight

switch(on

front

ponel)

ro

ON posirion.

o The

5 x LEDs

willilluminote.

r Turn

OFFwhen

notin use.

BAITERY

STATUS:

r Press

ondholdthe

Botfery

LevelButton.

o The

Voltoge

Meter

willshow

the

bottery

level.

o A reoding

of I3-_l 5 volts

meons

your

iumpstort

systemis

reody

touse.

o A reodingof 12 voltsmeons

your iumpsfort

iystemshouli be rechorged

os soen os

possible.

o A reoding

of below |2 voltsmeons

youshould

chorge

your

iumpstort

systemimmediotAly.

CHARGING

YOUR

JUiiPSTART

SYSTEM:

This

unit

hoso mointenonce

free,

built-in

seoled

leod

ocid

bottery.

Alihouqh

the

JumpstortSvsterrl

orrivesporliolly

chorged.from

thefoctory,

it must

befully

chorged

for3d hours

beior. firsi

,re,

even

ifthe

bottery

stotuslights

indic-ote

o "full"

chorge.

This

initiol

chorgepreconditions

the

bot-

teryond will provide

optimum

performonce

inthe

Tuture.

Foilure

to dlow this

procedure

moy

permonently

domoge

the

bottery.

ACCHARGING

ATHOME:

l. Use

o stondord

domestic

Ac 230v moins

power

socket

tochorgefrom

the

moins.

2. Only

usethechorgerprovided

withunit.

3. Keep

thepower

on,/offswitch

inthe

OFFposition

whilst

chirging.

4. Plug

the

AC chorging

cordinto

onystondtrd

wolloutlet

ond"the"other

endinto

theACl

chorging

input

sockel.

5. A full

chorge

from

ACtokes

opproximotely

34 hours.

6. Do

not

exceed

moximum

ACchorgingtime

of48 hours.

Z. Ensure

thot

chorgingtokesploce

ino well

ventiloted

oreoondinonoreowhere

the

cho,

stotus

conberegulorly

monitored.

DC

CHARGINGIN YOUR

VEHICIE:

L K,eep.the_p_ow3r

on/ofl switchinthe

OFFposition

whilst

chorging.

2 flu^S.!h9

D.Cchorging

cord

intoony12vol't(cigoreite

lighter)

s-ocklet

ondthe

orherend

inrorhe

AC/DC

chorging

input

socket.

3. A full

chorgefrom

DC

tokes

opproximotely

l2 hours.

4. Donot

exceedmoximum

DCchorging

time

of 24hours.

USING

THE

AIRCO'YIPRESSOR:

i . Openthe

comportment

door

otthe

bock

ofthepower

centre

ondpull

outthe

oir hose.

Moke

surethe

nozzlelever

isinthg

UPposition.

2. Attochthe

volveodoptor

tothe

volve

stem

onthetyreondpush

the

volve

odopior

lever

down

tolock

into

ploce.

3. Turncompressor

switch

onfrontponel

tothe

ON position.

4. Monitorthepressure

g-ouge

whileinfloiing

- do not

exceedrecommended

pressure

for the

tyre,/device

youoreinfloting.lt isrecommended

thot

youuseo seporote

oir gouge

tocheck

6

7

8

9

o Close

supervision

isnecessory

when

usedneor

children.

. Do

notuse

unitfor

opplicotions

other

thonitsintended

use.

' Rechorge

bottery

ofter

eoch.

use,or every2 monthsto moximizethe

life

ofthe

bottery.

o Avoid

touching

youreyes

when

workingwithbotteries.

o lt botteryocid comesin contoct

with skinor eyes,

immediotely

woshwith woter

ond seek

medicol

ottention.

r Remove

metol

iewelry

or othermetollic

obiects

thotmoy be exposed

to thebottery

clomps

tromyour

bodywhen

using

theunit.

r Neverollow

thered

ondblock

botteryclomps

totouch

eochother

ortotouch

the

some

metol

obiectotthe

sometime.

. Alwoys

connectlhe

red(+)

clomp

tothepositive

botteryterminol

first.

r Donot

connect

block

(-)

clomp

lo the

negotive

botteryterminol,

connect

it to o non-moving,

eorthed

metol

port

ofyour

vehicle.

the

octuolinflotion

pressure

foroccurory.

Whenthedesired

pressure

levelisreoched,

turnoff

the

compressor,

turn

thelocking

thumb

levertoUP

positionondremoveodoptorfrom

thevolve

stem.

5. When oppropriote

pressure

hosbeenreoched,

furncompressor

OFF

ond disconnect

hose.

USING

THEDC

12VOITPOWER,

PORT:

I . Removetheprotectivecover

fromthe 12Voccessory

socket.

2. Pluginyour I 2 voltoccessory.

3. Turn

powerporlswitch

toON.

4. Thellngrh Jf tir" forwhicho connected

device

con be pow.t"d'will dependon thebottery

chorge-stotus

ofyour

iumpstorter

ond

olsotheomoun!

ofcurrentrequired

bythe

devicewhich

youorepowering.

USING

THE

ACINVERTOR:

1 Priortoconnecting

theinvertor,

ensure

thot

theinvertorswitch

isintheOFF

position._

__

2. Priorto plugging-o

device

in to the invertor's

moins

socket,ensure

thedevice

isOFF

ond

ensure

thotihl d-evicedoesnotrequire

morethon200 wotts

of power.

3. Pfrrg

thedevice

iniotheinvertor's

socket.

4. Turn

lhe invertorswitch

to theON position.lf theinvertor

isworking

properly,o green

LED

indicotor

will illuminote.Now turnON the

powerswitchofyourdevice.

lfthe

greeninciicotor

renroins

on,then

thesystem

isoperoting

properly.

lf theinvertor's

gregl LEDlight

turns.OFF,

hrrn

off thedevice

ond turnoff ihe in"erior

immediotely.

Seethe

troubleshooting

guidefor

possible

couses.

Theinvertor

moyhove

beenoverloodedor theinputvoltoge

moybe too

i low.

.CAUTION:

,Some

rechorgeoble

devicesoreequipped

witho seporotechorger,

which

conbeconnected

to

'.he

invertor's-AC

socket.

However,

ceitoin

rechorgeoble

devices

oremonufoctured

withbuilt-in

\org"r. (see

device

owner's

monuol).

SuchdevicJs

moycouse

internol

domoge

toinvertorsond

tbul-d

noibeused

withthis

product.The

temperotureoFthe

connected

device

mustbemonitored

1r

thefirsil5 minutesofoperotion.

Anobnoimolly

highoperoting

temperotureofonyconnected

'iyice

is

oneorly

indicotionthot

itshould

notbeused

with

thisinvertor.

\npstannNc:

tn the cor ignition

OFF.

Turnoff oll your cor's occessories

suchos

',rditioner,

etc.

toovoid

furtherdroin

ofthebottery.

TROUBTESHOOTINGGUIDE:

Probleml:

Cquse

A:

Solution

A:

Problem

2:

Couse

A:

Solution

A:

Couse

B:

Solution

B:

Problem3:

Couse

A:

Solution

A:

\

Problem

4:

Couse

A:

Solution

A:

Couse

B:

Solution

B:

Couse

C:

Solution

C:

Couse

D:

Solution

D:

Problem

5:

Couse

A:

Solution

A:

Television,/power

toolwill notstortup.

High

surge/wottoge

requirement

when

productis

firstswitched

on.

Tolgle tlre

on/ofiswitch in quick

successiono totolof 5 times

in order

to

gei"erote

thenecessory

powdito stort

thedevice.

lfthedevicedoes

notturn

onorstort

upofter5 otlempts,

the

invertorwill notwork

withthe

device.

Television

interference/picture

breoki

ngup.

Electronic

interference.

Ploce

theinvertor

{power

centre)

os

forospossible

from

theTV,

theontenno

o

ndthecooxiolcoble.

TVstotion

moy

beout

or ronge.

Retune

too stronger

frequency.

Stotic/noise

interference

Sound

system

hosweokolternoting

current

shielding.

Donof

useinvertorwithlowquolity

oudio

ACfiltering

system.

Reploce

oudio

system

wiihhigh

quolity

noisefiltering.

No power

output.

Power

centrevoltoge

isbelow

I2 volts.

Rechorge

thepowercentre

immediotely.

Excessive

currentdrown

byopplionce.

Reduce

loodtoo moximum

of200 wotts

totol.

Invertor

isnotcompletely

wormed

up.

TurnOFF

thedevice

ondthe

invertor.

Disconnect

thedevice.

Turnthe

invertor

ON ond

leove

itrunning

foro minimumof2 minutes.

TurnOFF

theinvertor,

quickly

pluginyourdevice

tothe

invertor

(moking

suredevice

isOFF

prior

to

connection).

TurnON theinvertor

ond

thenthedevice.

lnvertor

fuse

isblown.

Reploce

the fusewith o new 25 omp roted fuse.To replocethe fuse,

disconnect

olldevices

ondchorging

leods.

Remove

thefusewith

needle

pliers

ondreploce

witho fuseofthesome

roting.

LEDlightdoes

notwork.

Inodequote

powerorexcessive

voltoge.drop.

.

Check'powercentre

ondrechorge

ifvoltogedrops

belowl2 volt.

lights,rodio,

oir

;ke sureollswitches

onthe

Jumpstort

Systemoreturned

OFF.

, jecurely

connect

the

Red

(+|

clomp

toyourvehicleboftery's

positive

(+!

bottery.terminol..

4. Donottonnect

o clomp

tothenegotive

vehicleboffery

terminol.Connect

the

block

(-)

clomp

too non-moving,

eorthed

metol

portofthevehicle.

5. Try

to stort

your

vehicle.

lfyourvehicle

doesnotstort

ofter

thefirst

ottempt,

woit 3 minutes

before

trying

ogoin(foilure

towoitmoydomoge

the

iumpstorter!.

6. Afterthe'veiiclestoits,disconnect

theblock

negotive

ciomp

first

ond then

thered positive

clomp.

SPECIFICATIONS:

Builtinbottery: l2-volt

rechorgeoble

seoled

leodocidbottery

Work

light:

Compressor:

lnvertor:

5 x LEDs

260PSIreoding

gouge

200

wotts

(peok:400wotts/O.3

sec.|

I2V powerporl I2-voltI IA mox.

Chorqing

time: 34-36hoursvioAC moins

chorger,

l4-16 hours

vio DCin-vehicle

chorger

\sq,/

C€A

Popular Air Compressor manuals by other brands

fiac

fiac New Silver Series Use & maintenance manual

Metabo

Metabo Power 160-5 18 LTX BL OF Original instructions

L&W Compressors

L&W Compressors LW 300 D MC operating instructions

Nuvair

Nuvair Q-325 user manual

Craftsman

Craftsman 919.167461 owner's manual

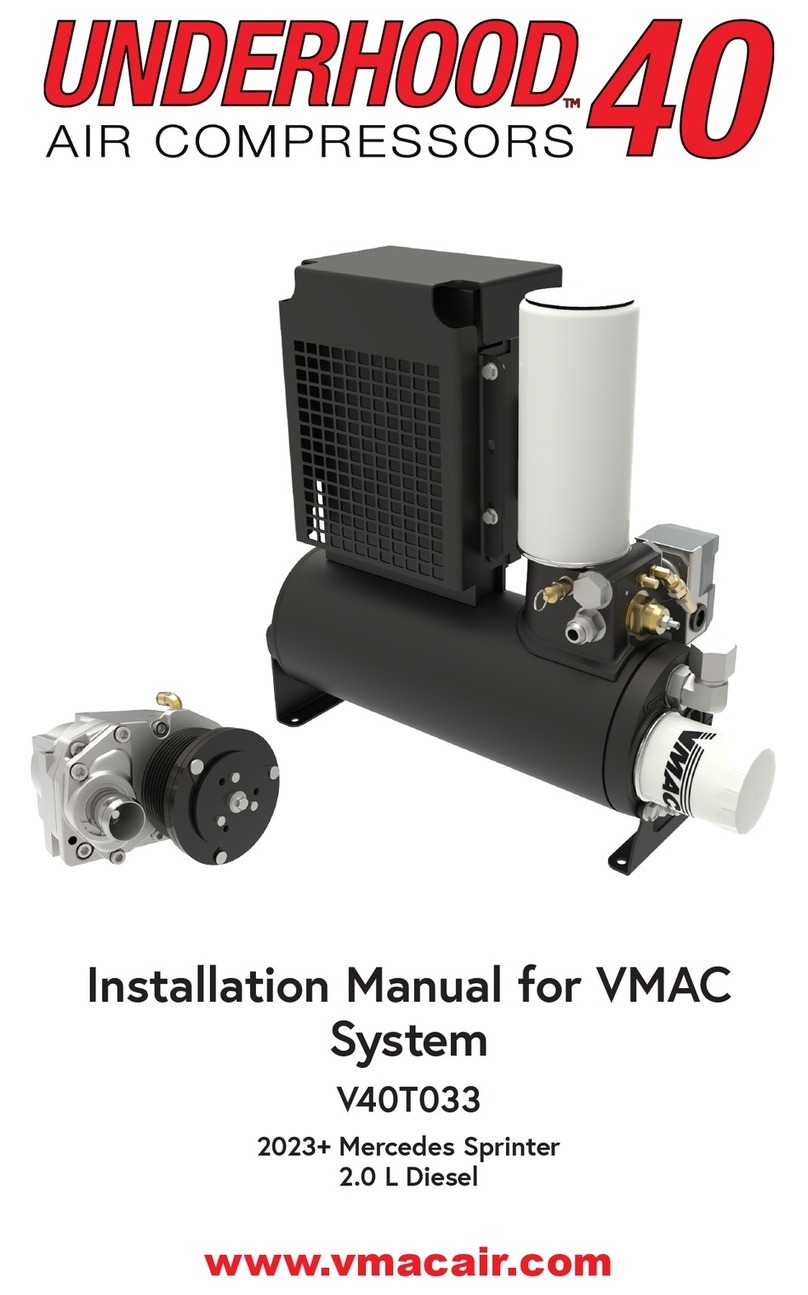

Vmac

Vmac G300003 Installation, owners and service manual