Vmac UNDERHOOD 40 Series User manual

Other manuals for UNDERHOOD 40 Series

14

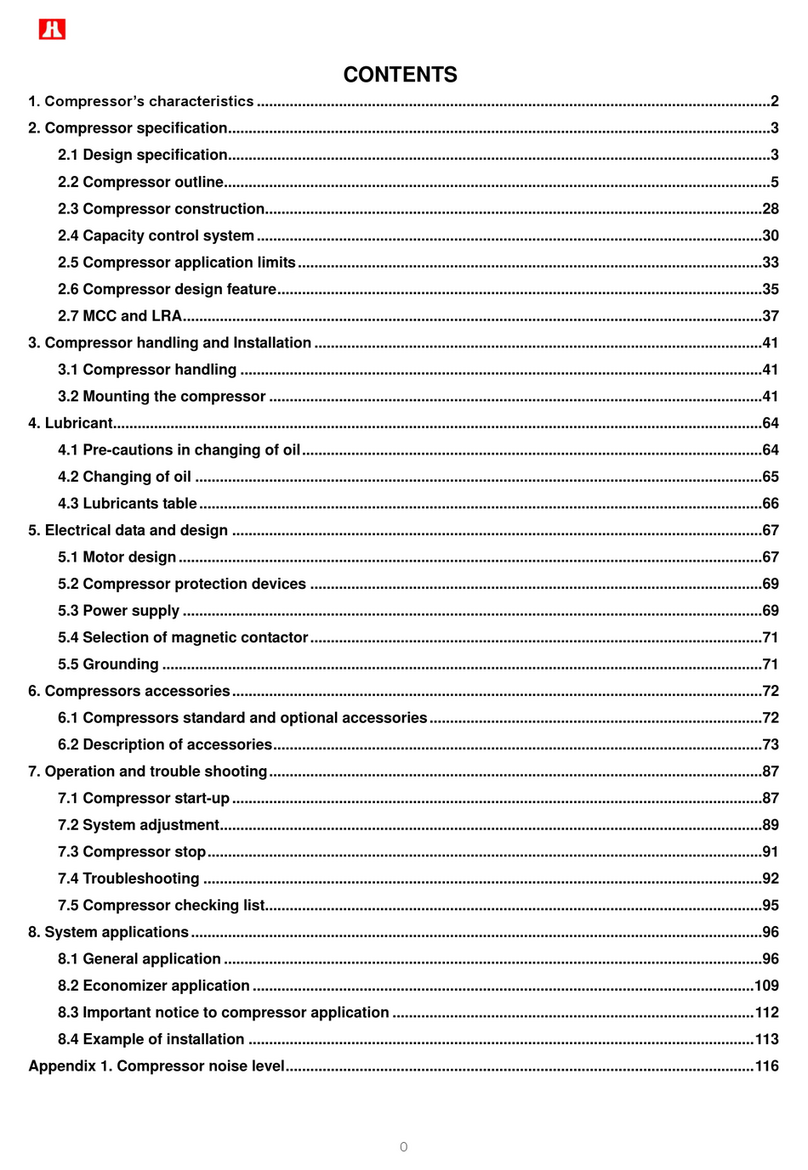

Table of contents

Other Vmac Air Compressor manuals

Vmac

Vmac RAPTAIR-MF D600007 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac G300004 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac AIR INNOVATED H400006 Installation instructions

Vmac

Vmac V900140 User manual

Vmac

Vmac DM2A030 User manual

Vmac

Vmac Underhood 70 User manual

Vmac

Vmac V400010 User manual

Vmac

Vmac V400011 User manual

Vmac

Vmac G300005 User manual

Vmac

Vmac RAPTAIR-MF Use and care manual

Vmac

Vmac VR70 User manual

Vmac

Vmac S700078 User manual

Vmac

Vmac RAPTAIR-G30 User manual

Vmac

Vmac G300003 User manual

Vmac

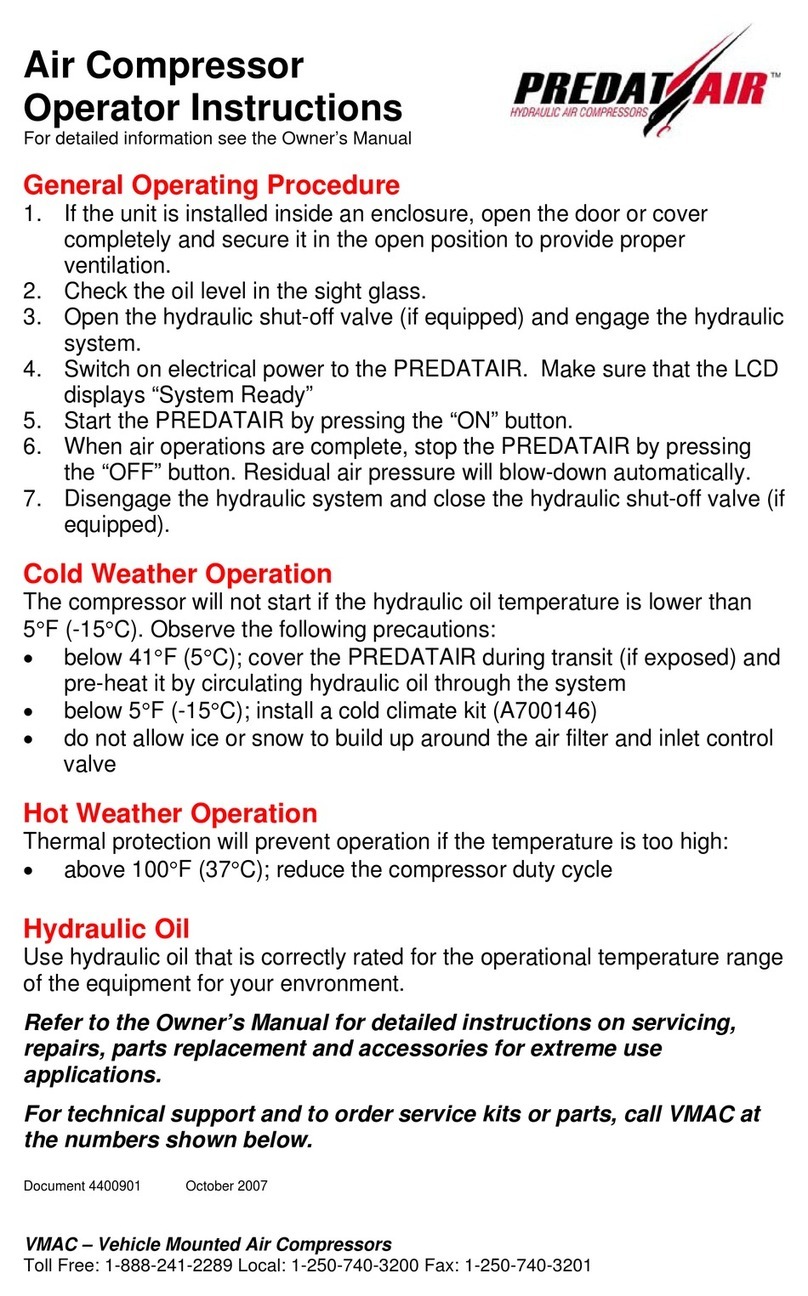

Vmac PredatAir Series Specifications

Vmac

Vmac V900170 User manual

Vmac

Vmac H400011 User manual

Popular Air Compressor manuals by other brands

Campbell Hausfeld

Campbell Hausfeld FP2200 Series operating instructions

Atmos

Atmos PDP 90 Operation and Maintenance Handbook

Sears

Sears 919.157151 owner's manual

ABB

ABB HT574653 Operation manual

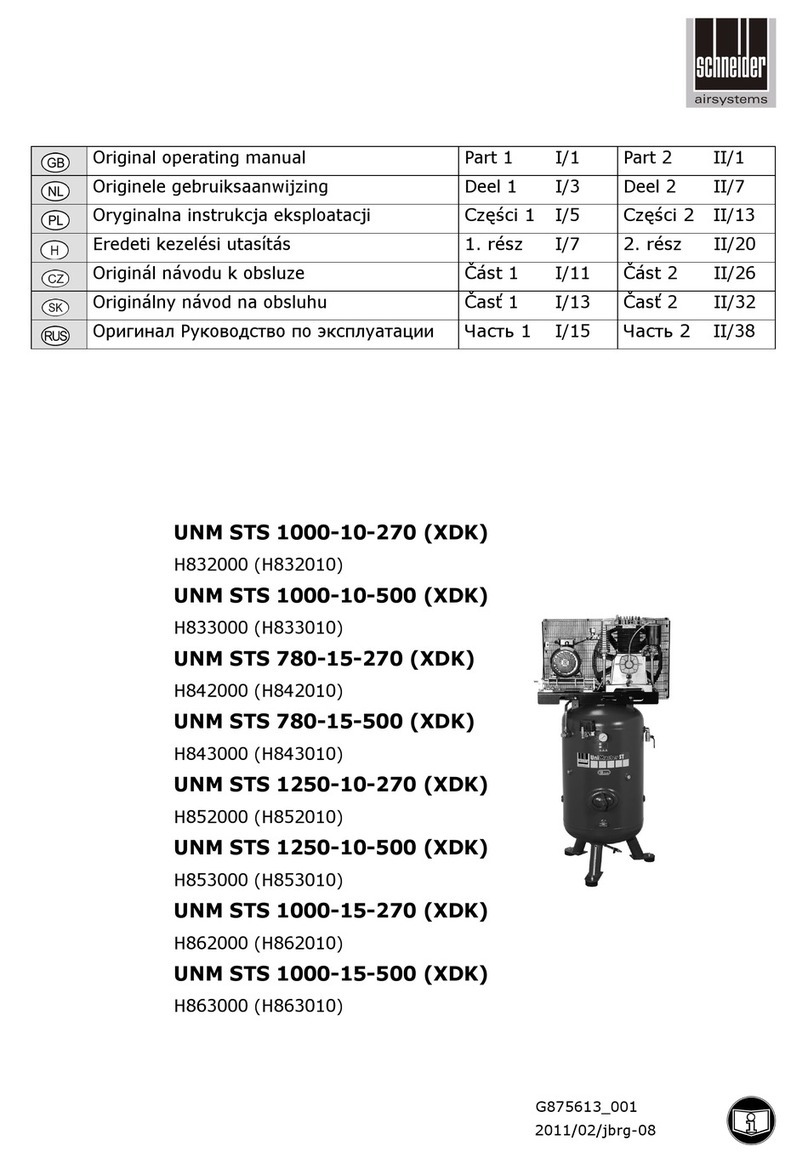

Schneider Airsystems

Schneider Airsystems UNM STS 1000-10-270 XDK operating manual

Strend Pro

Strend Pro HSV-50-08 instruction manual

WARRIOR

WARRIOR AC50VLF Operation manual

Regen-Tec

Regen-Tec Profi-AirTec 128-8-1.1 operating instructions

EINHELL

EINHELL 300/50 W operating instructions

Scheppach

Scheppach HC24 Translation of original instruction manual

EINHELL

EINHELL CE-CC 18 Li Original operating instructions

ULTIMATE SPEED

ULTIMATE SPEED UMK 10 C2 Operation and safety notes