Mea SMARTPACK 40H Owner's manual

7230-D0001-3

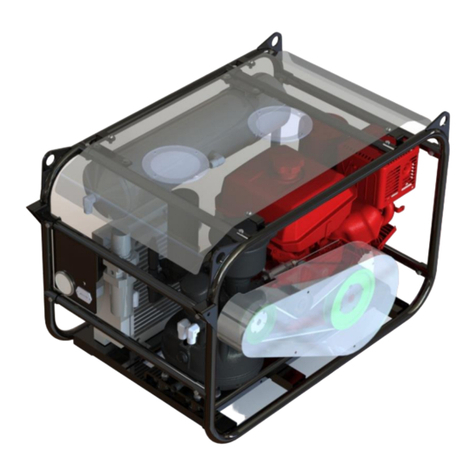

SMARTPACK 40H

Owners & Operators Manual

SERVICE MAINTENANCE AIR COMPRESSOR

–HYDRAULIC DRIVEN

Revision: 3

Reviewed: 10/01/2023

Document No 7230-D0001-3

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

MEA Product Registration Form

THE ATTACHED FORM MUST BE COMPLETED

AND

RETURNED WITHIN 30 DAYS OF INSTALLATION

OR

WARRANTY WILL BE VOID

ALTERNATIVELY, PLEASE GO ONLINE AND

COMPLETE WARRANTY FORM

www.mobileenergyaustralia.com.au/warranty-registration

Document No 7230-D0001-3

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

MEA Product Warranty Registration Form

This form must be completed and returned to MEA at the time of

Installation. Warranty will be void if this form is not received by MEA

within 30 days of installation.

MEA Dealer Information

Company Name: _____________________________________________________________

City: _______________ State: ___________________ Country: ___________________

MEA Installer Information

Company Name: ______________________________________________________________

City: _______________ State: ___________________ Country: ___________________

Installation Date: _______ / ________ / ______

Day Month Year

Owner Information

Company Name: ______________________________________________________________

Address: _____________________________________________________________________

City: _______________ State: ___________________ Country: ___________________

Postcode: _________________________ Phone #: ________________________________

Product Information

MEA Serial Number: __________________________________________________________

Model Number: _______________________________________________________________

CUT HERE

Document No 7230-D0001-3 1

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

TABLE OF CONTENTS

1. COMPRESSOR/COMPRESSED AIR SAFETY ...................................................................... 2

2. SPECIFICATIONS....................................................................................................................... 6

3. OPERATING PROCEDURE ...................................................................................................... 7

4. INSTALLATION.......................................................................................................................... 8

5. SCHEDULE MAINTENANCE.................................................................................................... 9

6. SPARE PARTS...........................................................................................................................10

7. TROUBLESHOOTING .............................................................................................................11

8. DRAWINGS & ILLUSTRATIONS..........................................................................................14

9. WARRANTY ..............................................................................................................................22

10. MOBILE ENERGY AUSTRALIA - CONTACTS....................................................................24

11. APPENDIX A –DESIGN REGISTRATION ..........................................................................25

12. APPENDIX B –FLUIDS & MATERIAL SAFETY DATA SHEETS...................................26

Document No 7230-D0001-3 2

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

1. COMPRESSOR/COMPRESSED AIR SAFETY

MEA DISCLAIMS ALL LIABILITIES FOR DAMAGE OR LOSS OF EQUIPMENT AND PROPERTY,

PERSONAL INJURIES (INCLUDING DEATH), AND CONSEQUENTIAL DAMAGES ARISING OUT OF

ANY MEA SYSTEM NOT USED IN ACCORDANCE WITH THE OPERATOR’S MANUAL.

ALL UNITS ARE SHIPPED WITH A DETAILED OPERATOR’S MANUAL. THIS MANUAL CONTAINS

VITAL INFORMATION FOR THE SAFE USE AND EFFICIENT OPERATION OF THE UNIT. READ THE

OPERATOR’S MANUAL BEFORE STARTING THE UNIT. FAILURE TO ADHERE TO THE

INSTRUCTIONS COULD RESULT IN SERIOUS BODILY HARM OR PROPERTY DAMAGE.

Care is required when working with an air compressor or compressed air. Compressed air is one of the many

ways energy can be stored. Releasing the stored energy in an uncontrolled manner can result in catastrophic

consequences. Death and permanent disability are possibilities that can occur due to misuse. The following

are suggested as minimum precautions to be used when operating the SMARTPACK Air Compressor. It is

important that each work site shall perform a risk analysis and produce a procedure to eliminate or control

the hazardous condition to minimise the risk to personnel and equipment. Health and Safety Regulations

necessitate that this is a compulsory process to be carried out on each site. These, together with site specific

safety procedures will help to minimize the risk of accidents, personnel injury and loss of life. It is the

responsibility of the employer to ensure that the work site is safe for all employees and that the safety

procedures are followed by all employees.

SAFETY WHEN OPERATING AN AIR COMPRESSOR

•Do not bypass or disable the oil temperature and pressure sensors –unless planning on running to

failure (MEA does not recommend the practice).

•Do not expose the tank or compressor to extreme heat.

•Do not perform any service or repairs until the system has been completely relieved of air pressure.

•Maintenance and repairs on the system should only be done by qualified personnel.

•Do not operate the compressor while driving (vehicle mounted systems).

•Do not tamper with the pressure relief valve.

•Follow safe work practice, wear the appropriate personal protective equipment (PPE) when operating

air-powered equipment, particularly eye and hearing protection.

•Avoid contact with rotating components, ensure all safety guards are in place.

•Avoid all contact with pressurized air. If it penetrates the skin, it can enter blood stream and cause

death.

•Vaporized oil propelled by high pressure is an explosive mixture. To prevent compressor explosion

or fire, make sure that the air entering the compressor is free of flammable vapors.

•Do not breathe the compressor air, vaporized oil is a respiratory hazard.

•Stay clear of all moving parts when the system is operating.

•Follow safety procedures for service operations as set by the authority.

•Run the system at idle speed and under no load conditions for 2 to 3 minutes before turning the

system off to allow system cooling and lubrication to occur.

Document No 7230-D0001-3 3

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

HYDRAULIC SAFETY

ALL HYDRAULIC EQUIPMENT MUST BE TREATED WITH EXTREME

RESPECT AND CARE. AS THE WORKING FLUID IS UNDER EXTREME

PRESSURE, UP TO 5000PSI, WITH HIGH FLOW RATES GENERATING

HIGH HEAT, ALL APPROPRIATE SAFETY PRECAUTIONS MUST BE

TAKEN IN TO ACCOUNT AND SAFETY EQUIPMENT MUST BE WORN IF

IN CONTACT WITH THE EQUIPMENT UNDER OPERATION. ALL LEAKS,

NO MATTER HOW MINOR, MUST BE RECTIFIED IMMEDIATELY AND

ANY WEAR IN THE HOSES MUST BE ADDRESSED AND EQUIPMENT

REPLACED. HYDRAULIC INJECTION IS DANGEROUS AND LIFE

THREATENING AND EVEN A PINHOLE LEAK WILL BLANKET AN ENTIRE

ENCLOSED SPACE VERY QUICKLY WITH HAZARDOUS VAPORIZED

HYDRAULIC OIL MIST.

Document No 7230-D0001-3 6

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

2. SPECIFICATIONS

Compressor Model: NK31

Compressor Type: Oil flooded rotary screw compressor

Hydraulic Motor Type: 11cc Gear Motor

Control: 24V/12V Electronic Control

Maximum Air Delivery: 40cfm @ 130psi, 1133 LPM @10 Bar

Oil Flow requirements: 44 LPM

Oil Pressure (Nominal): 128 Bar

Drive coupling speed: 4000 rpm

Pressure Regulation: Mechanical Inlet control valve modulates flow in response to demand

Safety Features: 200 PSI relief valve in compressor sump

Temperature safety sensor in compressor

Rapid blow-down valve to discharge system pressure on shutdown

Lubrication: MEA Certified and Approved Oil

Filters: Paper-type replaceable air filter

Spin-on type oil filter

Coalescing separator element

Document No 7230-D0001-3 7

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

3. OPERATING PROCEDURE

CAREFULLY READ THE OPERATING INSTRUCTIONS BELOW. FAILURE

TO ADHERE TO THE FOLLOWING COMPRESSOR OPERATING

INSTRUCTION COULD RESULT IN SERIOUS INJURY.

1. Check Oil Level.

2. Check Hoses and fittings for leaks. Make sure the hoses are not loosened nor damaged.

3. Check and make sure hydraulic supply/return/ (drain optional) are installed correctly.

4. Check Air Filter for Blockage.

5. Check the Safety circuit switch operation (Reset Switch).

6. Switch on the vehicle and activate the vehicle flow control (turn PTO on; for vehicle mounted system).

In other systems, start the hydraulic system by starting the hydraulic pump.

7. Turn on the compressor either at the control box (or in the cab) and ensure it is in the unloaded

state (check load/unload switch).

8. Turn on the unload/load switch to load and see if the compressor builds pressure to the regulated

setting.

9. Plug an air tool into the air outlet and operate. Ensure that the compressor works as required.

10. When the work is finished, switch the compressor to unload.

11. It is good practice to allow the compressor to run under no load for 2-3 minutes.

12. Switch off at either the control box or in Cab and switch off the vehicle.

13. It is good practice to check for any visible signs of hydraulic fluid leakage and or compressor fluid

leakage after each use.

WARNING

Document No 7230-D0001-3 8

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

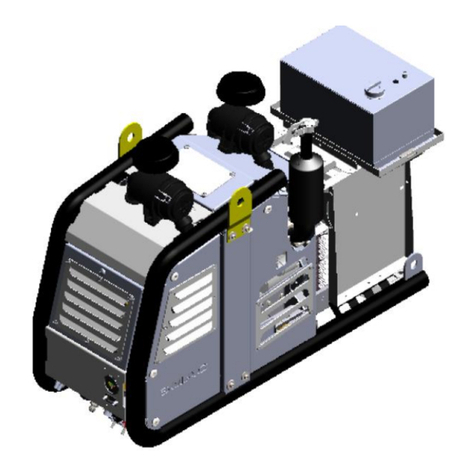

4. INSTALLATION

The SMARTPACK 40H is designed as an integrated compressor system for connection to an existing hydraulic

system. The SMARTPACK 40H only requires connection of a pressure line in and a return line out (optional: a

motor drain line) connections to the tank line and a method for controlling flow such as solenoid valve and flow

orifice.

WARNING(!) When setting the compressor unit up, ensure there is a safety mechanism in place to

prevent any excessive flow or pressure into the compressor hydraulic circuit. MEA will not warrant any

damage caused and will void warranty due to inadequate safety protection of the existing hydraulic

system.

IMPORTANT: COMPRESSOR MUST ROTATE IN THE COUNTER-CLOCKWISE DIRECTION WHEN

LOOKING AT THE COMPRESSOR SHAFT END.

1. Install SMARTPACK 40H into position on the vehicle using 6 x M12 x 1.75 Grade 8.8 Fasteners and

rubber isolators between the vehicle and compressor. Rubber isolator can be supplied if required (MEA

P/N 7251-P0032).

2. Install the hydraulic lines including any flow control (such as unloader valve), i.e., Pressure in, Tank out.

3. Connect the electrical harness to the vehicle.

a. If purchasing the electrical control box; be sure to place an in-line weatherproof fuse (30A –

12V and 15A –24V) within 300mm of the vehicle battery.

b. If purchasing the basic electrical control (Murphy) ensure the voltage supplied is compatible

with your vehicle’s voltage rating.

4. Connect the pressure gauge line from the control box to the compressor (black nylon tubing). Ensure

when you connect that the tube is inserted correctly.

5. Check the level of oil in the compressor. Fill if required to the level indicated.

6. Start the vehicle and turn on PTO to start hydraulic pump.

7. Turn on the compressor either at the control box or in cab and test the hydraulic solenoid for operation.

8. Turn the unload/load switch to load and check the compressor builds pressure to the regulated pressure

setting.

9. Plug an air tool into the air outlet and operate, checking that the compressor works as required, run for

10mins. Whilst it is running check for oil leaks and air leaks in any of the hosing and nylon tubing.

10. Unload the compressor, switch off the control box, switch off the vehicle and check for any visible

signs of hydraulic fluid leakage. When cool (safe to touch), and switched off, re-check compressor

oil level

ENSURE THAT A WATER SEPARATOR IS MOUNTED AS FAR FROM THE COMPRESSOR AS POSSIBLE

OR THAT IT HAS AT LEAST TWO METRES OF HOSING BETWEEN THE COMPRESSOR DISCHARGE

AND SEPARATOR INLET.

IMPORTANT: PLEASE CONTACT MOBILE ENERGY AUSTRALIA FOR MORE INFORMATION IF YOU

HAVE ANY QUESTIONS REGARDING THE SETUP AND OPERATION OF PRODUCTS.

Document No 7230-D0001-3 9

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

5. SCHEDULE MAINTENANCE

The maintenance intervals recommended are based on standard operating conditions. The intervals for

inspection, lubrication and maintenance given herein are maximum intervals and it should be noted to schedule

the maintenance accordingly to sites.

When the unit is being operated in a dusty environment, in high ambient temperatures or in other unusual

conditions, an assessment needs to be done for shorter service interval.

A planned program of periodic inspection and maintenance will help to avoid premature failure and costly

repairs. Daily visual inspections should become routine.

MAINTENANCE INTERVALS

MAINTENANCE WORK

BEFORE COMMISSIONING

CHECK OIL LEVEL IN SEPARATOR TANK

ONCE AFTER 50 HOURS

CHECK OIL LEVEL IN SEPARATOR TANK

TIGHTEN ALL SCREW PIPE FITTINGS AND

ELECTRICAL SCREW TERMINALS

CHECK ALL OTHER CONNECTIONS FOR FIRM

EVERY 400 HOURS OR 6 MONTHS

REPLACE OIL AND OIL FILTER

CHECK AND CLEAN AIR FILTER ELEMENT

EVERY 1000 HOURS OR 1 YEAR

REPLACE OIL AND OIL FILTER ELEMENT

REPLACE COALESCING FILTER ELEMENT

REPLACE AIR FILTER ELEMENT

CHECK SYSTEM FOR LEAKS

How to Check Oil Level

Document No 7230-D0001-3 10

Mobile Energy Australia Pty Ltd 39 Dulacca Street, Acacia Ridge QLD 4110 Australia ABN 98 674 578 946

P: +61 7 3273 6803 E: sales@mobileenergyaustralia.com.au www.mobileenergyaustralia.com.au

6. SPARE PARTS

PLEASE CONTACT MEA SALES-SPARE PARTS FOR FURTHER INFORMATION ON ANY

MAINTENANCE PARTS REQUIRED.

Part Number

Description

10008-P0019

AIR FILTER ELEMENT

10008-P0021

SPIN ON COALESCER

10008-P0016

OIL

FILTER

10019-K0005

5 LITRE SEMI SYNTHETIC COMPRESSOR OIL

10012-P0084

UNLOADER VALVE 24V

10012-P0083

UNLOADER VALVE 12V

20012-P0004

RELAY 12V

20012-P0005

RELAY 24V

TO BE REQUESTED

COUPLING SET

TO BE REQUESTED

COUPLING (SPIDER)

TO BE REQUESTED

SHAFT SEAL

Other manuals for SMARTPACK 40H

1

Table of contents

Other Mea Air Compressor manuals

Mea

Mea SMAC 35DG Owner's manual

Mea

Mea SMAC 90-H Owner's manual

Mea

Mea SMARTPACK 40H Owner's manual

Mea

Mea SMAC 35DWG 22HP Owner's manual

Mea

Mea SMAC 35D-24HP User manual

Mea

Mea SMARTPACK 180-H Owner's manual

Mea

Mea SMAC 35DG Owner's manual

Mea

Mea SMARTPACK 180-H Owner's manual

Mea

Mea SMAC35D-G 15HP Owner's manual

Mea

Mea SMAC 40D-15HP Owner's manual

Mea

Mea VR40 Owner's manual

Mea

Mea SMARTPACK 400-H Owner's manual

Mea

Mea SMARTPACK 75-H Owner's manual

Mea

Mea SMARTPACK 35 Owner's manual

Mea

Mea SMARTPACK 250-H Owner's manual

Mea

Mea SMARTPACK 70P Owner's manual

Mea

Mea SMARTPACK 100-H Owner's manual

Mea

Mea BATTCOM Owner's manual

Mea

Mea SMAC 35DG/BFM Owner's manual