Marathon Shredder Guide

Page 1

OPERATION

MAINTENANCE

AND INSTALLATION

Shredder

TM

Page 2

Table of

Contents Page

Introduction························································· 3

Pr e-Operating Instructions ······································· 4

E quipment Information ··········································· 5

O perating Instructions ············································ 6

E quipment Specifications········································· 7

Electric Safety Switch ············································· 8

Mai ntenance ······················································· 9

Mai ntenance Pictures ············································· 10

Trouble Shooting Guide··········································· 11

Instal lation Instructions ·········································· 12

Parts Ordering Information ······································ 13

No tes Page·························································· 14

Page 3

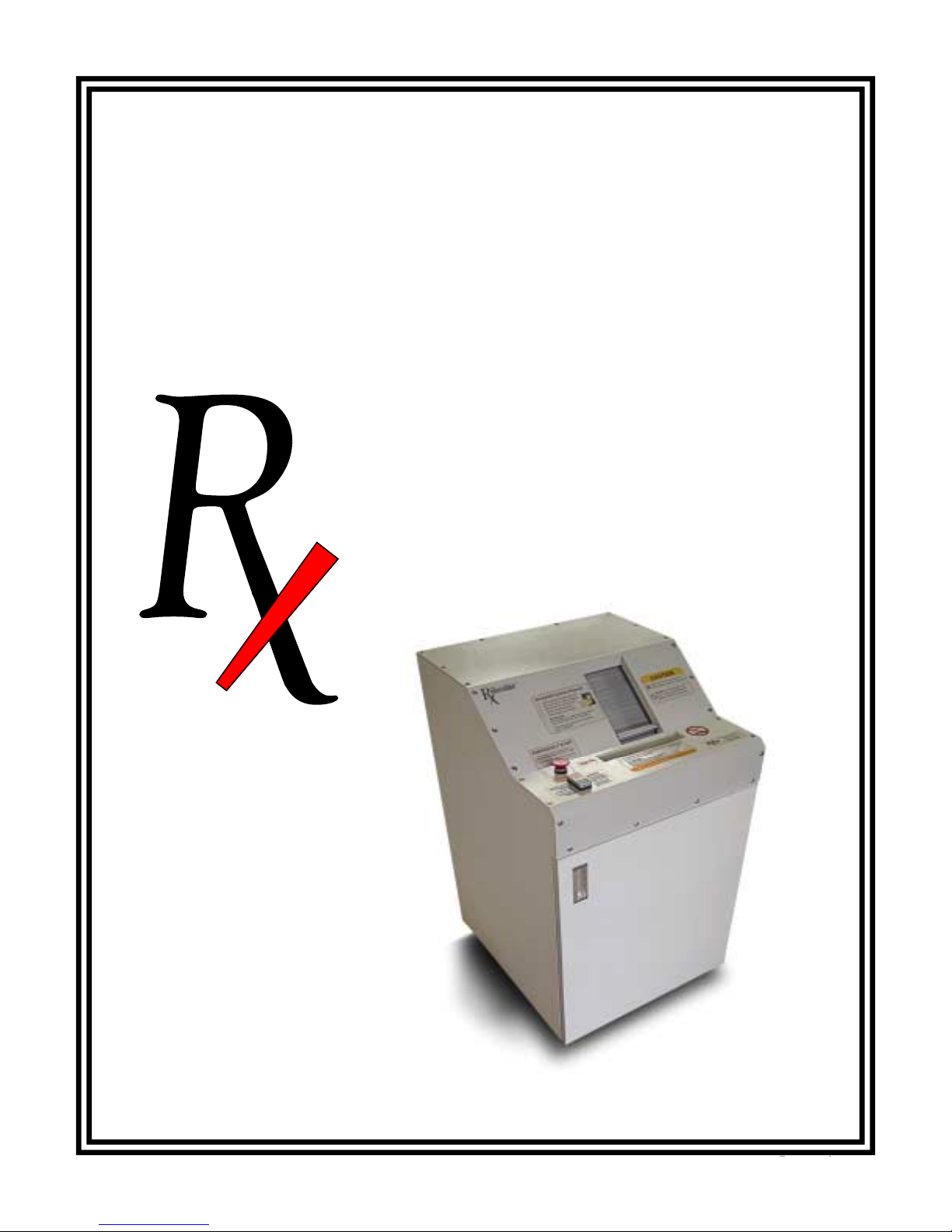

Dear Customer,

Thank you for purchasing a Rx Shredder.

This p roduct is d esigned t o g ive yo u rel iable servic e a nd sup erior p erformance fo r

years t o c ome. T o guarantee top p erformance fro m yo ur sh redder a nd sa fest

operation, every person involved in o peration, ma intenance, a nd inst allation should

read and thoroughly understand all instructions in this manual and follow all warnings.

If you need assistance with your shredder, please contact your equipment distributor.

When you contact your distributor, you will n eed to provide serial number, installation

date, and electrical schematic number.

If you have any safety concerns with equipment, or need further

information, please contact us at:

Ameri-Shred Corp.

P.O. Box 68

Alpena, MI 49707

1-800-634-8981

INTRODUCTION

Page 4

•

Employers should allow only authorized and trained personnel to operate this

equipment.

•

Do not remove access covers except for servicing.

•

This shredder utilizes a safety interlock switch and stops power to the motor when

the collection bag access door is open.

•

The electronic circuitry in this shredder performs several functions:

Senses the presence of paper in the shredder inlet and automatically starts

shredding and then stops the shredder after the paper has passed through.

Controls the safety functions of the shredder.

Operates the indicator lights.

•

The automatic start function of this shredder uses a diffuse type photo eye in the

paper feed slot to detect the presence of paper.

• Depress the stop switch when shredder is not in use.

CAUTION: Do not insert any objects other than what it was designed for.

Never insert hand, fingers or any foreign objects into the feed opening.

Serious injury may result.

Keep all loose articles of clothing, ties, jewelry, long hair or other loose

objects away from feed opening.

Serious injury may result.

Always turn off and unplug the machine before moving, servicing,

cleaning or any other conduct other than normal operation.

Serious injury may result.

PRE-OPERATING SAFETY INSTRUCTIONS

!

Page 5

EQUIPMENT INFORMATION

Physical Dimension: Depth:26 1/4”

W idth:24”

Heig ht:44 1/4”

Feed Openings: Paper:10” Wide

Bottles:4” Diameter x 6” Tall

Process Time: 5 Seconds to Process 20 Sheets of 8 1/2” x 11”

or 10 Sheets of Pressure Sensitive Labels

Shipping Weight: 480 Pounds

Sound Level: Less Than 65 Decibels

Bottle Disposal

Door

Emergency

Stop Switch

Forward / Reverse

Switch & Power

On Light

Paper and Label

Feed Slot

Collection Bag

Access Door

Page 6

TO SHRED PAPER:

1. I f “EMERGENCY STOP SWITCH” is illuminated, depress button and light will turn off.

2. “POWER ON” light indicates unit is ready to operate.

3. Insert paper in to feed slot and photo eye will sens e material is pr esent, shredder

will process material and automatically shut down.

TO SHRED BOTTLES:

1. I f “EMERGENCY STOP SWITCH” is illuminated, depress button and light will turn off.

2. “POWER ON LIGHT” indicates unit is ready to operate.

3. Operator raises feed door.

4. Operator places bottle with lid removed into chamber to be shredded.

5. Operator closes door.

6. Shredder starts, processes material and shuts down automatically.

HOW TO CLEAR A PAPER JAM:

1. The shredder will a utomatically at tempt to clea r it self by rot ating t he knives

forward a nd reverse if t oo muc h o r too larg e o f a p iece o f mat erial is in t he

chamber. This is normal. If this continues for more than 20 – 30 seconds depress

th e “EMERGENCY STOP SWITCH”.

2. Empty the collection bag if full.

3. Depress and hold “REVERSE S WITCH” the shredder will a ttempt to b ack paper

out of paper feed slot.

4. If shredder jams in reverse mode, depress and hold “FORWARD SWITCH”.

5. If shredder jams again, alternate slowly depressing the “REVERSE SW ITCH” and

“FORWARD SWITCH” to attempt t o m ove jam med pape r co mpletely th rough

shredder.

6. If yo u are una ble to c lear the j am using t his met hod, d epress “EMERGENCY

STOP SWITCH” an d “UNPLUG T HE S HREDDER”, remove t he collect ion bag

from cabin et and carefully re move an y pap er e xtending be low th e cu tting h ead.

Reinsert collection bag and repeat jam clearing procedure.

DANGER:

Because the sensor c annot t ell the difference between p aper and other o bjects, this

feature c an b e a ha zard. To a void accidents, d epress t he “EMERGENCY S TOP

SWITCH” on the shredder as soon as you are finished.

Remove elect ric plug from recept acle if shr edder will not be used for an ext ended

period.

OPERATING INSTRUCTIONS

Page 7

Product Destruction Specifications:

Input: Bottles up to 4 1/4” Wide x 3” Deep

or

3” Diameter x 5” Tall

Pressure sensitive labels: 8-1/2” x 11” paper

Output: Destruction will be limited to a maximum of 1/8” x 1-1/2” strips

Construction Specifications:

Drive System: Drive motor with heavy duty 87:1 cycloid gear reducer & #50 chain

final drive

Cutters: 1/8” wide ground and hardened tool steel

Collection System: 12 1/2 gallon disposable collection bag with sealed collection

chamber & HEPA filtration system for dust

Cabinet: Laminated 3/4” board with Melamine laminate

Electrical System Specifications:

Power Requirements: Single Phase, 20Amp, 120VAC

Control system: Illuminated Power On Light, Emergency Stop Switch, Forward

Switch, Reverse Switch, Full Bag Indicator

EQUIPMENT SPECIFICATIONS

Page 8

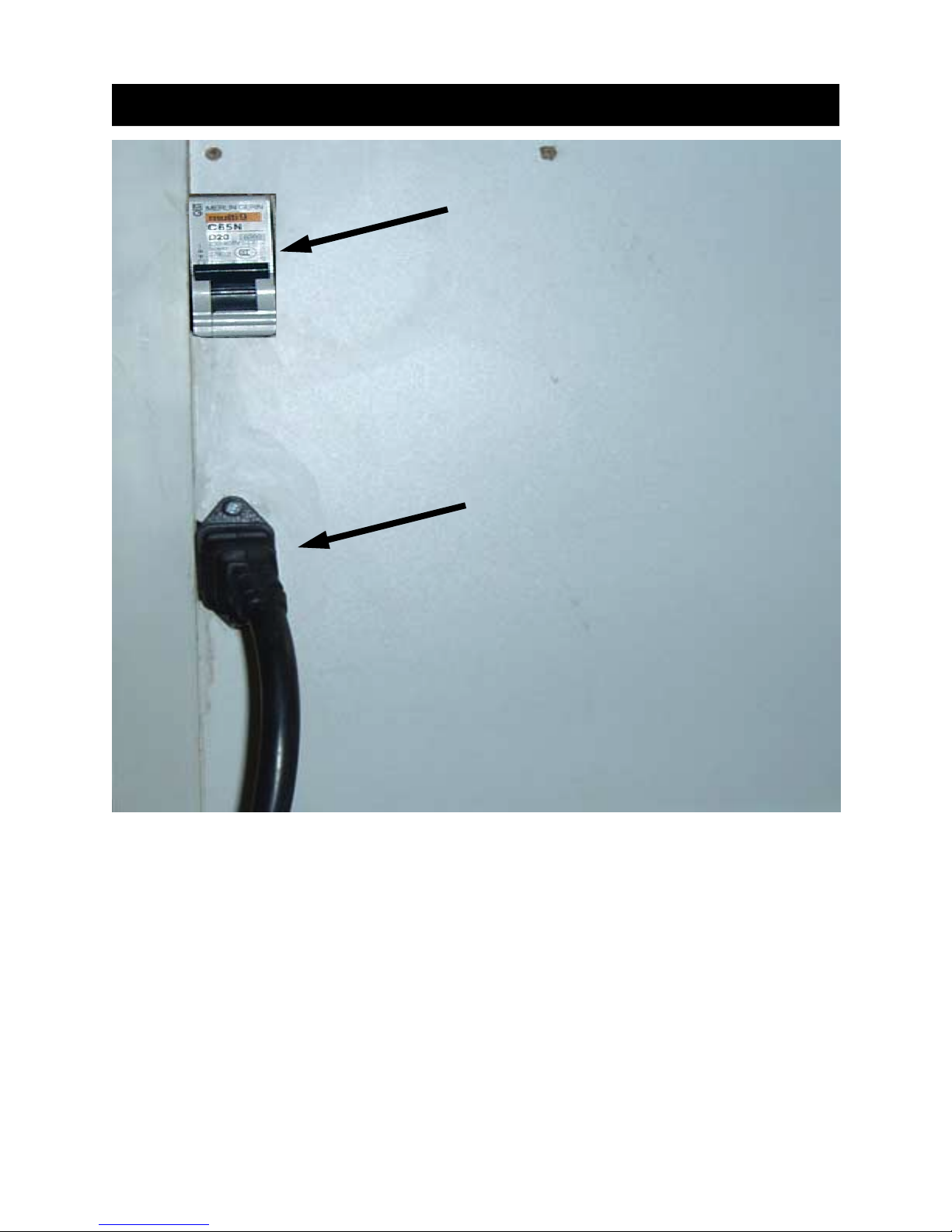

ELECTRIC SAFETY SWITCH

CIRCUIT BREAKER:

Located on rear panel, near

the bottom.

POWER CORD

Page 9

WARNING: Only authorized personnel should perform these functions.

DANGER: Unplug the shredder before doing any maintenance.

•

Inspect d oor sw itch, power c ord, a nd elec trical c ontrols a nd m ake sure t hey a re

functioning properly and in good condition.

•

Inspect HEPA filt er. Replace after 6 t o 12 months depending on usage or when it

appears full of debris.

•

Keep the disposal area clean and free of paper scraps.

•

Use the disposal bags specially designed for this unit.

KNIFE CARE:

Your shredder knives should be oiled weekly under normal use and circumstances.

OIL YOUR RX SHREDDER CUTTING HEAD:

1. Unplug the shredder power cord from power outlet, before doing any maintenance.

2. Apply a th in laye r of shredder lu bricant through th e paper fe eding s lot, movin g

from one side to the other.

3. Reconnect electric power cord of shredder, to power outlet.

4. Press and hold the “REVERSE Switch” for 10-15 seconds to allow the o il to spread

over the cutting head.

5. Shred a few sheets of paper to remove any excess oil.

OIL YOUR RX SHREDDER GEARS AND CHAIN:

1. Unplug the shredder power cord from power outlet, before doing any maintenance.

2. Open the clean-out access door and inspect the cutting mechanism for any residue

buildup. Clean any debris that may cause clogging.

3. Spray Marathon Shredder Lubricant on the chain drive and gear once a month.

4. Reconnect electric power cord of shredder in power outlet.

FULL COLLECTION BAG REMOVAL:

1. Press and hold “Forward Switch” to finish shredding any paper left in the feed slot.

2. Press “Emergency St op Swit ch” i t sho uld illumina te a nd display “ST OP” inside

bu tton.

3. Open “Collection Bag Access Door” and slide out the collection bag.

4. Fold bag along crease on bag.

5. Peel off paper covering adhesive strips and fold top flaps together to seal bag.

6. Insert new bag into chamber and continue shredding.

MAINTENANCE DIRECTIONS

Page 10

MAINTENANCE PICTURES

ACCESS DOOR

SAFETY SWTICH

HEPA

FILTER

COLLECTION BAG

MAGNET LATCH

FOR ACCESS DOOR

CHAIN AND

SPROCKET

GEAR

DRIVE

Page 11

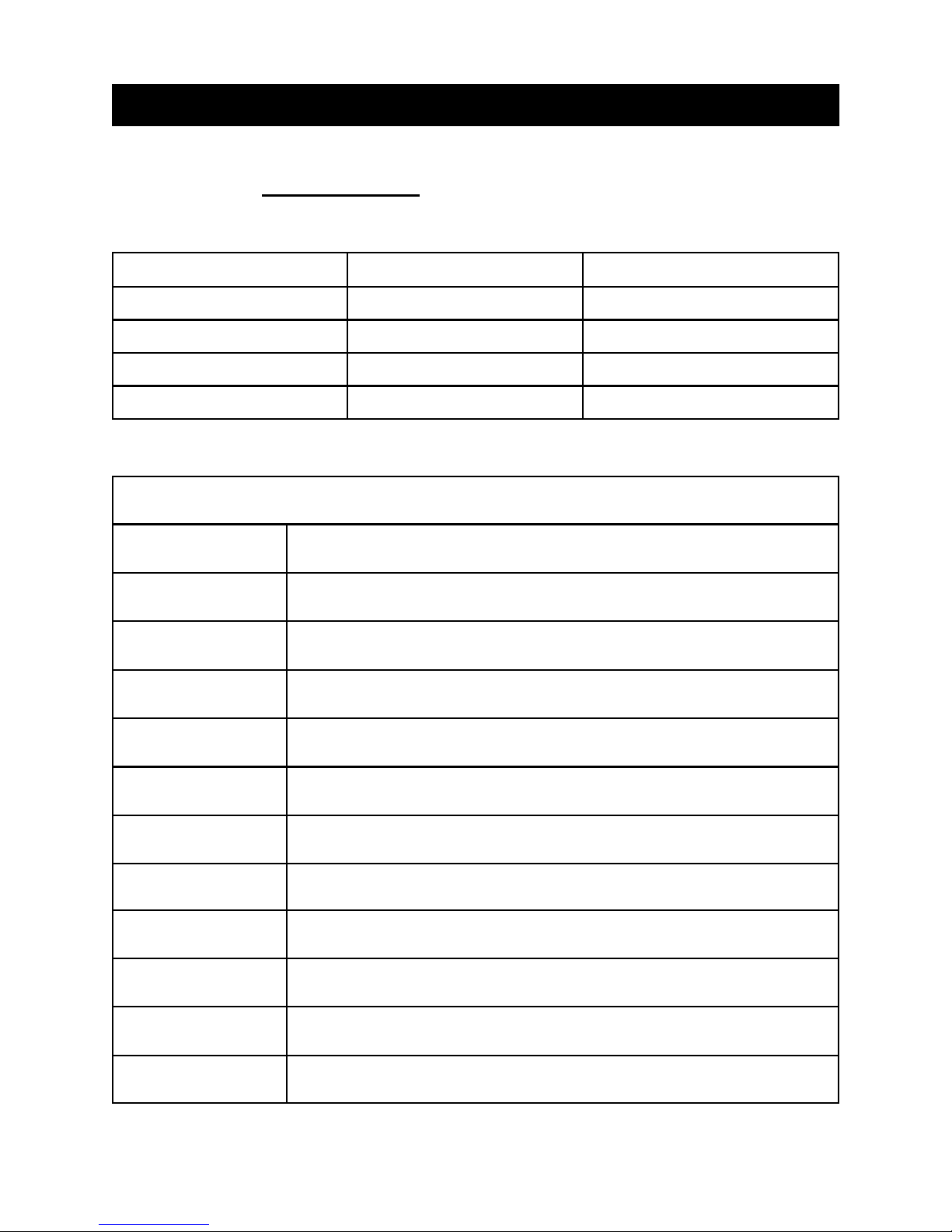

MALFUNCTION PROBLEM SOLUTION

Shredder won’t operate No electrical power to unit Plug shredder cord into

electric receptacle

Thermal overload could

be tripped

Check thermal overload on

rear of cabinet

Emergency Stop Switch is

in wrong position or

illuminated

Depress “Emergency Stop

Switch” light should turn off

and shredder should

operate

Collection bag is full Remove and replace bag

“Emergency Stop Switch”

is flashing

Collection bag is full

Shredder will not operate

in automatic mode

Shredder operates only

with manual switches

Photo eye needs cleaned,

adjusted or replaced

Shredder reverses

continuously

Shredder jam proximity

switch is faulty or out of

adjustment

Adjust or replace proximity

switch

Shredder will not reverse Shredder jam proximity

switch is faulty or out of

adjustment

Adjust or replace proximity

switch

TROUBLE SHOOTING GUIDE

Page 12

INSTALLATION INSTRUCTIONS

1. Shredder is shipped on a metal skid and wrapped with continuous sheets and

stretch film. Remove all strapping and protective covering.

2. The shredder is also shipped with a set of casters bolted to the bottom of the

shredder. However the unit must be lifted out of the skid so that the rollers can

make contact and allow the shredder to be rolled into place.

3. The power cord and replacement bags are shipped inside the bag access door.

4. Roll the shredder into it’s desired location. It should be placed within 5’ of a 20

amp 120 volt electrical receptacle. NOTE! It is recommend that it be placed on a

separate circuit for optimum performance. Do not plug into an electrical circuit that

also powers sensitive electrical equipment such as computer, printer, cash register.

5. Plug the power cord into shredder and then to the desired receptacle.

6. Turn the electrical switch at the rear of the shredder to the on position.

7. Refer to the operator instructions in the operation section of the manual.

Page 13

PARTS ORDERING INFORMATION

To purchase supplies, please call our parts department at 1-800-634-8981 .

Please have your SERIAL NUMBER on hand when you call.

ITEM QU ANITY PART NUMBER

Lubricant

Bag for Rx Shredder 1 05-4643

Bags for Rx Shredder 5 577399

PART # DESCRIPTION

03-4738 I nterlock Switch

06-2812 Interlocking Door Handle

06-2832 Cover Plate 2 x 4 x 42 3/16 16 GA

06-2833 Door Chute Plate 1 7/16 x 26 9/16 16 GA

06-2834 1 3/32 x 7 1/8 16 GA Door Chute

06-2835 Paper Chute 3 9/16 x 11 7/8

06-2836 3 x 9 7/8 16 GA

06-2980 Dec al Kit

PARTS LIST

06-2991 Collection Bag Access Door

Page 14

NOTES

Table of contents