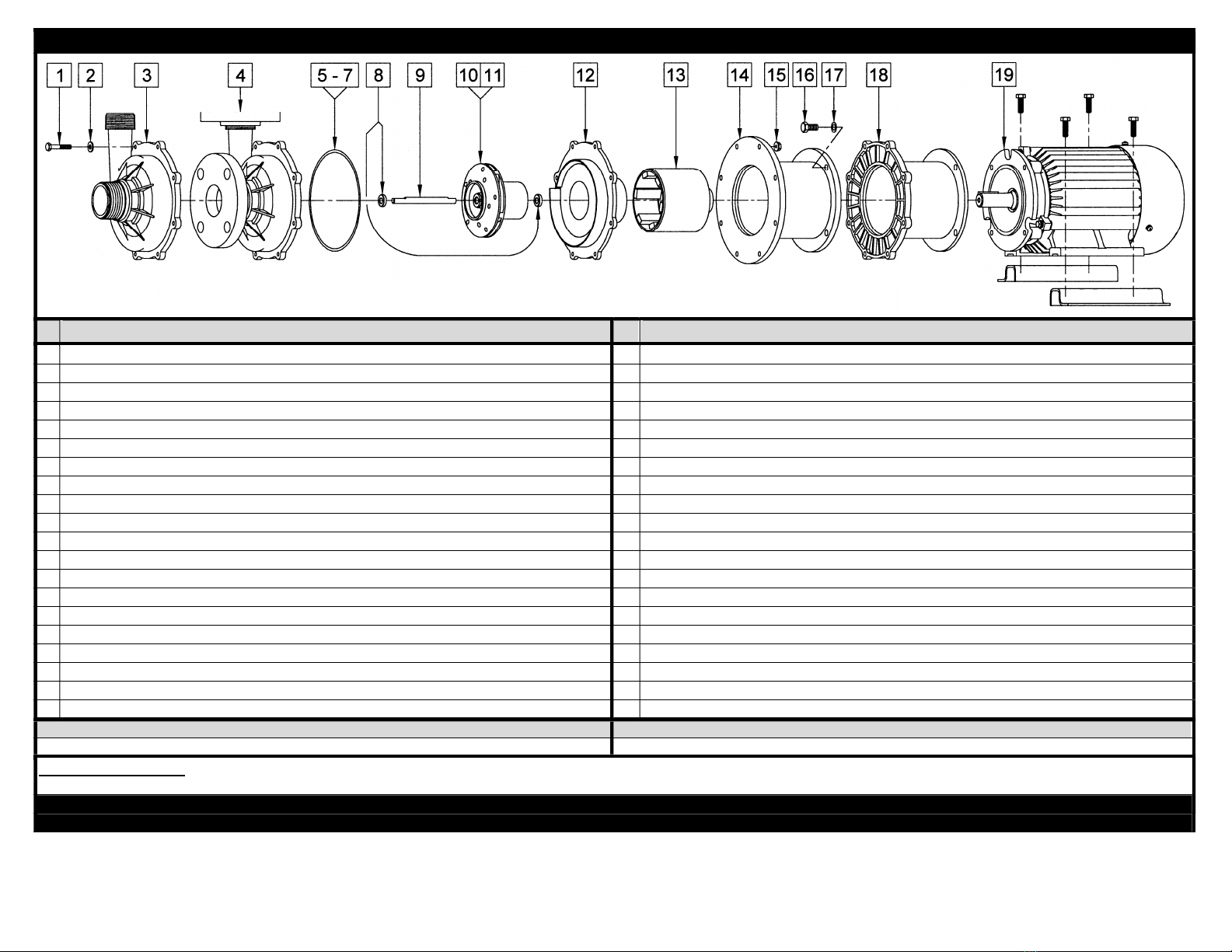

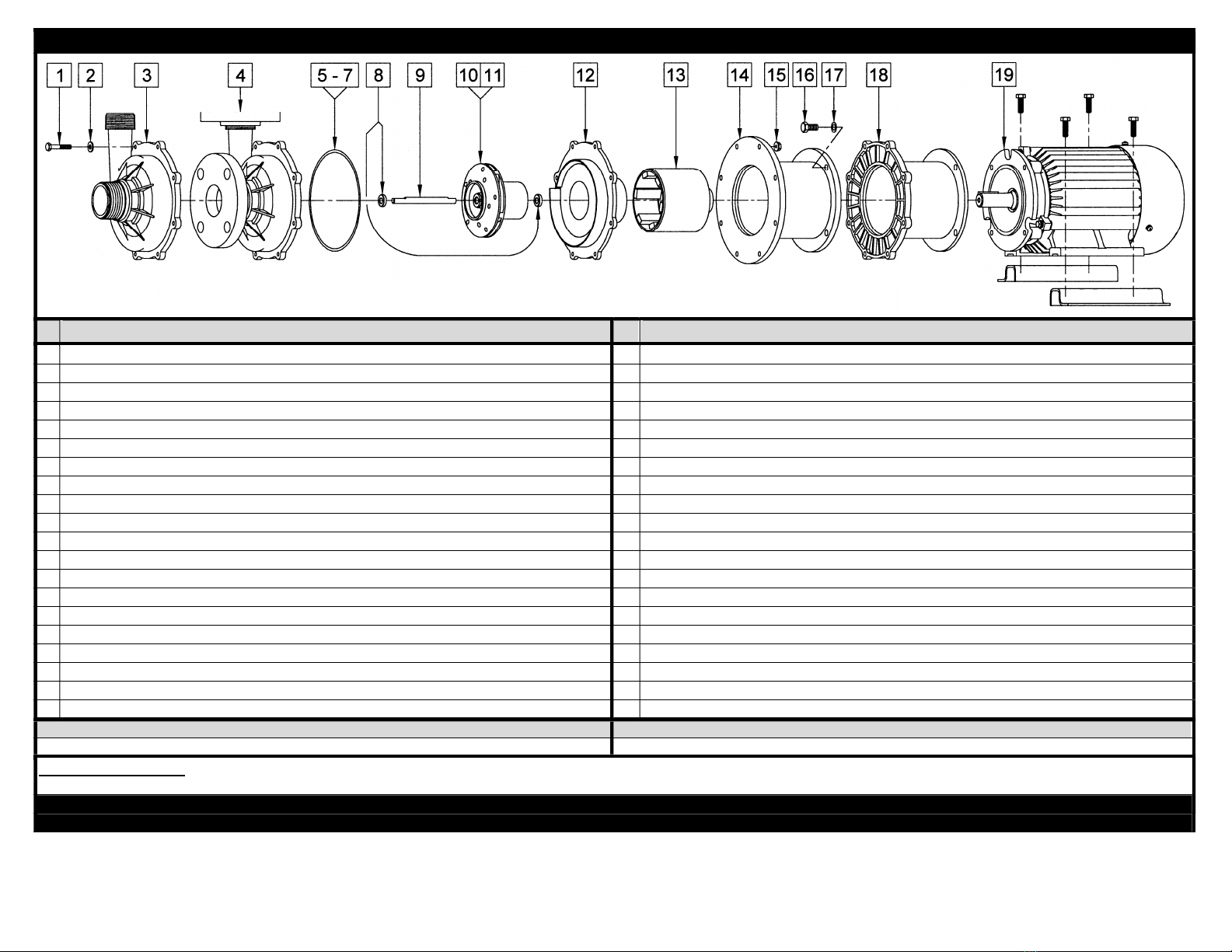

1

0153-0011-1000 | 8 | 1/4”-20 x 1-1/2” Lg. Screw (Stainless Steel) 1 0153-0011-1000 | 8 | 1/4”-20 x 1-1/2” Lg. Screw (Stainless Steel)

2

0157-0023-1000 | 8 | 1/4” ID x 5/8” OD Washer (Stainless Steel) 2 0157-0023-1000 | 8 | 1/4” ID x 5/8” OD Washer (Stainless Steel)

3

0156-0001-1000 | 1 | Front Housing (Natural Kynar) 3 0156-0060-1000 | 1 | Front Housing (Polypropylene)

4

0156-0029-0100 | 1 | Front Housing with Flanges (Natural Kynar) 4 0156-0068-0100 | 1 | Front Housing with Flanges (Polypropylene)

5

0156-0010-1000 | 1 | 0.157” CS x 6.457” ID “O” Ring (Viton) 5 0156-0010-1000 | 1 | 0.157” CS x 6.457” ID “O” Ring (Viton)

6

0156-0023-1000 | 1 | 0.157” CS x 6.457” ID “O” Ring (Viton/Teflon) – Option

7

0156-0034-1000 | 1 | 0.157” CS x 6.457” ID “O” Ring (EPDM) – Option 7 0156-0034-1000 | 1 | 0.157” CS x 6.457” ID “O” Ring (EPDM) – Option

8

0156-0016-1000 | 2 | Front & Rear Thrust Washer (Ceramic) 8 0156-0016-1000 | 2 | Front & Rear Thrust Washer (Ceramic)

9

0156-0007-1000 | 1 | 4.500” Lg. Shaft (Ceramic) 9 0156-0007-1000 | 1 | 4.500” Lg. Shaft (Ceramic)

10

0156-0004-0200 | 1 | Impeller w/Carbon Bushing (Natural Kynar) 10

0156-0064-0200 | 1 | Impeller w/Carbon Bushing (Polypropylene)

11

0156-0004-0300 | 1 | Impeller w/Mica Teflon Bushings (Natural Kynar) – Option

11

0156-0064-0300 | 1 | Impeller w/Mica Teflon Bushings (Polypropylene) – Option

12

0156-0002-1000 | 1 | Rear Housing (Natural Kynar) 12

0156-0061-1000 | 1 | Rear Housing (Polypropylene)

13

0156-0009-0100 | 1 | Drive Magnet 13

0156-0009-0100 | 1 | Drive Magnet

14

0156-0073-0010 | 1 | Motor Bracket (Aluminum) 14

0156-0073-0010 | 1 | Motor Bracket (Aluminum)

15

0156-0053-1000 | 8 | 1/4”-20 Hex Nut (Stainless Steel) 15

0156-0053-1000 | 8 | 1/4”-20 Hex Nut (Stainless Steel)

16

0155-0017-1000 | 4 | 3/8”-16 x 1” Lg. Screw (Stainless Steel) 16

0155-0017-1000 | 4 | 3/8”-16 x 1 Lg. Screw (Stainless Steel)

17

0155-0019-1000 | 4 | 3/8” ID x 5/8” OD Washer (Stainless Steel) 17

0155-0019-1000 | 4 | 3/8” ID x 5/8” OD Washer (Stainless Steel)

18

0156-0041-1000 | 1 | Motor Bracket (Plastic) – Option 18

0156-0041-1000 | 1 | Motor Bracket (Plastic) – Option

19

0156-0092-0100 | 1 | 3 Phase TEFC Motor,

2 HP, 230/460 V, 50/60 Hz

19

0156-0092-0100 | 1 | 3 Phase TEFC Motor,

2 HP, 230/460 V, 50/60 Hz w/Bolts & Rails

W

0156-0031-0100 | 1 | Wet End Kit (Items: 1, 2, 3, 5, 8, 9, 10, 12) W

0156-0066-0100 | 1 | Wet End Kit (Items: 1, 2, 3, 5, 8, 9, 10, 12)

Materials in Contact With Solution:

Materials in Contact With Solution:

Natural Kynar (PVDF), Ceramic, Viton, Carbon Polypropylene, Ceramic, Viton, Carbon

LIMITED WARRANTY: March pumps are guaranteed only against defects in workmanship or materials for a period of one year from date of manufacture

pumping water. For the complete

warranty and to register online go to www.marchpump.com/warranty-registration

Explosion proof and special voltage motors are available upon special order.

NOTE: Contact Factory for other materials and/or parts not listed.

0156-0015-1200