ENG

7

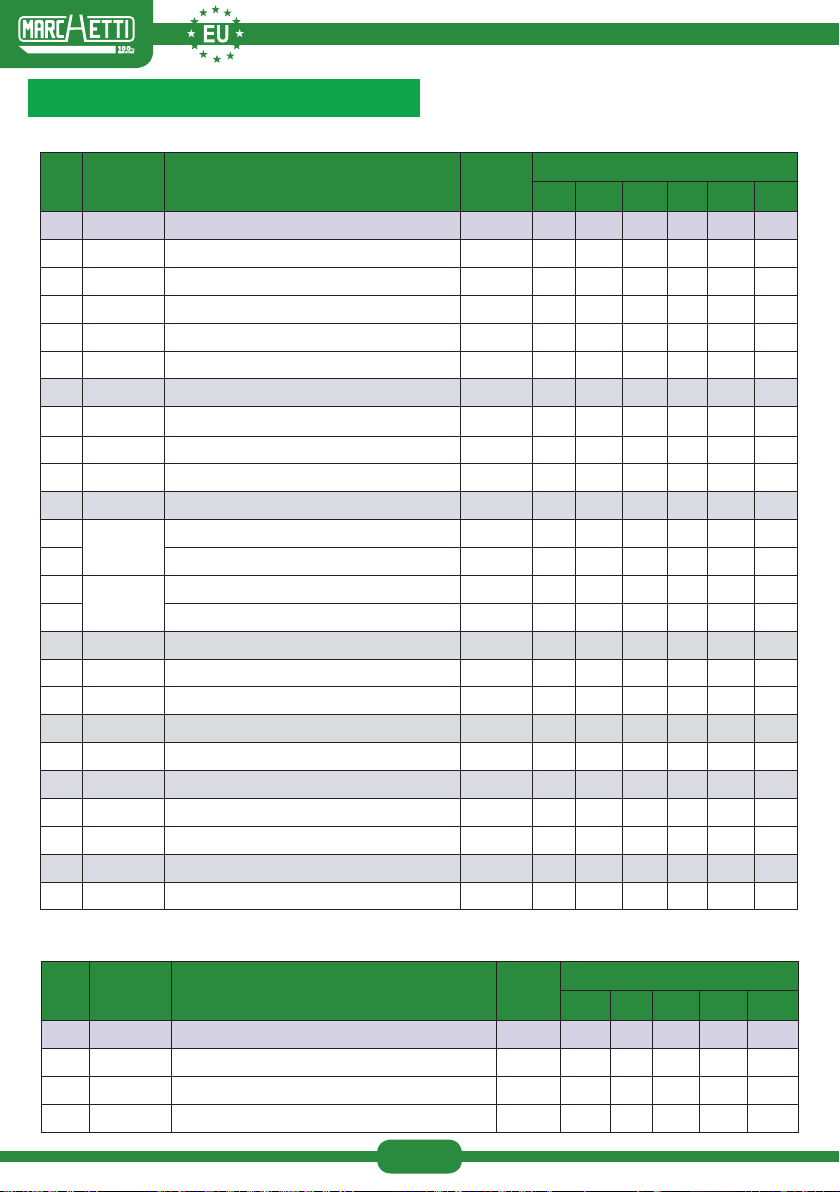

Cod. Component Elements Weight

Kg

CONFIGURATIONS

A1 A2 A3 A4 A5 B6 B7 B8

20580 EXTRACTABLE BASE

1 20551 Wheel-bearing section for extr. Base S120 12,70 1 1 1 1 1 1 1 1

2 20550 Wheel-bearing section for extr. Base S120 12,60 1 1 1 1 1 1 1 1

3 20554 Base brace - 180 6,00 2 2 2 2 2 2 2 2

4 20318 Extractable adjustable foot 3,50 4 4 4 4 4 4 4 4

5 30523 Handgrip screw M14x50 0,14 4 4 4 4 4 4 4 4

20584 TOWER

10 20556 Bearing frame - 120 9,50 2 4 6 8 10 12 14 16

11 20562 Connecting brace - 180 3,50 2 4 6 8 10 12 14 16

12 20566 Diagonal bracing - 180 1,20 4 8 12 16 20 24 28 32

21077 WORK PLATFORM - STEEL

24

21086

Platform w/trapdoor - 180x51 13,74 1 1 1 2 2 2 3 3

26 Long toeboard - 180 3,55 2 2 2 4 4 4 6 6

25 21087 Platform w/out trapdoor - 180x51 13,64 1 1 1 2 2 2 3 3

27 Short toeboard - 180 1,59 2 2 2 4 4 4 6 6

20749 COMPLETE GUARDRAILS

17 20631 Long guardrail - 180 5,10 2 2 2 2 2 2 2 2

18 20784 Short guardrail - 120 2,30 2 2 2 2 2 2 2 2

GUARDRAIL BARS

28 20600 Guardrail bar - 180 1,95 0 0 0 2 2 2 4 4

20753 COMPLETE STABILIZERS

19 20765 Stabilizers - 35 9,80 0 0 4 4 4 4 4 4

20 31383 Stabilizers coupler for round tube- 35 1,00 0 0 8 8 8 8 8 8

21557 COMPLETE STABILIZERS

19 21557 Telescopic Stabilizer - 35 6,25 0 0 4 4 4 4 4 4

Table of elements composing the congurations

IDENTIFICATION SYSTEM 120X180

For congurations with H=0,90 m terminal riser A1T-A2T-A3T-A4T-A5T-B6T-B7T, add the following elements:

Cod. Component Elements Weight

Kg

CONFIGURATIONS

A1T A2T A3T A4T A5T B6T B7T

20586 TOWER

21 20557 Bearing frame - 120 5,80 2 2 2 2 2 2 2

11 20562 Connecting brace - 180 3,50 2 2 2 2 2 2 2

22 20567 Terminal diagonal bracing - 180 1,10 4 4 4 4 4 4 4