MarineTech TrollMaster Series User manual

MERCURY – TILLER ONLY 15 & 20HP

2008-2009

TrollMaster is a precision throttle control designed to achieve the maximum in trolling speed

accuracy. The memory feature included in this control will allow returning to the best fishing

speed time and time again. Whether you are pulling your bait or back trolling, TrollMaster is

the answer to your speed control needs. Spend your time trolling, not going to the motor to

adjust the speed.

CALL: 866-228-7655

EMAIL: info@marinetechproducts.com

MAIL: - NEW$ADDRESS$AS$OF$MARCH$1ST,$2013$

MARINETECH PRODUCTS, INC.

TROLLMASTER

1360 EAST COUNTY ROAD E

VADNAIS HEIGHTS, MN 55110

PHONE: 651-486-2010

FAX: 651-486-6989

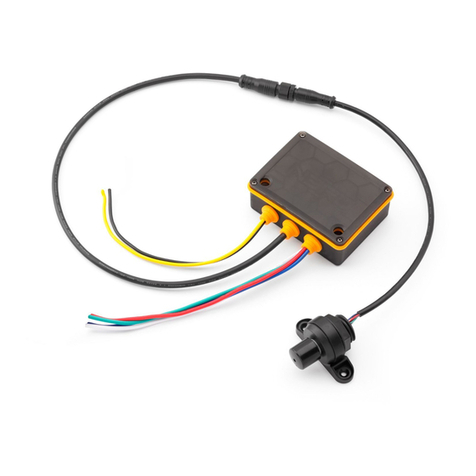

The servo motor pictured above is the old style servo motor. You will see

the old style servo motor pictured in the installation manual photos but we

have since upgraded to the TM-MG1 servo motor. You will receive the TM-

MG1 servo motor in your Trollmaster hardware kit. When installing your

servo motor follow the directions for your application and use the brass

barrel connector with the phillips head screw in it as your alignment point

when you set the position of the servo arm. See; Set The Servo Arm for

further instruction on how to install your servo motor properly.

Replacement servo motors are available for the Hitec HS322HD (shown

above) and the SG-5010 (not shown)

To purchase call MarineTech Products, Inc. PH: 866-228-7655

1.

Place a towel under the throttle mechanism to prevent dropped parts

from being lost.

2. Remove

top intake

bolt.

3. Place the bolt provided with your kit, through the servo bracket and

place the spacers on the bolt behind the bracket.

4. Mount the

servo in the

top intake bolt

hole. Make

sure the front

of the bracket

is in contact

with the

manifold.

5. Loosen the set screw at the brass piece on the carburetor and remove

the throttle rod.

6. Place the

loop in the

TrollMaster

cable over the

brass fitting and

replace the

Mercury

Throttle Rod.

7. Adjust the loop in the Mercury throttle rod as shown.

9. Place the servo arm with the brass piece aligned to 6 o’clock. Loosen the

set screw at

the brass

connector

on the servo

arm. Pull

the cable to

remove the

slack and

secure the

cables to the

arm

connector.

CAUTION: Make sure the throttle remains closed. Pull the cable tight

to remove slack. Then place the swedge provided over the cable behind

the brass connector and crimp in place.

10. Make a small slit in the rubber plug for the control cable connector

to pass through. Install the cable and secure with the tie straps provided.

Connect the servo to the cable.

Connecting to a power source:

It is recommended that you install a two-amp fuse on the positive power lead

of the PRO and PRO2 models before connecting to a power source. Connect

the two amp fused Red wire to +12 volts DC and the Black wire to -12

volts DC. For PRO3 models connect the RED wire to +12 volts DC and the

Black wire to -12 volts DC. PRO3 models come with a thirty (30) amp fuse

installed.

Connecting the servo:

Connect the servo cable to the control cable with the brown wire aligned to

the white mark on the control cable plug. After the servo is plugged in, move

on to set the servo arm.

Set the servo arm:

Power the unit ON and leave the unit in IDLE mode. By removing the

Phillips head screw that holds the servo arm on the servo body you can

remove the servo arm by pulling it off of the servo body. Adjust the servo

arm to be in the position as shown in the installation manual photos and

place the servo arm back on the servo body and return the Phillips head

screw to its original location to hold the servo arm in place.

Testing the controller:

You do not have to run your outboard motor to test the TrollMaster unit.

Test the controller by powering the unit on and press the IDLE button to put

the unit into RUN mode. By turning the control knob with a clockwise

rotation the servo should move the carburetor from IDLE to FULL

THROTTLE.

NOTE: Full throttle can be adjusted by changing the position of the servo

arm on the servo motor.

Troubleshooting:

If you should encounter an issue with your TrollMaster use these tips to

determine the best course of action to resolve the issue.

Problem: The unit powers on and the display functions properly, your

buttons show function on the screen and the numbers increase when turning

the speed adjustment knob but there is no response from the servo motor.

Solution: Verify the servo motor is plugged in accordingly with the brown

wire aligned with the white mark on the control cable plug and test again. If

there is still no response, replace the servo motor with a new one and test

again. If after replacing the servo motor and testing again there is still no

response contact MarineTech Products Inc. 866-228-7655 to have the unit

inspected at our facility.

Problem: The unit powers on works momentarily then powers off. The unit

will not stay powered on.

Solution: Check your battery voltage; if the battery voltage is low the unit

will not operate properly. When in doubt charge your battery to ensure there

is enough voltage to operate the TrollMaster unit to its fullest potential. If

the battery is fully charged and the unit is still not operating properly contact

MarineTech Products, Inc. 866-228-7655 to have the unit inspected at our

facility.

If you need assistance with Troubleshooting contact MarineTech

Products, Inc. For tech support. Call 866-228-7655

TrollMaster Replacement Parts:

TrollMaster Servo Motor (TM-MG1)

Note: A Servo Arm is included with the purchase of a replacement Servo

Motor.

TrollMaster Servo Arm (TM-Servo Arm)

Note: A replacement screw to mount the Servo Arm to the Servo Body is

included with the purchase of a replacement Servo Arm.

TrollMaster Hardware Kit (TMXXXHRDWRKIT)

Note: Replace the XXX with the Kit number that applies to your outboard

motor. See the Application Guide for kit number.

Example: TM206HRDWRKIT.

TrollMaster Electronics Unit Only (TMXXXXUNITONLY)

Note: Replace the XXXX with the model of Replacement TrollMaster

Electronics you wish to purchase. Comes with controller and wiring only,

does not include servo motor or hardware kit.

Examples: TMPROUNITONLY, TMPRO2UNITONLY,

TMPRO3UNITONLY.

To Order Replacement Parts:

If you would like to order any of the above mentioned replacement parts

check with your local retailer, if they do not have the item in stock they can

order it for you or you can order directly from MarineTech Products, Inc.

For pricing and availability call MarineTech Products, Inc. 866-228-7655

Installation Guides:

The installation Guide on this disk can also be found online at MarineTech

Products website, visit: www.marinetechproducts.com and follow the

TrollMaster link to the TrollMaster page where you will find the Installation

Guides for every motor we make a kit to fit. The Application Guide is also

on the same web page; the Application Guide shows the full list of motors

we make kits to fit with the product part numbers for those kits.

SERVICE'AND'WARRANTY

Should'your'unit'ever'require'service'please'do#not#return#the#product#to#your#dealer.#

Instead'call'the'number'below'for'special'instructions'on'shipping'and'handling.'Be'sure'to'call'

between'9'00'AM'and'4.00'PM'(Central'Time)'Monday'through'Friday.'If'the'service'required'is'

covered'by'the'warranty,'it'will'be'repaired'or'replaced'as'described'below.'If'the'service'

required'is'NOT'covered'by'warranty'replacement'parts'are'available'for'purchase'and'paid'for'

by'a'major'credit'card.

The'warranty'coverage'on'this'equipment'is'limited'to'the'terms'set'forth'below:

MarineTech'Products,'Inc.'warrants'this'product'to'be'free'of'defects'in'material'and'

workmanship'for'a'period'of'ONE'(1)'YEAR'from'the'date'of'original'retail'purchase.'Positive'

proof'of'date'of'purchase'is'required'for'warranty'service.'If'the'service'required'is'covered'by'

warranty,'you'must#obtain'a'Return#Authorization#number'from'MarineTech'Products.'The'

unit'will'be'repaired'or'replaced'with'new'or'factory'rebuilt'parts'at'no'charge.'The'defective'

components'must'he'returned'to'the'address'specified,'with'shipping'charges'prepaid.'Be'sure'

to'include'your'name,'address,'telephone'number'and'a'copy'of'the'sales'receipt'showing'the'

date'of'original'retail'purchase.'All'sales'receipts'are'subject'to'verification.

This'warranty'does'not'apply'if'the'unit'has'been'damaged'by'accident,'abuse,'misuse,'poor'

installation'or'misapplication,'or'if'It'has'been'modified'from'its'original'condition,'or'if'any'

serial'number'has'been'removed'or'defaced'or'altered.'This'warranty'does'not'cover'any'

expense'to'remove'or'reinstall'the'unit'or'any'of'its'components.'If'a'returned'unit'is'not'

covered'by'warranty,'the'sender'will'he'notified'and'given'an'estimate'of'the'charges'to'repair'

or'replace'the'unit'together'with'the'return'shipping'charges.

THIS'WARRANTY'DOES'NOT'COVER'SPECIAL,'INCIDENTAL,'OR'CONSEQUENTIAL'

DAMAGES'RESULTING'FROM'ANY'BREACH'OF'WARRANTY,'OR'UNDER'ANY'OTHER'

LEGAL'THEORY,'INCLUDING'BUT'NOT'LIMITED'TO'DAMAGE'TO'OR'REPLACEMENT'OF'

OTHER'EQUIPMENT'AND'PROPERTY.'THE'WARRANTY'AND'REMEDIES'SET'FORTH'ARE'

EXCLUSIVE'AND'IN'LIEU'OF'ALL'OTHERS,'WHETHER'ORAL'OR'WRITTEN,'EXPRESS'OR'

IMPLIED.'DUE'TO'THE'SPECIAL'AND'UNIQUE'CONDITIONS'THAT'MAY'EXIST'IN'EACH'

APPLICATION,'THE'MANUFACTURER'SPECIFICALLY'DISCLAIMS'ANY'AND'ALL'IMPLIED'

WARRANTIES'OF'MERCHANTABILITY'AND'FITNESS'FOR'A'PARTICULAR'PURPOSE.'NO'

DEALER,'AGENT'OR'EMPLOYEE'IS'AUTHORIZED'TO'MAKE'ANY'MODIFICATION,'

EXTENSION'OR'ADDITION'TO'THIS'WARRANTY.

Some'states'do'not'allow'exclusion'of'incidental'or'consequential'damages,'so'the'

above'exclusions'may'not'apply'to'you.'This'warranty'gives'you'specific'legal'rights,'and'

you'may'also'have'other'legal'rights,'which'may'vary'from'state'to'state.

FOR'SERVICE'CALL:'1'651'486'2010

This manual suits for next models

3

Table of contents