3

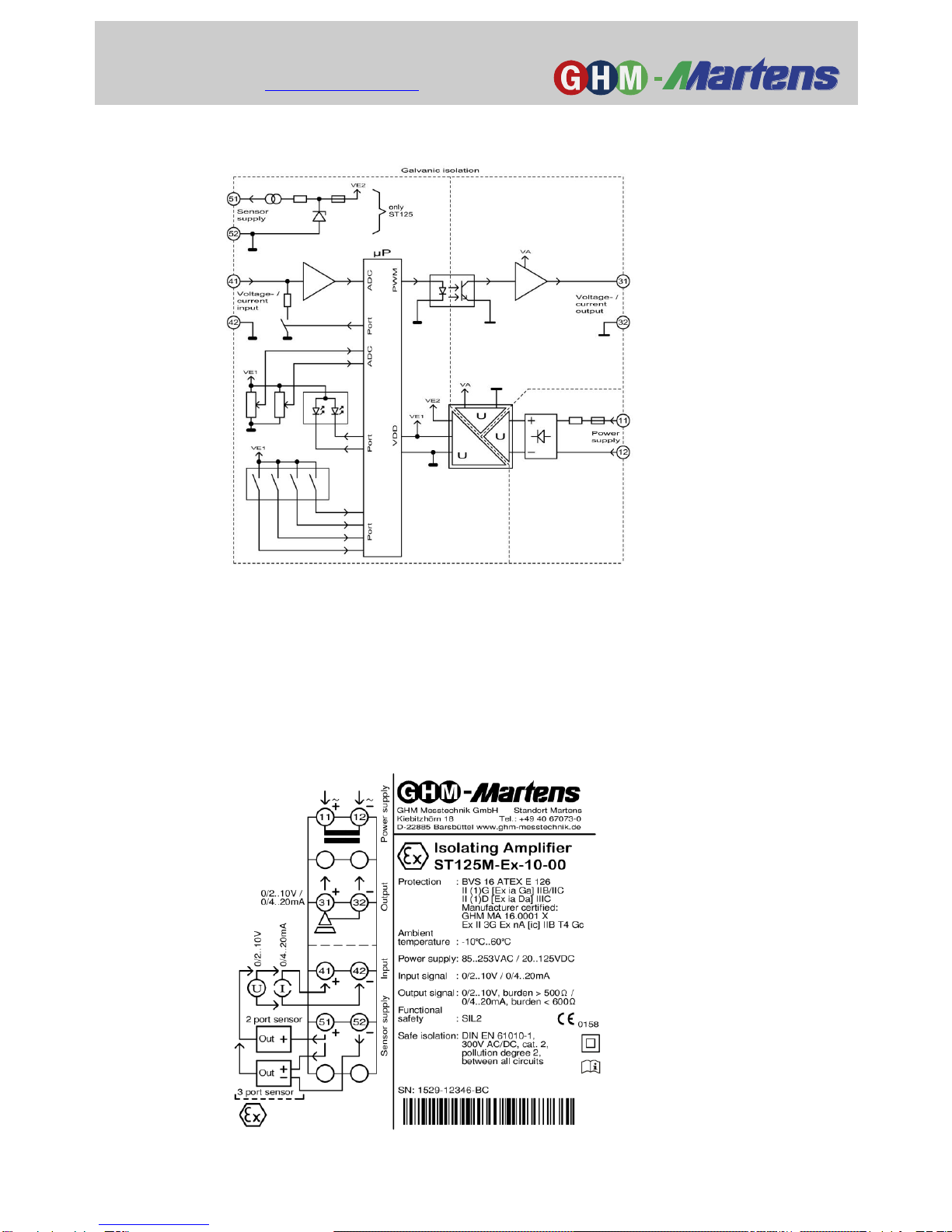

1 Intended use (areas of application)

Refer to the chapter 'Product description' for detailed specifications for

the area of application.

The operational safety of the device is only assured when used as in-

tended in accordance with the specifications in the operating manual.

Intervention beyond the actions described in the operating manual may only be car-

ried out by personnel authorised by the manufacturer for safety and warranty rea-

sons. Conversions or modifications made on one's own authority are expressly pro-

hibited.

Application-specific dangers can emanate from this device when used improperly or

not as intended.

Only device versions TV125M-Ex, TV125MP-Ex, ST125M-Ex and

ST125MP-Ex are permitted for use as operating equipment for connec-

tion of intrinsically safe sensors, installed in Zones 0 or 1 and/or 20

or 21.

All safety-relevant characteristic data must be observed in this connec-

tion.

The approval for all intrinsically safe operating equipment is voided if it

has been previously connected to non-intrinsically safe power circuit,

because compliance with the safety-relevant characteristic data cannot

be 100% guaranteed there.

Therefore, a safety test must be conducted by the manufacturer before

later use as an intrinsically safe operating device.

The device TV125MP-00, ST125MP-00 and all other versions of the

series TV****-Ex and ST****-Ex can be installed in the explosion-prone

Zone 2 under the following conditions:

- Installation in a clean environment in a conductive, earthed housing

(switch cabinet) with a minimum protection rating of IP54.

- Disconnection of connecting terminals only takes place in the

de-energised state

Basic standards: EN 60079-0 and EN 60079-15.

General safety instructions, use

This operating manual must be kept in a location such that qualified personnel can

refer to it at all times.

Any processes described in this operating manual may only be carried out by

trained, qualified personnel who are authorised by the owner and wearing protective

clothing. All rights reserved.