- 3 -

6. Keep people and animals away from working area

(minimum distance 15 meters).

If somebody should approach you, turn the engine off and

stop the blade (see section STARTING AND STOPPING

THE ENGINE), as during operation the blade or the nylon

string head might project grass, grit or other debris. The

blade is sharp. Be careful even if handling it when the

engine is off. Wear heavy-duty gloves. Turn the engine

off and wait for rotating parts to stop completely before

working on the machine or before touching the blade or

the string head.

DO NOT USE THE BRUSH CUTTER AT ALL, IF THE

SPECIFIED SAFETY GUARD IS NOT FIRMLY

ATTACHED (see sections SAFETY USAGE and

BLADES AND NYLON STRING HEAD ASSEMBLY).

Pay careful attention to any recommendations, as you

might put your life or somebody else’s in danger as a

result of:

a) possible contact with cutting or rotating parts,

b) possibility of projection of various objects

WARNING: Do not start engine if it is not attached to

the shaft, as the clutch might disintegrate.

[3] SAFETY USAGE

This product must be held to the right of the operator’s body.

This will exhaust fumes are directed away from the operator

and will not be obstructed by the operator’s clothing. If you

have not used a brush cutter before, spend some time in

becoming familiar with the controls and method of usage

before operation. Check the machine carefully before using

it. Make sure that there are no loosened screws, damaged

parts or fuel leakages. Replace damaged or excessively worn

accessories (blades, string heads, GUARDS).

Ensure all maintenance and repair work are carried out by an

authorized service center. Check the condition of the

antivibration components on a regular basis.

N.B. In order to maintain performance and safety, be sure to

use original spare parts and accessories. Avoid using the

brush cutter over excessively long periods of time.

Excessive amounts of vibration can be harmful.

Fig.2-6

Fig.3-1

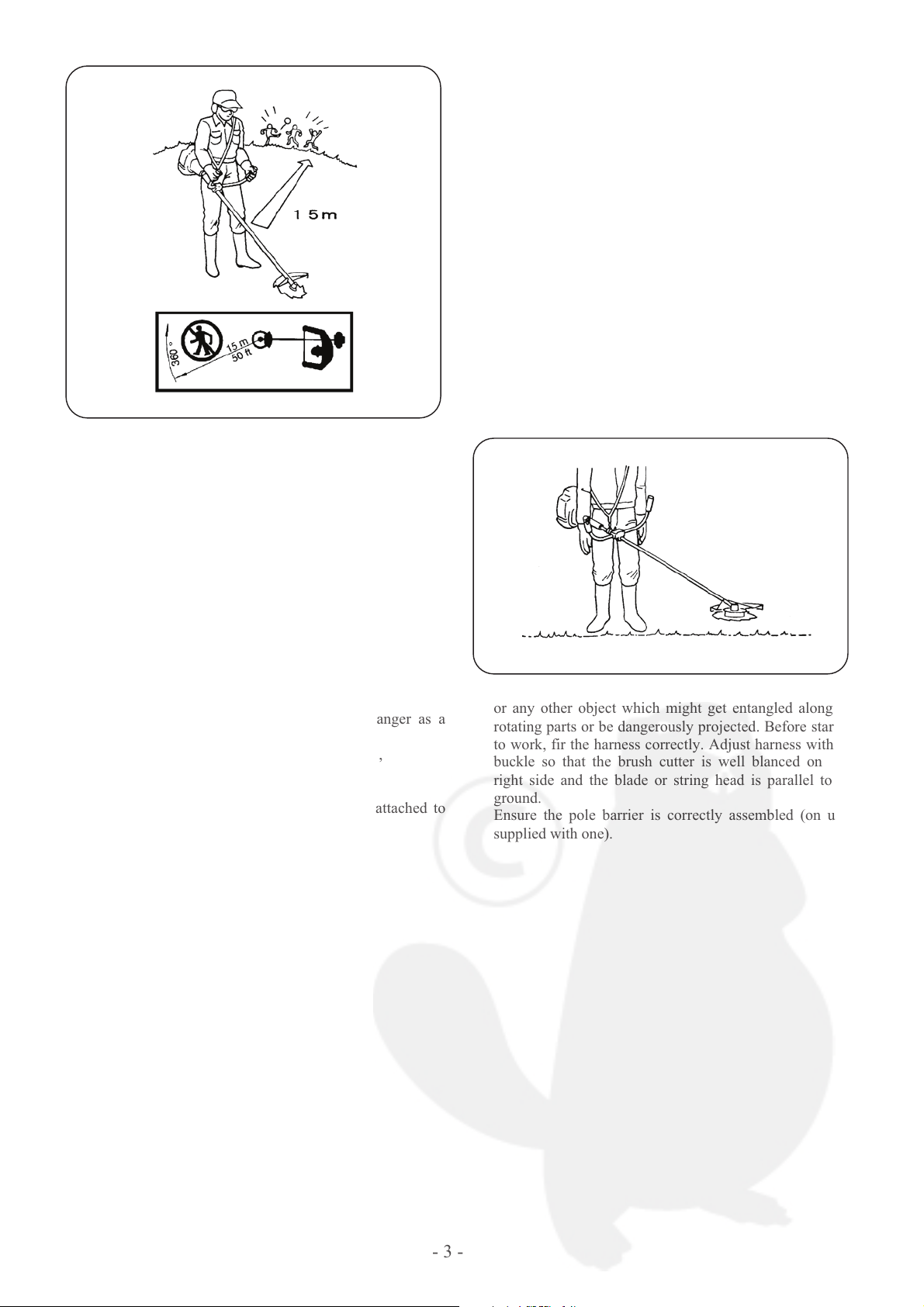

1. Remove from the work area grit debris ropes, metal parts

or any other object which might get entangled along the

rotating parts or be dangerously projected. Before starting

to work, fir the harness correctly. Adjust harness with the

buckle so that the brush cutter is well blanced on your

right side and the blade or string head is parallel to the

ground.

Ensure the pole barrier is correctly assembled (on units

supplied with one).