Marvel MLCR215-IS01B Application guide

OWNER’S GUIDE & SERVICE MANUAL

MARVEL UNDERCOUNTER REFRIGERATION

Model: MLCR215-IS01B

WELCOME

Welcome to the Marvel Experience!

Thank you for choosing our quality American-built product

to add to your home. We are thrilled to welcome you to

our growing community of Marvel owners, who trust in our

products and our support.

The information in this guide is intended to help you install

and maintain your new Marvel undercounter model to

protect and prolong its lifetime. We encourage you to

contact our Technical Support team at (616) 754-5601 with

any questions.

Got a Marvelous Design?

We would love to see how your Marvel product looks in its

new home. You can send us photos of your installed

might feature your Marvel home design on our website and

social media!

Online registration

available at

marvelrefrigeration.com

Warranty Registration

It is important you register your product warranty after

taking delivery of your appliance. You can register online at

www.marvelrefrigeration.com.

The following information will be

required when registering your

appliance:

Serial Number

Date of Purchase

Dealer’s name and address

The serial number can be found on the serial plate which is

located inside the cabinet on the left side near the top.

TABLE OF CONTENTS

Tip: Click on any section below to jump directly there

Safety

Important Safety Instructions

Installation

Unpacking Your Appliance

Electrical

Cutout & Product Dimensions

Side-by-Side & Stacking Installations

Installing the anti-tip device

Door Reversal

Integrated Panel Dimensions

Integrated Panel Installation

Installing The Water Supply

Maintenance

Care and Cleaning

Extended Non-Use

Operating Instructions

Ice Maker Operation

Service

Obtaining Service

Wire Diagram

Product Liability

Warranty Claims

Ordering Replacement Parts

R600a Specifications

System Diagnosis Guide

Defrost

Replace Ice Maker

Warranty

3

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution and

care must be exercised when installing, maintaining or

operating this appliance.

Recognize Safety Symbols,

Words and Labels

!WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!CAUTION

CAUTION -Hazards or unsafe practices which could

result in personal injury or property/product damage.

NOTE

NOTE -Important information to help assure a

problem-free installation and operation.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!WARNING

WARNING - This unit contains R600a (isobutane)

which is a ammable hydrocarbon. It is safe for

regular use. Do not use sharp objects to expedite

defrosting. Do not damage refrigerant circuit.

4

UNPACKING YOUR APPLIANCE

!WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding

internal components in place. The getting started guide is

shipped inside the product in a plastic bag along with the

warranty registration card and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condi-

tion. If there is any damage, the packaging will be needed

as proof of damage in transit. Afterwards, please dispose of

all items responsibly.

!WARNING

WARNING - Dispose of the plastic bags which can

be a suocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving out facility. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

NOTE

!CAUTION

If the appliance was shipped, handled or stored in other

than an upright position for any period of time, allow the

appliance to sit upright for a period of at least 24 hours

before plugging in. This will assure oil returns to the

compressor. Plugging the appliance in immediately may

cause damage to internal parts.

!WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous, even if they sit outside for “just a few hours”.

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take o the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

5

ELECTRICAL

Do not remove

ground prong

!WARNING

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any

• circumstances, be installed to an un-grounded

• electrical supply. Do not remove the grounding

prong from the power cord.

• Do not use an adapter.

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in

accordance with the National Electrical Code and

applicable local codes and ordinances. If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third-ground prong should not, under any

circumstances, be cut or removed.

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to

nuisance tripping which will cause the appliance to shut

down. GFCI’s are generally not used on circuits with power

equipment that must run unattended for long periods of

time, unles required to meet local building codes and

ordinances.

6

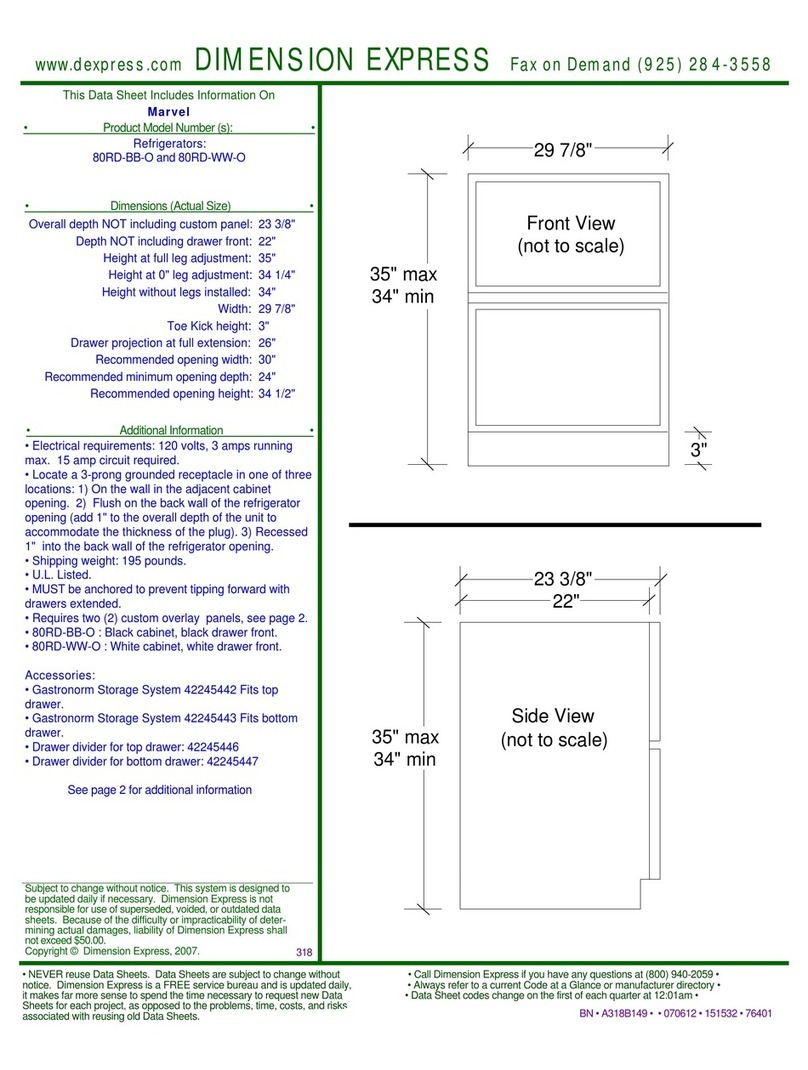

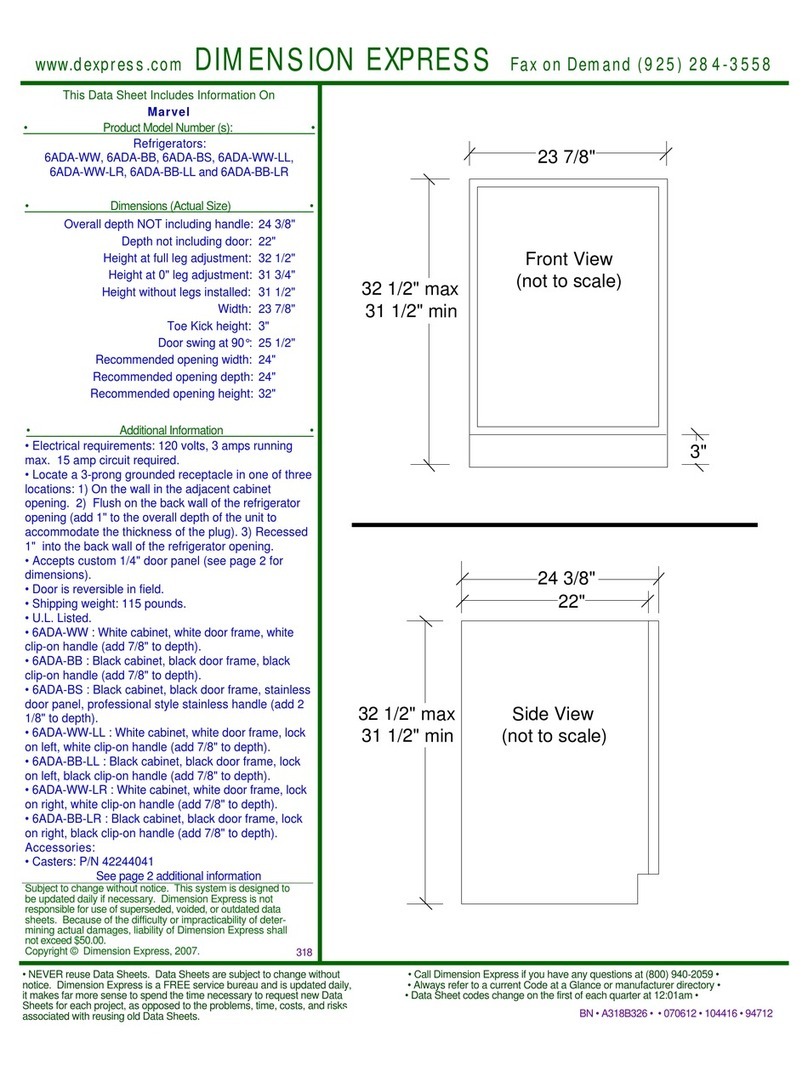

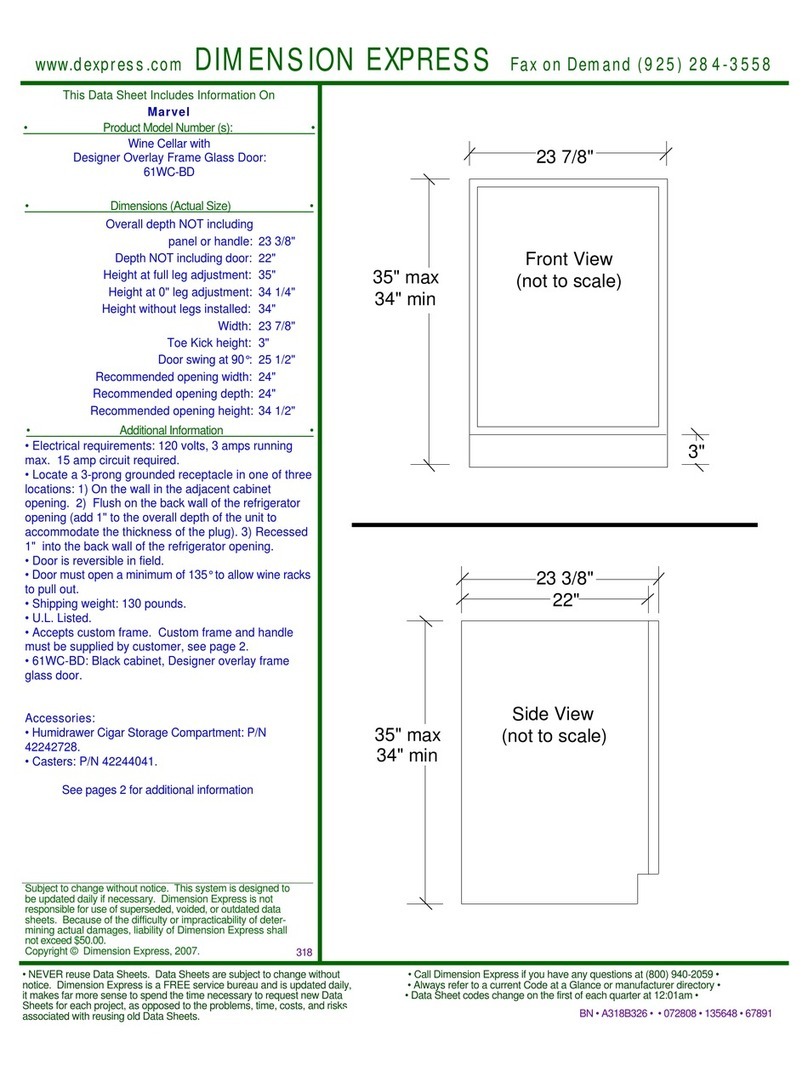

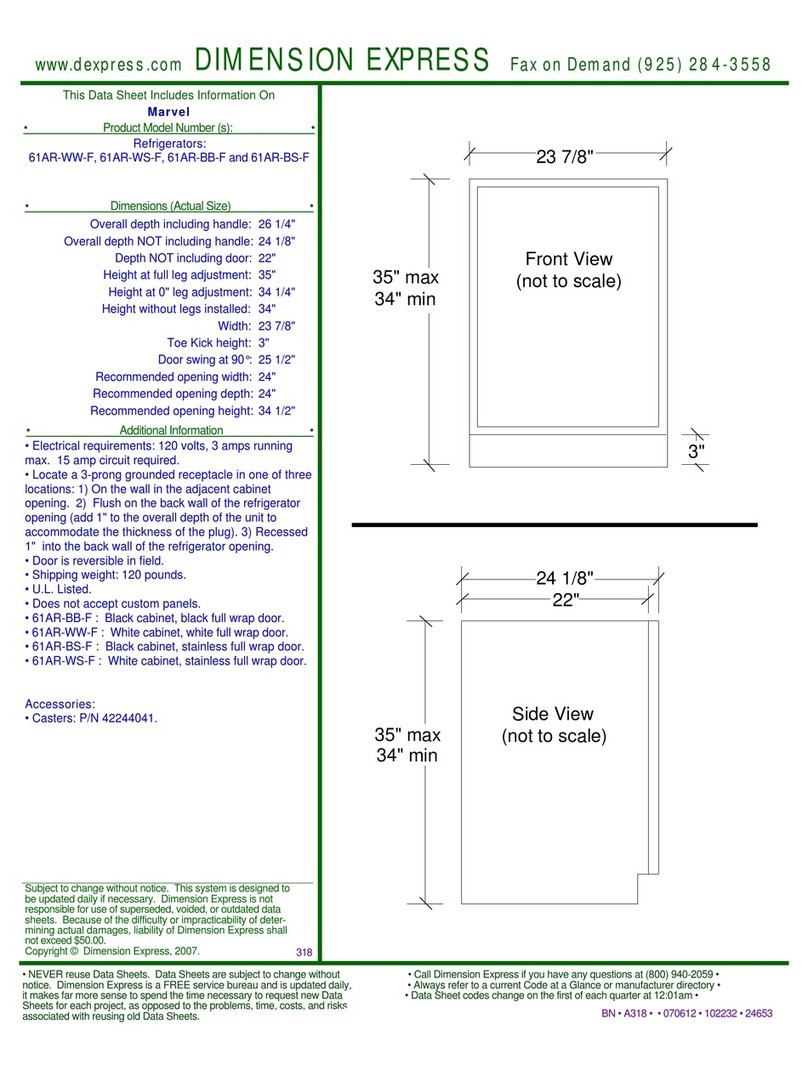

CUTOUT AND PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

"A" "B" "C" "D" "E" "F" "G" "H" "J"

15"

(8.1 cm)

34” to 35"

(85.7 cm to 88.3 cm)

24"

(61 cm)

(37.8 cm)

(86.4 cm to 88.9 cm)

(58.1 cm) -

(94.9 cm) -

Solid Door

Shown

"A"

"B"

"C"

"D"

"E"

If necessary, to gain clearance inside the rough-in

opening, a hole can be cut through the adjacent

cabinet and the power cord routed through this hole to

a power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this applica-

tion as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application.

7

CUTOUT AND PRODUCT DIMENSIONS

Glass Door

Shown

"F"

2112"

(54.6 cm)

"D"

"E"

"H"

"J"

"G"

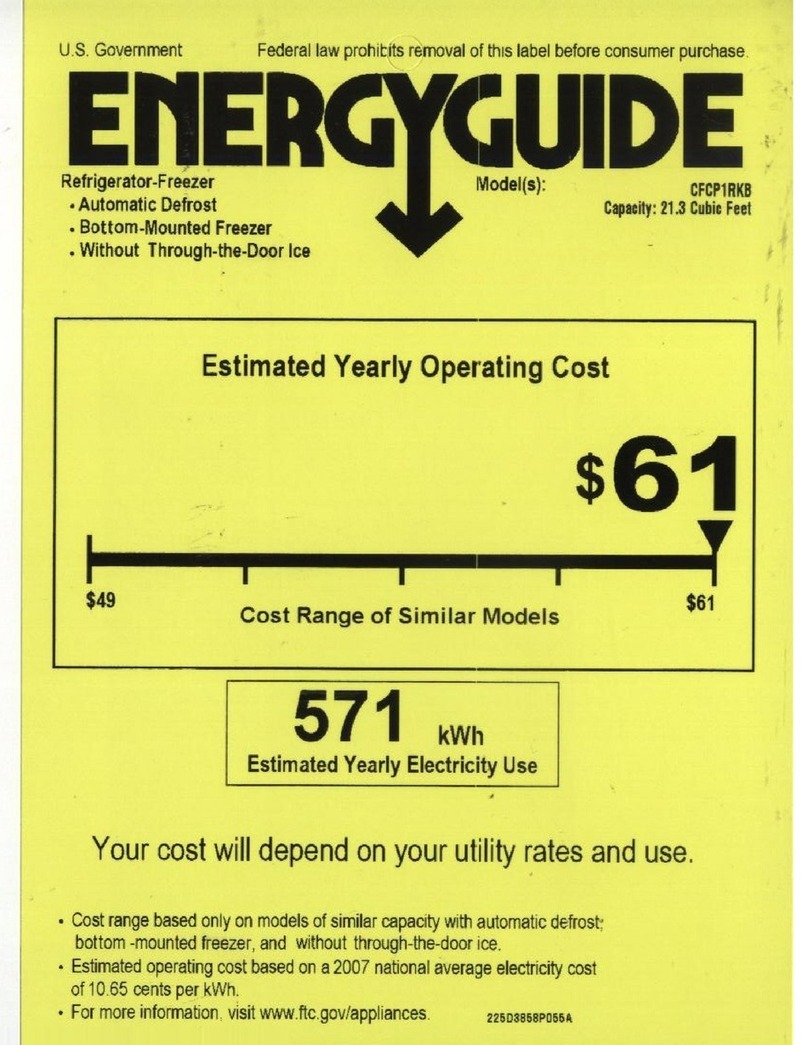

PRODUCT DATA

ELECTRICAL

REQUIREMENTS #

PRODUCT

WEIGHT

115V/60Hz/15A 105 lbs

(47.6 kg)

Minimum rough-in opening required is to be larger than the

adjusted height of the cabinet.

A grounded 15 amp dedicated circuit is required. Follow all

local building codes when installing electrical and

appliance. 8

Side-by-Side Installation

Two units may be installed side-by-side.

Cutout width for a side-by-side installation is the cutout

dimension of a single unit times two.

No trim kit is required. However, 1/4" (6 mm) of space

needs to be maintained between the units to ensure

unobstructed door swing.

Units must operate from separate, properly grounded

electrical receptacles placed according to each unit’s

electrical specifications requirements.

Side-by-Side Installation with Bracket

1. Slide both units out so screws on top of units are easily

accessible.

2. Remove screws as shown below.

3. Place bracket over holes and attach to unit with two

screws removed in step 2 using a T-25 Torx driver.

Tighten screws fully.

4. Gently push units into position. Be careful not to

entangle the electrical cord or water line, if applicable.

5. Re-check the leveling, from front to back and side to

side. Make any necessary adjustments. The unit’s top

surface should be approximately 1/8" (3 mm) below

the countertop.

9

INSTALLING THE ANTI-TIP DEVICE

Anti-Tip Bracket

1. Slide unit out so screws on top of unit are easily

accessible.

2. Remove the two screws from the opposite side of the

hinge assembly using a T-25 Torx driver (see below).

Place bracket over holes and attach to unit with two

screws removed in step 2 using a T-25 Torx driver.

Tighten screws fully.

Gently push unit into position. Be careful not to entangle

the electrical cord or water line, if applicable.

Check to be sure the unit is level from front to back and

side to side. Make any necessary adjustments. The

unit’s top surface should be approximately ¹»” (3 mm)

below the countertop.

Secure bracket into adjoining surface.

10

DOOR REVERSAL

Door Adjustments

Hinge Cover

Hinge cover included with the literature bag is optional.

To install hinge cover:

1. Press hinge cover squarely over hinge.

Door Alignment and Adjustment

Align and adjust the door if it is not level or is not sealing

properly. If the door is not sealed, the unit may not cool

properly, or excessive frost may form in the interior.

3URSHUO\DOLJQHGWKHGRRU¶VJDVNHWVKRXOGEH¿UPO\LQ

contact with the cabinet all the way around the door (no

gaps). Carefully examine the door’s gasket to ensure that

LWLV¿UPO\LQFRQWDFWZLWKWKHFDELQHW$OVRPDNHVXUHWKH

door gasket is not pinched on the hinge side of the door.

To align and adjust the door:

1. *HQWO\SU\RႇKLQJHFRYHUIURPWRSRIXQLW

2. Loosen (do not remove) top and bottom hinge screws

using a Torx T-25 screwdriver on the top and a 1/4”

socket on the bottom.

3. Align door squarely with cabinet.

4. 0DNHVXUHJDVNHWLV¿UPO\LQFRQWDFWZLWKFDELQHWDOO

the way around the door (no gaps).

5. Tighten bottom hinge screws.

6. Tighten top hinge screws and replace hinge cover.

Reversing the Door

Location of the unit may make it desirable to mount the

door on the opposite side of the cabinet.

The hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

Hinge Cover

NOTE

To Reverse the Door

Remove arrow clips:

1. :LWKDSXWW\NQLIHRURWKHUÀDWWRROJHQWO\SU\HDFK

arrow clip from hinge mounting holes.

2. Set aside arrow clips to be reused on the opposite side.

Remove top hinge and door:

1. Remove hinge cover from top of unit

2. Hold door to keep it from falling.

3. Remove top hinge from cabinet using a Torx T-25

screwdriver to remove three screws.

11

DOOR REVERSAL

1. 5HPRYHGRRUE\WLOWLQJIRUZDUGDQGOLIWLQJGRRURႇ

bottom hinge. Retain shoulder washers; they will be

reused.

2. Insert arrow clips into holes

Remove bottom hinge:

1. Remove bottom hinge from cabinet using a 1/4” socket.

2. Remove corresponding screws on opposite side of

cabinet. On some models there may be a nut behind

one or both screws on either side.

Install bottom hinge:

Install two or three screws, depending on model. Replace

nuts if used.

Prepare Door for Reinstallation

Rotate gasket

1. :LWKDÀDWWRROVXFKDVD

putty knife, gently pry up

beneath the gasket and

spacer until completely free

from the door surface.

2. Continue removing the

gasket by grabbing hold

and gently pulling outward,

exposing the gasket channel.

3. Remove the 3 pieces of

gasket channel filler and

reinstall on the opposite end

of door.

Gasket Channel

Filler

Gasket With Spacer

Beneath

1. Install gasket into channel,

beginning at one corner and

pressing in firmly.

2. Press down on middle

horizontal portion of gasket

until it adheres to the door

surface.

Install top hinge and door:

1. 5HPRYHSLYRWVFUHZIURPKLQJHÀLSKLQJHRYHUDQG

install the pivot screw in the same hole from the

opposite surface.

2. Lift the door onto the bottom

hinge.

3. Align edge of the hinge with

the outer edge of the unit.

4. Tighten three screws and

replace hinge cover.

5. Replace hinge cover.

Align and adjust the door:

Align and adjust the door (see Door Alignment and

Adjustment)

Gasket Channel

3UHVVGRZQɟUPO\

Top Hinge

Right Side

Top Hinge

Left Side

Pivot

Screw

12

Integrated Panel Dimensions

'XHWRGLႇHUHQFHVLQVXUURXQGLQJFDELQHWU\WKHSDQHO

PD\QRWSHUIHFWO\DOLJQZLWKGRRU7KHSURFHGXUHEHORZ

LVGHVLJQHGWRSURYLGHD¿QLVKHGLQWHJUDWHGSDQHOWKDW

VHDPOHVVO\LQWHJUDWHVZLWKVXUURXQGLQJFDELQHWU\

7KHGRRUSDQHOPXVWQRWZHLJKPRUHWKDQOEVNJ

,WLVLPSRUWDQWWRHQVXUHWKDWDOOGULOOHGKROHVDUHGULOOHGWR

WKHFRUUHFWGHSWKLQRUGHUWRDYRLGVSOLWVLQWKHZRRGZKHQ

KDUGZDUHLVLQVWDOOHG

:KHQDSSO\LQJDQLQWHJUDWHGSDQHOWRDXQLWHQVXUHWKDW

ERWKVLGHVDUH¿QLVKHGLQRUGHUWRSUHYHQWZDUSLQJ,QVRPH

SDQHOLQVWDOODWLRQVWKHSDQHOPD\EHYLVLEOHWKURXJKWKH

JODVVZKLOHWKHGRRULVRSHQ

$IXOOLQWHJUDWHGGRRUSDQHOFRPSOHWHO\FRYHUVWKHGRRU

IUDPHDQGSURYLGHVDEXLOWLQDSSHDUDQFH

Integrated Panel Preparation

&XWWKHSDQHOVWRWKHGLPHQVLRQVOLVWHGLQWKHGLDJUDP

EHORZ

2SWLRQDO6WDLQRU)LQLVKSDQHOWRGHVLUHGVWDLQRUFRORU

%HVXUHWRFORVHO\IROORZWKHLQVWUXFWLRQVSURYLGHGE\WKH

PDQXIDFWXUHU

2SWLRQDO,QVWDOOKDQGOHVDQGKDUGZDUH

INTEGRATED PANEL DIMENSIONS

NOTE

BACK SURFACE MUST HAVE AMPLE FLAT SURFACE

TO MOUNT OVERLAY PANEL FLAT AND WITHOUT

INTERFERENCE

3/4"

(20 mm)

Integrated Panel

14-3/4"

(375 mm)

30-1/4"

(768 mm)

13

INTEGRATED PANEL INSTALLATION

Integrated Panel Installation

1. Fully open door.

2. Starting at corner, pull gasket away

from door.

3. Continue to pull gasket free from

gasket channel.

4. Upon removal, lay gasket down on a

ÀDWVXUIDFH

5. Partially loosen the 3 screws, securing the top hinge to

the cabinet.

6. Align the panel with the outside edge (opposite the

hinge) and high enough to align with the highest point

in the door.

7. Insert panel underneath top hinge and apply upward

pressure while bringing the lower portion of the

SDQHOÀXVKWRWKHGRRULQVLGHWKHORZHUKLQJH7KH

SDQHOZLOO¿WVQXJJO\

$OLJQGRRUZLWKFDELQHW7LJKWHQWKHWRSVFUHZV

securing the top hinge to the cabinet.

'XHWRGLႇHUHQFHVLQÀRRUFRQVWUXFWLRQRUVXUURXQGLQJ

FDELQHWU\WKHSDQHOPD\QRWVLWÀXVKZLWKWKHWRSRIWKH

door.

Align Panel

Against

Door/Drawe

Edge First

Align Top Of Panel With Highest Point Of Door/Drawe

r

NOTE

Door

Panel

9. Secure integrated

panel to door/drawer

using clamps. A robust

tape may also be used.

Marvel recommends

the use of bar clamps

to secure the panel to

the door. If using tape,

be certain the tape will

not damage panel

¿QLVKXSRQUHPRYDO

10. Using a 7/64" drill

bit, drill 6 pilot holes into

the wood panel 1/2"

deep using the holes

in the door frame as a

guide.

It is important to ensure that all drilled holes are drilled to

the correct depth in order to avoid splits in the wood when

hardwood is installed.

11. Locate 6 of the #6x 1-1/4" screws provided with your

unit.

th d /d f

Wood

Panel

Door/Drawer

Bar

Clamp

Bar

Clamp

NOTE

14

11. Locate 6 of the #6x 1-1/4" screws provided with your

unit.

12. Using a Phillips screwdriver, place one screw

into each of the 6 pilot holes and screw down. Do not

overtighten screws.

13. Be sure the screws force their way past the opening

RQWKHJDVNHWFKDQQHODQGVLWÀXVKDJDLQVWWKHERWWRP

of the channel.

14. Remove clamps from door.

If panel requires additional adjustment after removing

clamps, slightly loosen each screw and adjust panel as

QHFHVVDU\7LJKWHQVFUHZVXSRQFRPSOHWLRQ

15. Starting at the corners, reinstall the gasket into the

gasket channel in the frame. Make sure the gasket is

IXOO\VHDOHG7KLVPD\WDNHVRPHIRUFH

Integrated Panel Inte

g

rated Panel

NOTE

INTEGRATED PANEL INSTALLATION

15

INSTALLING THE WATER SUPPLY

Prepare Plumbing

Plumbing installation must observe all state and local

codes. All water and drain connections MUST BE made by

DOLFHQVHGTXDOL¿HGSOXPELQJFRQWUDFWRU)DLOXUHWRIROORZ

recommendations and instructions may result in damage

and/or harm.

Water Supply Connection

:KHQFRQQHFWLQJWKHZDWHUVXSSO\SOHDVHQRWHWKH

IROORZLQJ

•%HIRUHLQVWDOOLQJWKHXQLWDQGFRQQHFWLQJWRWKHFROG

ZDWHUVXSSO\UHYLHZWKHORFDOSOXPELQJFRGHV

•7KHZDWHUSUHVVXUHVKRXOGEHEHWZHHQDPLQLPXPRI

DQGDPD[LPXPRISVLDQGN3D

•:DWHUKDVOHVVWKDQPJ/SSPWRWDOGLVVROYHG

VROLGVDQGKDUGQHVVOHYHOEHORZPJ/SSP²LH

EHORZJUDLQVSHUJDOORQ&KHFNE\XVLQJ7'6PHWHU

RUFRQVXOWLQJZLWKORFDOZDWHUFRPSDQ\

•7'6DQGRUZDWHUKDUGQHVVDERYHWKHVHOLPLWVVKRXOG

be treated with a reverse osmosis system or other

¿OWUDWLRQV\VWHP

•6RIWHQHGZDWHULVQRWUHFRPPHQGHGDVLWPD\UHVXOWLQ

VRIWHULFHWKDQGHVLUHG

•&RQQHFWLRQWRWKHZDWHUPDLQLVPDGHZLWKKRVHVHW

only.

•+RVHVHWPXVWEHQHZQRWUHXVHGDQGLQFRPSOLDQFH

ZLWK,(&

•7KHZDWHUOLQH0867KDYHDVKXWRႇYDOYHLQWKH

VXSSO\OLQH

•7KHZDWHUOLQHVKRXOGEHORRSHGLQWRFRLOV7KLVZLOO

DOORZWKHXQLWWREHUHPRYHGIRUFOHDQLQJDQGVHUYLFLQJ

0DNHFHUWDLQWKDWWKHWXELQJLVQRWSLQFKHGRUGDPDJHG

during installation.

!CAUTION 'RQRWXVHDQ\SODVWLFZDWHUVXSSO\OLQH7KHOLQHLVXQGHU

SUHVVXUHDWDOOWLPHV3ODVWLFPD\FUDFNRUUXSWXUHZLWKDJH

DQGFDXVHGDPDJHWR\RXUKRPH'RQRWXVHWDSHRUMRLQW

FRPSRXQGZKHQDWWDFKLQJDEUDLGHGÀH[LEOHZDWHUVXSSO\

OLQHWKDWLQFOXGHVDUXEEHUJDVNHW7KHJDVNHWSURYLGHV

DQDGHTXDWHVHDO±RWKHUPDWHULDOVFRXOGFDXVHEORFNDJH

RIWKHYDOYH)DLOXUHWRIROORZUHFRPPHQGDWLRQVDQG

LQVWUXFWLRQVPD\UHVXOWLQGDPDJHDQGRUKDUPÀRRGLQJRU

YRLGWKHSURGXFWZDUUDQW\8VHQHZKRVHVHW'RQRWUHXVH

old hose set.

7XUQRႇZDWHUVXSSO\DQGGLVFRQQHFWHOHFWULFDOVXSSO\WR

XQLWSULRUWRLQVWDOODWLRQ8VHFDXWLRQZKHQKDQGOLQJEDFN

SDQHO7KHHGJHVFRXOGEHVKDUS

!CAUTION

!CAUTION

16

INSTALLING THE WATER SUPPLY

7XUQRႇZDWHUVXSSO\DQGGLVFRQQHFWHOHFWULFDOVXSSO\

WRSURGXFWSULRUWRDWWHPSWLQJLQVWDOODWLRQ

2. 5HPRYHWKHEDFNSDQHO

7KUHDGZDWHUOLQHWKURXJKEDFNSDQHOKROHZLWK

EXVKLQJ

4. Locate water valve inlet and connect to valve.

5. 7XUQRQZDWHUVXSSO\DQGFKHFNIRUOHDNV

5HLQVWDOOEDFNSDQHO

3

4

17

Ice Cube Thickness Adjustment

Interval - As Required.

On ice maker equipped models, adjust the cube size

by changing water amount injected into the ice maker

assembly as follows:

1. Remove the ice maker assembly

cover (1).

2. Find the adjusting screw on the ice

maker assembly control box (2).

The adjusting screw is just below

the minus (-) and plus (+) signs on

the control box.

Too large of an adjustment to the screw can cause the

ZDWHUWRRYHUÀRZWKHLFHPDNHUDQGFDQFDXVHSURSHUW\

damage.

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+)

sign (counterclockwise) for larger cubes.

4. Install the ice maker assembly cover.

Adjusting Ice Harvest

1. Remove the front grille.

8VLQJDÀDWWLSVFUHZGULYHUWXUQWKHDGMXVWLQJVFUHZ

a small increment clockwise for a COLDER setting (slower

ice production) or counterclockwise for a WARMER setting

(faster ice production).

3. Reinstall the front grille (two

screws).

Ice Maker Operation

When the ice bucket is full, the ice making mechanism will

VKXWRႇ+RZHYHUWKHUHIULJHUDWLRQV\VWHPZLOOFRQWLQXHWR

cool and maintain the ice supply.

Do not place cans or bottles in the ice

compartment because they will freeze.

7RWXUQRႇLFHSURGXFWLRQ

Raise the bin arm into an upright and

locked position. The unit will preserve

temperature for ice storage.

If not intending to use the ice maker, turn the water supply

YDOYHRႇ,WLVDOVRLPSRUWDQWWRUDLVHWKHELQDUPRIWKHLFH

maker (see above). Failure to raise the bin arm may result

in damage to the water valve.

Certain sounds are normal during the unit’s operation. You

may hear the compressor or fan motor, the water valve, or

ice dropping into the ice bucket.

NEVER use an ice pick, knife or other sharp instrument to

separate cubes. Shake the ice bucket instead.

During periods of limited use or high ambient temperatures,

it is common for cubes to fuse together. Gently shake the

bucket to break apart cubes. If not using the ice maker

regularly, empty the ice bucket periodically to ensure fresh

cubes. It is normal for cubes to appear cloudy. The cause

is air trapped in the water because of fast freezing. It is not

caused by the health, taste or chemical make up of the

water. It is the same air that is in every glass of water you

drink. Remove the ice bucket for emptying and cleaning. To

remove the ice bucket, raise the bin arm and remove the

bucket from the ice compartment. Use the ice bucket for ice

storage only.

ICE MAKER OPERATION

NOTE

NOTE

!CAUTION

!CAUTION

C

O

L

D

E

R

Warmer Colder

18

CARE AND CLEANING

Exterior Cleaning

Stainless door panels, handles and frames can discolor

when exposed to chlorine gas, pool chemicals, saltwater or

cleaners with bleach.

Keep your stainless unit looking new by cleaning with a

good quality all-in-one stainless steel cleaner and polish

monthly. For best results use Claire®Stainless Steel

Polish and Cleaner. Comparable products are acceptable.

Frequent cleaning will remove surface contamination that

could lead to rust. Some installations may require cleaning

weekly.

Do not clean with steel wool pads.

Do not use stainless steel cleaners or polishes on any

glass surfaces.

Clean any glass surfaces with a non-chlorine glass cleaner.

'RQRWXVHFOHDQHUVQRWVSHFL¿FDOO\LQWHQGHGIRUVWDLQOHVV

steel on stainless steel surfaces (this includes glass, tile,

and counter cleaners).

If any surface discoloring or rusting appears, clean it

quickly with Bon-Ami®or Barkeepers Friend Cleanser®and

a nonabrasive cloth. Always clean with the grain. Always

¿QLVKZLWK&ODLUH®Stainless Steel Polish and Cleaner or

comparable product to prevent further problems.

Using abrasive pads such as ScotchBrite™ will

cause the graining in the stainless steel to

become blurred.

Rust not cleaned up promptly can penetrate the

surface of the stainless steel and complete

removal of the rust may not be possible.

Integrated Models

To clean integrated panels, use household cleaner per the

cabinet manufacturer’s recommendations.

Interior Cleaning

Disconnect power to the unit.

Clean the interior and all removed components using a mild

nonabrasive detergent and warm solution applied with a soft

sponge or non-abrasive cloth.

Rinse the interior using a soft sponge and clean water.

Do not use any solvent-based or abrasive cleaners. These

types of cleaners may transfer taste and/or odor to the

interior products and damage or discolor the interior.

Defrosting

This unit is a manual defrost model and will require

occasional defrosting. When there is build-up of 1/4”

(6 mm) or more of frost, manually defrost the unit.

DO NOT use an ice pick or other sharp instrument to help speed

up defrosting. These instruments can puncture the inner lining

or damage the cooling unit. DO NOT use any type of heater to

defrost. Using a heater to speed up defrosting can cause personal

injury and damage to the inner lining.

!CAUTION

19

CARE AND CLEANING

To Defrost:

1. Disconnect power to the unit.

2. Remove ice bucket and discard ice.

3. Place towel or other absorbent material on bottom of

ice bin.

4. Fill the ice bucket half full with warm, not hot water.

This will help the unit defrost faster.

5. Place the ice bucket back into the unit on top of the

towel or other absorbent material.

6. Prop the door in an open position (2 in. [50 mm]

minimum).

7. After about 1 hour remove the ice bin and discard

water.

8. Allow the frost to melt naturally.

9. After the frost melts completely clean the interior and

all removed components. (See Interior Cleaning).

DO NOT clean ice bucket using a dishwasher. The bucket

is not dishwasher safe and will be damaged.

10. When the interior is dry, reconnect power and turn unit

on.

To safeguard against contaminates in ice, discard

¿UVWWKUHHEDWFKHVRILFHDIWHUGHIURVWLQJ

NOTE

NOTE

Cleaning Condenser

Interval - every six months

7RPDLQWDLQRSHUDWLRQDOHႈFLHQF\NHHSWKHIURQWJULOOHIUHH

of dust and lint, and clean the condenser when necessary.

Depending on environmental conditions, more or less

frequent cleaning may be necessary.

DO NOT use any type of cleaner on the condenser unit.

Condenser may be cleaned using a vacuum, soft brush, or

compressed air.

1. Remove the grille.

2. Clean the condenser coil using a soft brush or vacuum

cleaner.

3. Install the grille.

Condenser Fins

!WARNING

WARNING-Disconnect electric power to the unit

before cleaning the condenser.

NOTE

20

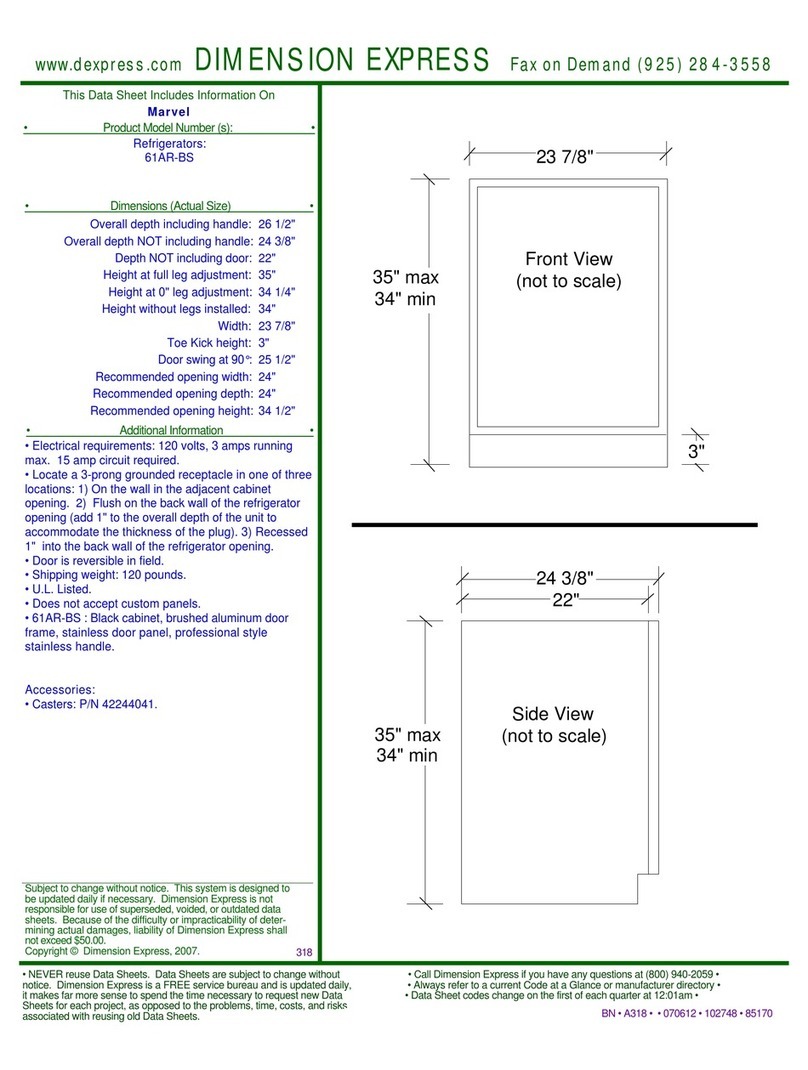

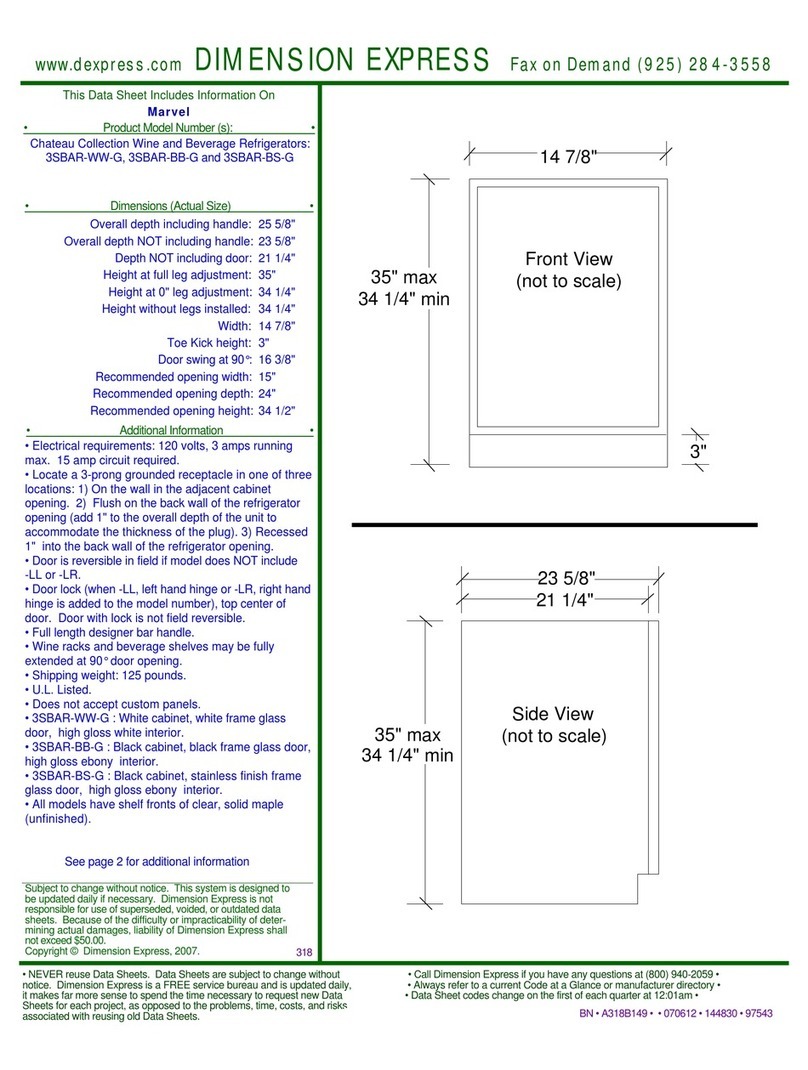

Other manuals for MLCR215-IS01B

1

Table of contents

Other Marvel Refrigerator manuals

Marvel

Marvel MS24FASHRW Manual

Marvel

Marvel 6ADA-BB User manual

Marvel

Marvel 61WC-BD User manual

Marvel

Marvel 61AR-BS User manual

Marvel

Marvel MARE124 User manual

Marvel

Marvel MORI224-SS31A User manual

Marvel

Marvel 3SBAR-BB-G User manual

Marvel

Marvel ML15BC Manual

Marvel

Marvel MLBD224-SG01A User manual

Marvel

Marvel 80RD Guide

Marvel

Marvel MLCP215-IS81A User manual

Marvel

Marvel MLCL215 User manual

Marvel

Marvel MORF224 User manual

Marvel

Marvel MS24RF Series Manual

Marvel

Marvel 60RDE-BB-F Manual

Marvel

Marvel MLNP115 User manual

Marvel

Marvel 61AR-BB-F User manual

Marvel

Marvel MLRE124 User manual

Marvel

Marvel ML24BC Manual

Marvel

Marvel MOKR124-SSD1A User manual