Marvel MLWD224-IG01A User manual

OWNER’S GUIDE & SERVICE MANUAL

MARVEL UNDERCOUNTER REFRIGERATION

Model: MLWD224-IG01A

WELCOME

Welcome to the Marvel Experience!

Thank you for choosing our quality American-built product

to add to your home. We are thrilled to welcome you to

our growing community of Marvel owners, who trust in our

products and our support.

The information in this guide is intended to help you install

and maintain your new Marvel undercounter model to

protect and prolong its lifetime. We encourage you to

contact our Technical Support team at (616) 754-5601 with

any questions.

Got a Marvelous Design?

We would love to see how your Marvel product looks in its

new home. You can send us photos of your installed

might feature your Marvel home design on our website and

social media!

Online registration

available at

marvelrefrigeration.com

Warranty Registration

It is important you register your product warranty after

taking delivery of your appliance. You can register online at

www.marvelrefrigeration.com.

The following information will be

required when registering your

appliance:

Serial Number

Date of Purchase

Dealer’s name and address

The serial number can be found on the serial plate which is

located inside the cabinet on the left side near the top.

TABLE OF CONTENTS

Tip: Click on any section below to jump directly there

Safety

Important Safety Instructions

Installation

Unpacking Your Appliance

Electrical

Cutout & Product Dimensions

Installing Your Appliance

Side-by-Side & Stacking Installations

Installing the anti-tip device

Door Reversal

Integrated Panel Dimensions

Integrated Panel Installation

Maintenance

Care and Cleaning

Stainless Steel Maintenance

Extended Non-Use

Operating Instructions

Using Your Electronic Control

Interior Adjustments

Energy Savng Tips

Service

Obtaining Service

Troubleshooting

Wire Diagram

Product Liability

Warranty Claims

Ordering Replacement Parts

R600a Specifications

System Diagnosis Guide

Compressor Specifications

Troubleshooting Extended

Control Operation - Service

Service Mode

Defrost

Remove Fan and Cover

Warranty

3

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution and

care must be exercised when installing, maintaining or

operating this appliance.

Recognize Safety Symbols,

Words and Labels

!WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!CAUTION

CAUTION -Hazards or unsafe practices which could

result in personal injury or property/product damage.

NOTE

NOTE -Important information to help assure a

problem-free installation and operation.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!WARNING

WARNING - This unit contains R600a (isobutane)

which is a ammable hydrocarbon. It is safe for

regular use. Do not use sharp objects to expedite

defrosting. Do not damage refrigerant circuit.

4

UNPACKING YOUR APPLIANCE

!WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding

internal components in place. The getting started guide is

shipped inside the product in a plastic bag along with the

warranty registration card and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condi-

tion. If there is any damage, the packaging will be needed

as proof of damage in transit. Afterwards, please dispose of

all items responsibly.

!WARNING

WARNING - Dispose of the plastic bags which can

be a suocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving out facility. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

NOTE

!CAUTION

If the appliance was shipped, handled or stored in other

than an upright position for any period of time, allow the

appliance to sit upright for a period of at least 24 hours

before plugging in. This will assure oil returns to the

compressor. Plugging the appliance in immediately may

cause damage to internal parts.

!WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous, even if they sit outside for “just a few hours”.

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take o the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

5

ELECTRICAL

Do not remove

ground prong

!WARNING

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any

• circumstances, be installed to an un-grounded

• electrical supply. Do not remove the grounding

prong from the power cord.

• Do not use an adapter.

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in

accordance with the National Electrical Code and

applicable local codes and ordinances. If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third-ground prong should not, under any

circumstances, be cut or removed.

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to

nuisance tripping which will cause the appliance to shut

down. GFCI’s are generally not used on circuits with power

equipment that must run unattended for long periods of

time, unles required to meet local building codes and

ordinances.

6

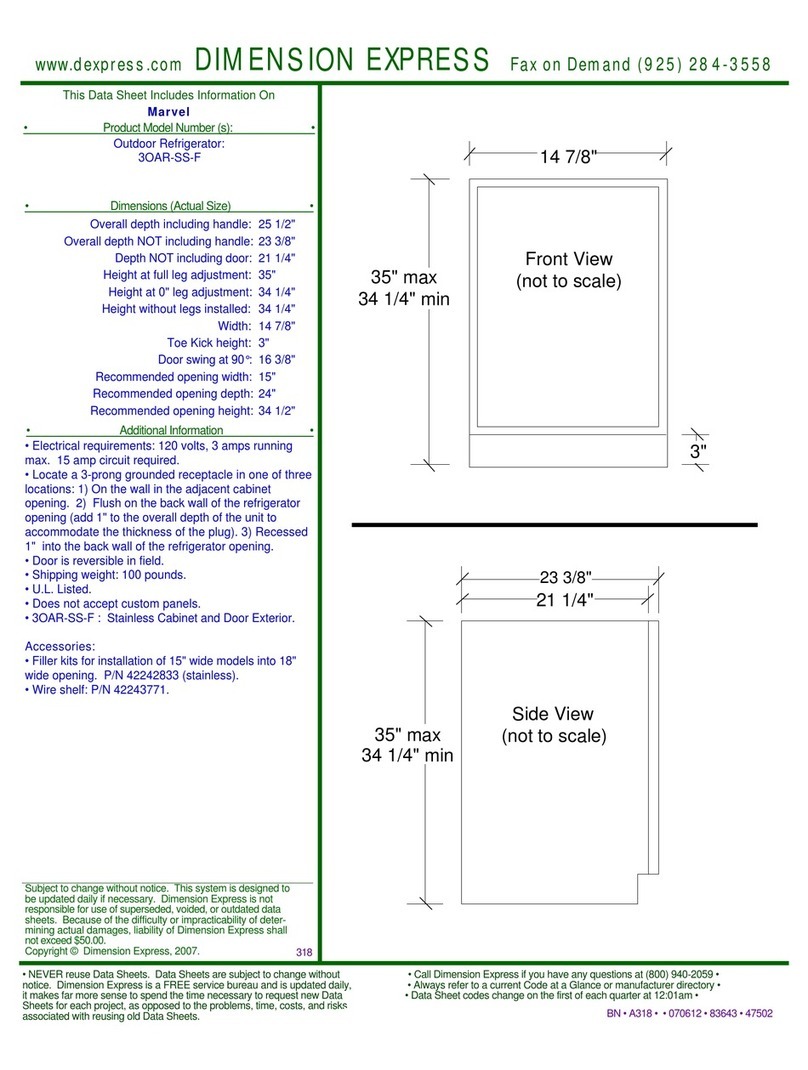

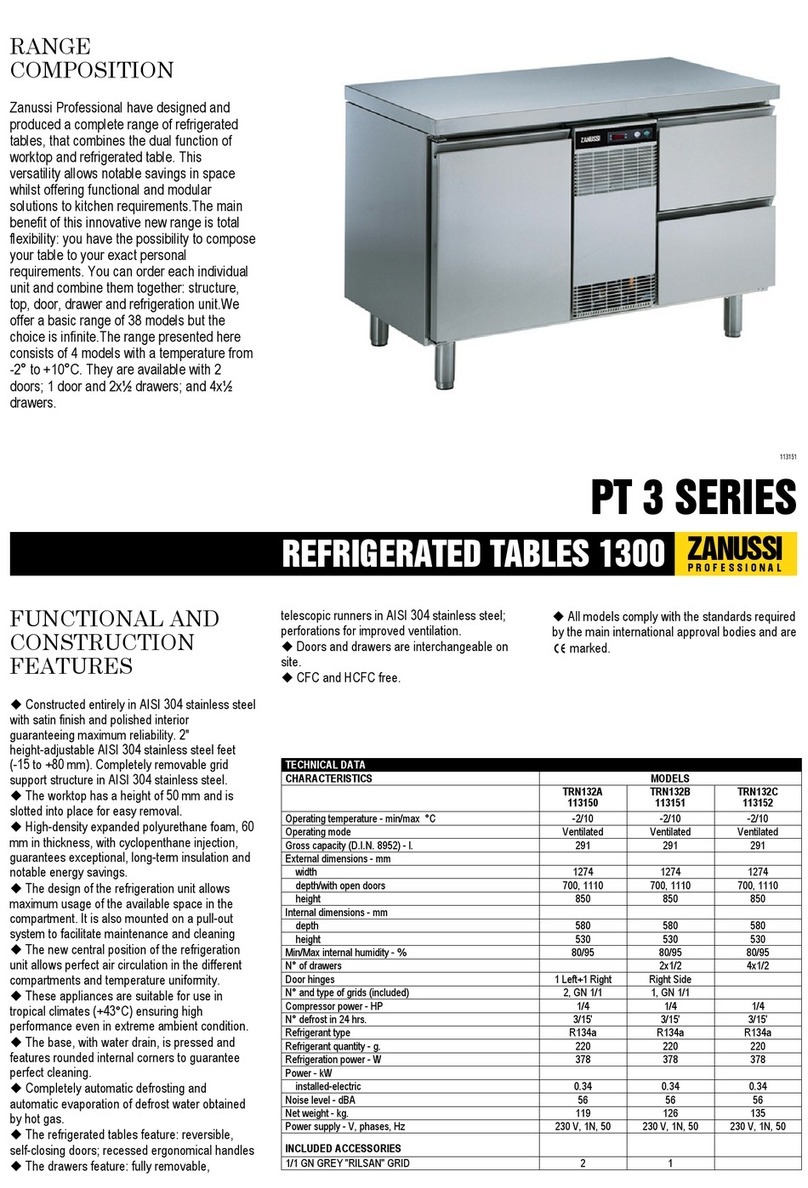

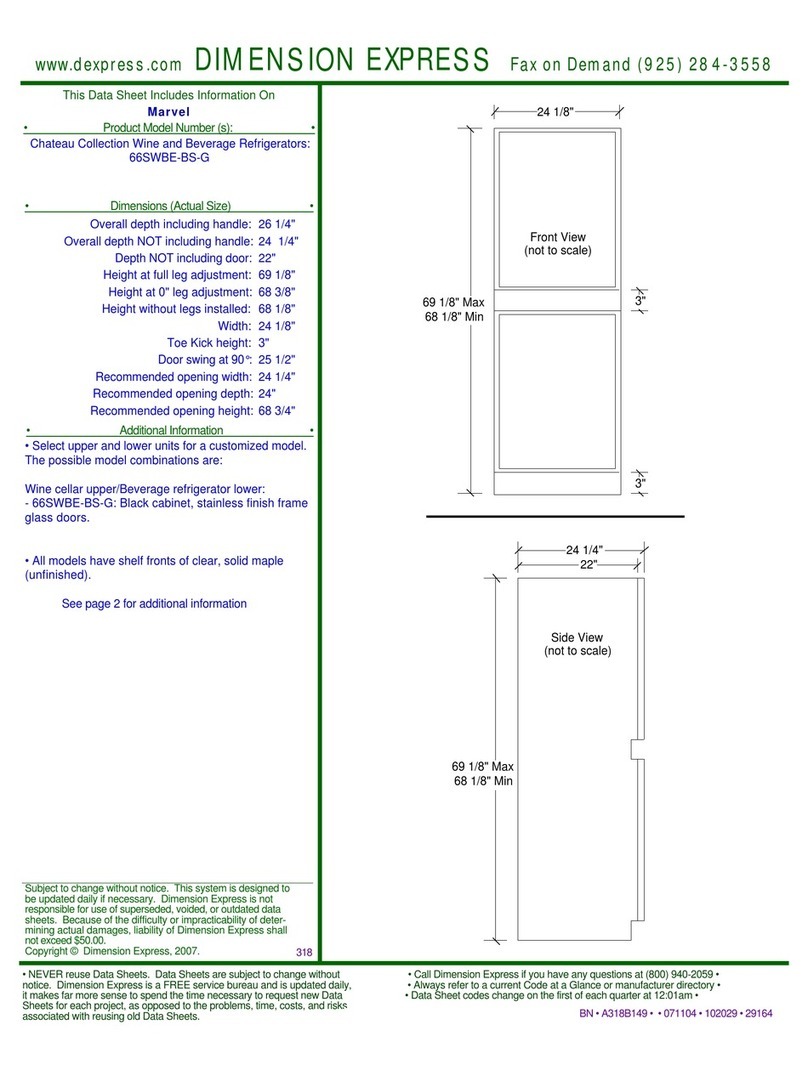

CUTOUT AND PRODUCT DIMENSIONS

"A"

"B"

"D"

"E" Solid Door

Shown

If necessary, to gain clearance inside the rough-in

opening, a hole can be cut through the adjacent

cabinet and the power cord routed through this hole to

a power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this applica-

tion as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application.

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

"A" "B" "C" "D" "E" "F" "G" "H" "J"

24"

(61 cm)

34” to 35"

(85.7 cm to 88.3 cm)

24"

(61 cm)

(60.7 cm)

(86.4 cm to 88.9 cm)

(58.1 cm) -

(118.1 cm) -

"C"

7

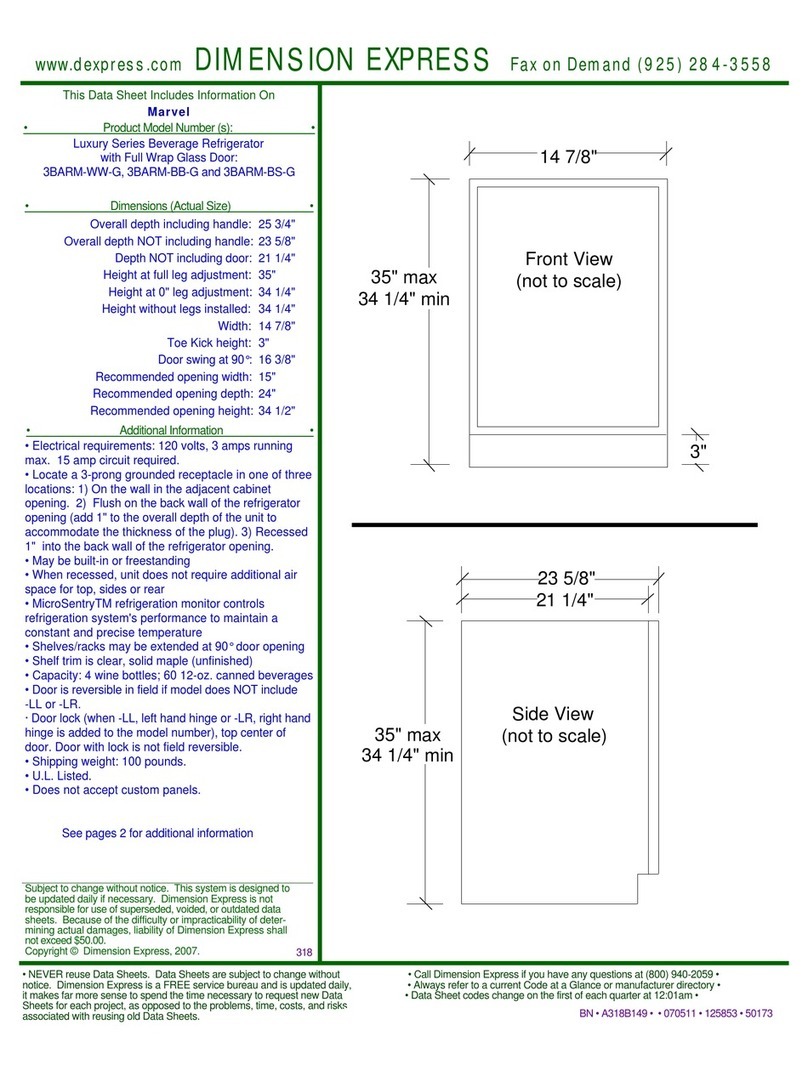

CUTOUT AND PRODUCT DIMENSIONS

312" (8.9 cm)

Minimum

"D"

"E"

"F"

"G"

"J"

Solid Door

Shown

2112"

(54.6 cm)

PRODUCT DATA

ELECTRICAL

REQUIREMENTS #

PRODUCT

WEIGHT

115V/60Hz/15A 140 lbs

(63.6 kg)

Minimum rough-in opening required is to be larger than the

adjusted height of the cabinet.

A grounded 15 amp dedicated circuit is required. Follow all

local building codes when installing electrical and

appliance.

"H"

8

Front grille

screws

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the unit will

be out of direct sunlight and away from heat sources. To

ensure your product performs to specications, the recom-

mended installation location temperature range is from 55

to 100°F (13 to 38°C).

Cabinet Clearance

Ventilation is required from the bottom front of the appli-

ance. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the appliance as long as the front grille remains unobstruct-

ed. All Marvel Professional models with articulated hinges

are intended for built-in applications only.

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat ex-

changer. Restrictions to this air ow will result in increased

energy usage and loss of cooling capacity. For this reason

it is important this area to not be obstructed and the grille

openings kept clean. Marvel does not recommend the use

of a custom made grille as air flow may be restricted.

INSTALLING YOUR APPLIANCE

!WARNING

An optional stacking kit, for 24" wide models, is re-

quired to stack products. Failure to use a stacking kit

could result in personal injury. Contact your dealer or

Marvel customer service at 616-754-5601 to order.

For safety concerns 15" wide models should not be

stacked.

Front Leveling

Legs

Leveling Legs

Adjustable legs at the front and rear corners of the appli-

ance should be set so the unit is rmly positioned on the

oor and level from side to side and front to back. The over-

all height of your Marvel appliance may be adjusted higher

(by turning the leveling leg out, CCW) and lower (by turning

the leveling leg in, CW).

To adjust the leveling legs, place the appliance on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the appliance back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning

the legs. Repeat this process for the rear by tilting the appli-

ance forward using caution. On a level surface check the

appliance for levelness and adjust accordingly.

The front grille screws may be loosened and the grille ad-

justed to the desired height. When adjustment is complete

tighten the two front grille screws.

Rear

Leveling

Legs

Front grille screw

Front grille

9

SIDE-BY-SIDE AND STACKING INSTALLATIONS

Side-by-Side Installation

Other Site Requirements

Units must operate from separate, properly grounded elec-

trical receptacles placed according to each unit's electrical

To ensure unobstructed door swing (opening both doors at

the same time), 1/4" (6.4 mm) of space needs to be maint-

ained between the units.

Hinge-by-Hinge Installation (Mullion)

When installing two units hinge-by-hinge, 13/16" (22 mm)

is required for integrated models. Additional space may be

needed for any knobs, pulls or handles installed.

Stainless steel models which include the standard stainless

handle will require 4-9/16" (116 mm) to allow both doors to

open to 90° at the same time.

Figure 10

Figure 11

Figure 12

Figure 13

Hinge-by-Wall Installation

When installing a unit hinge-by-wall or adjacent cabinetry,

7/16” (11mm) is required for integrated models. Additional

space may be needed for any knobs, pulls or handles installed.

¼”

13/16”

7/16”

4-9/16”

10

INSTALLING THE ANTI TIP DEVICE

Step by step instructions for locating the po-

sition of the bracket:

1) Decide where you want to place the beverage center.

leaving 1" (2.5 cm) of clearance from the rear wall to allow

room for the anti-tip bracket.

¹" (6 mm) to

allow engagement with the anti-tip bracket. Level the unit

by adjusting all the leveling legs as required. Turning the

leveling leg counterclockwise will raise the unit and clock-

wise will lower the unit.

3) Make sure the beverage center is in the desired loca-

cabinet where the anti-tip bracket will be installed. If the

installation does not allow marking the rear corner of the

beverage center out of the way. From the temporary line

12" (54.6 cm) as shown in

Figure 15.

the side of the bracket lines up with the side of the cabinet

mark, and the "V" notches on the anti-tip bracket line up

with the end of the 2112" (54.6 cm) line (Rear of cabinet

line).

screw. (See Figure 15).

6) Slide the cabinet back into position, making sure the rear

cabinet leveling leg slides under the anti-tip bracket engag-

ing the slot.

Front of cabinet

Figure 14

2112"

(54.6 cm)

Anti-Tip

Bracket Leveling Leg

Bottom View of

Beverage

Center

Floor Mount Installation

or right rear corner of the wine cellar as shown in Figure 14.

!WARNING

• ALL APPLIANCES CAN TIP

RESULTING IN INJURY.

• INSTALL THE ANTI-TIP

BRACKET PACKED WITH

THE APPLIANCE.

• FOLLOW THE INSTRUC-

TIONS BELOW

!CAUTION

NOTE

material to avoid damage when moving the unit.

required, (not included with the anti-tip kit).

Anti-Tip Device

!WARNING

If your beverage center is not located under a counter

top (free standing), you must use an anti-tip device

installed as per these instructions. If the beverage

center is removed from its location for any reason,

make sure that the device is properly engaged with

the anti-tip bracket when you push the beverage

center back into the original location. If the device is

not properly engaged, there is a risk of the beverage

center tipping over, with the potential for property dam-

age or personal injury.

11

NOTE

INSTALLING THE ANTI TIP DEVICE

-

mum adjusted height of the cabinet is increased by

38" (9 mm).

Figure 15a

"V" notches

in bracket

"V" notches

in bracket

Figure 15

2112"

(54.6 cm)

Front of cabinet line

Rear Leveling leg

Side of cabinet line

Rear of cabinet line

Screw

12

Door Reversing Instructions

Tools Needed:

• 1/8” Hex Key

• 5/32” Hex Key

• Phillips Screwdriver

Open door and remove Hinge Pin from the Upper Hinge using a 1/8” Hex Key tool making sure to steady the

Using a Phillips Screwdriver, remove the 6 screws from both the Upper and Lower Hinges and save for later steps

Once the Hinges are removed from the unit, using a Phillips Screwdriver, remove the Bushing Screw and Hinge Pin

Screw and save for later steps

On the Bottom Hinge, reattach the Bushing Screw and Hinge Pin Screw to the opposite side

Lower Hinge Bracket

(Before Reversal)

Upper Hinge Bracket

(After Reversal)

Lower Hinge Bracket

(After Reversal)

5. Using a 5/32” Hex Key, remove the Upper and Lower Hinge Brackets from the door saving all components.

screw into place

on the opposite side of the door (where plugs were removed). Remove the Cam Closer from the Lower-Hinge Bracket

and attach it to the opposite side

DOOR REVERSAL

Hinge Pin

Upper Right Hinge

Orientation

(Before Reversal)

Hinge Pin

Screw

Bushing

Screw

Lower Right Hinge

Orientation

(Before Reversal)

pper Left Hinge

Orientation

(After Reversal)

Upper Left Hinge

Orientation

(After Reversal)

Hinge

Bushing

Cam Closer

Upper Hinge Bracket

(Before Reversal)

13

6. Remove the door switch actuator tab from the door and attach it to the opposite side

DOOR REVERSAL

Door switch actuator tab

7. Reattach the Upper and Lower Hinges, and Hinge Brackets to opposite sides. Then install the door.

14

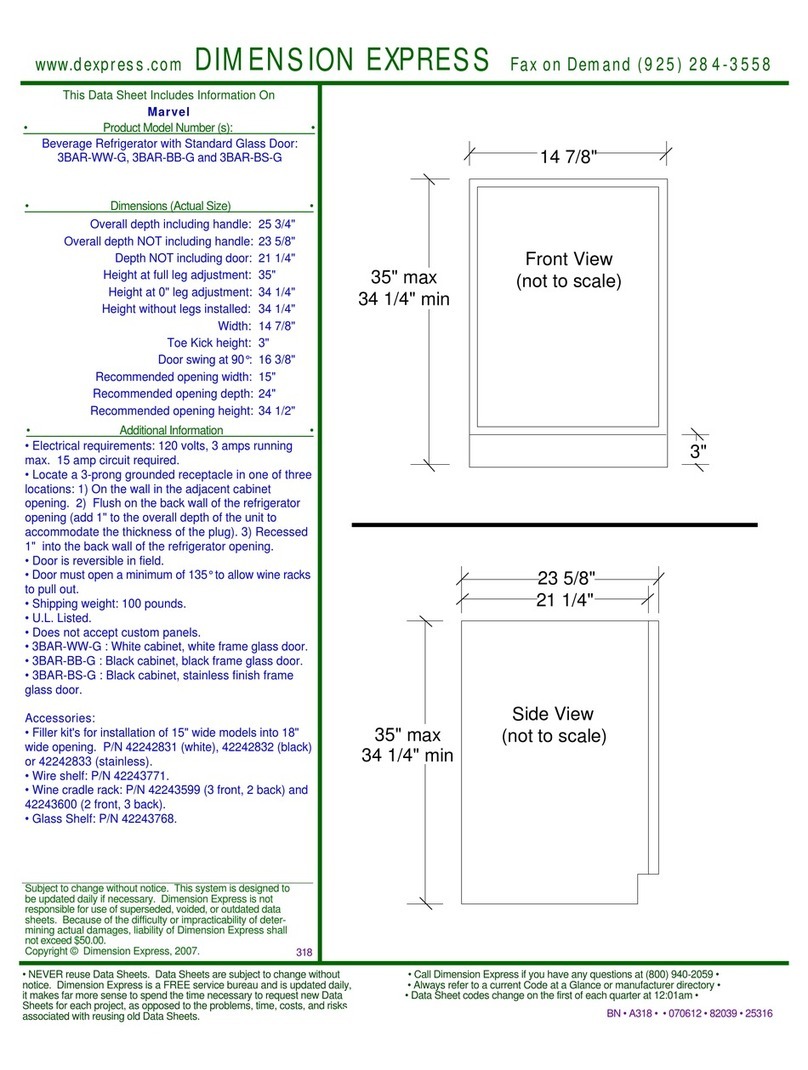

15⁄32"

(2.9 cm)

NOTE

•Panel thickness may be 5/8" or 3/4"

•Center the unit in the 24" opening

•If the hinge side of the product is pressed

against the adjacent cabinet, use a 5/8" thick

panel

•The window cutout is for glass door models only

•Do not use a solid door panel on a glass door

model

INTEGRATED PANEL DIMENSIONS

Top of door

24" (60 cm) wide appliance

24" (60 cm)

Door Dimensions

Back of Panel

Back of Panel

Front of Panel

Front of Panel

15

12

!CAUTION

Step 1: Removing the Door and Hinges

Hold the door secure in the closed position and remove

Hinge Pin from the Upper Hinge using a 1/8” Hex Key tool.

Slowly remove the door by sliding outward away from the

the door, remove hinges from cabinet per Door Reversal

Remove the hinge bushing from the adaptor plate. A new

bushing is included in the literature pack with your unit.

Cut and prepare panels according to the information

through the condenser. The use of a custom grille is not

recommended and will void the warranty.

INTEGRATED DOOR PANEL INSTALLATION

Step 2: Remove the Door Gasket

corner of the door, remove the magnetic door gasket from

surface.

There are 10 holes in the gasket retainer extrusions (3 on

each side and 2 at the top and bottom) which are used to

fasten the panel to the front of the door. The screws are

provided in the literature pack.

Step 3: Assemble the Panel to the Door

The preferred method of attaching the panel to the door

is to clamp the panel to the door so it cannot move while

drilling the screw pilot holes. Use bar clamps or "C" clamps

with pads on the clamping surfaces that will not mar the

the top of the door and centered along the width of the

door. Drill holes through the gasket extrusion using the 10

holes as pilot holes. Use the drill size from the chart in the

table below being careful not to drill through the front sur-

face of the panel. Fasten the panel to the door with the 10

screws provided in the literature pack. Remove the clamps

and replace the gasket in the gasket extrusion channels of

the door. Some force may be required to seat the gasket

into the channels. Be sure the gasket corners are seated

properly.

door

door

Holes in gasket

container

Material Type #10 Wood Screw

Hardwood ¹" (3.2 mm) Diameter. Pilot Hole

Softwood (2.8 mm) Diameter. Pilot Hole

16

13

INTEGRATED DOOR PANEL INSTALLATION

Step 4: Install the Door

into adaptor plate.

Align hinge bushing with top hinge and reinstall upper hinge

17

USING YOUR ELECTRONIC CONTROL

Control Function Guide

Function Command Notes

ON/OFF Press and release. Unit will immediately turn ON or OFF.

Adjust Temperature

Interior lights indicates zone temperature being set;

Light Off = Upper (38oF to 65oF)

Light On = Lower (38oF to 65oF)

Toggle Between oF / oC Hold and for 5 seconds. The display will change units.

Leave Interior Light On Press and release to leave interior light on for

12 hours; press again to deactivate.

After 12 hours, factory default is restored; light will turn on when

door is open.

Hide Display Hold and press . operate. Repeat command to turn on display.

Enable Sabbath Mode Press and hold for 5 seconds and release.

light and display will go dark and remain so until user

resets mode - unit continues to operate.

Disable Sabbath Mode Press and hold for 5 seconds and release. Display and interior light return to normal operation.

Showroom Mode Hold and for 5 seconds.

The oF / o

will function. Unit will not cool. Repeat command to return to

normal operation.

When the door is left open for more than 30 minutes:

• A tone will sound for several seconds every minute

• will appear in display

• Close door to silence alert and reset

First Use

Initial startup requires no adjustments. When plugged in, the unit will

during installation, simply press and the unit will immediately switch on.

ogressing

towards the selected temperature. Time to reach set point varies based

upon ambient temperature, temperature of product loaded, door openings,

etc. Marvel recommends allowing the unit to reach set points before

loading.

NOTE

High/Low Temp Notifications

When the compartment temperature exceeds the control

setting for an extended amount of time:

•“HH” will appear in display (High

Temp)

•“LL” will appear in display (Low Temp)

Contact service dept. for further instructions.

Press or and release to adjust the upper

zone. Press to change to lower zone.

Press or and release to adjust.

Note: The set temperature of the lower zone can't be

colder than the set temperature of the upper zone.

Adjusting the set temperature of the upper zone may

cause the lower zone to automatically adjust. The lower

zone cannot be more than 20oabove the set temperature

of the upper zone.

See table on next page.

18

Control Operation

Dual Zone Temperature Table

Note: The temperature of the lower zone

cannot be less than the temperature of

the upper zone.

Dual Zone

Upper Zone:

38° - 65°

Lower Zone: 38° - 65°

Minimum Maximum

38 38 58

39 39 59

40 40 60

41 41 61

42 42 62

43 43 63

44 44 64

45 45 65

46 46 65

47 47 65

48 48 65

49 49 65

50 50 65

51 51 65

52 52 65

53 53 65

54 54 65

55 55 65

56 56 65

57 57 65

58 58 65

59 59 65

60 60 65

61 61 65

62 62 65

63 63 65

64 64 65

65 65 65

19

INTERIOR ADJUSTMENTS

Figure 33

Figure 33a

!CAUTION

Never try to remove a loaded shelf, remove everything from

the shelf before removing. Use both hands when removing

the shelf.

To remove a shelf:

Extend the shelf out of the cabinet until it stops.

Unload the shelf (see Figure 33).

Depress the locking tabs on both sides of the shelf and pull

the shelf straight out (see Figure 29a). When the shelf is

removed, push the extended cabinet mounted shelf exten-

sions back into the cabinet.

To re-install a shelf:

Pull out the cabinet mounted shelf extensions to assist the

engagement with the wire rack shelf.

Insert the wire rack side track into the cabinet mounted

shelf extensions on both sides.

Push the wire rack completely into the cabinet to engage

the locking tabs.

Pull the shelf out, (unloaded), to verify the wire rack is

locked into the side rails. If the wire rack falls out, the lock-

ing tabs are not engaged; repeat the installation.

Load the shelf as required.

Locking tab

Remove the

wine from the

shelf to be

removed

20

Table of contents

Other Marvel Refrigerator manuals

Marvel

Marvel 66WBM-BS-G User manual

Marvel

Marvel MLBV024-SS01A User manual

Marvel

Marvel 6BARM User manual

Marvel

Marvel 24" Refrigerated Drawers 6ORDE Manual

Marvel

Marvel 3BAR-BB-G User manual

Marvel

Marvel MLNP115-IG01A User manual

Marvel

Marvel 66SWBE-BS-G User manual

Marvel

Marvel MP15BCG4 Series Manual

Marvel

Marvel MOCL215-SS01B User manual

Marvel

Marvel MLRE215-SG01A User manual

Marvel

Marvel MORE124 User manual

Marvel

Marvel MS15RA Manual

Marvel

Marvel MLBV215-SG01A User manual

Marvel

Marvel 3BARM-BB-G User manual

Marvel

Marvel 5CAF fmar User manual

Marvel

Marvel 3SBAR Guide

Marvel

Marvel 66SBWE-BN User manual

Marvel

Marvel MLBV215 User manual

Marvel

Marvel MLBD224 User manual

Marvel

Marvel MABV224-SG31A User manual