GB - 9

Personal Safety

Only trained adults may operate unit.

Training includes actual operation.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

NEVER allow anyone to operate this unit

when their alertness or coordination is

impaired.

DO NOT operate unit without wearing

adequate winter outer garments. Wear

adequate safety gear and protective gloves.

Wear proper footwear to improve footing on

slippery surfaces.

Protect eyes, face and head from objects that

may be thrown from unit. Wear appropriate

hearing protection.

Avoid sharp edges. Sharp edges can cut.

Moving parts can cut off fingers or a hand.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

ALWAYS keep hands away from all pinch

points.

DO NOT touch unit parts which might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust or service.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

DO NOT wear loose clothing or jewelry and tie

back hair that may get caught in rotating parts.

Keep children and people away from unit

during operation.

Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects. Use extreme caution on gravel

surfaces. Stay alert for hidden hazards or

traffic.

Deflected materials can cause injury and

property damage.

Always stand clear of the discharge area when

operating this unit.

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

Service

Before cleaning, removing clogs or making

any inspections, repairs, etc.: disengage

clutch(es), stop unit and engine, remove key,

allow moving parts to stop. Allow hot parts to

cool.

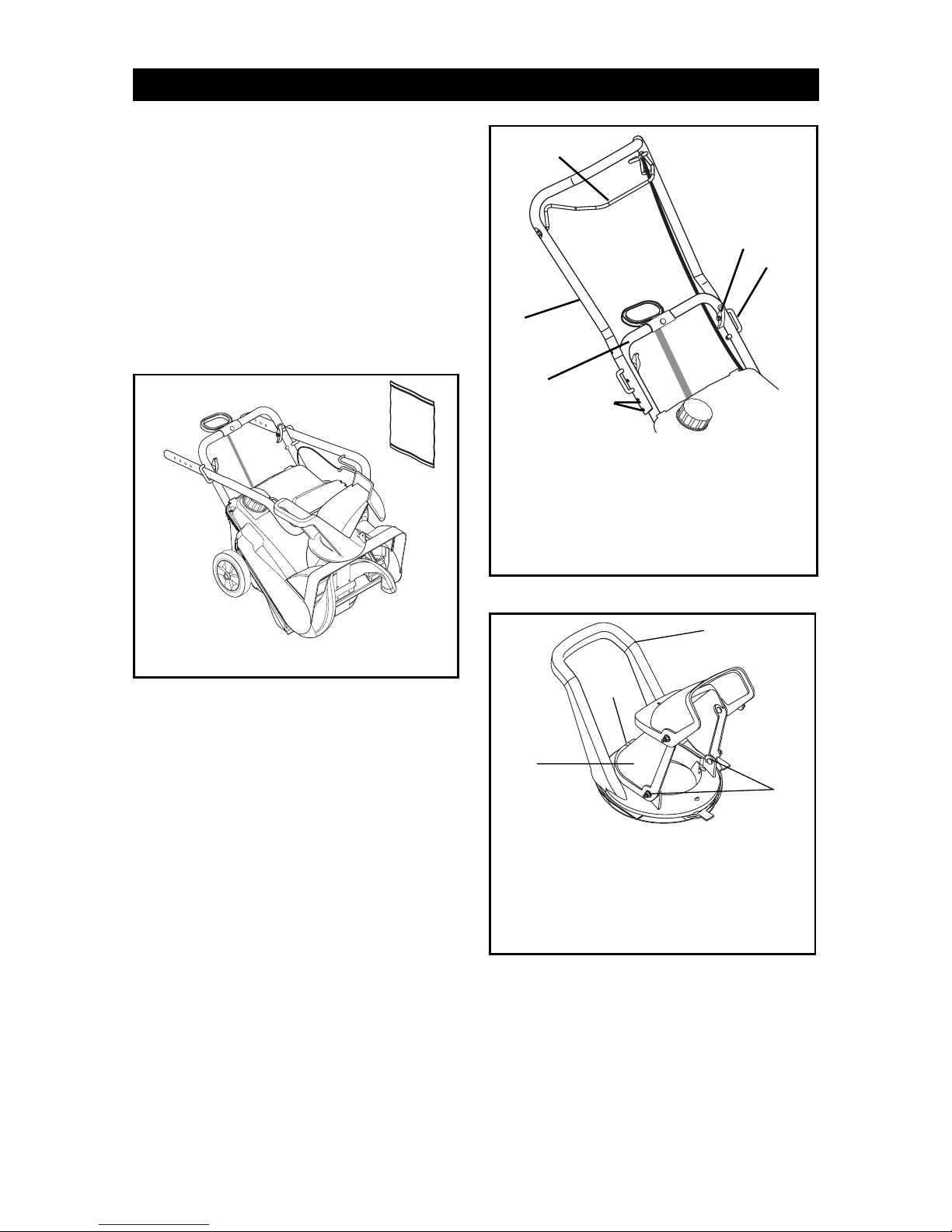

Before tipping unit up onto housing, remove

enough fuel so no spills will occur. Ensure unit

is secure and will not tip over during

maintenance.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use an approved

fuel container.

NO smoking, NO sparks, NO flames. ALWAYS

allow engine to cool before servicing.

NEVER fill fuel tank when engine is running or

hot from operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled

fuel.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

Keep all hardware properly tightened.

Cleaning

Keep unit free of ice or other debris. Clean up

oil or fuel spills.

Storage

For unit storage or extended storage:

•NEVER store with fuel in fuel tank, inside

a building where any ignition sources are

present.

•Allow engine to cool completely.

•For extended storage, clean unit

thoroughly. See Engine Manual for proper

storage.

Transport

ALWAYS shut off engine and drain fuel when

transporting unit on a truck or trailer.

Use extra care when loading or unloading unit

onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

Spark Arrester

This product is equipped with an internal

combustion type engine. DO NOT use unit on

or near any unimproved, forest-covered or

brush covered land unless exhaust system is

equipped with a spark arrester meeting

applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in

effective working order by operator.