10

SAMPLER SYSTEM READY

HH:MM:SS MM/DD/YYYY

BATTERY CHARGING

The Composite Sampler is equipped with an internal four

state battery charger capable of diagnosing and automatically

charging the internal battery. The operator only needs to

connect the AC/DC Universal Power Supply/Converter or

Automotive Power Adapter accessory. The sampler system

will automatically power up and begin charging the battery.

After 10 minutes the LCD display on the control console will

power down, going blank. The battery will continue to charge

until it has reached is full potential. Once the battery is fully

charged, the battery will be placed on a float or maintenance

charge until the external power source is disconnected.

The system may run or be programmed while the unit is

charging. Battery charging will continue in the background

while other operations are taking place. Allow a minimum of

8 hours to fully charge the battery from a fully discharged

state with no other operations occurring. During battery

charging all functions of the sampler are operational.

WARNING! The AC/DC Power Supply/Converter

is rated for INDOOR USE ONLY.

DO NOT use the AC/DC Power

Supply/Converter in an outdoor

environment to either charge the

battery or power the drive. Electrical

shock, severe injury and/or death is

possible if this warning is ignored.

SETTING THE TIME AND DATE

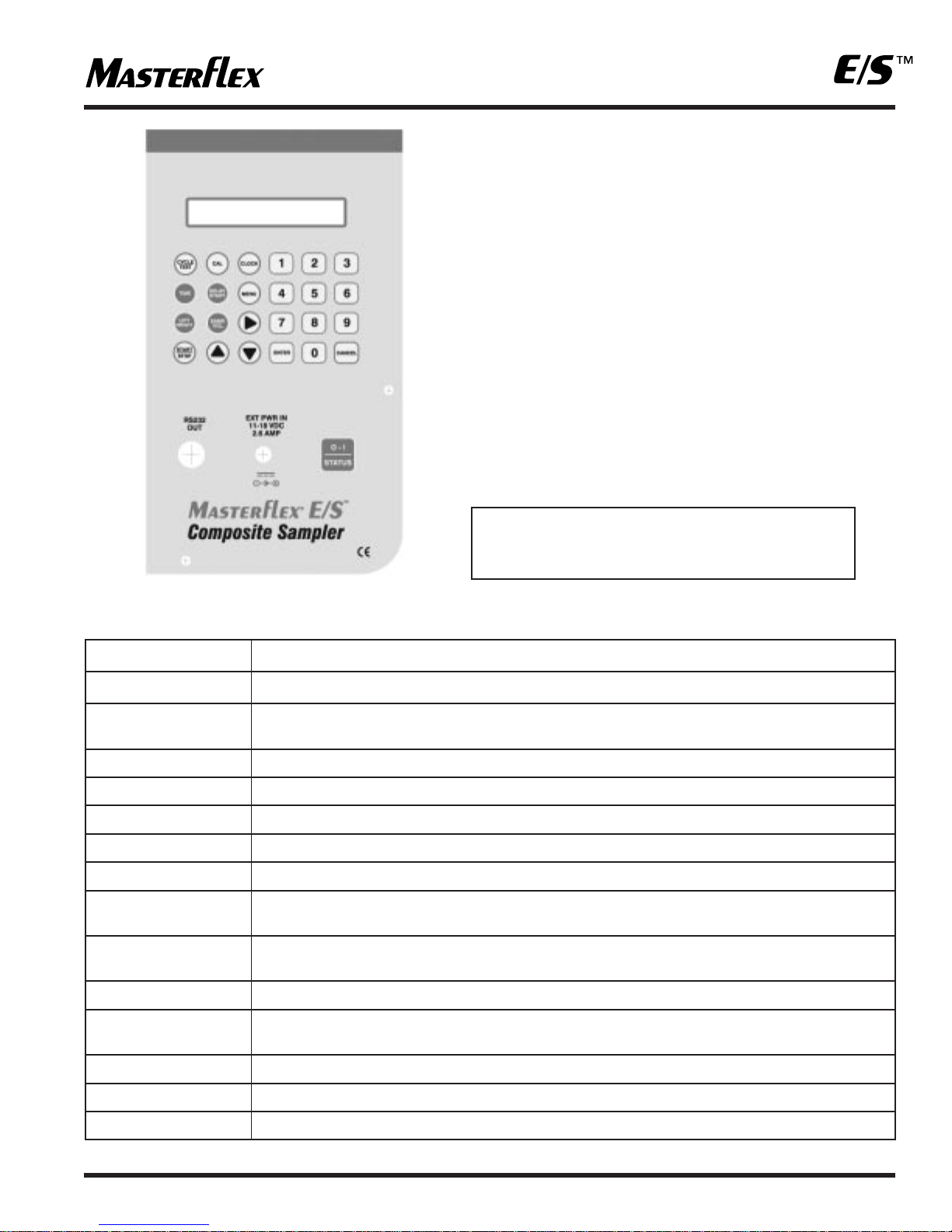

Press the keypad's CLOCK key. The display will read:

TIME

The clock used in the Composite Sampler is a 24-hour clock,

does not use an AM or PM notation and shows the time in

an HH:MM:SS format. The clock displays 12:00 AM midnight

as 00:00:00 (the starting point of the clock), 6:00:00 AM as

06:00:00, 12:00:00 PM (or noon) as 12:00:00 and 6:00 PM

as 18:00:00.

If a sample was taken at 3:00 PM the clock will read 15:00:00.

The Composite Sampler clock was set at the factory based

upon our local time. The time is expressed as hour, hour,

minute, minute, second, second. If the current time on the

clock is correct, bypass setting the time by pressing ENTER

or CANCEL and you will be taken to the screen where you

may change the date. See the screen below.

If you need to correct the time shown on the clock, use the

numeric keypad to enter the current time and press ENTER.

The display will change to the date correction screen as

shown below.

DATE:

The calendar date is expressed as month, month, day, day,

year, year.

If the date is correct, press ENTER or CANCEL and you will

be taken back to the system prompt.

If you need to correct the date shown, use the numeric

keypad, enter the date and press ENTER.

EXAMPLE: To enter January 1, 2003, press 10103 on the

numeric keypad and press ENTER.

To enter December 31, 2002, press 123102 on

the numeric keypad and press ENTER.

You will then be taken back to the system prompt screen

which will now display the current time and date.

SECURITY

The Composite Sampler will be exposed to an outdoor

environment in which the operator may or may not be

present or in attendance. To protect the unit from tampering

by unauthorized individuals the sampler housing may be

locked using the two locking latches on the exterior of

the housing.

In addition a security feature has been incorporated into

the Composite Sampler to lock the keypad.

SET TIME (HR:MIN:SEC)

20:30:57 (23:59:59)

SET DATE (MON/DAY/YR)

09/21/02 (MM/DD/YY)