©2011 Mate Precision Tooling Dimensions in Inches(millimeters) Page 3

1. Safety Rules

Installation and operation of the machine must comply with regulations valid in the country in which the

machine is installed. The person using the machine is responsible for observing the following regulations.

Modifications of the machine are not permitted. Only skilled operators who have been properly trained

and are acquainted with the operating instructions should operate the machine.

While working with the machine, observe the working instructions and warning labels. The following

activities are prohibited:

●Utilization of the grinding machine for purposes other than the purposes for which the grinding

machine is intended for

●Insertion of any objects in any way under the work pieces

●Grinding of work pieces made of aluminium, magnesium or other materials which pose a fire or

explosion hazard

●Utilization of the appliance without protective covers

Before every start of the machine, always carry out a visual inspection to check that the power cable is

undamaged. When working with the machine, always use safety goggles.

Loading or unloading of tooling, adjustments of the cooling liquid nozzle, and of the grinding wheel cover

may only be carried out when the machine is turned off.

CAUTION: All the adjustment or maintenance operations may only be carried out with the

machine disconnected from the supply mains.

The user is obligated to operate the machine solely in the perfect state. In the case of a repair, only

original spare parts and accessories may be used.

Apart from these instructions, safeguards to prevent injuries and generally accepted safety rules must be

observed!

Following is an Outline of Possible Risks which may arise as a consequence of improper

machine use or an operator not acquainted with the operating instructions.

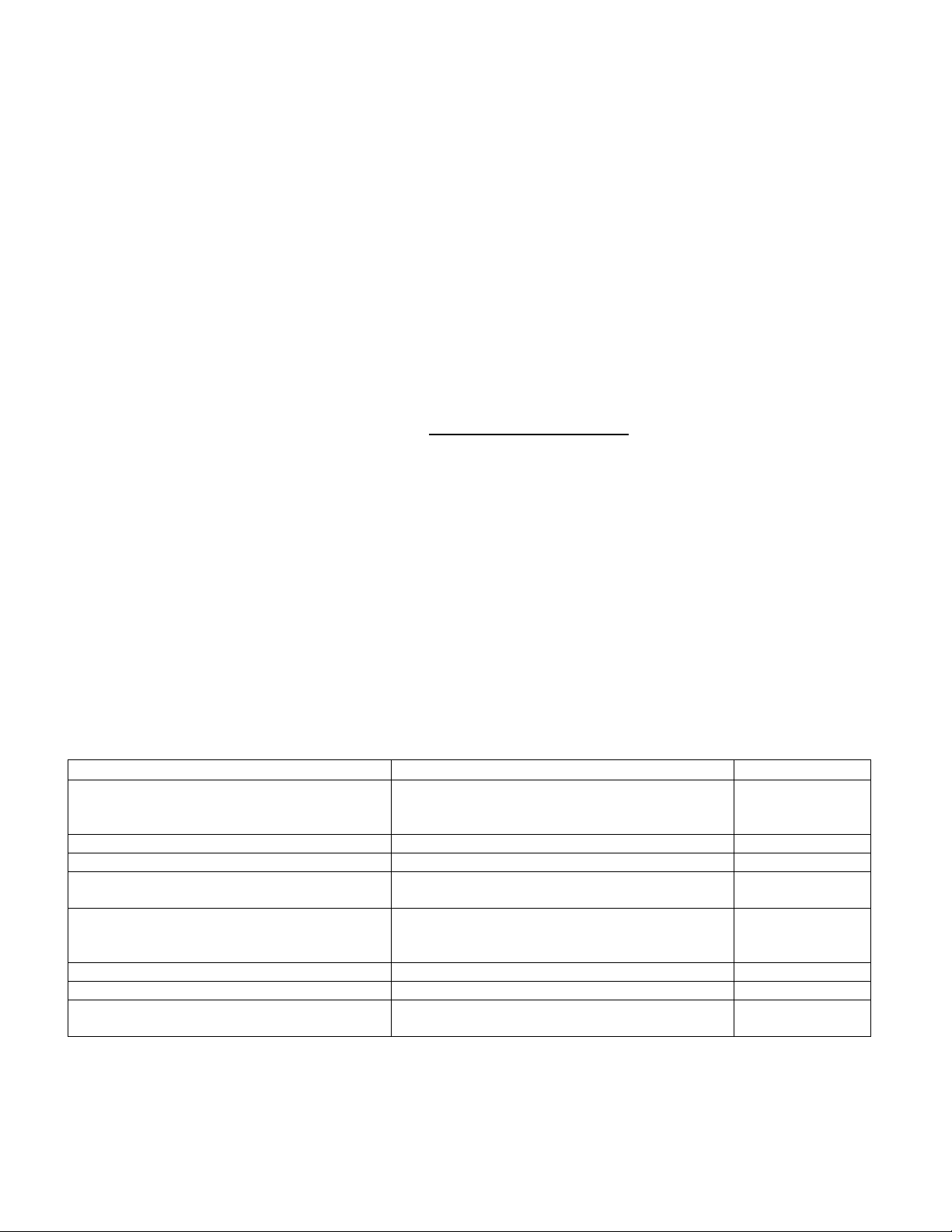

Type of danger Dangerous point Risk

Danger to parts of the body arising from the

pressure of mechanical parts

Space between the motor and the knob used to

control the travel, operational range of the

rotating arm

Danger of injury

Danger arising from the grinding wheel Rotating grinding wheel Danger of injury

Danger arising from flying objects Grinding wheel, fixtures not properly clamped Danger of injury

Danger of cutting oneself with the ground

tool

Removing and installing tooling Danger of injury

Danger arising from electric current Directly - parts which are normally live

Indirectly - parts which are live in the event of a

failure

Danger to life

Danger to life

Danger arising from sparks and filings Working area of the grinding machine Danger of injury

Danger arising from the sprayed out liquid Hose, Nozzle Danger of injury

Danger arising from the inhalation of vapours

and dusts

Working area of the grinding machine Danger to health