Maxcess MAGPOWR B Series Manual

Other Maxcess Spring Applied Brake manuals

Popular Spring Applied Brake manuals by other brands

Kendrion

Kendrion 76..P..B00 Series operating instructions

INTORQ

INTORQ BFK471-25 Translation of the original operating instructions

INTORQ

INTORQ BFK455 operating instructions

Nexen

Nexen AIR CHAMP DBSE user manual

Kendrion

Kendrion EEX Series operating instructions

Leantechnik

Leantechnik SHB Series operating instructions

Kobelt

Kobelt 5022-A Owner's Operation, Installation & Maintenance Manual

Mayr

Mayr ROBA-stop-M 250 Operational instructions

INTORQ

INTORQ BFK458 Original operating instructions

COREMO OCMEA

COREMO OCMEA E4N-ID User and maintenance manual

Nexen

Nexen AIR CHAMP DPB-9T user manual

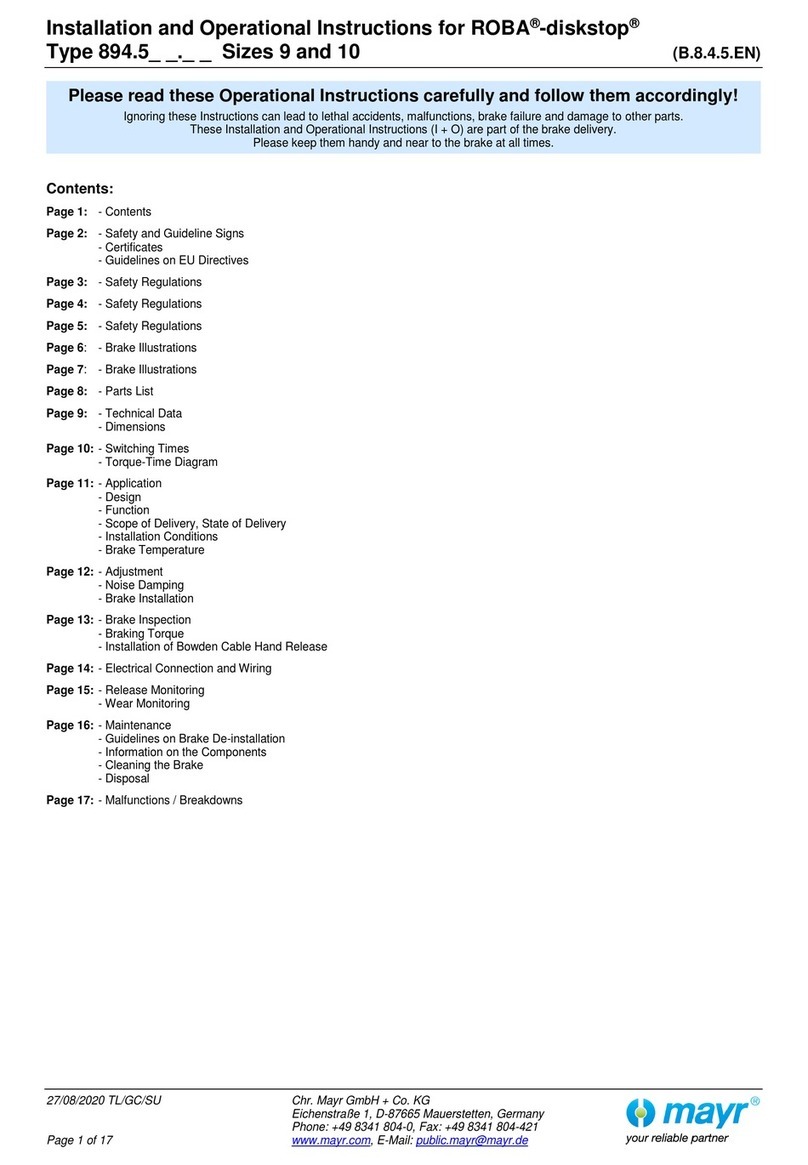

Mayr

Mayr ROBA-diskstop 894.5 Series Installation and operational instructions

INTORQ

INTORQ BFK468 operating instructions

INTORQ

INTORQ BFK458-ATEX Translation of the original operating instructions

WABCO

WABCO PAN 17 Assembly and maintenance instructions

Kendrion

Kendrion INTORQ BFK458-ATEX Original operating instructions

INTORQ

INTORQ 14.105 Series operating instructions

Haldex

Haldex Maxibrake 50 Series Service parts