Contents

1 General information................................................................................................................................................... 5

1.1 Using these Operating Instructions ...................................................................................................................... 5

1.2 Conventions in use............................................................................................................................................... 5

1.3 Safety instructions and notices ............................................................................................................................ 6

1.4 Terminology used................................................................................................................................................. 7

1.5 Abbreviations used............................................................................................................................................... 7

2 Safety instructions..................................................................................................................................................... 9

2.1 General safety instructions................................................................................................................................... 9

2.2 Disposal ............................................................................................................................................................... 9

3 Product description ................................................................................................................................................. 10

3.1 Proper and intended usage................................................................................................................................ 10

3.1.1 Standard applications ............................................................................................................................ 10

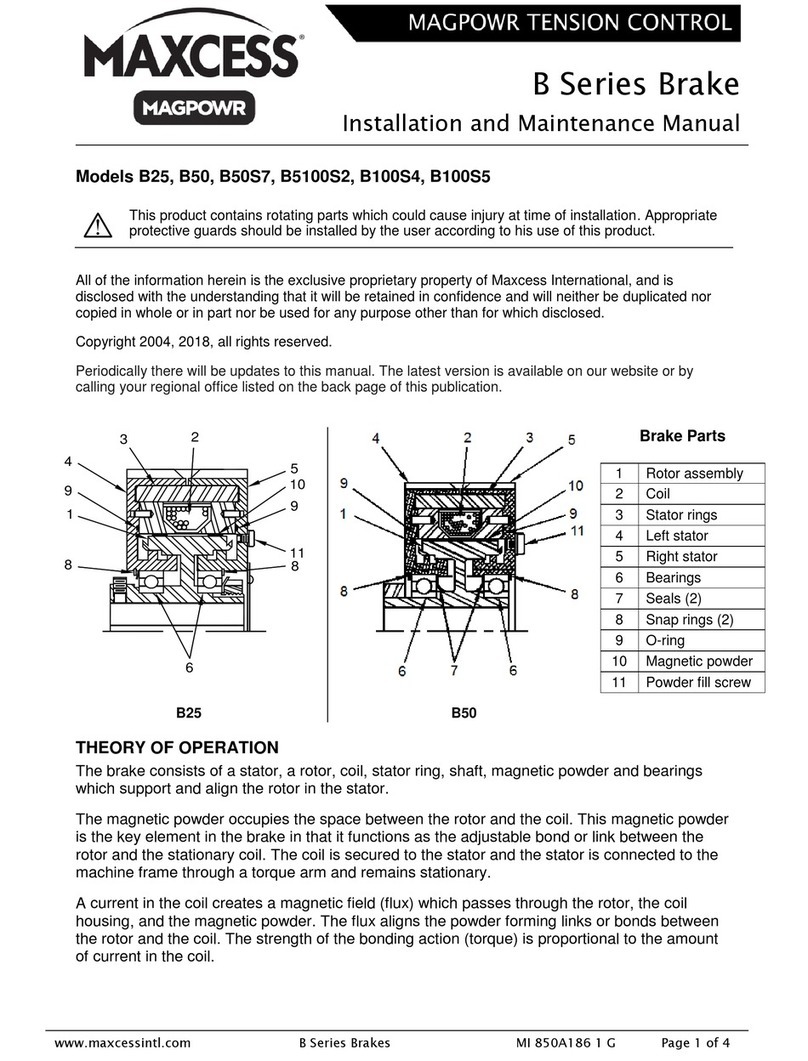

3.2 Layout ................................................................................................................................................................ 10

3.2.1 Spring-applied brake BFK518 ............................................................................................................... 10

3.3 Function ............................................................................................................................................................. 11

3.4 Braking and release ........................................................................................................................................... 11

3.5 Project planning notes........................................................................................................................................ 11

4 Technical specifications.......................................................................................................................................... 12

4.1 Possible applications of the INTORQ spring-applied brake ............................................................................... 12

4.2 Rated data.......................................................................................................................................................... 12

4.3 Switching times .................................................................................................................................................. 13

4.4 Electromagnetic compatibility............................................................................................................................. 15

4.5 Emissions........................................................................................................................................................... 15

4.6 Rust film on friction parts.................................................................................................................................... 15

4.7 Labels on product............................................................................................................................................... 16

5 Mechanical installation............................................................................................................................................ 18

5.1 Design of end shield and shaft........................................................................................................................... 18

5.2 Tools .................................................................................................................................................................. 18

5.3 Preparing the installation.................................................................................................................................... 18

5.4 Installing the hub onto the shaft ......................................................................................................................... 19

5.5 Brake mounting .................................................................................................................................................. 20

INTORQ | BA 14.0222 | 06/2020 3