Page - 5 - of 23

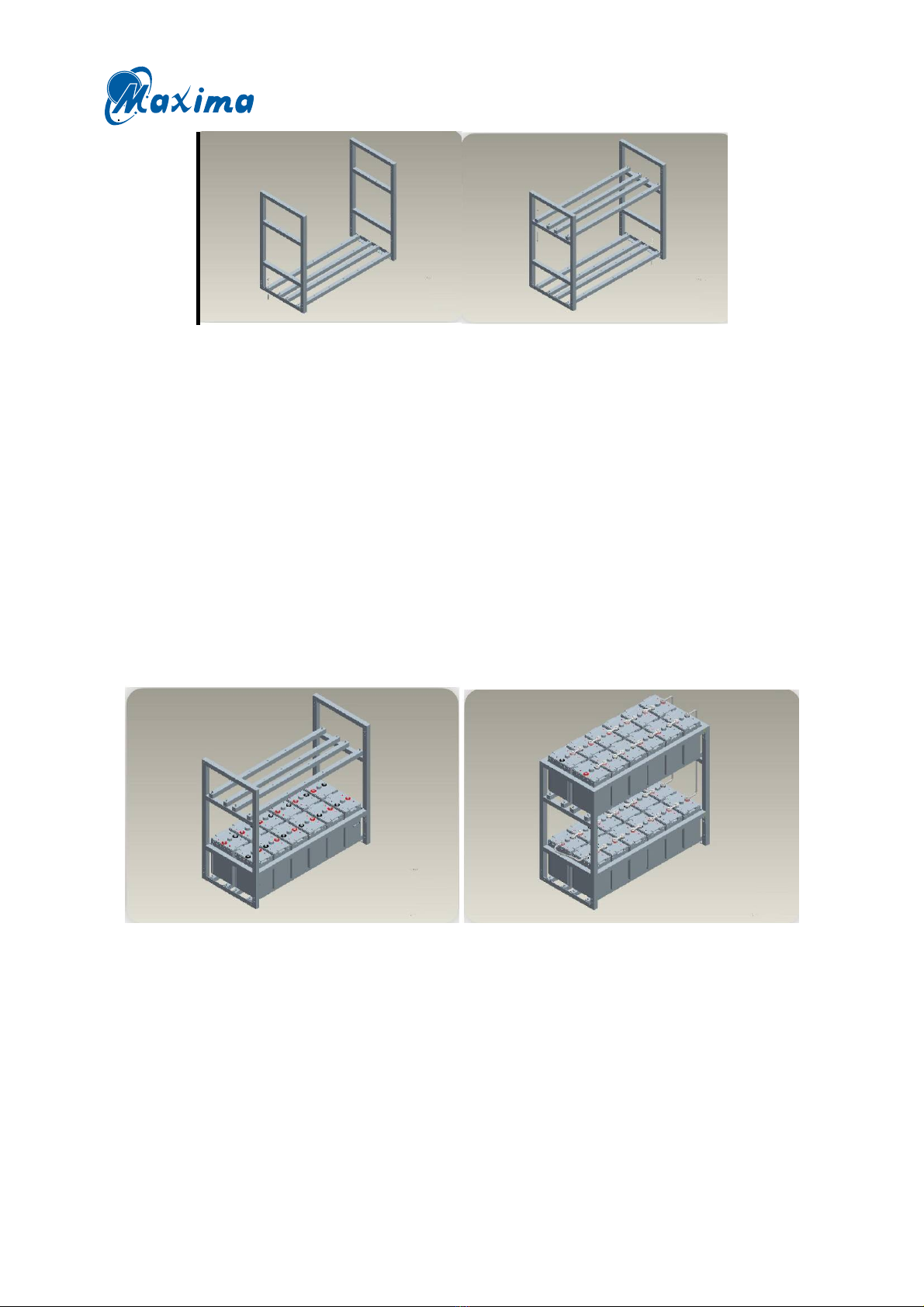

5. Installation of batteries

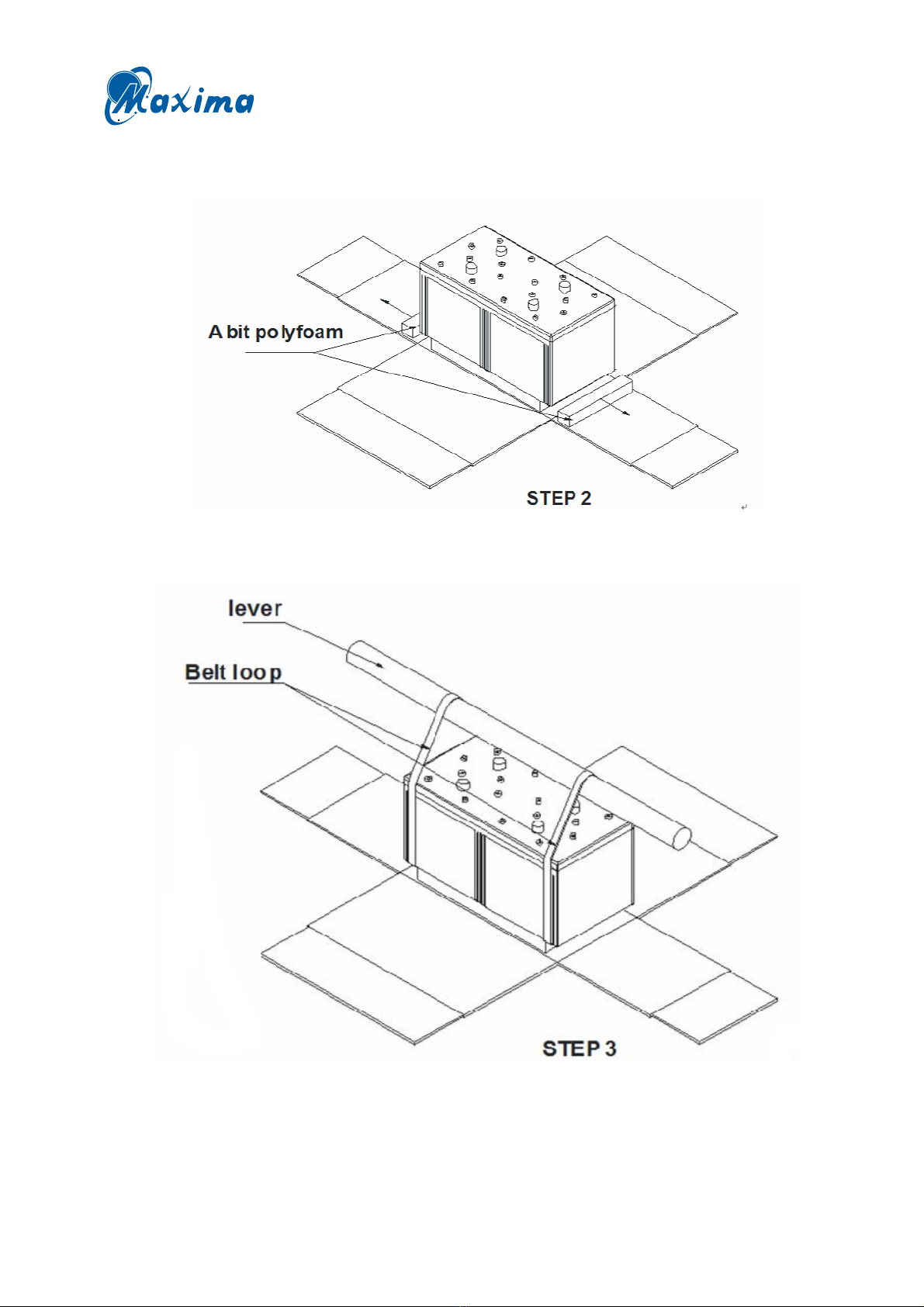

5.1 Unpack and check

Delivery: Prevent any force on the terminal; do not tamper with any seals.

Do not place upside down, Do not throw or cause any impact to the battery;

Do not cause any metallic short circuit.

Inspection: packaging / appearance of battery for signs of damage;

Check parts list: battery quantity; accessories;

Reference: catalogue; installation drawing; other notices.

5.2 Notices before Installation

If no abnormity after check, install the batteries in the designated position;

If installing the batteries in the battery chamber, place them starting at the bottom of chamber;

Avoid installing the batteries near any heat supply such as transformers or heat exhaust of other

equipment;

A battery may cause flammable gas during storage, avoid enclosing with any apparatus which

produce flames / sparks

Before connecting, clean the terminals to bright metal.

Ensure that no conductive material can connect between positive and negative terminals.

Before installation all tools are insulated;

5.3 Installation and connection

Use insulated tools only;

Connect batteries, then connect battery group with charger or load;

When multi-group batteries are parallel connected, connect in series first and then parallel

connection;

To ensure good ventilation, the batteries per row should keep around 10 - 20mm inter-bloc spacing;

Before connection, clean the battery terminals to bright metal;

Before and after connection, apply antirust compound such as petroleum gel on the surface of

battery terminal;

After batteries are installed, test the voltage of the battery group, if correct link battery to load.

Use correct torque on all terminals, ensuring every connecting nut and screw is secure; see torque

settings as table 1

Table 1 Suggested torque table

JUBILEE STORE L.L.C