Model 70154, 70155 Page 3

Personal and Work Area Safety (continued)

F. While assembling and using the Swivel

Jack keep work area clean and well lighted.

Keep spectators and children out of the work

area.

3. Use of the Swivel Jack

A. Trailer tongue weight (TW) is the down-

ward pressure that the trailer coupler places

on the hitch ball. Usually, TW is about 10%

of the Gross Trailer Weight (GTW); GTW is

the weight of the trailer when fully loaded.

Only use a Swivel Jack that has a capac-

ity that matches or exceeds the trailer

tongue weight (TW).

Do not exceed this Swivel Jack’s 2,000

Lbs. maximum capacity.

B. When assembling and setting-up the

Swivel Jack, the trailer must be on a smooth,

C. Use this product in accordance with De-

partment of Transportation (DOT) rules and

regulations. More information can be found

at www.dot.gov/regulations.html.

D. The Swivel Jack is designed to be

mounted to the trailer’s tongue and is used

when hitching and unhitching the trailer’s

hitch from the vehicle. Use of the Swivel

Jack for operations other than those intend-

ed could result in serious personal injury and

property damage. The Swivel Jack is not for

aircraft applications.

E. Frequently check and maintain the Swiv-

el Jack. Check for loose hardware, misalign-

ment or binding of moving parts and damage

to components. If the Swivel Jack needs

servicing, it should only be performed by a

F. Chock trailer wheels when setting up this

product and when using the Swivel Jack to

raise or lower the trailer tongue.

G. Keep clear of the underside of trailer, and

a safe distance from the Swivel Jack when

raising or lowering the load and when re-

positioning the trailer.

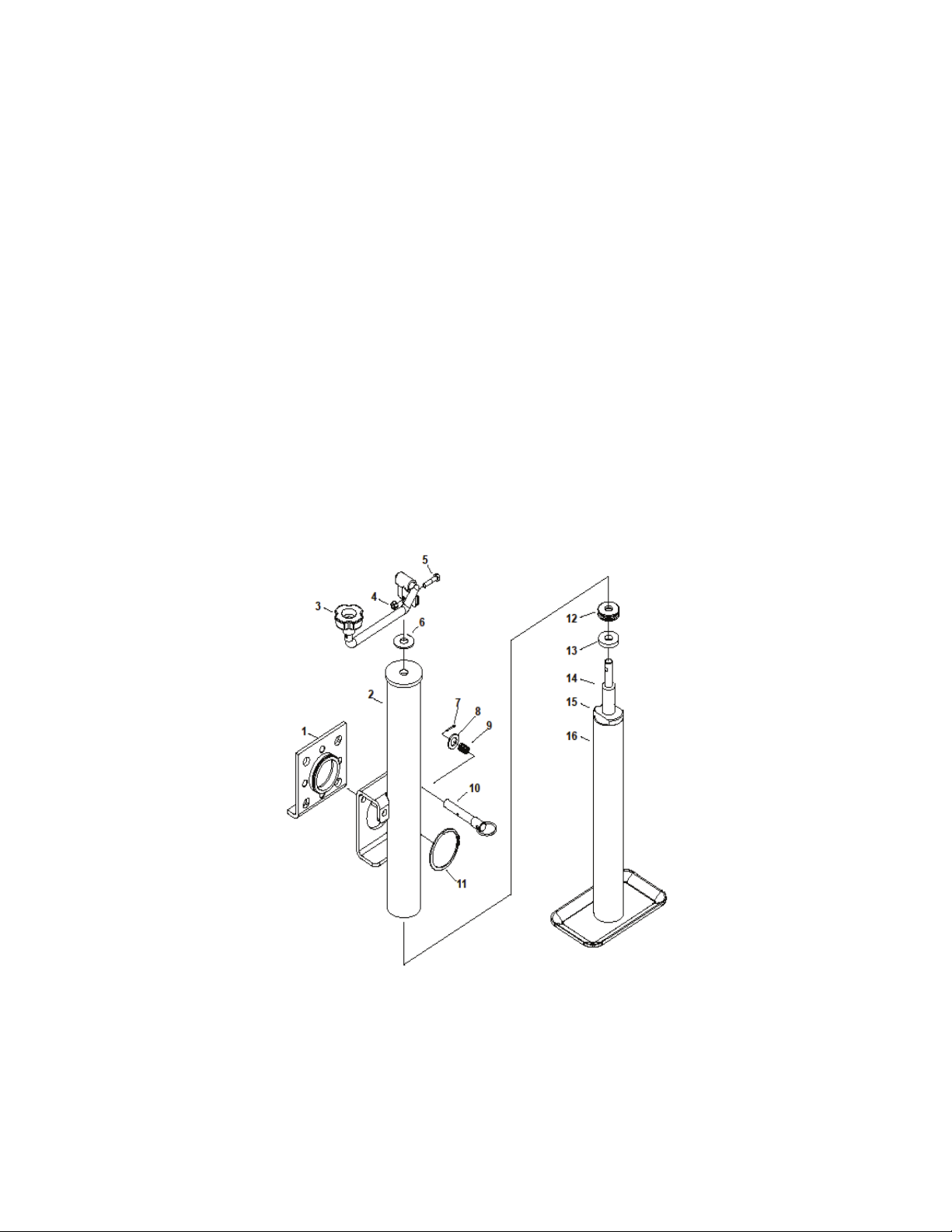

H. Swivel Jack must be locked in vertical

position before the load is applied. Make

sure the Locking Pin (10) is fully inserted

into the Swivel Plate (1). Before moving

the trailer, the Swivel Jack must be secured

properly in its horizontal position, with Lock-

ing Pin fully inserted in Swivel Plate.

I. The Swivel Plate (1) must be welded to

the trailer tongue. Never try to modify or

disassemble the Swivel Plate or the Locking

Pin (10) when Swivel Jack is under load.

J. Always wear ANSI approved safety

glasses when mounting and using the Swivel

Jack. Keep spectators and children away

when using the Swivel Jack.

K. Be aware of the danger of “dynamic

loading”. This situation arises when a load

is dropped onto the Swivel Jack or trailer

tongue, resulting in a short term excessive

load. Dynamic loading can result in damage

and failure of the Swivel Jack and/or trailer

tongue, and personal injury to the person us-

ing the Swivel Jack.

L. If Swivel Jack is used on a boat trailer,

never disconnect the trailer from vehicle and

use the Swivel Jack to maneuver the boat

down a boat ramp.

Keep in mind that the warnings previous-

ly discussed cannot cover all possible

events and circumstances. It is impor-

tant that the person using this product

use common sense at all times.

WARNING

MAXXHAUL is not responsible for the at-

tachment or the installation of this