112204- 2 Maytag Co. 7

Installation Procedures _______________

Before installing the dryer, ensure the location conforms to

local codes and ordinances. In the absence of such codes

or ordinances the location must conform with the National

Fuel Gas Code ANSI.Z223.1 LATEST EDITION, or in

Canada, the installation must conform to applicable

Canadian Standards: CAN/CGA-B149.1-M91 (Natural Gas)

or CAN/CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION

(for General Installation and Gas Plumbing).

The operation of this dryer may affect the operation of other

types of gas dryers, which take their air for safe combustion

from the same room. If in doubt, consult the dryer

manufacturer(s).

The dryer must be installed on a sound level floor capable

of supporting its weight. Carpeting must be removed from

the floor area that the dryer is to rest on.

Provisions for adequate air supply must be provided as noted

in this manual (refer to Fresh Air Supply Requirements

section).

Clearance provisions must be made from combustible

construction as noted in this manual (refer to Dryer Enclosure

Requirements section).

Provisions must be made for adequate clearances for

servicing and for operation as noted in this manual (refer to

Dryer Enclosure Requirements section).

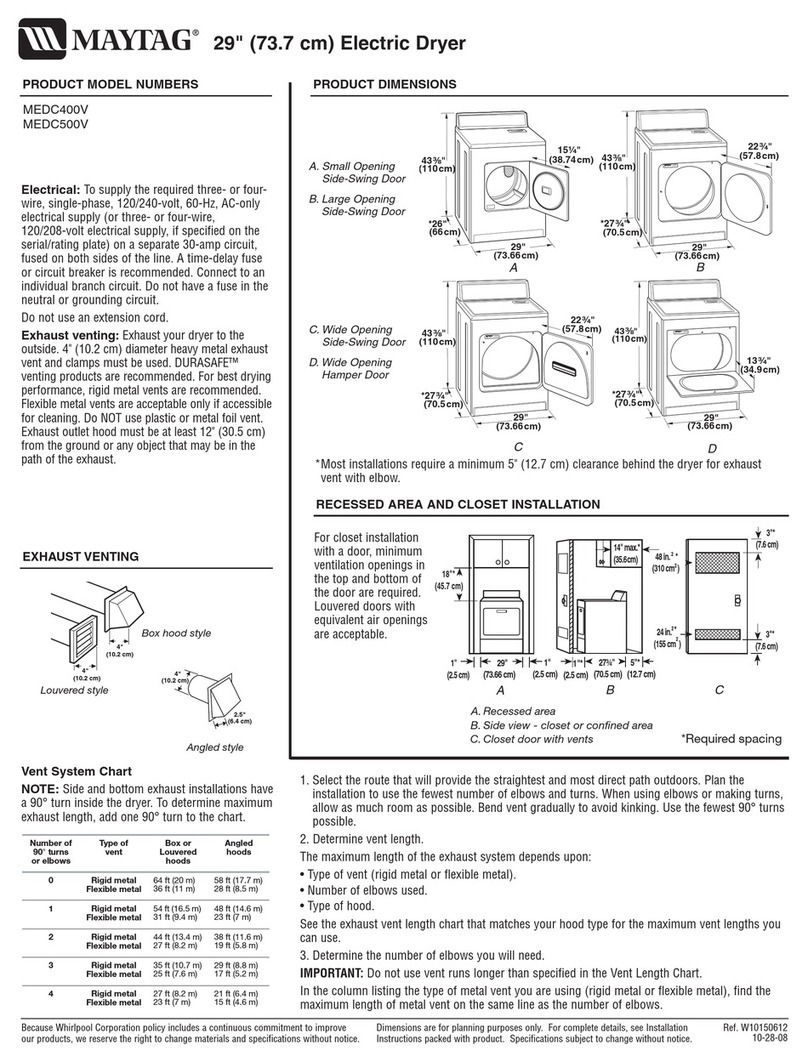

The dryer must be installed with a proper exhaust duct

connection to the outside as noted in this manual (refer to

Exhaust Requirements section).

The dryer must be located in an area where correct exhaust

venting can be achieved as noted in this manual (refer to

Exhaust Requirements section).

IMPORTANT: The dryer should be located where a

minimal amount of exhaust ducting will be necessary.

The dryer must be installed with adequate clearance for air

openings into the combustion chamber.

IMPORTANT: The dryer must be installed in a location/

environment, where the ambient temperature remains

between 0° F ( . ° C) and 130° F (5 . ° C).

Excessive Weight Hazard

Use two or more eo le and mechanical

equi ment to lift, move and install dryer.

Failure to do so can result in back or other injury.

Ex losion Hazard

Kee flammable materials and va ors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, ex losion, or

fire.

Location Requirements _______________

Installation should be performed by competent professional

in accordance with local, state, and country codes. In the

absence of these codes, the installation must conform to

applicable American National Standards: ANSI Z223.1-

LATEST EDITION (National Fuel Gas Code) or ANSI/NFPA

NO. 70-LATEST EDITION (National Electrical Code) or in

Canada, the installation must conform to applicable

Canadian Standards: CAN/CGA-B149.1-M91 (Natural Gas)

or CAN/CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION

(for General Installation and Gas Plumbing) or Canadian

Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST

EDITION (for Electrical Connections).

Leveling Dryer

The dryer is equipped with 4 leveling legs, 1 at each corner

of the base. For optimum performance the dryer should be

level front-to-back and side-to-side.

Tools Required

■Utility Knife to remove packaging

■9/16” Box wrench or 9/16” socket to remove pallet bolts

■#2 Phillips screwdriver to open front toe panel

■Pipe wrench for gas connections

■7/8” open end wrench or adjustable wrench

to install coin box lock

■TORX® T20 TORX® T25 to open rear bottom guard

to get foot adjustment ends

■1/4” socket or 1/4” open end wrench to make the

leg adjustment

■A pair of slip-joint pliers

®TORX is a registered trademark of Textron Innovations, Inc.

Installing Door Handle

1. Remove handle from dryer tumbler.

2. Unwrap door handle from bubble wrap.

3. Locate handle standoff in the handle slots.

4. Insert 1/4-20 x 2-1/4” stainless Truss Head Phillips screws

through preexisting door holes.

5. Having handle flushed against door, tighten the two

stainless Phillips screws.

!WARNING

!WARNING