Maytag MLG31PCB User manual

Other Maytag Dryer manuals

Maytag

Maytag 3RLGR5437 User manual

Maytag

Maytag MDG6700AWM User manual

Maytag

Maytag CYE3005AYW User manual

Maytag

Maytag W10155111A User manual

Maytag

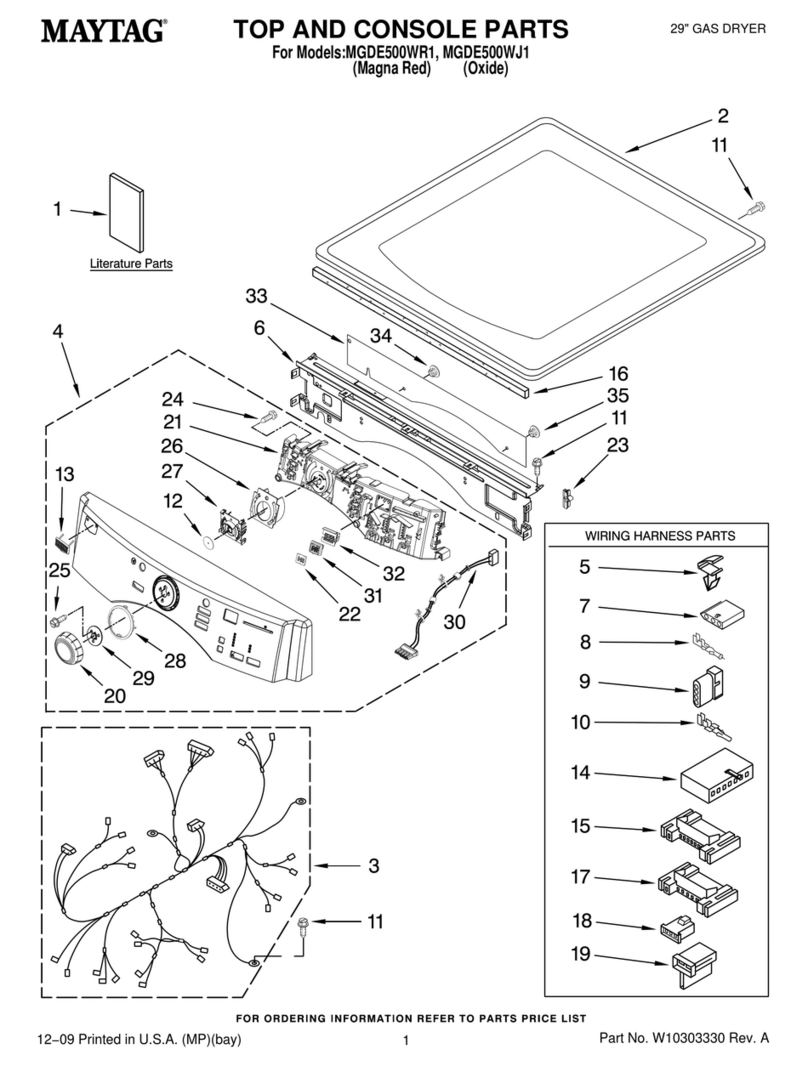

Maytag MGDE500WJ1 User manual

Maytag

Maytag YMEDB725CG0 User manual

Maytag

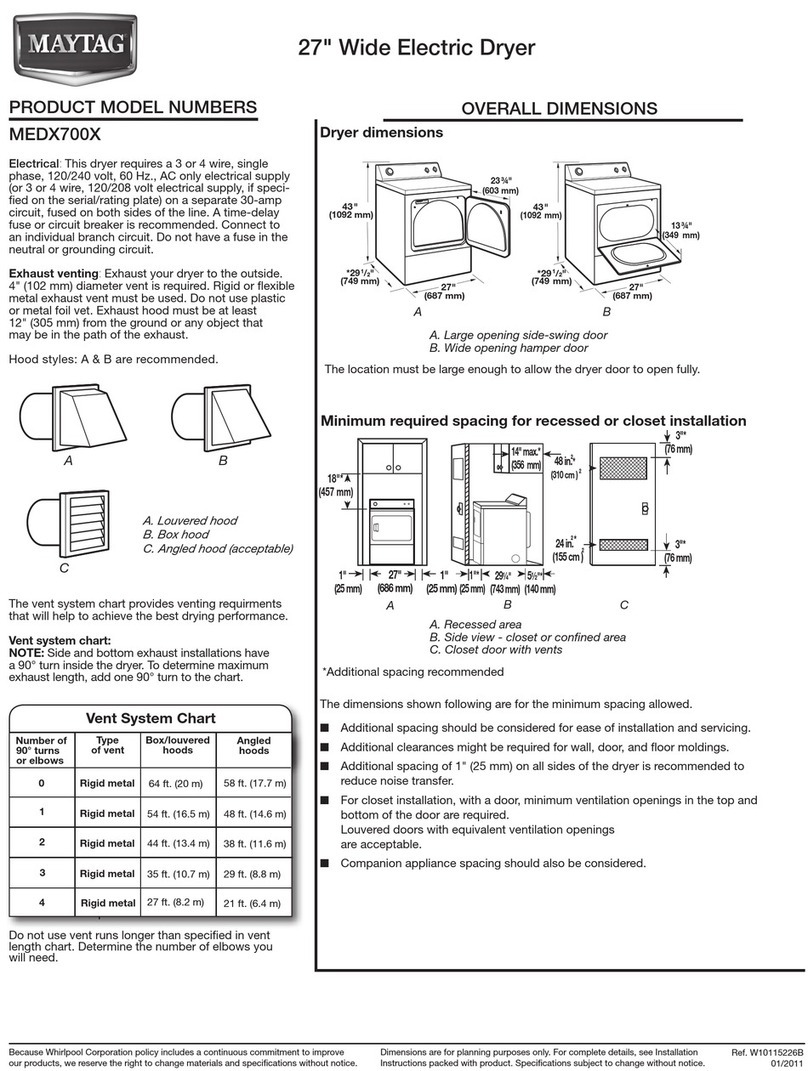

Maytag MEDX700X Parts list manual

Maytag

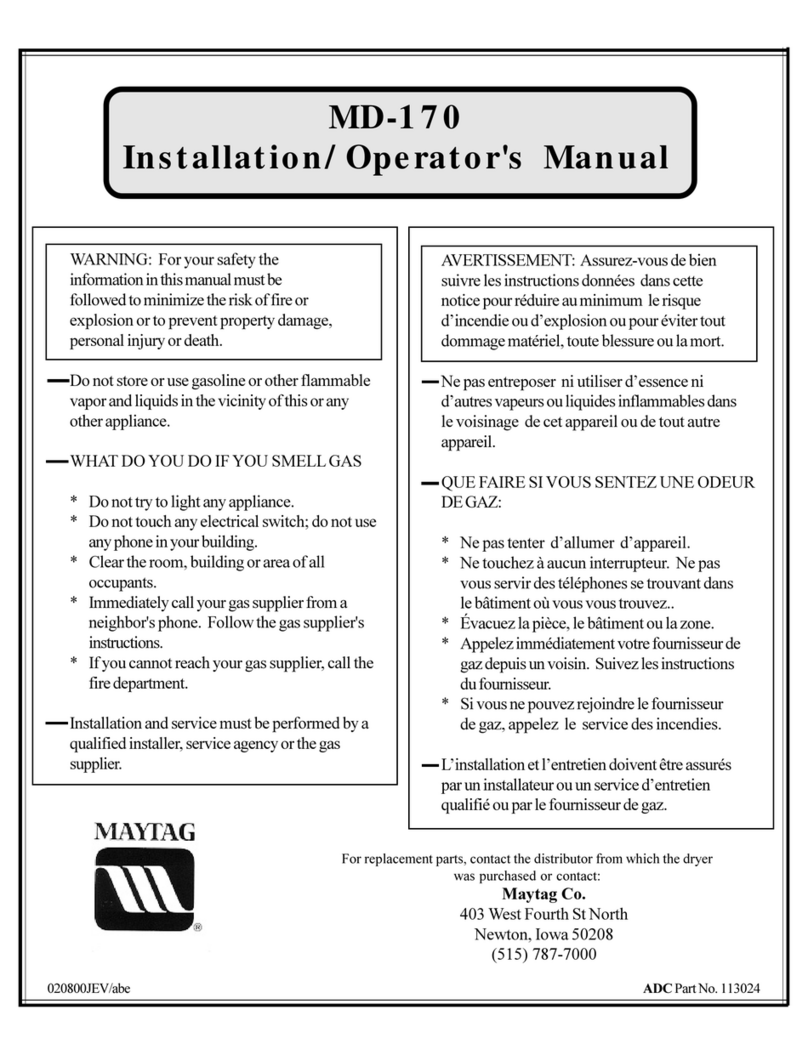

Maytag MDG-170 Administrator Guide

Maytag

Maytag MDG28PD User manual

Maytag

Maytag W10150622A User manual

Maytag

Maytag MEDC215EW Installation instructions

Maytag

Maytag MEDB766FW0 User manual

Maytag

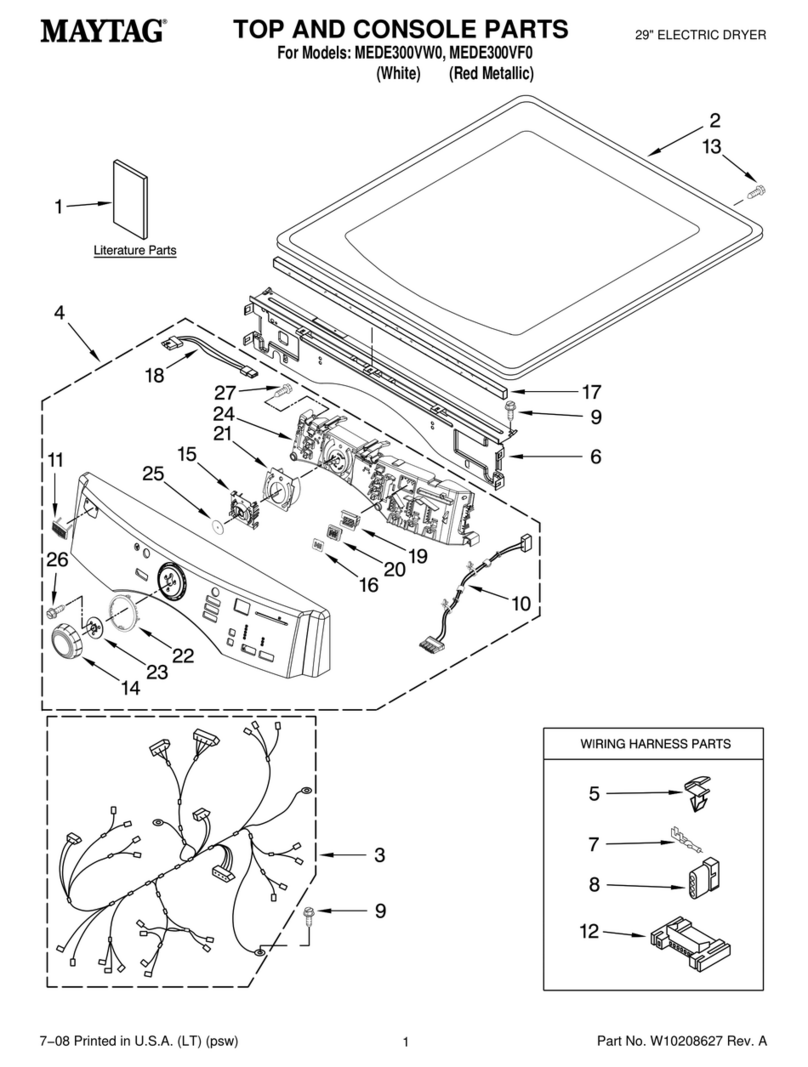

Maytag MEDE300VF0 User manual

Maytag

Maytag MED6400TQ0 User manual

Maytag

Maytag MEDB700BW User manual

Maytag

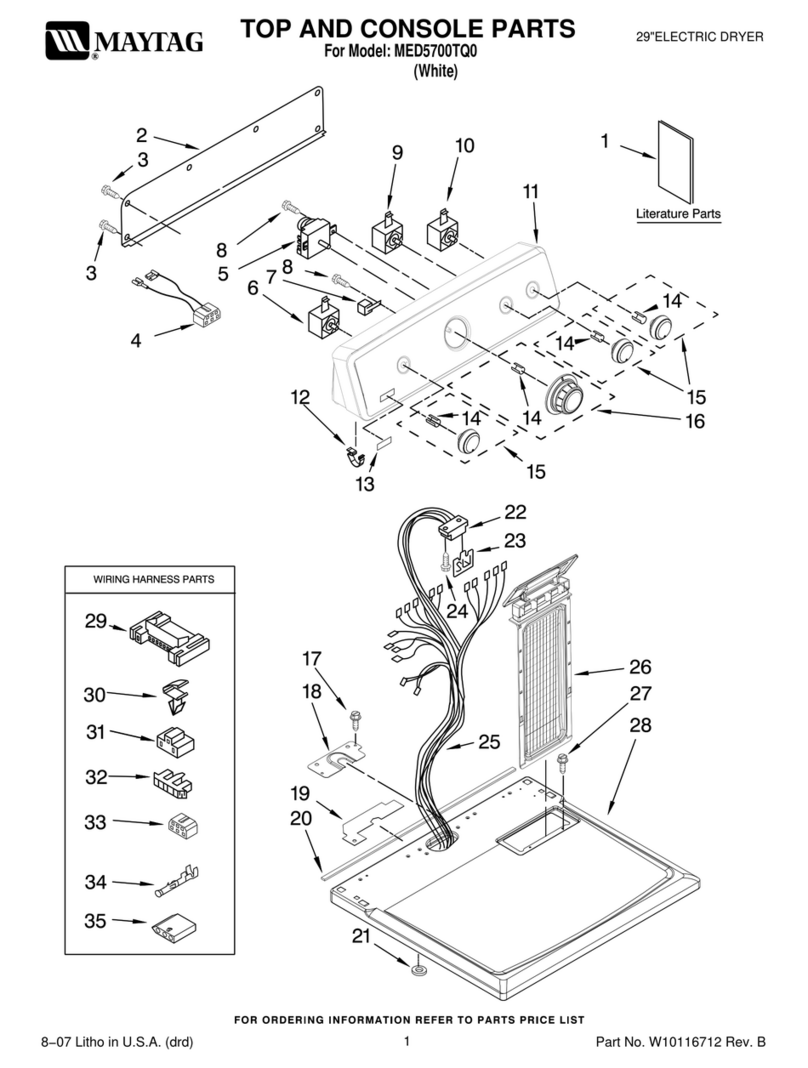

Maytag MED5700TQ0 User manual

Maytag

Maytag YMEDX700AG0 User manual

Maytag

Maytag MGDC700VW - Centennial Gas Dryer User manual

Maytag

Maytag MEDC500VW - Centennial Series 29 Inch Electric... User manual

Maytag

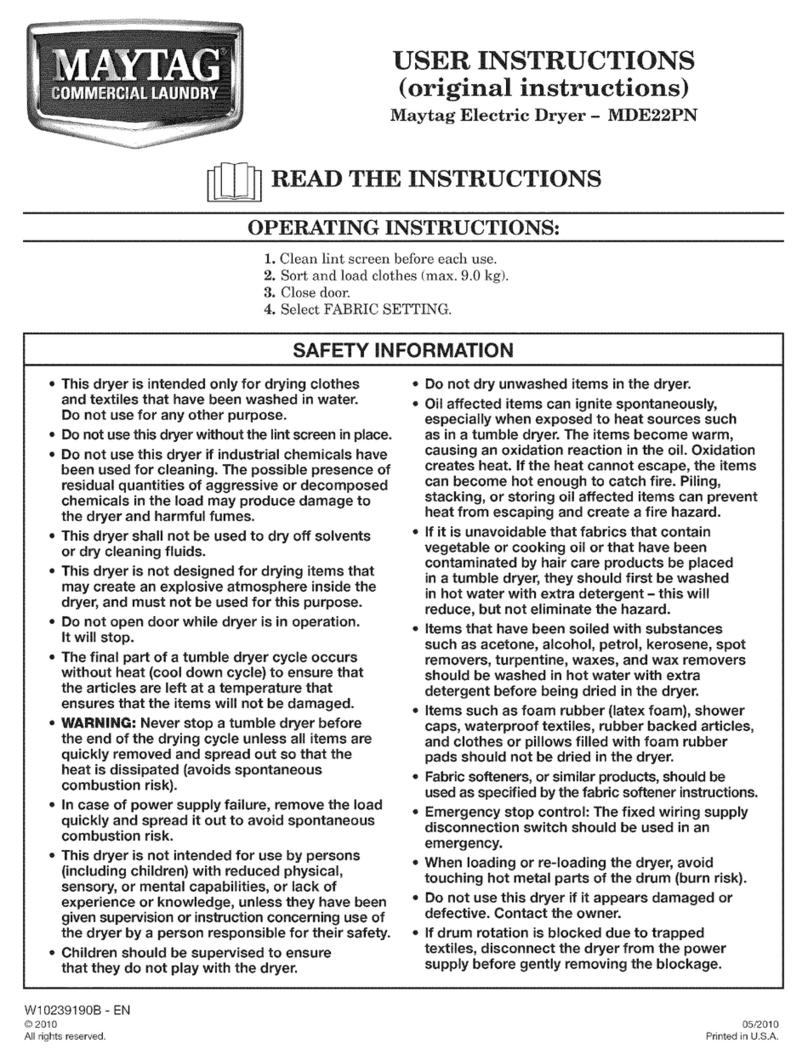

Maytag MDE22PN User manual

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual