3

PRE-INSTALLATION

INSTALLATION TIME

About 3.5 hours are required to complete this installation (assuming unmodied vehicle).

TOOLS AND SUPPLIES NEEDED

● Wire Strippers and Crimpers ● Phillips Screwdriver

● Flush Cut Wire Cutters (for trimming zip ties) ● Small, Straight (Jeweler’s) Screwdriver

● High-Quality Electrical Tape ● Heat Gun or Lighter

● Hand-Held Battery-Powered Drill, 9/64” & 1/8” Drill Bits ● Bojo Tools (Non-Marring Pry Tools)

● Ratchet, 8mm Socket ● 10mm Socket (Gauge Cluster/Battery)

● 13mm Socket and 13mm Box Wrench (Seat Removal) ● 18mm Socket (Seat Removal)

● 1/2” Socket (Subwoofer Enclosure Front Brackets) ● 7/16” Socket (Optional 3rd Amp Plate)

● T-25 and T-27 Torx Drivers (Dash & Housing Hardware) ● T-30 Torx Driver (Dash/Console)

Depending on which vehicle-specic UTV-tuned audio system you are installing, you may or may not need

all of the tools listed above. You may also own more specialized tools to complete the installation. Share the

pics of your installation on our social media channels to help others.

In addition to the tools listed, have music ready for INITIAL TESTING and FINE TUNING steps.

● USB thumb drive with music pre-loaded

● Bluetooth device such as a smartphone with music or a music app

SAFETY PRECAUTIONS

Safely prepare your vehicle for the installation before proceeding.

● Turn the ignition off and remove the key

● Use a packing blanket other soft material to protect your machine

● Safety Glasses - always wear eye protection

● Once all of the seats are removed, disconnect the negative battery cable before proceeding

PREPARATION FOR INSTALLATION & DISASSEMBLY

Before fully dismantling your vehicle, we suggest you prepare all your components, enclosures and wiring

harnesses. It increases efciency to have everything ready when each component is installed. Please note

some models with seat belts will require seat belt attachment point removal to remove the whole seat.

REMOVE SEATS - DISCONNECT BATTERY

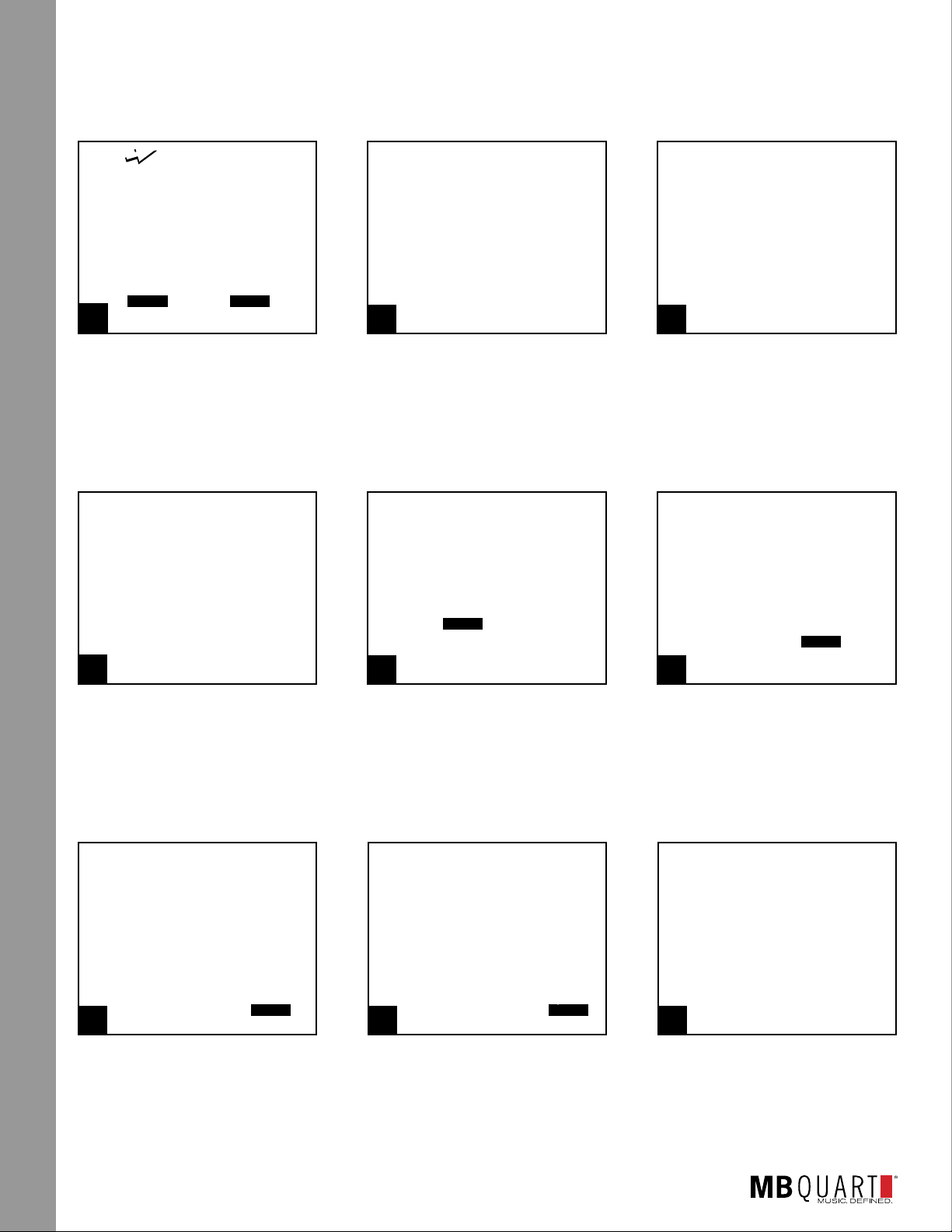

1 2 3

Slide driver’s seat forward

and remove two 18mm bolts

securing the rear of the seat

frame. If the vehicle has

factory-installed seats, you

can also access these bolts by

ipping up the seat cushion (a

socket extension is required).

Slide driver’s seat back to

access front 13mm through-

bolts and nuts. Using a socket

and box wrench, remove inner

and outer front seat hardware.

Unplug seat belt sensor.

Remove front driver’s seat and

set aside with all hardware.

Repeat seat removal on

front passenger’s side (and

rear seats - if present). Once

passenger seat near battery is

removed, disconnect (black)

negative battery cable by

removing a 10mm bolt and set

the negative cable aside.