Installation and use

3

SEEDER MAT MCK 2500 SX

Index

1. General instructions and warnings ..................................................................... 5

1.1 Introduction ....................................................................................................... 5

1.2 Terms of guarantee ........................................................................................... 6

1.3 Support Service ................................................................................................ 6

2. General description .............................................................................................. 7

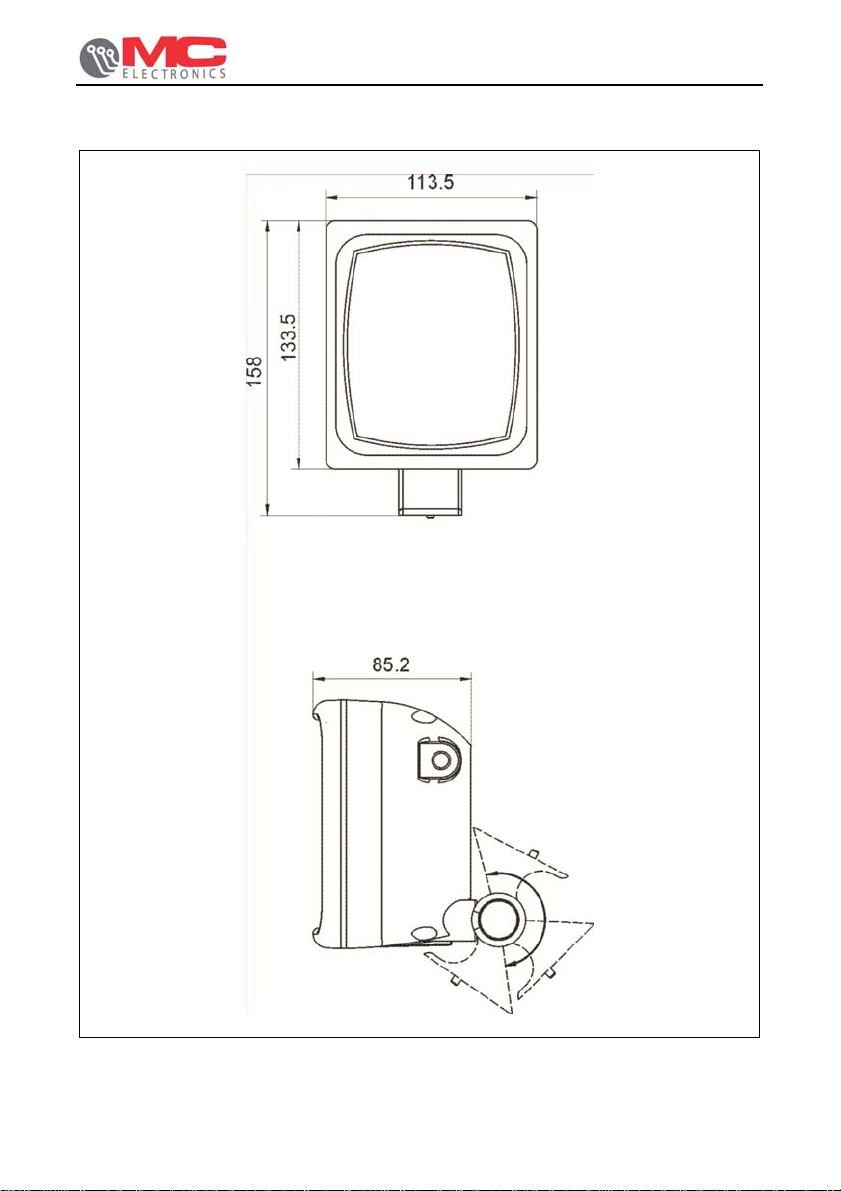

3. How to install the system ..................................................................................... 8

3.1 How to install the computer ............................................................................... 9

3.1.1 Electrical connections .............................................................................. 10

3.2 How to install the sensors ............................................................................... 13

3.2.1 How to install the Ø18 speed sensor – code 1404 ................................... 13

3.2.2 RPM sensor installation examples ........................................................... 14

3.2.3 How to install the Ø12 magnetic sensor – code 00SEN-1402.................. 15

3.2.4 How to install the Ø18 seed level sensor – code 1403 ............................ 17

4. Front view ............................................................................................................ 18

4.1 Keyboard ......................................................................................................... 19

5. Programming ....................................................................................................... 21

5.1 Programming the operating width ................................................................... 21

5.2 Programming the calibration of the advancing speed ..................................... 22

5.3 Practical example for calculating the “C” parameter to be programmed ......... 23

5.4 Automatic calibration of the “C” parameter (recommended!) .......................... 24

5.5 Programming the number of “paths” ............................................................... 25

5.5.1 Example for programming the number of “paths” ..................................... 26

5.5.2 Table of activations .................................................................................. 32

5.6 Programming the alarms RPMs, “Speed”, “Mode”, “Tramline”, and “Disk”

constants, and SELF-ACQUISITION procedure .................................................. 34

5.7 “S”, “M”, “t” , “d” constants ............................................................................... 35

5.8 Self-acquisition ................................................................................................ 36

5.9 Checking speed sensor operation ................................................................... 37

5.10 Checking turbine RPM sensor operation ....................................................... 37

5.11 Checking row tracer sensor operation........................................................... 38

5.12 Checking product level sensor operation ...................................................... 38

6. Operation ............................................................................................................. 39

7. Maintenance ........................................................................................................ 43

7.1 Ordinary maintenance ..................................................................................... 43

7.1.1 Protection fuses ....................................................................................... 43

7.1.2 How to protect the main connector .......................................................... 43

7.2 Extraordinary maintenance ............................................................................. 43

8. Troubleshooting .................................................................................................. 44

9. Technical data ..................................................................................................... 46