Table of contents

Introduction...................................................4

Foreword ........................................................4

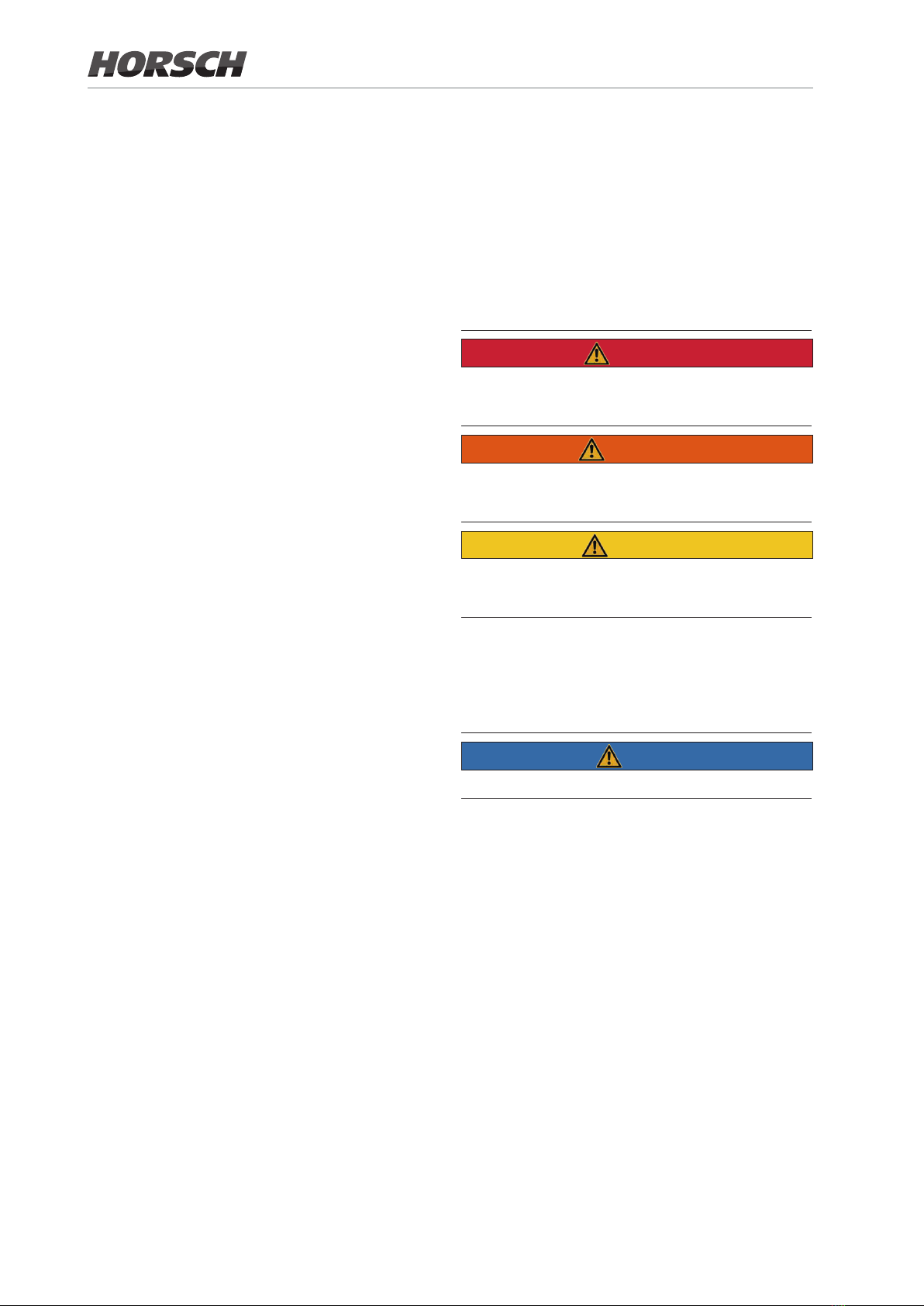

Notes on representation .................................4

Service............................................................5

Warranty claim processing .............................5

Consequential damage...................................5

Safety and accident prevention ..................6

Intended use...................................................6

Qualication of personnel...............................7

Children in danger ..........................................8

Personal protective outt................................8

Safety in trac................................................8

Safety in operation..........................................9

Fertiliser and dressed seed ..........................13

Environmental protection..............................13

Retrots ........................................................14

Care and maintenance .................................14

Danger zone.................................................15

Safety stickers ..............................................16

Technical data.............................................19

Type plate.....................................................21

Requirements for the tractor.........................25

Structure......................................................28

Overview.......................................................28

Hydraulics.....................................................29

Identication of hydraulic hoses ...................35

Aluminium clips.............................................35

Lighting.........................................................36

Instruction stickers........................................37

Commissioning...........................................41

Delivery.........................................................41

Transport ......................................................41

Installation ....................................................41

Operation.....................................................42

Commissioning / Tractor change..................42

Adapting the propshaft...............................42

Adjust the height of drawbar eye/

spherical cap..............................................43

Connecting/Parking ......................................43

Connecting ...................................................43

Transport position.........................................45

Parking .........................................................46

Folding..........................................................48

Unfolding....................................................48

Folding.......................................................48

Use in the eld..............................................50

At the headland..........................................50

Checks..........................................................52

Pneumatic system......................................53

Hopper..........................................................53

Railing...........................................................54

Solid fertiliser facility.....................................54

Fan - fertiliser ...............................................56

Direct drive.................................................56

Fan with PTO-shaft pump..........................57

Maestro 24 SW..........................................58

Maestro 36 SW..........................................58

Fan speeds................................................61

Fertiliser quantities.....................................61

Retightening the fan ange........................62

Fan - vacuum................................................63

Seed on Demand system .............................64

Fertiliser metering unit...............................67

Rotors...........................................................67

Rotor change................................................68

Rotor change with gate valve .......................68

Rotor change at full hopper

without gate valve.........................................69

Adjusting the sealing lip................................69

Maintenance of metering unit .......................70

Fertiliser coulter............................................71

Single-disc coulter (option) ........................73

Aligning the seed bar....................................77

2