McConnel MAGNUM 130 Product manual

MAGNUM

FLAIL MOWER/SHREDDE

R

Models 130, 170, 190 & 225

Publication 408

January 2002

Part No. 41570.09

OPERATOR AND PARTS MANUAL

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with McConnel Limited within

7 days of delivery to the end user – failure to do so may affect the validity of the machine

warranty.

To register machines go to the McConnel Limited web site at www.mcconnel.com, log

onto ‘Dealer Inside’ and select the ‘Machine Registration button’which can be found in

the Service Section of the site. Confirm to the customer that the machine has been

registered in the section below.

Should you experience any problems registering a machine in this manner please contact

the McConnel Service Department on 01584 875848.

Registration Verification

Dealer Name:

……………………..…………………………………………………………….

Dealer Address: …….………………………………………………………………………….

Customer Name: ……………………..…………………………………………………………

Date of Warranty Registration: ……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below. The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines general maintenance procedure.

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP Setting Metric

BSP Setting Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm 19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm 22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm 27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm 30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm 32 mm

1” 125 Nm 41 mm 1” 203 Nm 41 mm

1.1/4” 190 Nm 50 mm 1.1/4” 305 Nm 50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm 55 mm

2” 420 Nm 70 mm 2” 400 Nm 70 mm

EC DECLARATION OF CONFORMITY

Conforming to EEC Machinery Directive 98/37/EC*

We,

McCONNEL LIMITED,

Temeside Works, Ludlow, Shropshire SY8 1JL.

Declare under our sole responsibility that:

The product (type) ……………………………………………………………………

Tractor Mounted Flail Mower / Shredder

………………………………………………………………………………………….

Product Code …………………………………………………………………………..

MA13, MA17, MA19, MA225

Serial No. & Date ……………………………………. Type …………………………

Manufactured by the above company/* ………………………………………

………………………………………………………………………………………….

(* insert business name and full address if not stated above)

Complies with the required provisions of the Machinery Directive 98/37/EC, *

previously Directive 89/392/EEC as amended by Directives 91/368/EEC, 93/44/EEC

and 93/68/EEC.

The machinery directive is supported by;

•BS EN ISO 12100:2003 Safety of Machinery. This standard is made up of two

parts; Part 1 Terminology, methodology, Part 2 Technical Specifications.

•BS EN 1050 Safety of machinery - Principles of risk assessment.

•and other national standards associated with its design and construction as

listed in the Technical File.

The Machinery Directive is fully implemented into UK law by means of the Supply

of Machinery (Safety) Regulations 1992 (SI 1992/3073) as amended by The Supply

of Machinery (Safety) (Amendment) Regulations 1994 (SI 1994/2063).

Signed …………………………..……………………………………………………...

on behalf of McCONNEL LIMITED Responsible Person

Status: Chief Design Engineer Date: 25th January 2005

1

CONTENTS Pa

g

e

1. GENERAL INFORMATION 2

1.1. Introduction. 2

1.2. Identifying the machine. 2

2. TECHNICAL FEATURES 3

2.1. General description. 3

2.2. Technical Specifications. 4

2.3. Width of cut. 4

2.4. Equipment. 4

3. SAFETY RULES 6

3.1. General safety rules. 6

3.2. Safety rules - concerning road traffic. 6

3.3. Safety rules - during use. 7

3.4. List of guards. 7

3.5. Description and location of safety decals. 8

4. INSTRUCTION FOR INSTALLATION AND HANDLING 9

4.1. Lifting and unloading. 9

4.2. Unpacking. 9

4.3. Attachment and detachment from the tractor. 9

4.4. Fitting the PTO shaft. 10

4.5. Tractor stability. 11

4.6. Parking. 11

5. ADJUSTMENT AND SETTING UP 12

5.1. Regulating the height of cut. 12

6. USE AND OPERATING RULES 12

6.1. Starting. 12

6.2. Working mode. 12

6.3. Side shift - Non hydraulic models 12

6.4. Side shift - Hydraulic models 13

6.5. Stopping. 13

6.6. Transport position. 13

7. MACHINE MAINTENANCE 14

8. TROUBLE SHOOTING 15

9. REPLACING PARTS 15

9.1. Flail replacement. 15

9.2. Belt replacement. 16

10. DEMOLITION & DISPOSAL 16

11. SPARE PARTS SECTION 17

Magnum 130 18

Magnum 170 22

Magnum 190 & 225 26

2

1. GENERAL INFORMATION

1.1 Introduction

This operation and maintenance manual is intended for the professional user. It is

mandatory to follow these instructions in order to prevent events which could

endanger the operator’s and other people’s safety, apart from the correct functioning

of the shredder. In case of doubt, do not experiment, call McConnel after-sales

service instead, or the specialised McConnel dealer.

1.2 Identifying the machine

Each shredder is fitted with an identification plate: both the data necessary to identify

the model and the serial number to order spare parts or after-sales service are stamped

on the plate.

It is strongly recommended to use genuine spare parts to avoid altering the technical

features of the shredder. McConnel is not responsible for any damage or injuries to

people due to unauthorized modifications or the use of non-genuine spare parts.

This machine is in conformity with the following provisions of law:

Directive Machine 89/392/CEE and following additions:

91/368/CEE, 93/44/CEE and 93/68/CEE;

Regulations UNI EN 292/1 and 292/2 (machinery safety).

3

2. TECHNICAL FEATURES

2.1. General description

The Magnum mower, from now also called machine, has been designed for

cutting grass on amenity areas, in orchards and for cutting crop residues on small

agriculture areas, for sticks and shrubs laying on the ground of up to 3 cm diameter

(proper use)

Its light weight and low power requirement means that it is best suited to small

tractors. Any other use is considered improper and the manufacturer disclaims all

responsibility for any consequential injuries to people, or for damage to the machine.

Proper use also refers to the safety and maintenance rules provided for by the

manufacturer.

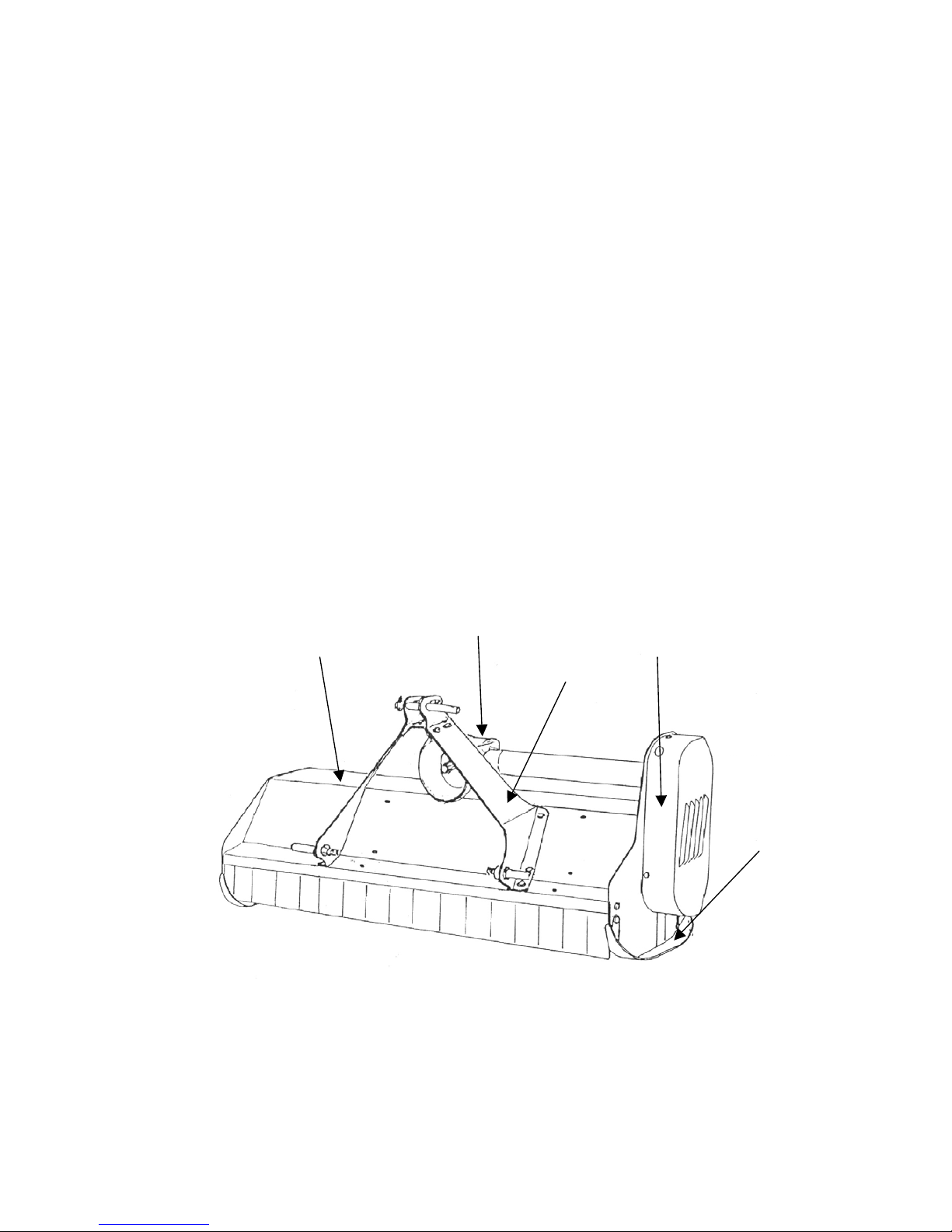

Technical names (see diagram below)

1 - frame

2 - gearbox

3 - connecting bow

4 - side transmission

5 - rear adjustable roller

6 - adjustable skids

7 - blades or hammers

1

2

3

4

6

4

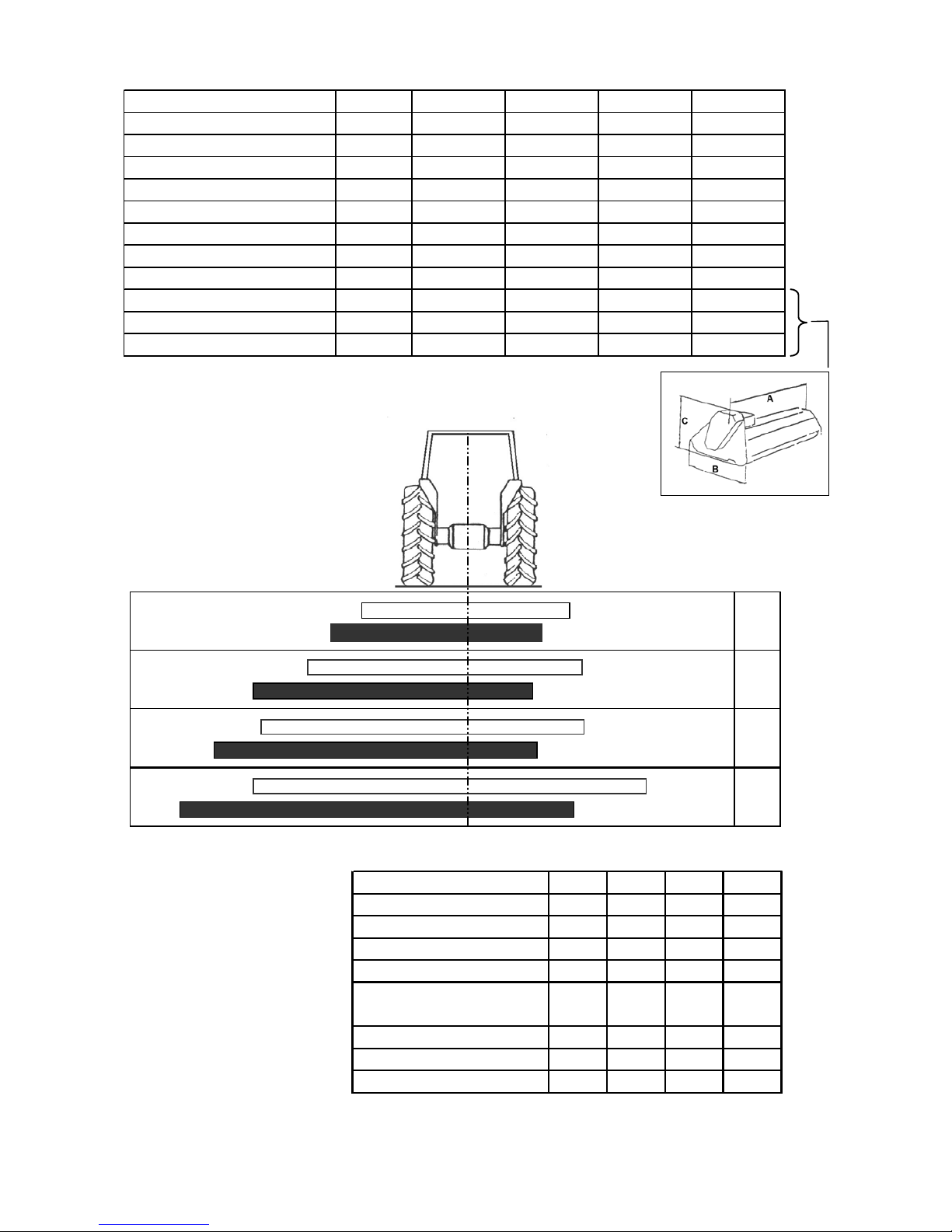

EQUIPMENT 130 170 190 225

Hammer. Std. -Std. Std.

Y-Blades, flails. Opt. Std. Opt. Opt.

Fine cut blades - Opt. Opt. Opt.

Rear roller. Std. Std. Std. Std.

Mechanical side movement

2 fixed positions.

Hydraulic side movement -Opt. Opt. Opt.

Std. = Standard Equipment Skids -Opt. Opt. Opt.

Opt. = Optional Equipment Hydraulic rotary side cutter -Opt. Opt. Opt.

Std. Std.Std. Std.

2.2 Technical Specification

2.3 Width of cut

2.4 Equipment

65 65

50

80

126 42

82

86

106

121

161 66

150 42

82

110

130

170

190

225

SPECIFICATION 130 170 190 225

Width of cut. cm. 130 168 191 226

M in. re q'd.tractor powe r. KW/HP 23-27/30-35 30-38/40-50 34-38/45-50 42-45/55-60

PTO speed. rpm. 540 540 540 540

Weight. kg. 185 285 385 427

Tractor attachment. Cat. II II II II

Flails. No.36724856

Scoop blades N/A N/A 36 N/A N/A

Hammer blades. No.18202428

Width 'A' cm. 145 188 208.5 243.5

Length 'B' cm. 80 76 100 100

He ight 'C' cm. 80 80 100 100

5

FOR NOTES

6

3. SAFETY RULES

3.1 General safety rules:

• It is mandatory to read and follow the instructions for the use and maintenance

manual before carrying out any operation or move with the shredder.

• Improper use or an incorrect move may seriously damage things and people.

• Both the operator and the maintenance fitter must know the shredder well,

especially regarding dangers resulting from improper use or incorrect repairs.

• Before starting, checks on tractor and shredder, must be carried out as regards:

functionality, road safety, accident prevention rules.

• Even when using the shredder correctly, stones or other objects may be thrown a

long distance. Therefore nobody must stand within the danger area. Special

attention must be paid when working near roads or buildings.

• Use tractor with cabs.

• The condition of flails and of all guards must be checked before beginning the

daily work - they must be replaced if damaged or missing.

• During checks or repairs, make sure nobody could start the shredder by mistake,

• Never wear loose or fluttering clothes.

• Never carry passengers on the tractor.

• Never carry passengers on the shredder.

• Never connect the power takeoff with the engine running.

• Never approach the shredder until the rotor has completely stopped.

• Do not enter the working zone of the PTO shaft. It is dangerous to approach the

rotating parts of the machine.

• Keep the PTO shaft guard in good order.

• Before starting check the surrounding area for the likely presence of children

and/or animals.

• Do not stand in the range of the operation of the machine.

• The PTO shaft must be assembled and disassembled only with the engine stopped

and the starting key removed.

• Before connecting the power takeoff, check that the speed and the rotational

direction correspond to those of the shredder.

• Before leaving the tractor with the tool attached, proceed as follows:

1. Disconnect the power takeoff,

2. Put the machine steadily on the ground (with the hydraulic lift)

3. Apply the hand brake and, if the ground is steeply sloping, wedge the tractor.

4. Take out the starting key.

• Immediately replace any safety sign, or any missing or damaged decal.

3.2 Safety Rules concerning Road Traffic

• In transport, reduce speed, especially on bumpy roads. The very weight of the

shredder may render driving difficult and damage the shredder itself.

• Check moreover that the levers that operate the hydraulic lift are locked, to avoid

the lowering of the machine during transport.

• When driving on public roads, respect all road rules in force.

• Never transport the shredder with the rotor moving, even for short distances.

7

3 12

4

5

3.3 Safety Rules during use

• Pay special attention when working with the machine, not to touch fixed objects,

such as road drain, walls, shafts, kerbs, guard rails, tracks etc. This could cause the

breakage of the flails, which would be thrown at very high speed.

• If wires, ropes or chains should get entangled in the rotor, stop immediately, to

prevent damage or dangerous situations; stop the rotor and the tractor, take out the

starting key. Put working gloves on, clear the rotor with the aid of pliers or shears.

Do not try to disentangle by inverting the rotational direction of the rotor.

• Do not use the machine when there is vibration in the flail head, as this would

cause breakage and serious damage. Find the cause of the vibration and eliminate

it.

3.4 List of Guards fitted to the shredder (see diagram below).

1. PTO shaft guard

2. Belt guard

3. Danger and warning decals

4. Front guard

5. Side guard-skids

8

3.5 Description and location of Safety decals

Carefully follow the instructions given on the decals (see illustrations below).

1. Always take the machine off the tractor and read the instructions carefully before

starting servicing and/or lubricating operations.

2. Keep at a safety distance from the machine to avoid the risk of projection of

objects.

3. Never remove the guards while the parts of machine are moving. It is dangerous

and may cause injury to hands.

4. Keep at a safety distance from the machine to avoid the risk of cutting feet.

5. It is forbidden to mount on the machine because of the risk of fall.

9

4. INSTRUCTIONS FOR INSTALLATION AND HANDLING.

4.1 Lifting and unloading

To handle the shredder use a hoist or crane with a lifting capability suitable to the

weight of the machine (see technical specifications on page 4).

4.2 Unpacking

To make transport easier, the machine can be supplied with connecting bow split In

this case use bolts, locknuts and washers enclosed to fix the bar and the flap on the

machine.

4.3 Attachment to and detachment from the tractor

Before carrying out this operation and whenever the shredder is used, it is mandatory

to:

• Visually check the machine in general.

• Check that all guards are fitted and in good condition.

• Confirm that all flails are fitted and in good condition.

• Grease the bearings and any other part as indicated by the decal.

• Check that the number or revolutions and the rotational direction of the power

takeoff correspond to those required by the machine (see diagram below).

• To attach the machine to the tractor (see illustration on page 10) bring the tractor

lower links (1) near the machine, to the points corresponding to the pins.

• Insert the pins (2) and secure them with the spring clips (3).

10

5

4 cm

4

4

3

1

6

• Fit the top link (4), raise the machine to a perpendicular position with the ground.

Adjust the two tractor lower linkage stabilizers (3) thus fixing the machine to the

tractor in a central position.

• Proceed in reverse order to detach the shredder from the tractor.

4.4 Fitting the PTO shaft

• Following the Instructions in 4.3 assemble the PTO shaft (6) and check that the

overlap is not less than 2/3 of L. Be sure to keep a 4 cm backlash (see illustration

above) if it needs shortening, proceed as shown below (see illustration).

• The guards of the PTO shaft must be fixed to the machine and to the tractor with

chains, to prevent rotation. The minimum overlap of the guard and the PTO shaft

must not be less than 5 cm. (see illustration below).

11

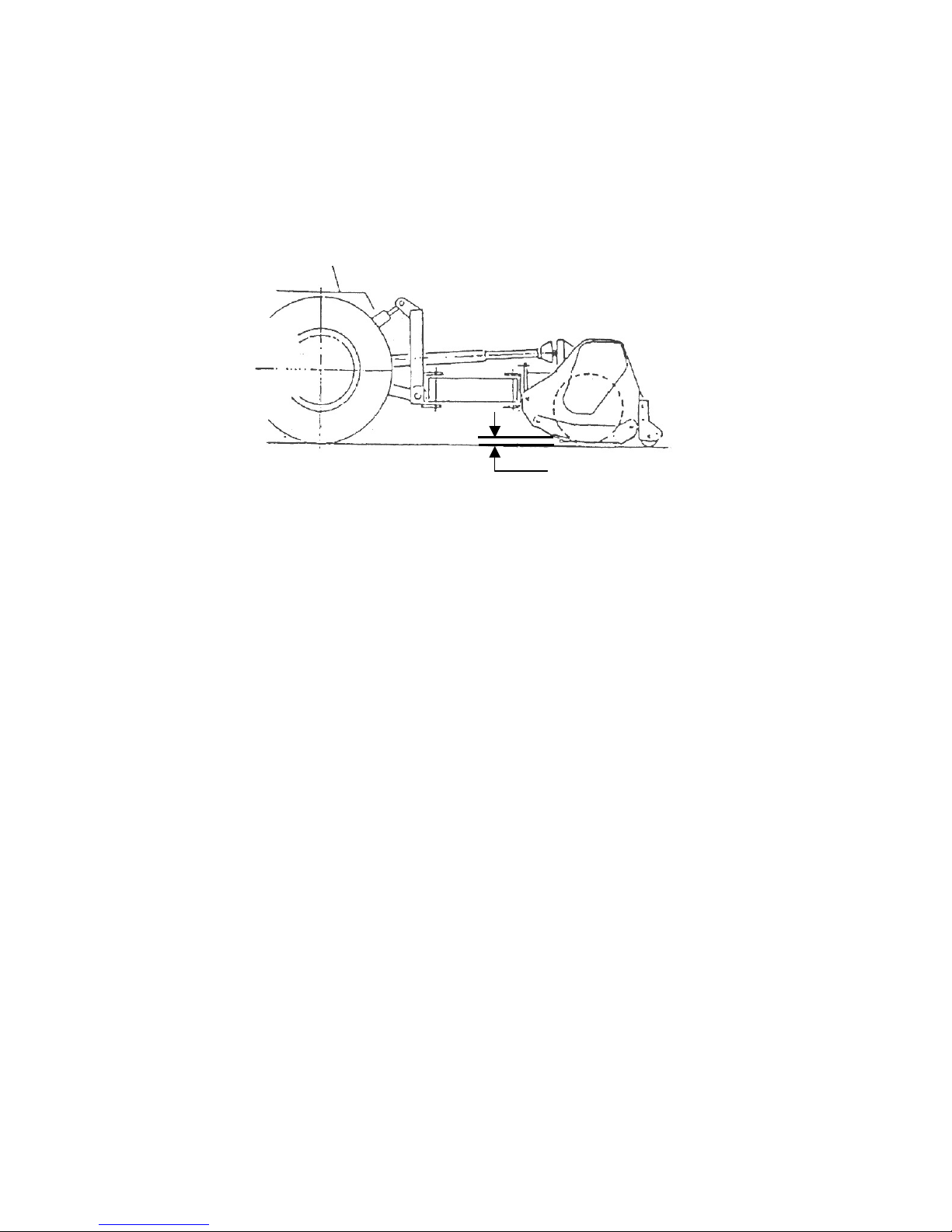

4.5 Tractor stability

Due to the design of the mowers and the work they do, it is essential to ensure tractor

stability, in order to eliminate any risk of imbalance or overturning.

• Lift the machine and check that the tractor does not mount up. In case it does,

ballast the rear wheel of the tractor opposite to the extended machine and at the

front of the tractor (see illustration below).

4.6 Parking

• Park the machine in a safe place, on flat and firm ground in order to prevent the

risk of rolling over.

• Lower the shredder to the ground with the aid of the hydraulic lift of the tractor.

(see illustration below).

12

= 1-3 cm

5. ADJUSTMENT AND SETTING UP

5.1 Adjustment

Adjustment of the height of cut is obtained by shifting the flail head roller in order to

suit the material to be cut and the required degree of chopping (see illustration

below).

IMPORTANT: Flails must never touch the ground.

6. USE AND OPERATING RULES

6.1 Starting

Before using the shredder check the tightness of all bolts and the integrity of all

guards. Check that the number of revolutions and the rotational direction of the

power takeoff of the tractor correspond to those required by the machine see decal on

the gearbox (see page 9). Engage the power takeoff at low engine RPM to avoid

damaging the transmission gearbox and belts.

6.2 Working mode

• Adjust the machine to suit the type of work to be done and the material to be cut:

adjust the height of cut, as shown (see illustration above).

• Working speed is chosen to suit the material to be cut and the degree of chopping

required. The optimum speed ranges from 3 to 8 km per hour.

6.3 Side shift - Non-hydraulic models

IMPORTANT: if you want to move the machine from the central to side position

proceed as follows:

• Unscrew the connecting bow.

• Bore the holes on marked points. (upper cover already has got the holes).

• Put the connecting bow on the new position.

• Tighten the screws.

13

6.4 Side shift – Hydraulic models

IMPORTANT: Ensure that the machine is lifted clear of the ground before side

moving, failure to observe this may result in damage to the frame.

IMPORTANT: During reverse movement lift the machine off the ground to

avoid damaging the machine.

6.5 Stopping

• Close the arms and lower the machine to the ground.

• Disconnect the power takeoff.

• Stop the tractor, take out the starting key and apply the hand brake.

• If the ground is sloping, block the tractor wheels.

6.6 Transport position

For transport it is mandatory to:

• Observe all road transport requirements and note the necessary warning signs.

• Reduce speed especially on bumpy roads, The weight of the machine may render

driving difficult and damage the machine itself.

• The power take off must be disconnected.

IMPORTANT: during transport on bumpy roads it is mandatory to move the

machine into the central position.

14

7. MACHINE MAINTENANCE

All maintenance, cleaning and repair operations must be carried out with the shredder

firmly lowered to the ground and detached from the tractor, or with disconnected

PTO, and the tractor engine switched off and starting key out.

After the first two hours operation from new (or after fitting new belts) check belt

tension.

Regularly and after every 8 hours of machine operation:

• Tighten bolts and nuts.

• Check wear and condition of flails.

• Check the safety guards.

• Check belt condition.

• Visually check the frame to detect possible damage caused by earlier work.

• Check gearbox and extension lubricating levels.

• Grease the parts indicated on the appropriate decal. (see below).

This operation must be always carried out at the end of each working day. This

facilitates the removal of mud or other material from the rotating parts (bearing, pins

etc.) in order to avoid rust and possible seizure.

• Every 100 hours operation grease the moving parts of the PTO shaft, extracting

the two parts of the shaft.

• After long inactivity, repeat the operation before re-using the machine.

• Use grease classification DIN 51825 (KR 2 K)

• For gearbox use compatible oils - classification ISO VG 220

Oil level point

Oil level point

15

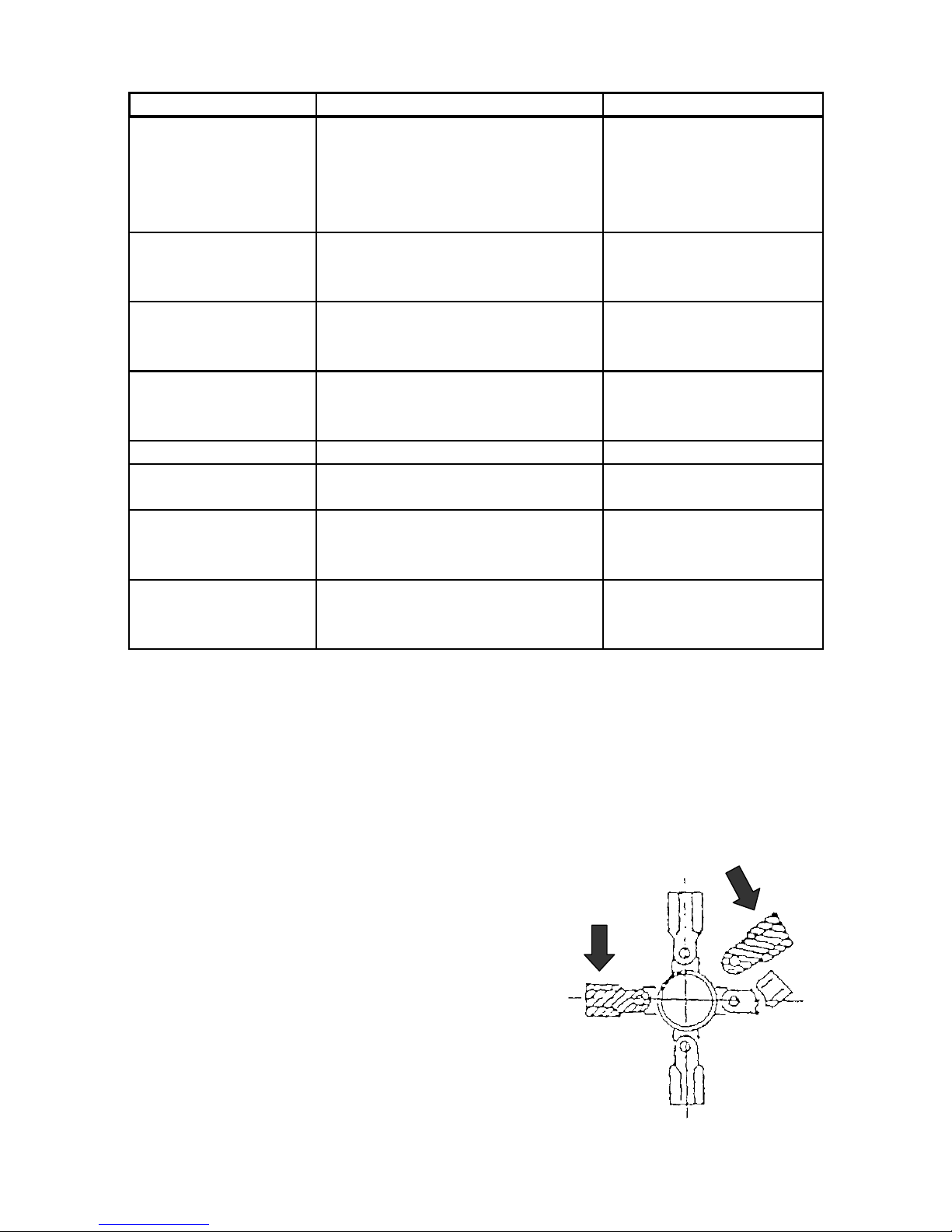

PROBLEM CAUSES REMEDIES

Irregular cut - Worn, bent or broken flails. -Replace.

-Machine is not in level with the -Level.

ground. -Reduce working speed.

Clogged material due to

excessive working speed.

Machine noise - Loose bolts. -Tighten bolts.

-Cracks or initiation of flail head. -Have it repeared in

specialized workshops.

Gearbox noise - Lack of oil. -Fill to level.

-Worn gears. -Replace.

-Worn bearings. -Replace.

Vibration - Broken or worn flails. -Replace.

-Unbalanced rotor. -Replace in authorized

-Worn rotor bearings. workshops.

Premature flail wear - Flails touching the ground. -Adjust the height of cut.

Excessive backlash - Worn pins. -Replace.

in joints

Breakage of roller - Violent impact on the ground -Lower it gently.

bearings when the machine is lowered. -Clean and grease.

-Dirty or little greased bearings.

Belts overheating - Flails touching to the ground. -Adjust the height of cut.

-Working speed unsuitable to the -Reduce speed.

amount of the material to be cut.

8. TROUBLE SHOOTING CHART

9. REPLACING PARTS

Before carrying out any work, it is mandatory to:

• Lower the machine to the ground

• Disconnect the power takeoff, stop the tractor and take out the starting key.

• Wear working gloves

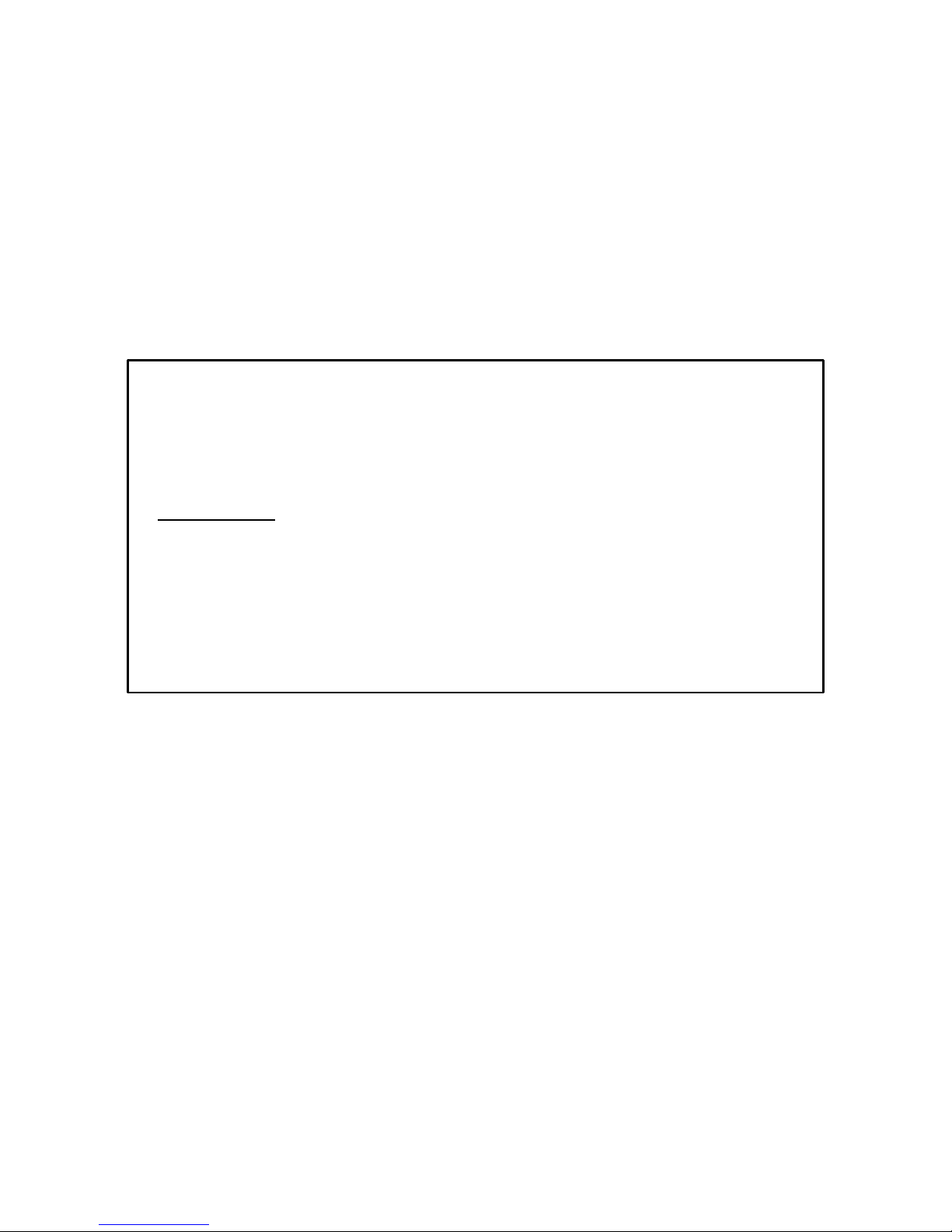

9.1 Flail replacement

When the flails are worn, they must all be replaced.

In cases of a partially broken flail it is advisable to

replace the broken one and the one diametrically

opposite, in order to maintain the balance

(see illustration opposite).

16

9.2 Belt replacement

• This operation must be carried out with the machine touching the ground, the

power take-off disconnected and the starting key out.

• Remove the belt guard, slacken the screws (1) (see diagram below), unscrew the

tightener (2), remove the belts and replace them with the same ones (dimension

and type).

IMPORTANT: more complex operations must be done in authorised workshops.

10. DEMOLITION, DIFFERENTIATED DIVISION OF THE MATERIALS

AND DISPOSAL

If the machine is out of order and requires disposal, all its parts that may cause danger

have to be made inoffensive. The materials forming the machine that have to undergo

a differentiated division are:

• Steel

• Mineral oil

• Rubber

• Plastic

All the above mentioned operations and the disposal have to be carried out in total

respect of the present provisions of law on the subject.

We reserve right to modify the technical data and characteristics of the machines at

any time without prior notice.

17

SPARE PARTS SECTION

For best performance…

USE ONLY GENUINE SERVICE PARTS

To be assured of the latest desi

g

n improvements purchase

y

our ‘Genuine

R

eplacements’

f

rom the Ori

g

inal Equipment Manu

f

acturer throu

g

h

y

ou

r

local Dealer or Stockist.

Always quote:

• Machine Type

• Serial Number

• Part Number

D

esi

g

n Improvements ma

y

have altered some o

f

the parts

l

isted in this

manual – The latest part will alwa

y

s be supplied when it is interchan

g

eable

with an earlier one.

Other manuals for MAGNUM 130

1

This manual suits for next models

3

Table of contents

Other McConnel Lawn Mower manuals

McConnel

McConnel ECON HEDGEMASTER Mk3 User manual

McConnel

McConnel MAGNUM MULCHA 225 User manual

McConnel

McConnel SR15-6 User manual

McConnel

McConnel MERLIN Xtreme Offset Programming manual

McConnel

McConnel PA5054 VERSI User manual

McConnel

McConnel ROBOMAX User manual

McConnel

McConnel Twose Series User manual

McConnel

McConnel MAGNUM HEAVY DUTY Series User manual

McConnel

McConnel ROBOCUT RC28 User manual

McConnel

McConnel PA5040-40 User manual