McConnel MAGNUM HEAVY DUTY Series User manual

Publication 533

March 2008

Part No. 41571.33

Revised: 15.04.14

Operator Manual

2008 Models

HEAVY DUTY SERIES: 245, 270 & 300

SHREDDER MOWERS

MAGNUM

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

Dealer Warranty Information & Registration Verification

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user –failure to do so may affect the validity of the machine warranty.

To register machines; log onto https://my.mcconnel.com and select ‘Machine Registration’

which can be found in the ‘Warranty’section of the site. Confirm to the customer that

the machine has been registered by completing the verification form below.

Registration Verification

Dealer Name:

……………………..……………………………………………………………..

Dealer Address:

…….…………………………………………………………………………..

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...… Dealer Signature: ………………..………

Note to Customer / Owner

Please ensure the section above has been completed and signed by the dealer to verify

your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in –where

this occurs it can be cured by re-tightening the connection –refer to torque settings chart below. The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machine’s general maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

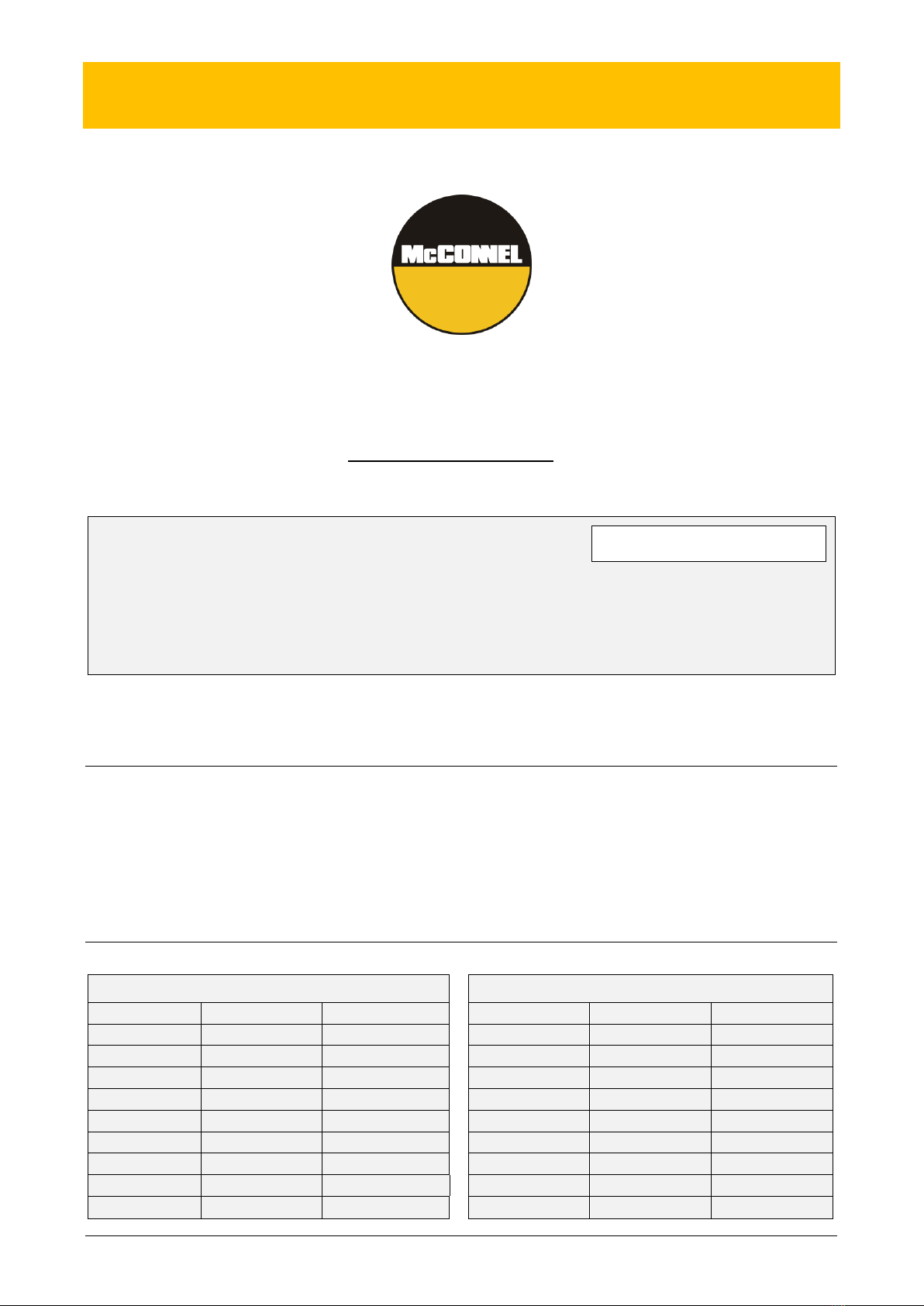

Torque Settings for Hydraulic Fittings

Hydraulic Hose Ends

Port Adaptors with Bonded Seals

BSP

Setting

Metric

BSP

Setting

Metric

1/4”

18 Nm

19 mm

1/4”

34 Nm

19 mm

3/8”

31 Nm

22 mm

3/8”

47 Nm

22 mm

1/2”

49 Nm

27 mm

1/2”

102 Nm

27 mm

5/8”

60 Nm

30 mm

5/8”

122 Nm

30 mm

3/4”

80 Nm

32 mm

3/4”

149 Nm

32 mm

1”

125 Nm

41 mm

1”

203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2”

250 Nm

55 mm

1.1/2”

305 Nm

55 mm

2”

420 Nm

70 mm

2”

400 Nm

70 mm

Serial No.

Warranty Policy (page 1 of 3)

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the end user.

On receipt of the goods it is the buyer’s responsibility to check that the Verification of Warranty

Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All mounted machines supplied by McConnel Ltd are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

All Self Propelled Machines supplied by McConnel Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12 months

or 1500 hours. Engine warranty will be specific to the Manufacturer of that unit.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be free from

defects in material and workmanship from the date of sale to the original purchaser for a period of 6

months. All parts warranty claims must be supported by a copy of the failed part invoice to the end

user. We cannot consider claims for which sales invoices are not available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement for the

purchaser any part or parts found, upon examination at its factory, to be defective under normal use

and service due to defects in material or workmanship. Returned parts must be complete and

unexamined. Pack the component(s) carefully so that any transit damage is avoided. All ports on

hydraulic items should be drained of oil and securely plugged to prevent seepage and foreign body

ingress. Certain other components, electrical items for example, may require particular care when

packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate has

been removed or altered.

1.05. The warranty policy is valid for machines registered in line with the terms and conditions detailed and

on the basis that the machines do not extend a period of 24 months or greater since their original

purchase date, that is the original invoice date from McConnel Limited.

Machines that are held in stock for more than 24 months cannot be registered for warranty.

1.06. This warranty does not apply to any part of the goods, which has been subjected to improper or

abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident damage,

or damage resulting from contact with overhead power lines, damage caused by foreign objects (e.g.

stones, iron, material other than vegetation), failure due to lack of maintenance, use of incorrect oil or

lubricants, contamination of the oil, or which has served its normal life. This warranty does not apply

to any expendable items such as blades, belts, clutch linings, filter elements, flails, flap kits, skids, soil

engaging parts, shields, guards, wear pads, pneumatic tyres or tracks.

1.07. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.08. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired

will be rejected.

1.09. Machines must be repaired immediately a problem arises. Continued use of the machine after a

problem has occurred can result in further component failures, for which McConnel Ltd cannot be held

liable, and may have safety implications.

1.10. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine part.

Warranty Policy (page 2 of 3)

1.11. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of McConnel Ltd.

1.12. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.12.1. Hoses, exposed pipes and hydraulic tank breathers.

1.12.2. Filters.

1.12.3. Rubber mountings.

1.12.4. External electric wiring.

1.12.5. Bearings and seals

1.12.6. External Cables, Linkages

1.12.7. Loose/Corroded Connections, Light Units, LED’s

1.12.8. Comfort items such as Operator Seat, Ventilation, Audio Equipment

1.13. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

1.14. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair work

are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be held

responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the McConnel web

site and confirms the registration to the purchaser by completing the confirmation form in the

operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs. Continued use

of a machine, after a fault has occurred, can result in further component failure for which McConnel

Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be

rejected, unless the delay has been authorised by McConnel Ltd. Please note that failure by the

customer to release the machine for repair will not be accepted as a reason for delay in repair or

submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days of the

date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for any valid

claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate labour and mileage

allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd. is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with respect to

the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for

damages incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may

be brought more than one (1) year after the cause of the action has occurred.

Warranty Policy (page 3 of 3)

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

McConnel Limited

FLAIL MOWER & TRACTOR PRE-OPERATION INSPECTION

A daily equipment inspection of machine and tractor

should be conducted before the equipment is used.

Use the inspection sheets on the following pages to assist with these daily inspections.

Damaged or missing guards should be repaired or replaced before operating the

mower. Failure to repair or replace damaged guards can result in objects being thrown

from the mower and possibly hitting the operator and/or bystanders.

Inspect the Mower for Safe Operating Condition

•Make sure the driveline guards and shielding are in place and in good repair.

•Inspect the chain guards, flexible and/or solid defector thrown object shielding to

assure that they are in place on the front and rear of the mower deck and in good

repair. Repair or replace any damaged or missing thrown object shields.

•Ensure the mower cutting height is set high enough to reduce the possibility of the

mower blades contacting the ground. Actual height will be dependent on the ground

conditions. Increase the height when working in rough or undulating conditions.

•Inspect for broken, chipped, bent, missing, or severely worn blades. Replace damaged

blades before operating the mower. Ensure the blade retaining bolts and fasteners are

secure and tight.

•Lubricate the driveline universal joints and telescoping members daily.

•Inspect the wheel lug bolt/nuts to assure that they are tight.

•If mower is equipped with pneumatic tyres, make sure they have the required air

pressure.

•Inspect for worn or damaged decals and safety instructions. Replace any unreadable,

damaged or missing safety decals.

•Follow the operator’s manual(s) inspection and maintenance instructions for lubricating

parts, and keeping thrown object shielding, driveline guards, rotating parts shields,

mower blades and decals in good repair.

Inspect the Tractor for Safe Operating Condition

•Inspect the controls, lights, SMV’s (Slow Moving Vehicle sign), seat belts, and ROPS to

ensure they are in place and in good working order.

•Ensure tyres, wheels, lug bolts/nuts are in good condition.

•Make sure the tractor brakes and steering are in proper operating condition.

•Follow the operator’s manual(s) inspection and maintenance procedures for keeping

the tractor in good and safe condition before operating.

Copies of the inspection sheets on the following pages should be retained

in this manual for reference; two sets are included to allow removal of one

set for photocopying purposes. Alternatively, these inspection sheets can

be download from our website via the QR code or using the link below;

https://my.mcconnel.com/service/pre-operation-inspection-documents/

FLAIL MOWER PRE-OPERATION INSPECTION

Mower ID ………………….. Date: ………………….. Shift: ……………………...

WARNING: Before conducting the inspection, make sure the tractor engine is off, the

key removed, all rotation has stopped and the tractor is in park with the parking brake

engaged. Make sure the mower is resting on the ground or is securely blocked up and

supported and all hydraulic pressure has been relieved.

Item

Condition at

start of shift

Specific Comments if not O.K.

The operator’s manual is in the canister on the mower.

All warning decals are in place, clean and legible.

The hydraulic cylinder pins are tight and correctly secured.

The hydraulic cylinder hose connections are tight.

There are no oil leaks.

There are no damaged hoses.

Flails are not missing chipped, broken or excessively worn.

The flail bolts are tight.

The front and rear flaps are fitted and in good condition.

The skid shoes are in good condition and tight.

The rotor bearings are in good condition and greased.

The roller bearings are in good condition and greased.

There are no cracks or holes in flail casing.

The drive line/gearbox shaft guard is in good condition.

The drive line/gearbox shaft guard is correctly secured.

Driveline telescoping members & u-joints are lubricated.

Driveline yokes are securely attached to tractor and mower.

All linkage mounting pins are securely fastened.

Operators Signature: ……………………………………………

DO NOT OPERATE AN UNSAFE TRACTOR OR MACHINE

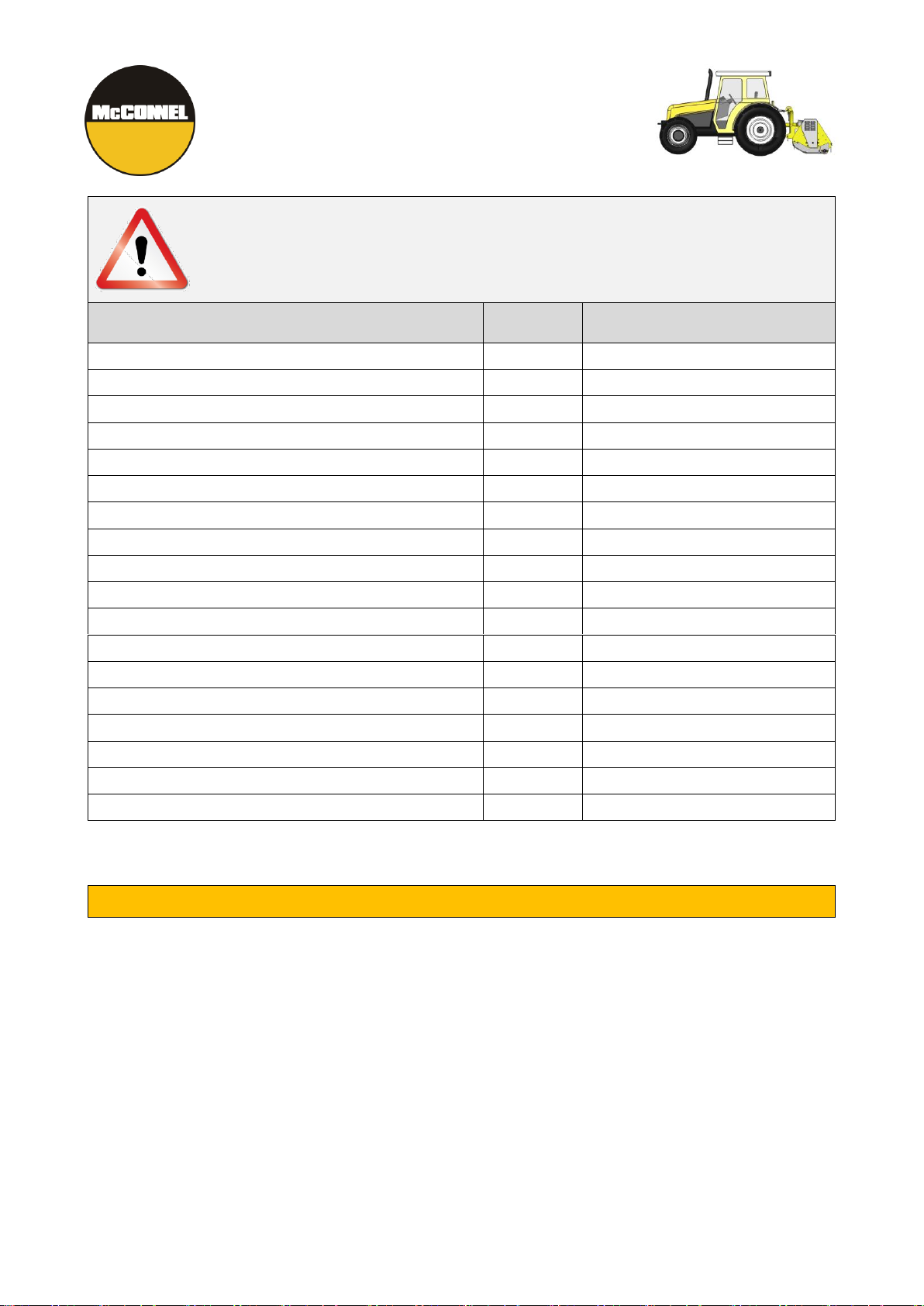

TRACTOR PRE-OPERATION INSPECTION

Power Arm ID ………………….Date: ………………….Shift: ………………….

WARNING: Before conducting the inspection, make sure the tractor engine is off, the

key removed, all rotation has stopped and the tractor is in park with the parking brake

engaged. Ensure any implement attached to the tractor is firmly on the ground.

Item

Condition at

start of shift

Specific Comments if not O.K.

The flashing lights function properly.

All lights are clean and working correctly.

All cab windows are clean and wipers working correctly.

The SMV sign, where required, is clean and visible.

The tyres are in good condition with correct pressure.

The wheel nuts are tight.

The tractor brakes are in good condition.

The steering linkage is in good condition.

There are no visible oil leaks.

The hydraulic controls function properly.

The ROPS or ROPS cab is in good condition.

The seatbelt is in place and in good condition.

The 3-point hitch is in good condition.

The drawbar/pick up hook is secure and in good condition.

The PTO master shield is in place.

The engine oil level is full.

The brake fluid level is full.

The power steering fluid level is full.

The fuel level is adequate.

The engine coolant fluid level is full.

The radiator and oil cooler are free of debris.

The air filter is in good condition.

Operators Signature: ………………………………………………

DO NOT OPERATE AN UNSAFE TRACTOR OR MACHINE

FLAIL MOWER PRE-OPERATION INSPECTION

Mower ID ………………….. Date: ………………….. Shift: ……………………...

WARNING: Before conducting the inspection, make sure the tractor engine is off, the

key removed, all rotation has stopped and the tractor is in park with the parking brake

engaged. Make sure the mower is resting on the ground or is securely blocked up and

supported and all hydraulic pressure has been relieved.

Item

Condition at

start of shift

Specific Comments if not O.K.

The operator’s manual is in the canister on the mower.

All warning decals are in place, clean and legible.

The hydraulic cylinder pins are tight and correctly secured.

The hydraulic cylinder hose connections are tight.

There are no oil leaks.

There are no damaged hoses.

Flails are not missing chipped, broken or excessively worn.

The flail bolts are tight.

The front and rear flaps are fitted and in good condition.

The skid shoes are in good condition and tight.

The rotor bearings are in good condition and greased.

The roller bearings are in good condition and greased.

There are no cracks or holes in flail casing.

The drive line/gearbox shaft guard is in good condition.

The drive line/gearbox shaft guard is correctly secured.

Driveline telescoping members & u-joints are lubricated.

Driveline yokes are securely attached to tractor and mower.

All linkage mounting pins are securely fastened.

Operators Signature: ……………………………………………

DO NOT OPERATE AN UNSAFE TRACTOR OR MACHINE

TRACTOR PRE-OPERATION INSPECTION

Power Arm ID ………………….Date: ………………….Shift: ………………….

WARNING: Before conducting the inspection, make sure the tractor engine is off, the

key removed, all rotation has stopped and the tractor is in park with the parking brake

engaged. Ensure any implement attached to the tractor is firmly on the ground.

Item

Condition at

start of shift

Specific Comments if not O.K.

The flashing lights function properly.

All lights are clean and working correctly.

All cab windows are clean and wipers working correctly.

The SMV sign, where required, is clean and visible.

The tyres are in good condition with correct pressure.

The wheel nuts are tight.

The tractor brakes are in good condition.

The steering linkage is in good condition.

There are no visible oil leaks.

The hydraulic controls function properly.

The ROPS or ROPS cab is in good condition.

The seatbelt is in place and in good condition.

The 3-point hitch is in good condition.

The drawbar/pick up hook is secure and in good condition.

The PTO master shield is in place.

The engine oil level is full.

The brake fluid level is full.

The power steering fluid level is full.

The fuel level is adequate.

The engine coolant fluid level is full.

The radiator and oil cooler are free of debris.

The air filter is in good condition.

Operators Signature: ………………………………………………

DO NOT OPERATE AN UNSAFE TRACTOR OR MACHINE

LIST OF CONTENTS

Troubleshooting

15

Maintenance

13

Detachment and Storage

12

Operation

11

Drive Belts

10

Setting Up and Adjustment

9

Pre-Operational Checks

8

PTO Shaft

8

Machine Attachment

7

Vehicle / Tractor Preparation

6

Safety Decals

5

Safety Information

4

Technical Specifications

3

Technical Data

2

Machine Identification

2

Machine Description & Purpose of Use

2

General Information

1

1

GENERAL INFORMATION

Always read this manual before fitting or operating the machine – whenever any doubt

exists contact your dealer or the McConnel Service Department for advice and assistance.

Use only McConnel Genuine Service Parts on McConnel Equipment and Machines

DEFINITIONS –The following definitions apply throughout this manual:

WARNING

An operating procedure, technique etc., which –

can result in personal injury or loss of life if not observed carefully.

CAUTION

An operating procedure, technique etc., which –

can result in damage to either machine or equipment if not observed carefully.

NOTE

An operating procedure, technique etc., which –

is considered essential to emphasis.

LEFT AND RIGHT HAND

This term is applicable to the machine when attached to the tractor and is viewed

from the rear – this also applies to tractor references.

MACHINE & DEALER INFORMATION

Record the Serial Number of your machine on this page and always quote this number when

ordering parts. Whenever information concerning the machine is requested remember also to state

the make and model of tractor to which the machine is fitted.

Machine Serial Number:

Installation Date:

Machine Model details:

Dealer Name:

Dealer Address:

Dealer Telephone No:

Dealer Email Address:

2

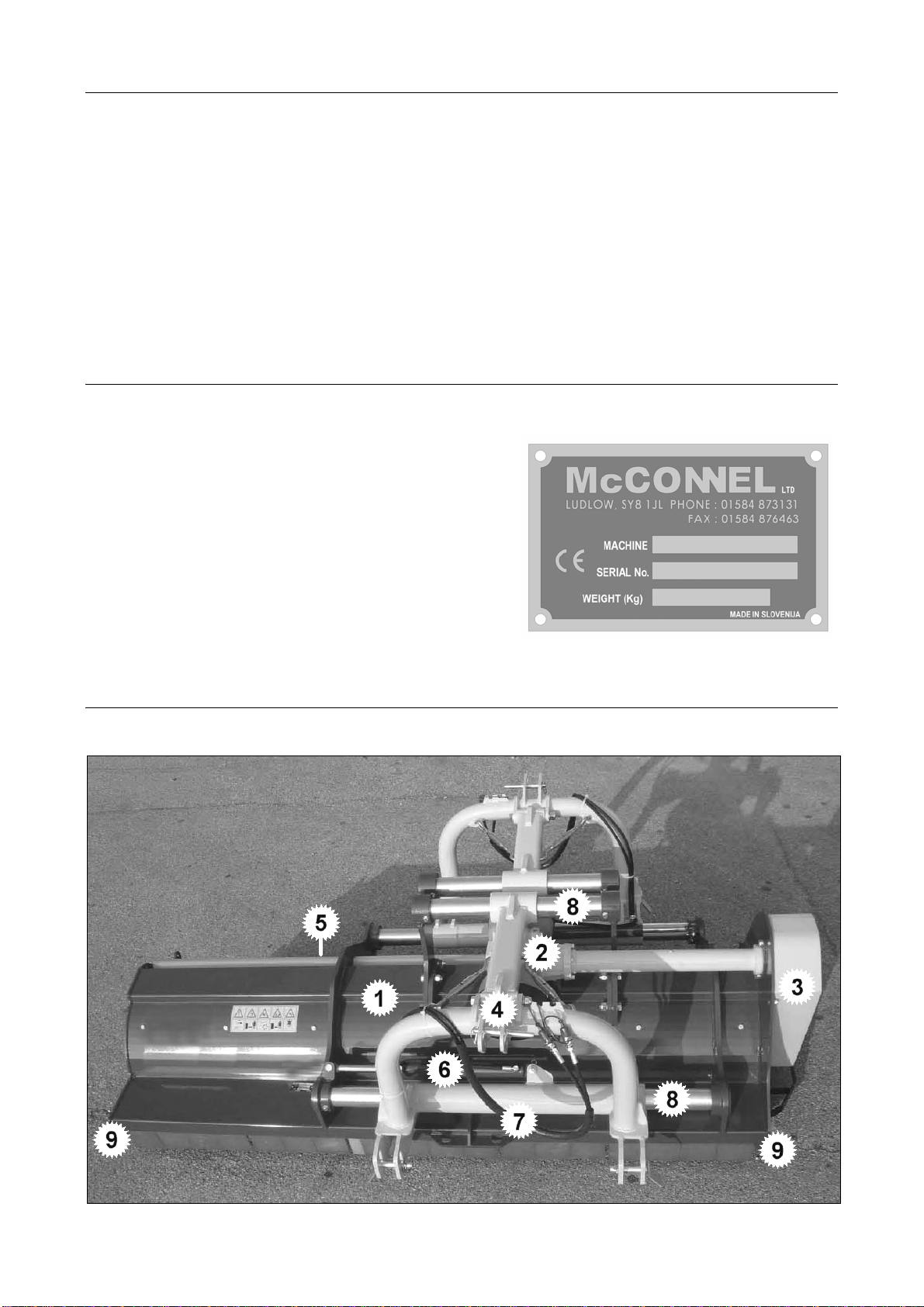

Machine Identification Plate

MACHINE DESCRIPTION & PURPOSE OF USE

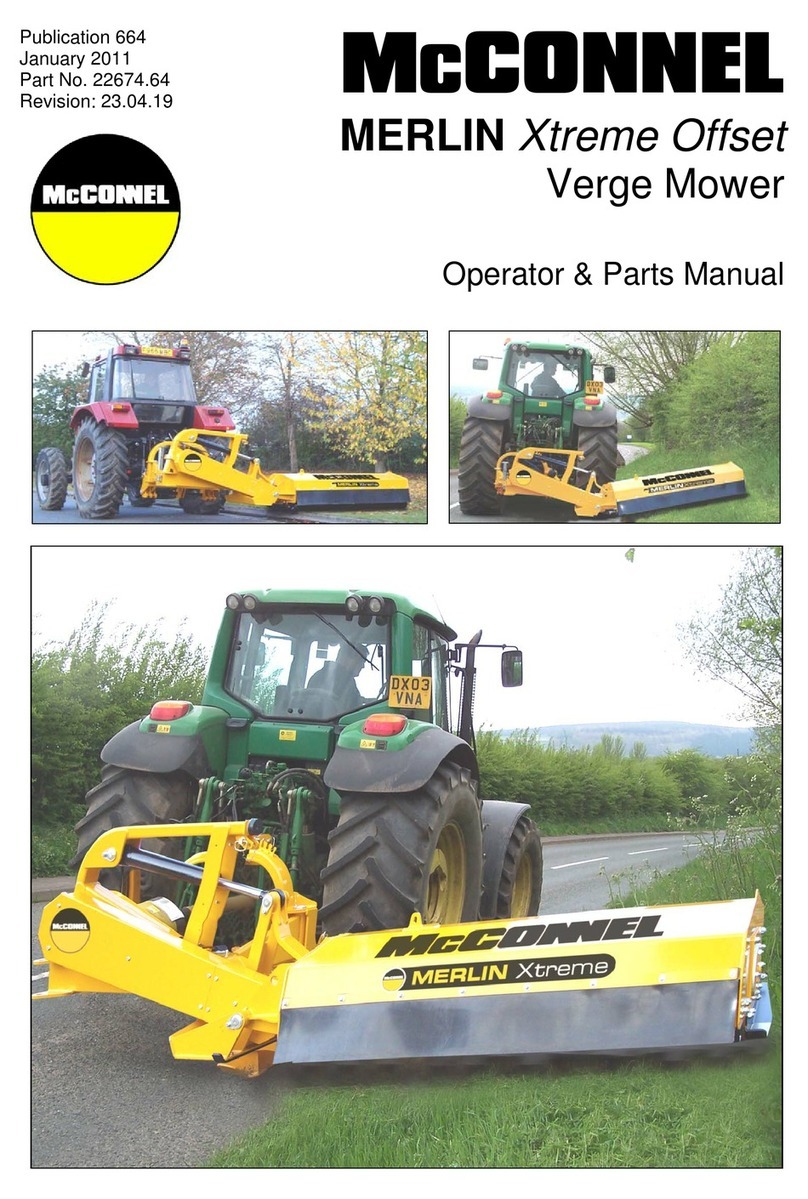

The Magnum 245, 270 & 300 series of machines are ‘3-point linkage’ tractor mounted

heavy duty professional mowers designed primarily for the mulching of maize, grasses,

bushes, branches, vines, and general crop residues. Their strong, tough construction with

working widths of 2.4, 2.7 or 3.0m and offset capability of over 0.5m makes them ideal for

maintenance use in all green areas, vineyards, orchards, on verges and in scrubland by

farmers and contractors alike.

These machines should only be used to perform tasks for which they were designed – use

of the machine for any other function may be both dangerous to persons and damaging to

components and is therefore not advisable.

MACHINE IDENTIFICATION

Each machine is fitted with an identification plate with the following information:

1. Machine (Part Number)

2. Machine Serial No.

3. Machine Weight

When ordering spares or replacement parts from

your local dealer it is important to quote both Part

Number and Serial Number as stated on the

identification plate so the machine and model can

be quickly and correctly identified.

TECHNICAL DATA

COMPONENT IDENTIFICATION

1. Main Frame

2. Gearbox

3. Belt Drive / Belt Guard

4. 3-Point Linkage

5. Rear Roller

6. Hydraulic Ram

7. Hydraulic Hoses

8. Sliding Tubes

9. Skids

Combi model with double linkage option illustrated

3

1. PTO Shaft Guard

2. Belt Guard

3. Front Flap Guard

4. Side Guard

5. Rear Rubber Guard

TECHNICAL SPECIFICATIONS

SPECIFICATION Model 245 Model 270 Model 300

Working Width 2450mm 2700mm 3000mm

Tractor Power Requirement 68-80 HP 75-100 HP 90-130 HP

PTO RPM (* Option) 540 /1000* RPM 540 /1000* RPM 540 /1000* RPM

Hammer Blades 26 28 32

Y-Blades 78 84 96

Machine Weight 880kg 950kg 1020kg

Offset Capability 530mm 530mm 530mm

Linkage Type 3-Point (Cat. II) 3-Point (Cat. II) 3-Point (Cat. II)

Machine Width (Total) 2510mm 2670mm 3000mm

MACHINE BUILDS

Standard machines are rear mounted left hand build, optional builds right handed, front

mounted or Combi models.

MACHINE RPM

Standard machines are 540RPM with 1000RPM optional on request.

OPTIONAL EQUIPMENT

The standard flails fitted to the machine are the hammer blade type, Y-blade flails are

optional. The cutting capability of the each particular type of flail will be dependant on the

sort, hardness, and density of the material being cut, but in general the following cutting

thicknesses apply:

Y-blade flails – for materials up to a maximum of 30mm diameter.

Hammer flails – for materials up to a maximum of 50mm diameter.

NOISE LEVEL

The sound level of this machine, as measured at the operator’s ear, is within the range of

70 to 90 dB when the rear window of the tractor is open. We recommend that ear

protectors are worn and the tractor windows kept closed at all times when operating this

machine.

SAFETY GUARDS

The photo opposite indicates the

locations of the machine safety

guards – the machine must never

be operated with any of these

guards missing or damaged.

4

SAFETY INFORMATION

General safety rules:

▲Always read and follow the instructions for the use and maintenance of the machine

before carrying out any work operations or servicing tasks.

▲Improper use of the machine is both highly dangerous to persons and damaging to the

machine components – only use the machine for its designated task.

▲Both operators and the maintenance fitters should be familiar with the machine and

fully aware of dangers surrounding improper use or incorrect repairs.

▲Before starting, checks to both tractor and machine must be carried out as regards:

functionality, road safety, accident prevention rules.

▲Even when using the machine correctly, stones or other objects may be thrown a long

distance. Therefore nobody must stand within the danger area. Special attention must

be paid when working near roads or buildings.

▲Use tractor’s fitted with safety cabs.

▲The condition of flails and of machine guards must be checked before beginning the

daily work - they must be replaced if damaged or missing before you use the machine.

▲During checks or repairs, make sure nobody could start the machine by mistake.

▲Never wear loose or fluttering clothes.

▲Never carry passengers on the tractor.

▲Never carry passengers on the machine.

▲Never connect the power takeoff with the engine running.

▲Never approach the machine until the rotor has completely stopped.

▲Do not enter the working zone of the PTO shaft. It is dangerous to approach the

rotating parts of a machine.

▲Keep the PTO shaft guard in good condition.

▲Before starting, check the surrounding area for the likely presence of children and/or

animals.

▲Do not stand near the machine when it is operating.

▲The PTO shaft must be assembled and disassembled only with the engine stopped

and the starting key removed.

▲Before connecting the power takeoff, check that the speed and the rotational direction

correspond to those of the machine.

▲Immediately replace missing or damaged safety decals.

▲Before leaving the tractor with the machine attached, proceed as follows:

1. Disconnect the power takeoff,

2. Put the machine steadily on the ground using the tractor’s hydraulic lift.

3. Apply the hand brake and, if the ground is steeply sloping, wedge the tractor.

4. Remove the starting key.

5

Transportation Safety

▲In transport, reduce speed, especially on bumpy roads, the weight of the machine may

render driving difficult and damage the machine itself.

▲Ensure the levers that operate the hydraulic lift are locked, to avoid the lowering of the

machine during transport.

▲When driving on public roads, respect all road rules in force.

▲Never transport the machine with the rotor running, even for short distances.

Operating Safety

▲Pay special attention when working with the machine not to touch fixed objects such as

road drain, walls, shafts, kerbs, guard rails, tracks etc. This could cause the breakage

of the flails, which would be thrown out of the machine at very high speed.

▲If wires, ropes or chains should become entangled in the rotor stop immediately to

prevent damage or dangerous situations; stop the rotor and the tractor, take out the

starting key. Put working gloves on; clear the rotor with the aid of pliers or shears. Do

not try to disentangle by inverting the rotational direction of the rotor.

▲Do not use the machine when excessive vibration is experienced, as this may cause

breakage and serious damage - find the cause of the vibration and eliminate it before

using the machine again.

Although the information given here covers a wide range of safety subjects, it is impossible to

predict every eventuality that can occur under differing circumstances whilst operating this machine.

No advice given here can replace ‘good common sense’ and ‘total awareness’ at all times, but will go

a long way towards the safe use of your McConnel machine.

SAFETY DECALS

1. Always switch machine off, remove starting key and read instruction manual before

performing service or maintenance work on the machine.

2. Keep a safe distance from the machine at all times - risk from projection of objects.

3. Risk of hand injury – always ensure all guard are fitted and in place when machine

is operating.

4. Risk of feet injury – keep at a safe distance from the machine when it is operating.

5. Never stand or ride on the machine.

This manual suits for next models

3

Table of contents

Other McConnel Lawn Mower manuals

McConnel

McConnel RoboCut Programming manual

McConnel

McConnel MAGNUM 130 Programming manual

McConnel

McConnel MAGNUM MULCHA 225 User manual

McConnel

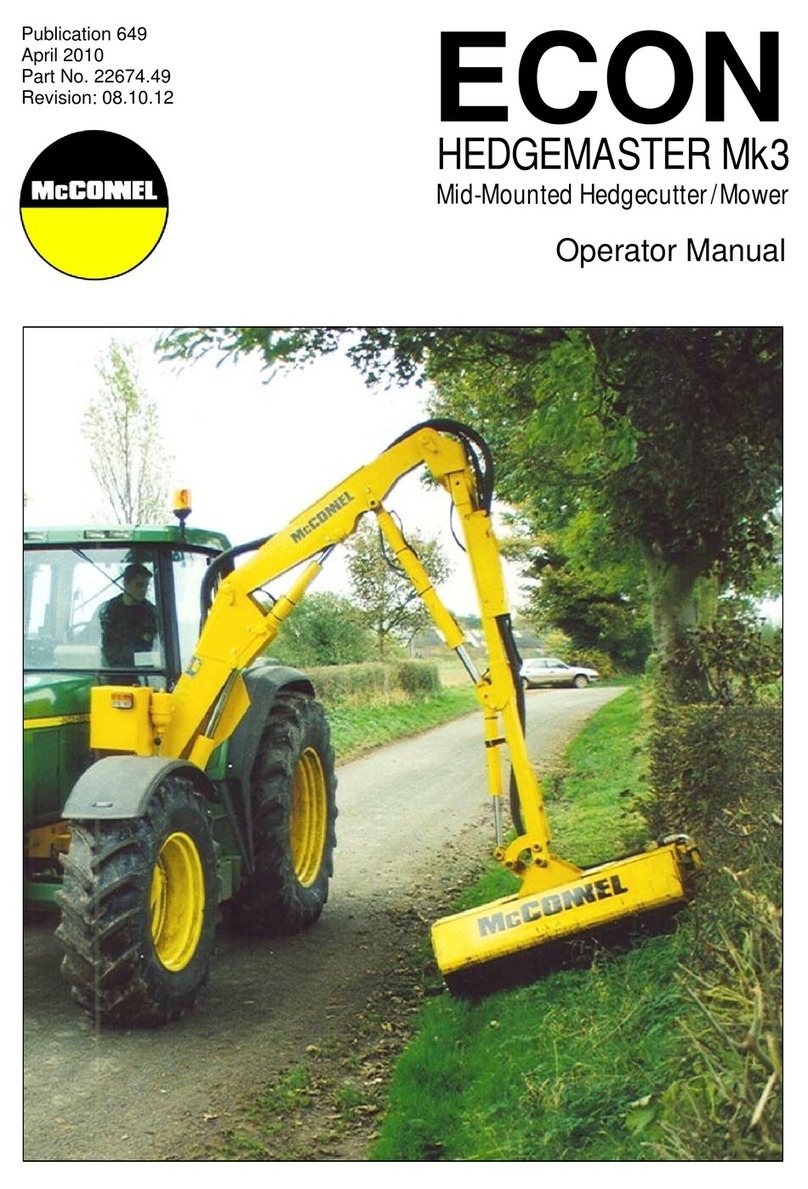

McConnel ECON HEDGEMASTER Mk3 User manual

McConnel

McConnel Twose Series User manual

McConnel

McConnel ROBOMAX User manual

McConnel

McConnel MAGNUM EURO MINI Series Programming manual

McConnel

McConnel PA5054 VERSI User manual

McConnel

McConnel PA5040-40 User manual

McConnel

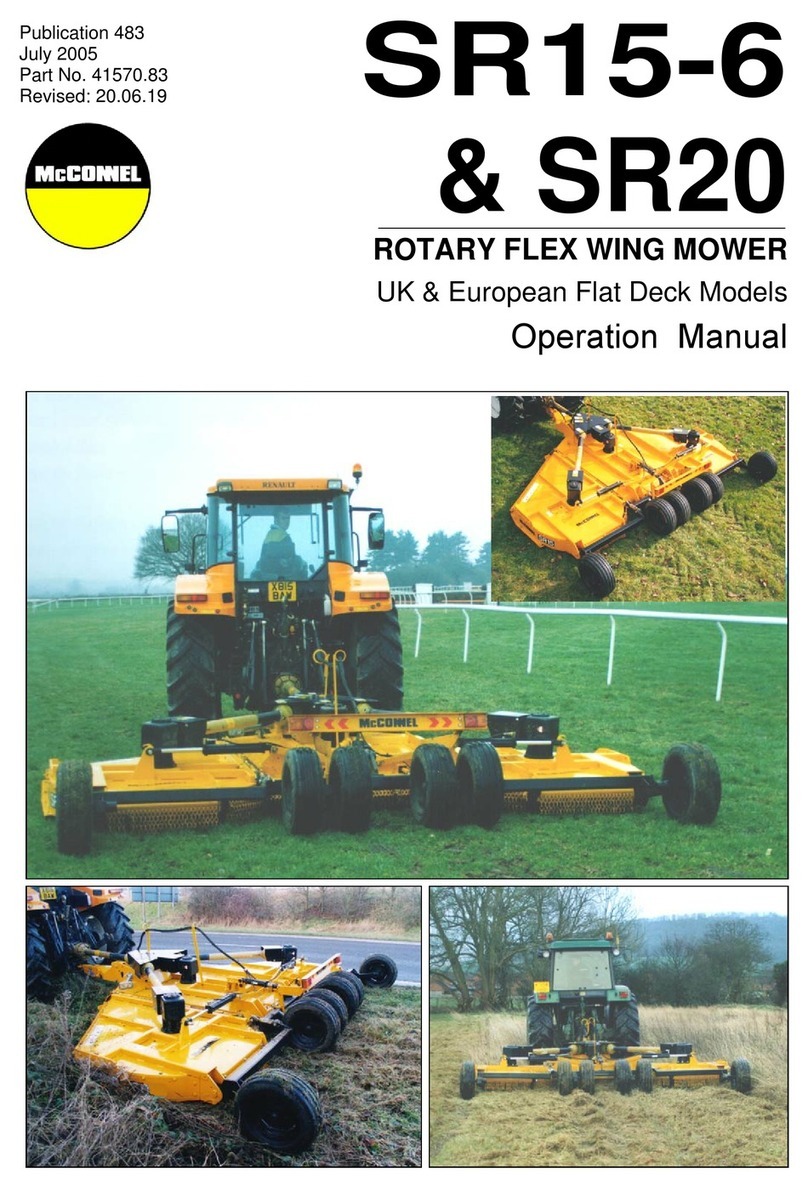

McConnel SR15-6 User manual