McConnel SR420 User manual

Publication 608

July 2009

Part No. 22674.08

McCONNEL

SR420

ROTARY WING MOWER

Operator Manual

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user – failure to do so may affect the validity of the machine warranty.

To register machines go to the McConnel Limited web site at www.mcconnel.com, log

onto ‘Dealer Inside’ and select the ‘Machine Registration button’which can be found in

the Service Section of the site. Confirm to the customer that the machine has been

registered in the section below.

Should you experience any problems registering a machine in this manner please contact

the McConnel Service Department on 01584 875848.

Registration Verification

Dealer Name:

……………………..…………………………………………………………….

Dealer Address:

…….………………………………………………………………………….

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below.The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines general maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP

Setting

Metric

BSP

Setting

Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm

19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm

22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm

27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm

30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm

32 mm

1” 125 Nm 41 mm 1” 203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm

55 mm

2” 420 Nm 70 mm 2” 400 Nm

70 mm

Warranty Policy (page 1 of 3)

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the end user.

On receipt of the goods it is the buyer’s responsibility to check that the Verification of Warranty

Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All mounted machines supplied by McConnel Ltd are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

All Self Propelled Machines supplied by McConnel Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12 months

or 1500 hours. Engine warranty will be specific to the Manufacturer of that unit.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be free from

defects in material and workmanship from the date of sale to the original purchaser for a period of 6

months. All parts warranty claims must be supported by a copy of the failed part invoice to the end

user. We cannot consider claims for which sales invoices are not available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement for the

purchaser any part or parts found, upon examination at its factory, to be defective under normal use

and service due to defects in material or workmanship. Returned parts must be complete and

unexamined. Pack the component(s) carefully so that any transit damage is avoided. All ports on

hydraulic items should be drained of oil and securely plugged to prevent seepage and foreign body

ingress. Certain other components, electrical items for example, may require particular care when

packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate has

been removed or altered.

1.05. The warranty policy is valid for machines registered in line with the terms and conditions detailed and

on the basis that the machines do not extend a period of 24 months or greater since their original

purchase date, that is the original invoice date from McConnel Limited.

Machines that are held in stock for more than 24 months cannot be registered for warranty.

1.06. This warranty does not apply to any part of the goods, which has been subjected to improper or

abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident damage,

or damage resulting from contact with overhead power lines, damage caused by foreign objects (e.g.

stones, iron, material other than vegetation), failure due to lack of maintenance, use of incorrect oil or

lubricants, contamination of the oil, or which has served its normal life. This warranty does not apply

to any expendable items such as blades, belts, clutch linings, filter elements, flails, flap kits, skids, soil

engaging parts, shields, guards, wear pads, pneumatic tyres or tracks.

1.07. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.08. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired

will be rejected.

1.09. Machines must be repaired immediately a problem arises. Continued use of the machine after a

problem has occurred can result in further component failures, for which McConnel Ltd cannot be held

liable, and may have safety implications.

1.10. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine part.

Warranty Policy (page 2 of 3)

1.11. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of McConnel Ltd.

1.12. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.12.1. Hoses, exposed pipes and hydraulic tank breathers.

1.12.2. Filters.

1.12.3. Rubber mountings.

1.12.4. External electric wiring.

1.12.5. Bearings and seals

1.12.6. External Cables, Linkages

1.12.7. Loose/Corroded Connections, Light Units, LED’s

1.12.8. Comfort items such as Operator Seat, Ventilation, Audio Equipment

1.13. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

1.14. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair work

are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be held

responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the McConnel web

site and confirms the registration to the purchaser by completing the confirmation form in the

operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs. Continued use

of a machine, after a fault has occurred, can result in further component failure for which McConnel

Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be

rejected, unless the delay has been authorised by McConnel Ltd. Please note that failure by the

customer to release the machine for repair will not be accepted as a reason for delay in repair or

submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days of the

date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for any valid

claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate labour and mileage

allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd. is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with respect to

the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for

damages incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may

be brought more than one (1) year after the cause of the action has occurred.

Warranty Policy (page 3 of 3)

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

McConnel Limited

DECLARATION OF CONFORMITY

Conforming to EU Machinery Directive 2006/42/EC

We,

McCONNEL LIMITED, Temeside Works, Ludlow, Shropshire SY8 1JL, UK

Hereby declare that:

The Product; Tractor Trailed Flex Wing Mower

Product Code; MR42, MR46, MR62, MR82

Serial No. & Date ………………………………… Type …………………………

Manufactured in; United Kingdom

Complies with the required provisions of the Machinery Directive 2006/42/EC

The machinery directive is supported by the following harmonized standards;

■BS EN ISO 12100 (2010) Safety of machinery –General principles for design –Risk

assessment and risk reduction.

■BS EN 349 (1993) + A1 (2008) Safety of machinery - Minimum distances to avoid the

entrapment with human body parts.

■BS EN ISO 14120 (2015) Safety of machinery - Guards general requirements for the

design and construction of fixed and movable guards.

■BS EN 4413 (2010) Hydraulic fluid power. Safety requirements for systems and their

components.

McCONNEL LIMITED operates an ISO 9001:2008 quality management system,

certificate number: FM25970.

This system is continually assessed by the;

British Standards Institution (BSI), Beech House, Milton Keynes, MK14 6ES, UK

BSI is accredited by UK Accreditation Service, accreditation number: UKAS 003.

The EC declaration only applies if the machine stated above is used in

accordance with the operating instructions.

Signed …………………................ Responsible Person

CHRISTIAN DAVIES on behalf of McCONNEL LIMITED

Status: General Manager Date: January 2018

ROTARY MOWER INSPECTION AND MAINTENANCE

A daily equipment inspection of the trac tor and mower should be conduct ed before the

equipment is used. You may use the ins pection sheets to assist with these daily

inspections. Any damaged or missing guar ds should be repaired or replaced befor e

operating the mower. Failure t o repair the damaged shield c an result in objects being

thrown from the mower and possibly hitting the operator or bystander.

Inspect the Mower for Safe Operating Condition

Make sure the driveline guards and shielding are in place and in good repair.

Inspect the chain guards, flexible and/or solid defector thrown object shielding t o

assure that they are in place on the front and rear of the mower deck and in good

repair. Repair or replace any damaged or missing thrown object shields.

Remove all debris and cut material from the deck and around the gearboxes.

Ensure the mower cutting height is se t high enough to reduce the possibility of the

mower blades contacting the ground. Actual height will be dependent on the ground

conditions. Increase the height when working in rough or undulating conditions.

Inspect for broken, chipped, bent, missi ng, or severely worn blades. Replace

damaged blades before operating the mower. Ensure the blade retaining bolts and

fasteners are secure and tight.

Lubricate the driveline universal joints and telescoping members daily.

Inspect the wheel lug bolt/nuts to assure that they are tight.

If mower is equipped with pneumatic tires, make sure they hav e the required air

pressure.

Inspect for worn or damaged decals and s afety instructions. Replace unreadable,

damaged or missing safety decals.

Follow the operator’s manual(s) inspec tion and maintenanc e instructions for

lubricating parts, and keeping thrown obj ect shielding, driveline guards, rotating

parts shields, mower blades and decals in good repair.

Inspect the Tractor for Safe Operating Condition:

Inspect the controls, lights, SMVs (Slow Moving Vehicle sign), seat belts, and

ROPS to assure that they are in place and in good working order.

Be sure the tires, wheels, lug bolts/nuts are in good condition.

Make sure the tractor brakes and steering are in proper operating condition.

Follow the operator’s manual(s) inspection and maintenance procedures for

keeping the tractor in good and safe condition before operating.

The inspection sheet on the foll owing page should be kept in this book a s a record. A

second sheet is included for you to cut out and photocopy or the inspection sheets can be

down loaded from our web site at;

http://www.mcconnel.com/support/aftersales/default.aspx?nav=After Sales

FLEX WING MOWER PRE-OPERATION Inspection

Mower ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key removed, all

rotation has stopped and the tractor is in park with the parking brake engaged. Make sure

the mower wings are resting on the ground or securely blocked up, or are retained in the

transport by pins and all hydraulic pressure has been relieved.

Item Condition at

start of shift Specific Comments if not O.K.

The Operator’s Manual is in the Canister on the mower

All Warning Decals are in place and legible

All Lights are clean and working

Tongue/Hitch connection bolts & pins are tight

There are no cracks in Tongue or Hitch

Hyd. Cylinder pins are properly retained

There are no oil leaks

There are no damaged hoses

Gearboxes & mower decks are clear of cut grass and debris

Chain Guards/Deflectors are in place & in good condition

Driveline/Gearbox shields/guards are in good condition

Driveline clutches are in good condition, not frozen

Driveline telescoping members & u-joints are lubricated

Driveline yokes are securely attached to tractor & mower

Gearbox mounting bolts are tight

Blade carrier retaining nut is tight

Blades are not chipped, cracked, bent or worn out

Blade bolts are tight

Side skirts and skids are in good condition

There are no holes or cracks in the machine deck

Wheel nuts are tight

Tyre pressures are correct

Transport locks are in good condition

All axle mounting pins are correctly secured

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION Inspection

Power Arm ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key is removed

all rotation has stopped and the tractor is in park with the parking brake engaged. Any

implement attached to the tractor is firmly on the ground.

Item Condition at

start of shift Specific Comments if not O.K.

The flashing lights function properly.

All lights are clean and working correctly

All cab windows are clean and wipers working correctly

The SMV sign, where required, is clean and visible.

The tyres are in good condition with correct pressure.

The wheel nuts are tight.

The tractor brakes are in good condition.

The steering linkage is in good condition.

There are no visible oil leaks.

The hydraulic controls function properly.

The ROPS or ROPS cab is in good condition.

The seatbelt is in place and in good condition.

The 3-point hitch is in good condition.

The drawbar/pick up hook is secure & in good condition

The PTO master shield is in place.

The engine oil level is full.

The brake fluid level is full.

The power steering fluid level is full.

The fuel level is adequate.

The engine coolant fluid level is full.

The radiator & oil cooler are free of debris.

The air filter is in good condition

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

FLEX WING MOWER PRE-OPERATION Inspection

Mower ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key removed, all

rotation has stopped and the tractor is in park with the parking brake engaged. Make sure

the mower wings are resting on the ground or securely blocked up, or are retained in the

transport by pins and all hydraulic pressure has been relieved.

Item Condition at

start of shift Specific Comments if not O.K.

The Operator’s Manual is in the Canister on the mower

All Warning Decals are in place and legible

All Lights are clean and working

Tongue/Hitch connection bolts & pins are tight

There are no cracks in Tongue or Hitch

Hyd. Cylinder pins are properly retained

There are no oil leaks

There are no damaged hoses

Gearboxes & mower decks are clear of cut grass and debris

Chain Guards/Deflectors are in place & in good condition

Driveline/Gearbox shields/guards are in good condition

Driveline clutches are in good condition, not frozen

Driveline telescoping members & u-joints are lubricated

Driveline yokes are securely attached to tractor & mower

Gearbox mounting bolts are tight

Blade carrier retaining nut is tight

Blades are not chipped, cracked, bent or worn out

Blade bolts are tight

Side skirts and skids are in good condition

There are no holes or cracks in the machine deck

Wheel nuts are tight

Tyre pressures are correct

Transport locks are in good condition

All axle mounting pins are correctly secured

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION Inspection

Power Arm ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key is removed

all rotation has stopped and the tractor is in park with the parking brake engaged. Any

implement attached to the tractor is firmly on the ground.

Item Condition at

start of shift Specific Comments if not O.K.

The flashing lights function properly.

All lights are clean and working correctly

All cab windows are clean and wipers working correctly

The SMV sign, where required, is clean and visible.

The tyres are in good condition with correct pressure.

The wheel nuts are tight.

The tractor brakes are in good condition.

The steering linkage is in good condition.

There are no visible oil leaks.

The hydraulic controls function properly.

The ROPS or ROPS cab is in good condition.

The seatbelt is in place and in good condition.

The 3-point hitch is in good condition.

The drawbar/pick up hook is secure & in good condition

The PTO master shield is in place.

The engine oil level is full.

The brake fluid level is full.

The power steering fluid level is full.

The fuel level is adequate.

The engine coolant fluid level is full.

The radiator & oil cooler are free of debris.

The air filter is in good condition

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

LIST OF CONTENTS

Page No.

Introduction 1

Tractor Requirements 1

Safety Information 2

Safety Decals 5

Tractor Attachment 6

PTO Shaft 6

Machine Setup 7

Operation 8

Transportation 9

Machine Protection - Slip Clutch 9

Service & Maintenance 10

Troubleshooting Guide 16

1

INTRODUCTION

The SR420 Rotary Wing Mower is a heavy duty rotary mower primarily designed for set-aside,

stubble and pasture topping work. With a cutting width of 4.2m they are suitable for use with

tractors of between 85 and 120HP.

The cutting height of the machine is controlled and regulated via the rear centre deck wheels

and adjustable wing skids with addition wing wheels offered as an option.

The wings of the machine ‘float’ mechanically during work to eliminate ram seal wear and are

raised by independent single acting hydraulic rams for transportation of the machine –

mechanical lift locks are provided for complete safety. Power from the tractor to the machine is

transferred via a series of gearboxes and PTO shafts with slip clutch protection to absorb shock

loads and protect driveline components.

For personal safety and protection of components the machines should never be used to

perform tasks they were not designed to do.

TRACTOR REQUIRMENTS

The tractors used should be:

Minimum of 85HP.

Equipped with Category 2 three-point linkage.

Fitted with Check Chains and/or Stabilisers and correctly tightened (We particularly

recommend 'turnbuckle' type Check Chains).

Minimum weight of 3700kg.

1000RPM PTO.

Equipped with 1 external hydraulic service, single acting with float facility for wings.

Sufficient weight on the front wheels to ensure stability during transportation and work.

Extra ballast should be added if required.

Before attachment; set lift rods to equal length and ensure position control is selected -

never attempt to hitch in draft control.

2

SAFETY

Safety Information

Read, Understand and Follow the Safety Messages - Serious injury or death may occur unless

care is taken to follow the warnings and instructions given in the safety messages,

CAUTION! The lowest level of Safety Message; warns of possible injury.

WARNING! Serious injury or possible death.

DANGER! Imminent death/critical injury.

Never operate the tractor or machinery until you have read and completely understand this

manual and the tractor operator’s manual and each of the safety messages found in the

manuals and those displayed on the tractor and implement.

DANGER! DO NOT attempt any maintenance of or adjustment to the machine while it is

running. Before carrying out any work on the machine follow the three safety

instructions below:

a LOWER THE MACHINE ON TO THE GROUND

b PUT THE PTO OUT OF GEAR

c STOP THE TRACTOR ENGINE

WARNING! The operator and all support personnel must wear the appropriate safety clothing

i.e. safety glasses and safety shoes at all times for protection from injury by

objects thrown from the machine.

DANGER! Never allow passengers especially children to ride on the tractor or implement.

Falling off can kill.

DANGER! Do not mount or dismount the tractor or machine while it is moving. Mount or

dismount only when stopped – falling off can kill.

DANGER! At all times ensure that the PTO shaft guard is in position, securely fitted and in

good condition and that the tractor PTO shaft shield is fitted.

CAUTION! Replace the PTO shaft guard if any of the following are evident:- guard cracked or

damaged any part of the PTO shaft exposed. Ensure the PTO shaft guard is free

to rotate and the anti-rotation chains are securely fitted and effective.

WARNING! Ensure that the correct guards are properly fitted to the machine and tractor at all

times and check that they are in good condition. Ensure you have the correct

guards fitted for the type of operation being performed. Missing or damaged

guards must be replaced immediately.

DANGER! AVOID WIRE. It can be extremely dangerous if wire catches in the blades of

the machine, and every care must be taken to ensure this will not happen.

Inspect the working area before commencing. Remove all loose wire and

obstructions and clearly mark those that are fixed so that you can avoid them.

Any unusual noise from the cutting unit area indicates that the blades may have

been fouled by an obstruction. A visual indication that wire has become

entangled may be a sudden movement of the vegetation ahead of the machine.

In any such event STOP the tractor engine INSTANTLY. On no account move

the machine until blades have completely stopped. When the machine has

stopped inspect it and remove any obstruction that may be present. If working

under a raised machine ensure that it is safely supported. Before working on

the machine always stop the tractor engine and remove the ignition key.

3

SAFETY

WARNING! While the tractor is running all personnel should keep well clear of the area

around the machine as there are numerous crushing, shearing, impact dangers

caused by the machine operation.

DANGER! Do not operate with wings raised off the ground. Operating with the wings

raised exposes the blades and can cause objects to be thrown and there is also

danger of entanglement in or being hit by rotating blades.

DANGER! Do not work under a wing in the raised position unless it is supported on blocks

or propped. A sudden or inadvertent fall by one of these components could

cause serious injury or even death.

DANGER! These machines are capable under adverse conditions of throwing objects

great distances at high velocity. CHECK the blades for wear and the

attachment bolts for tightness every day during work .A few moments whenever

the machine is stopped, e.g. whenever removing obstructions, will help reduce

blade wear or loss.

DANGER! Keep your forward speed to a level appropriate to the operating conditions.

High-speed manoeuvres are very dangerous, particularly on uneven ground

where there is risk of overturning.

DANGER! Keep a careful watch for passers-by who may inadvertently get in the way of cut

material being ejected from the machine. These machines are capable under

adverse conditions of throwing objects great distances at high velocity. Stop the

blades until all people are well clear.

WARNING! Extreme care should be taken when operating near loose objects such as gravel,

rocks, wire, and other debris. Inspect the area before mowing. Foreign objects

should be removed from the site to prevent machine damage and/or bodily

injury or even death. Any objects that cannot be removed must be clearly

marked and carefully avoided by the operator. Stop mowing immediately if

blades strike a foreign object. Repair all damage and make certain the blade

and carrier are still balanced before resuming cutting operations.

WARNING! Transport the machine only at safe speeds. Serious accidents and injuries can

result from operating this equipment at unsafe speeds

DANGER! When the wings are folded for transport, the centre of gravity is raised and the

possibility of overturn is increased. Turn slowly and with extra care on hillsides.

Overturning the mower could cause the mower to overturn the tractor and vice

versa. Never fold wings on a hillside, the mower may overturn

WARNING! Do not transport unless wings are well secured in the transport position. Wings

that are not well secured can fall during transport, causing serious damage to

the tractor and mower and possibly causing the operator or passers by to be

injured or killed.

WARNING! Release hydraulic pressure from the rams before attempting maintenance. Lower

the machine to the ground and lower the wings or securely block up, disengage

the PTO and turn off the engine.

DANGER! Do not operate this Equipment with hydraulic oil leaking. Oil is expensive and its

presence could present a hazard. Do not check for leaks with your hand! Use a

piece of heavy paper or cardboard. High-pressure oil streams from breaks in the

line could penetrate the skin and cause tissue damage including gangrene. If oil

does penetrate the skin, have the injury treated immediately by a physician

knowledgeable and skilled in this procedure.

4

SAFETY

WARNING! Periodically inspect all moving parts for wear and replace when necessary with

authorised service parts. Look for loose fasteners, worn or broken parts, and

leaky or loose fittings. Make sure all pins have cotter pins and washers.

Serious injury may occur from not maintaining this machine in good working

order.

WARNING! Never un-couple the machine without using the hitch support jack. The hitch is

very heavy. Attempting to lift the hitch without using the jack could cause

strains. Allowing the hitch to fall suddenly and unexpectedly could result in

crushing injury. Use the support jack for lifting the mower only. Overloading the

jack can cause failure with possible serious bodily injury or even death.

WARNING! Never attempt to lubricate, adjust, or remove material from the Implement while

it is in motion or while tractor engine is running. Make sure the tractor engine is

off before working on the Implement.

Emergency Stop

To stop the blades in an emergency use the tractor stop control. The use of the tractor stop

control must only be done in an emergency. Its use to stop the machine can cause damage.

After an emergency stop of the machine; ensure that the PTO is disengaged before restarting

the tractor.

Safety Decals

Safety decals are located on various points of the machine. They can be identified by the

yellow upper panel depicting the hazard, and the lower white panel indicating means of

avoidance or precautions to be taken. These decals have no text. It is essential that all

operators and personnel associated with the machine fully understand their meanings, which

are shown on the following pages.

Any safety decals that are missing should be replaced at the earliest possible opportunity.

5

SAFETY DECALS

In addition to company branding and model identification the following safety decals are

displayed – familiarise yourself with, and heed the messages they state, they are there for your

safety and guidance. If any of the safety decals go missing or become damaged beyond a

readable state they should be replaced at the earliest possible opportunity.

WARNING!

Avoid fluid escaping under

pressure. Consult technical

manual for services

procedures.

WARNING!

Danger – flying objects keep

safe distance from the

machine as long as the

engine is running.

WARNING!

Stay clear of mower blade

as long as engine is

running.

WARNING!

Stay clear of swinging area

of implements.

WARNING!

Shut off engine and remove

key before performing

maintenance or repair work.

WARNING!

Check all nuts are tight

every 8 hours.

WARNING!

Carefully read operator’s

manual before handling this

machine. Observe

instructions and safety rules

when operating.

6

TRACTOR ATTACHMENT

Fit the machine to the tractor in the standard way, ensuring the correct match of linkage

(category 2). Check that the top link is in good order and the threads are well lubricated. Use

stabilisers to eliminate any sideways sway.

Before lifting the machine with the tractor linkage you should ensure there is sufficient front

weight to keep the front wheels in contact with ground - This is vital for both safe

transportation and stability when turning on sloping ground.

It is essential to ensure that the tractor drawbar cannot foul the PTO shaft, we

advise to remove it altogether if there is any doubt.

PTO SHAFT

Before fitting the PTO for the first time, it may be necessary to adjust the length. There

should be maximum engagement of the sliding tubes without bottoming at the shortest

operation position. To check, first connect the mower to the tractor. Pull the PTO shaft apart

and connect to the tractor PTO output shaft and the gearbox input shaft. Hold the half shafts

next to each other in the shortest working position. If necessary, shorten the inner and outer

guard tubes equally (Fig. 1). Shorten the inner and outer sliding profiles by the same length

as the guard tubes. File all sharp edges and remove burrs. Grease the sliding profiles.

To fit the PTO, first clean and grease. Press pins on the yoke and simultaneously push the

PTO drive shaft onto PTO shaft of the tractor until pins engage.

The PTO shaft is fitted with a non-rotating safety guard. It should be secured to the machine

and tractor with the two retaining chains provided.

Connect the hydraulic hose to a single acting service with a dump facility. This is important to

allow the wings to be able to follow the ground contours.

Connect the top link and adjust to ensure there is some slack in the wire ropes, before raising

the machine.

Raise the parking stands (Fig. 2) and secure locking pin.

Fig. 2 Parking Stands

Table of contents

Other McConnel Lawn Mower manuals

McConnel

McConnel Twose Series User manual

McConnel

McConnel RoboCut Programming manual

McConnel

McConnel PA5040-40 User manual

McConnel

McConnel RoboCut Programming manual

McConnel

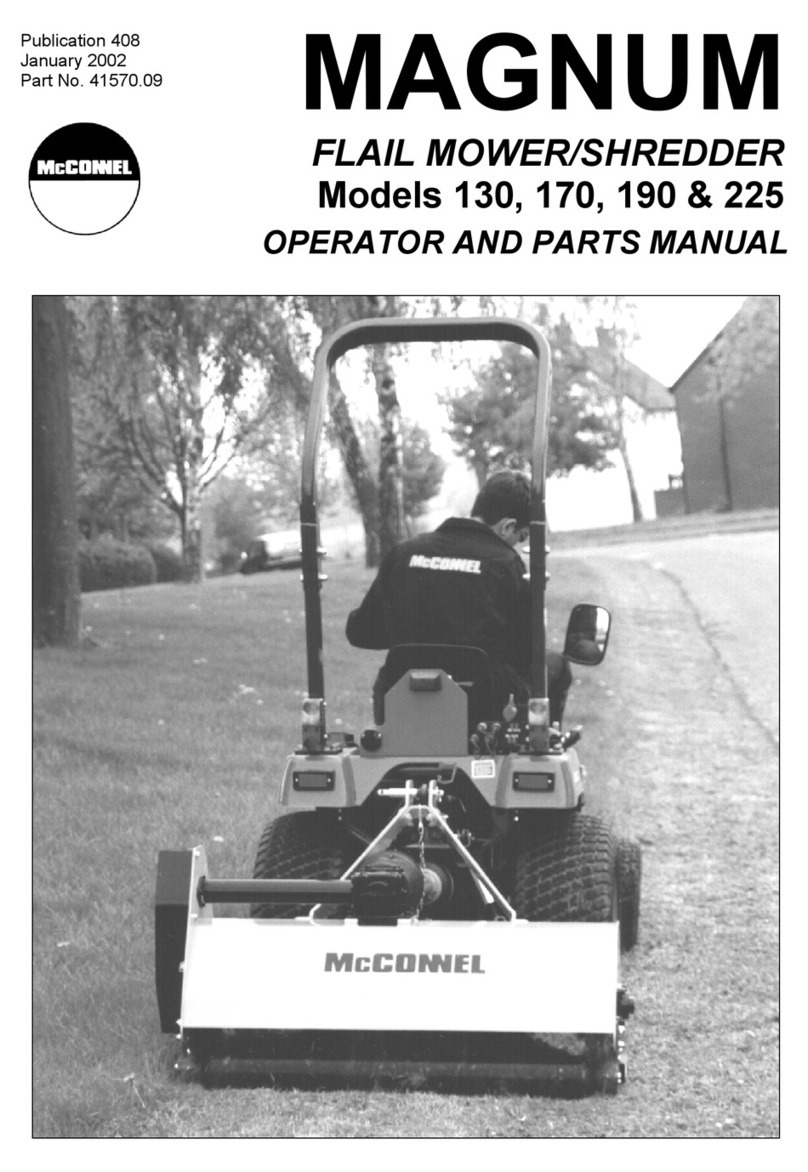

McConnel MAGNUM HEAVY DUTY Series User manual

McConnel

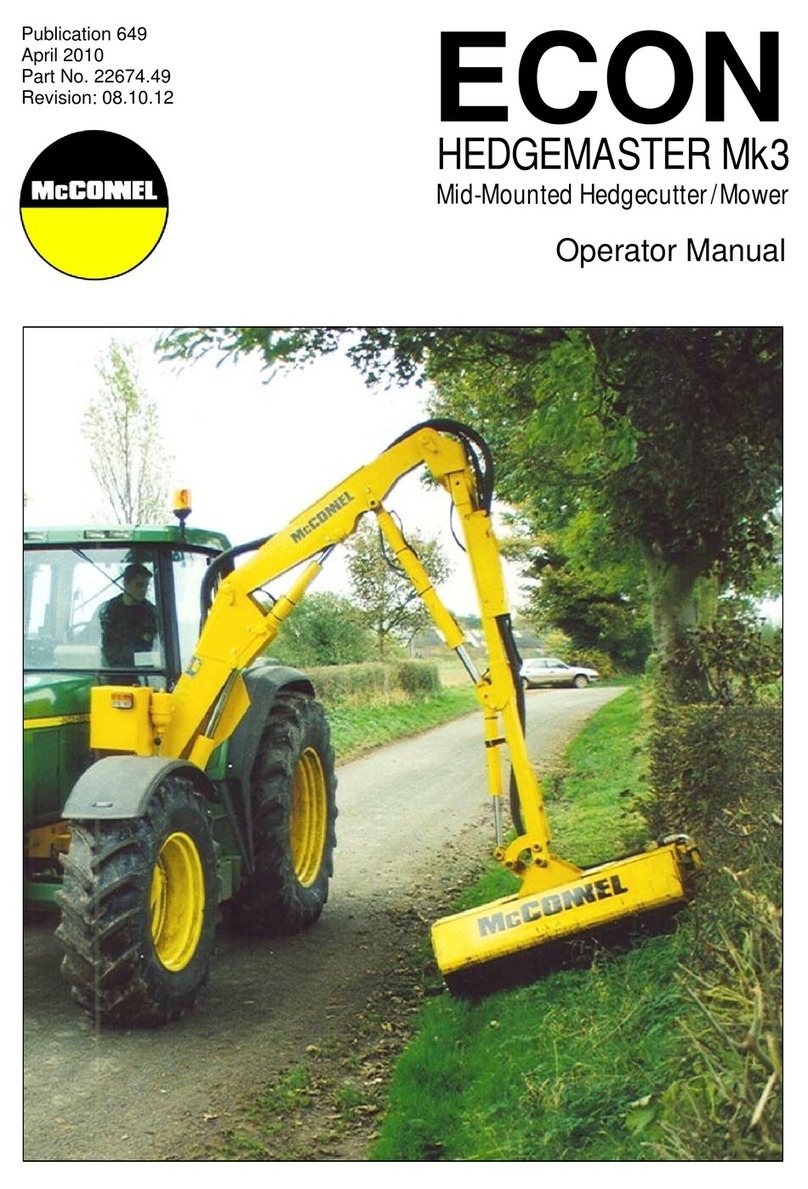

McConnel ECON HEDGEMASTER Mk3 User manual

McConnel

McConnel ROBOCUT RC28 User manual

McConnel

McConnel MAGNUM EURO MINI Series Programming manual

McConnel

McConnel MAGNUM 130 Product manual

McConnel

McConnel PT6 Application guide