©M

c

KELLAR AERO DESIGN

2

Ver. 1.3

Table of Contents

Introduction…………………………………….…………..……2

Kit contents…………………………………….……………..….2

Required to co plete……………………….……………...2

General building instructions………………...………3

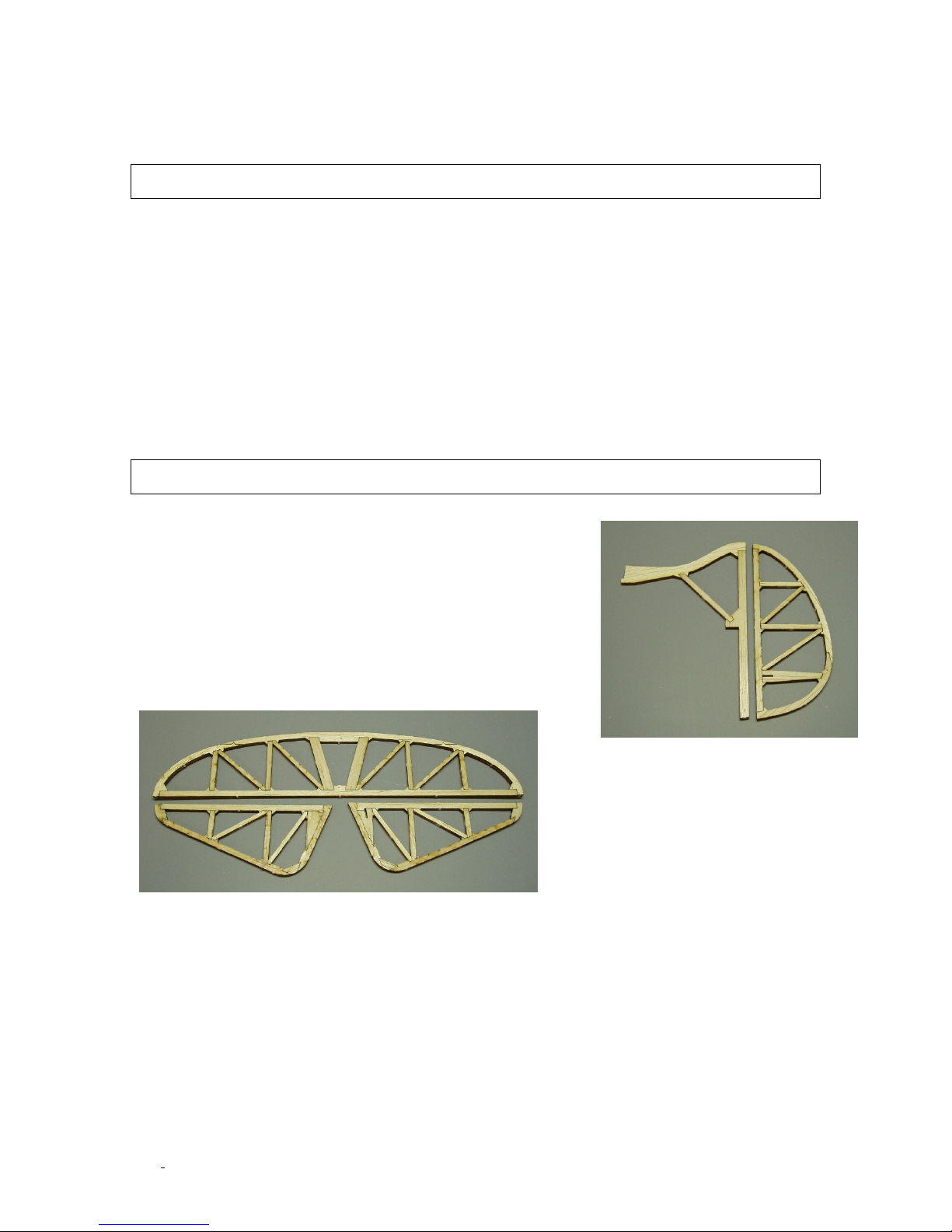

Building the vertical and horizontal tail………3

Building the wing………………………..………..…………..4

Building the cowl……………………………………….……..5

Building the fuselage…………………….……….……..…7

Building the wheel pants………….…………….……….17

Reco ended equip ent………………………………..20

Final asse bly……………………………………………………21

Prepare for flight……………………………….……………22

First flight……………………………………….……………….22

Introduction

Thank you for purchasing this odel kit. We have worked very hard to provide a odel that

is both easy to build and fly. Please read through all the instructions before you begin

building so that errors can be avoided.

Kit Contents

•Four sheets of laser cut 1/16” balsa

•Three sheets of laser cut 1/32” balsa

•One sheet of laser cut 1/8” balsa

•Two sheets of laser cut 1/4” balsa

•One sheet of laser cut 1/8” light plywood

•One sheet of laser cut 1/32” plywood

•Vacuu for ed canopy

•Plans

Required to Complete

•0.032” usic wire

•0.047” usic wire

•Two plastic tubes (Evergreen Plastics 3/32” styrene tubes)

•Two 1/8” dia eter by 1/16” or 1/8” long rare-earth agnets

•Two Dubro Micro E/Z Connectors

•8-32 nylon bolt

•Covering (Nelson LiteFil or equivalent)

•Self-adhesive Velcro (can be found at ost hardware stores)

•Mediu and thin cyanoacralate (CA)

•10 inute epoxy

•Three icro servos weighing 6-8g with 8-10 oz-in torque rating