Contents

5.1 SENSOR INFORMATION TEST..................................................................................................... 23

6MAINTENANCE .................................................................................................................. 25

6.1 OVERVIEW................................................................................................................................ 25

6.2 PERIODIC MAINTENANCE.......................................................................................................... 25

6.3 BATTERY MAINTENANCE.......................................................................................................... 25

6.3.1 Checking the internal battery.......................................................................................25

6.3.2 Remove an internal battery..........................................................................................26

6.3.3 Install the internal battery............................................................................................26

7CLEANING AND DISINFECTION ................................................................................................ 27

7.1 PREPARATIONS ............................................................................................................................. 27

7.2 CLEANING....................................................................................................................................27

7.3 DISINFECTION............................................................................................................................... 28

7.4 AIR DRYING AND TRANSPORTATION ........................................................................................ 29

8CALIBRATION .................................................................................................................... 30

8.1 TOUCH SCREEN CALIBRATION.................................................................................................. 30

8.2 SYRINGE SIZE POTENTIOMETER CALIBRATION......................................................................... 30

8.3 DISTANCE POTENTIOMETER CALIBRATION............................................................................... 30

8.4 CLAW ANGLE SENSOR CALIBRATION ....................................................................................... 30

8.5 CLUTCH POTENTIOMETER CALIBRATION.................................................................................. 31

8.6 PRESSURE SENSOR CALIBRATION ............................................................................................. 31

8.7 SYRINGE ACCURACY CALIBRATION ......................................................................................... 31

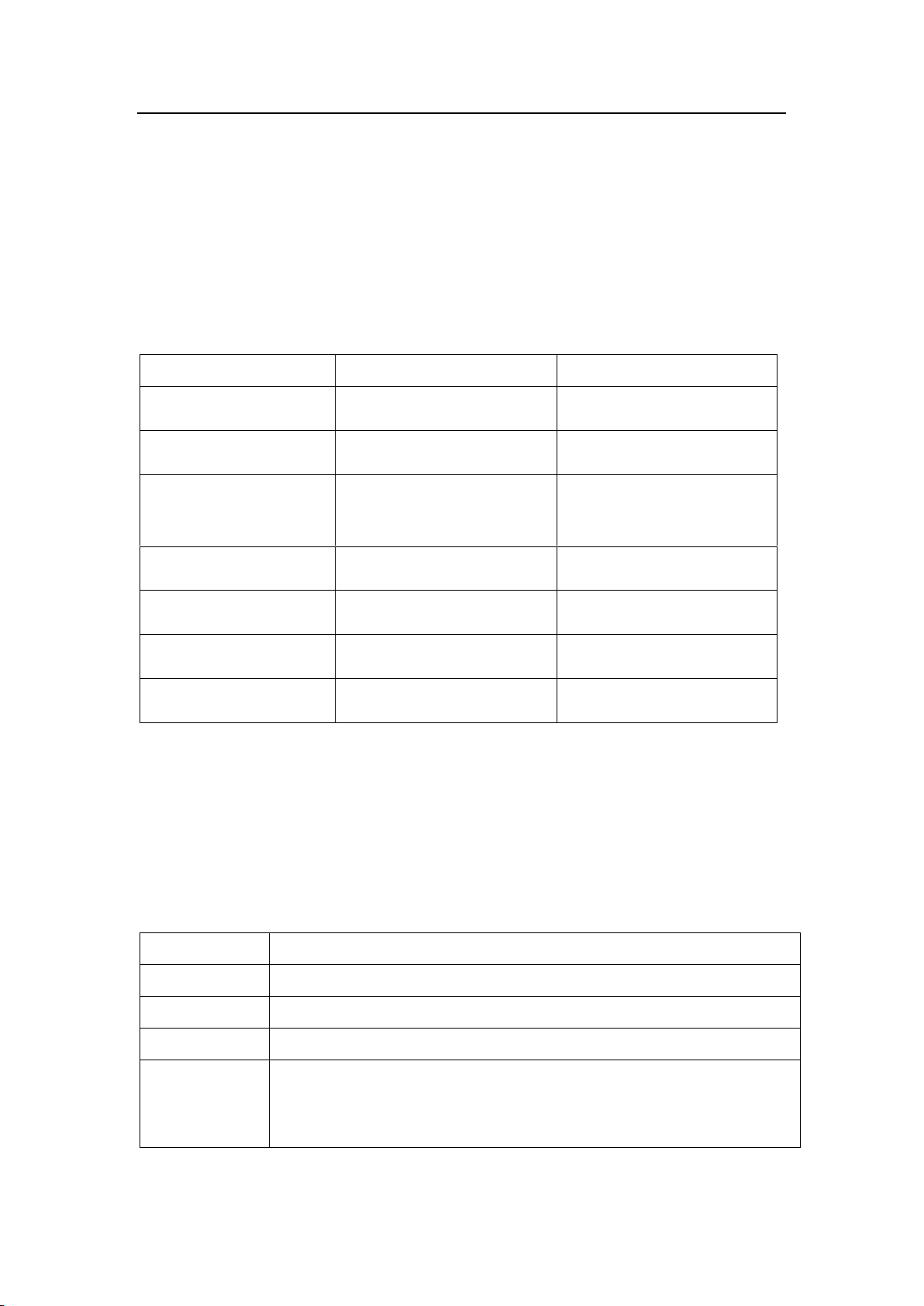

9ALARMS AND TROUBLESHOOTING.............................................................................. 34

9.1 ALARM LEVELS ........................................................................................................................ 34

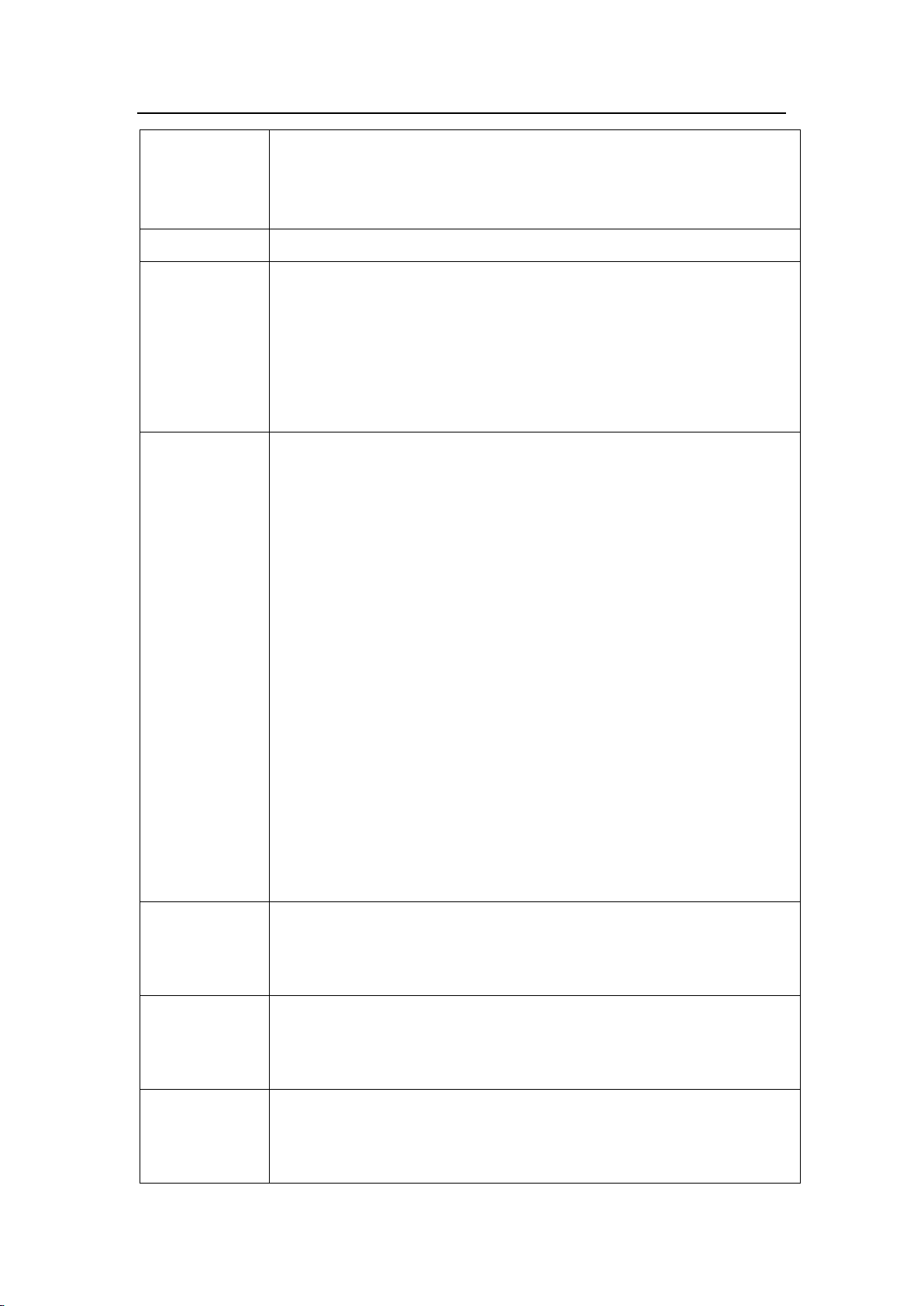

9.2 FAULTS AND TROUBLESHOOTING ............................................................................................. 35

9.3 SYRINGE PUMP FAULTS AND TROUBLESHOOTING ....................................................................36

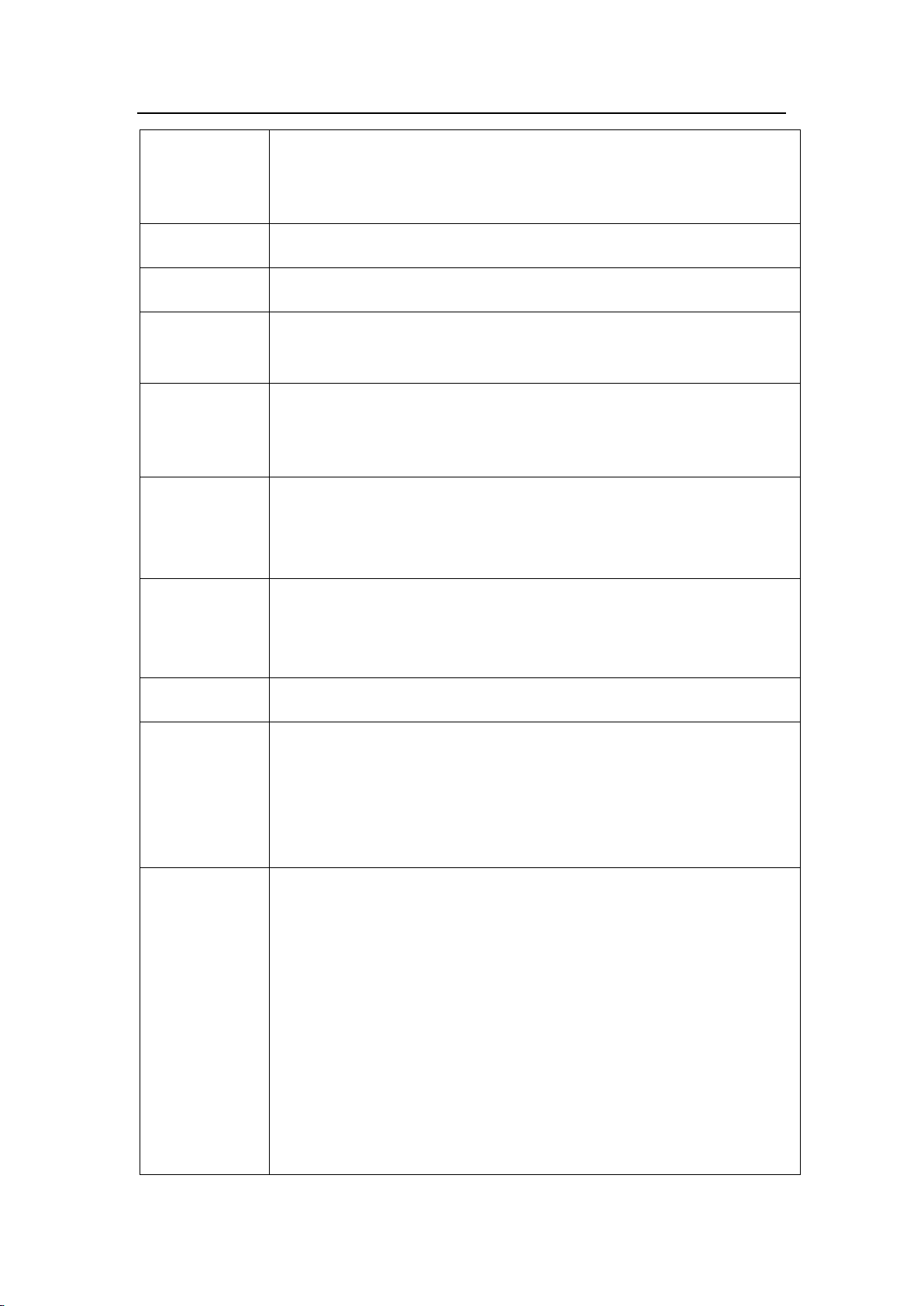

9.4 SYSTEM FAULTS AND TROUBLESHOOTING................................................................................ 36

9.5 CHECK AFTER REPAIR...................................................................................................................... 40

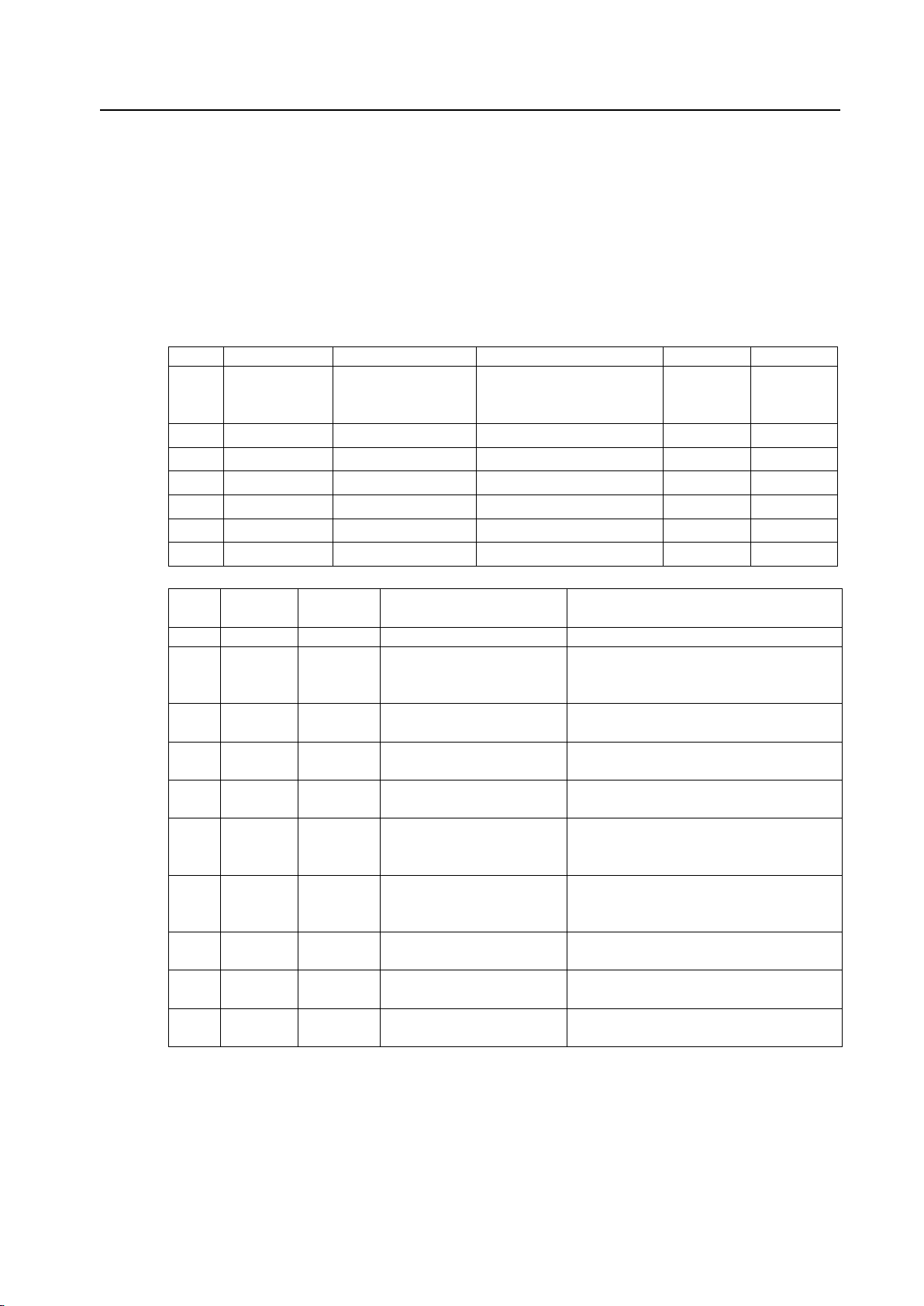

10 DISASSEMBLY AND ASSEMBLY ..................................................................................... 41

10.1 DISMANTLING THE LOWER SHELL SMALL COVER PLATE FOR UPGRADE AND LOWER SHELL

SCREWS 41

10.2 DISMANTLING THE UPPER SHELL AND BATTERY .................................................................42

10.3 DISMANTLING THE MIDDLE PLATE AND LOWER SHELL....................................................... 43

10.4 DISMANTLING THE TRIP POTENTIOMETER............................................................................44