Medora GridBee SN15 User manual

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

O&M_SN15_10030_20200619

GridBee SN15

Owner's Manual

Table of Contents

About Ixom

Ixom combines knowledge and experience from across the water quality spectrum to help solve

real-world problems. Whether in Lakes, Stormwater Retention Ponds, Raw Drinking-Source Reservoirs, Water

Treatment Plants, Potable Storage Tanks, or Wastewater Treatment Processes, Ixom equipment continues to

be at the forefront as the #1 world leader for in-situ water body treatment.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Table of Contents

10014_20200528

GridBee SN15

Owner's Manual

Safety 1

Placement 4

Electrical 6

Startup and Operation 8

Troubleshooting 9

Technical Specifications 10

Exploded Parts Diagram 11

Dimension Drawing 12

Warranty 13

Customer Service 14

O&M_SN15_10030_20200619

Carefully read safety information when you see

any safety symbols.

Be sure you have read all installation, operation, maintenance and safety instructions before

you install, service or begin to operate this unit.

Accidents occur every year because of careless use of industrial equipment. You can avoid hazards

by following these safety instructions, and applying some ordinary common sense when operating or

servicing this unit.

Keep in mind that full operator attention and alertness are required when operating or servicing

this unit.

USE COMMON SENSE!! Most accidents can be avoided by using common sense and

concentration on the job being done.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Safety

Safety

1949_10036_20200528 O&M_SN15_10030_20200619 - 1

IMPORTANT!!!

Follow all federal and state laws in regards to

safety regulations of working at heights, conned

spaces, rescue, etc. as required by the U.S.

Department of Labor, Occupational Safety and

Health Administration. Use necessary PPE when

placing and servicing this unit.

Identify all possible hazards. Determine what

safeguards are needed and implement them.

Only you, the user, understand your product

and system characteristics fully. The ultimate

responsibility for safety is with you. Your

safety ultimately rests in your hands. Do

your part and you will enjoy safe, trouble free

operation for years to come. This instruction

manual is not intended to include a

comprehensive listing of all details for all

procedures required for placement, operation

and maintenance. If you have a question about

a procedure or are uncertain about any detail,

Do Not Proceed. Please contact Ixom

Customer Service at 866-437-8076 to speak

to a representative.

ELECTRICAL HAZARD

WARNING: THIS EQUIPMENT CONTAINS

HIGH VOLTAGE! ELECTRICAL SHOCK CAN

CAUSE SERIOUS OR FATAL INJURY. ONLY

QUALIFIED PERSONNEL SHOULD ATTEMPT

PLACEMENT, OPERATION AND MAINTENANCE

OF ELECTRICAL EQUIPMENT. REMOVE ALL

SOURCES OF ELECTRICAL POWER BEFORE

PERFORMING ANY SERVICE WORK TO THE

MACHINE. USE PROPER LOCKOUT TAGOUT

(LOTO) PROCEDURES TO ENSURE A SAFE

WORK ENVIRONMENT.

Rotating Hazard

CAUTION: KEEP BODY APPENANDAGES OR

LOOSE CLOTHING AWAY FROM EQUIPMENT

WHILE OPERATING. ENSURE EQUIPMENT IS

OFF BEFORE ATTEMPTING SERVICE.

Crush Hazard

WARNING: DO NOT REMOVE ANY FLOAT

ASSEMBLY BOLTS OR PINS WHILE EQUIPMENT

IS FLOATING IN WATER. EQUIPMENT MUST BE

SECURELY SUPPORTED BEFORE PERFORMING

SERVICE.

Laceration Hazard

CAUTION: EDGES MAY BE SHARP AND CAUSE

LACERATION IF PROPER CARE IS NOT USED.

Entanglement Hazard

WARNING: ENSURE THAT PERSONNEL ARE

CLEAR OF THE ELECTRIC CORD AND CHAIN TO

AVOID ENTANGLEMENT.

Thin Ice Hazard

WARNING: ICE SURROUNDING MACHINE MAY

NOT SUPPORT WEIGHT, KEEP CLEAR OF THIN

ICE.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Safety

Safety

1949_10036_20200528 O&M_SN15_10030_20200619 - 2

Permit-Required

Conned Spaces

A conned space has limited openings for

entry or exit, is large enough for entering and

working, and is not designed for continuous

worker occupancy. Conned spaces include

underground reservoirs, ground storage tanks,

elevated tanks, silos, manholes, and pipelines.

Conned Space Tips

• Do not enter permit-required conned spaces

without being trained and without having a

permit to enter.

• Review, understand and follow employer’s

procedures before entering permit-required

conned spaces and know how and when

to exit.

• Before entry, identify any physical hazards.

• Before and during entry, test and monitor for

oxygen content, ammability, toxicity or

explosive hazards as necessary.

• Use fall protection, rescue, air monitoring,

ventilation, lighting and communication

equipment according to entry procedures.

• Maintain contact at all times with a trained

attendant either visually, via phone, or by

two-way radio. This monitoring system

enables the attendant and entry supervisor

to order you to evacuate and to alert

appropriately trained rescue personnel to

rescue entrants when needed.

Refer to 29 CFR 1910.146 for complete

regulations set by OSHA. Refer to your state's

regulations if your state established and operates

their own safety and health programs approved

by OSHA.

Protect Yourself

It is important that you comply with all relative

OSHA and local regulations while installing

and performing any maintenance to the mixer

circulation equipment.

Key OSHA Compliance Standards that must

be followed (and not limited to) are:

• 1910.146 Permit-required conned spaces

• 1910.147 Lockout/Tagout

• 1926.500 Fall Protection

Fall Protection Tips

• Identify all potential tripping and fall hazards

before work starts.

• Look for fall hazards such as unprotected

oor openings/edges, shafts, open hatches,

stairwells, and roof openings/edges.

• Inspect fall protection and rescue equipment

for defects before use.

• Select, wear, and use fall protection and

rescue equipment appropriate for the task.

• Secure and stabilize all ladders before

climbing.

• Never stand on the top rung/step of a ladder.

• Use handrails when you go up or down stairs.

• Practice good housekeeping. Keep cords,

welding leads and air hoses out of walkways

or adjacent work areas.

Refer to 29 CFR 1926.500 for complete

regulations set by OSHA. Refer to your state's

regulations if your state established and operates

their own safety and health programs approved by

OSHA.

Lockout Tagout

When the On/Off switch is in the "ON" position,

the mixer may start up at any time if not already

operating. The mixer's On/Off switch can be

locked out by placing a pad lock thru the door latch

of the controller after the switch has been turned

to the "OFF" position. The On/Off switch is to be

used as the emergency stop.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Safety

Safety

1949_10036_20200528 O&M_SN15_10030_20200619 - 3

Control Panel Secondary Disconnect

& Tank Penetration

Source Power

SN Machine

Submersible cable ran from tank penetration to

SN machine.

Electrical conduit ran to top of tank, 4

Conductors sized according to NEC.

Spray system installed through hatch. Tethered

with dual tether system

Electrical Control Panel located at bottom of

tank.

Blower placed over top of machine.

Blower size depends on tank specics and

application. (Blower shown as roof mount,

certain models may require ground mount.)

Machine safety disconnect located near tank

entry

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Placement

Placement Overview

SN Large Frame Series

10041_20200221 O&M_SN15_10030_20200619 - 4

FRONT VIEW SN DUAL TETHERING

TOP VIEW SN DUAL TETHERING

ROOF CONNECTION DETAIL

4” Diameter Chain Loop

316 Stainless Steel Chain

Approx. 6”

MOORING CONNECTION DETAIL

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

SN Machine

Dual Tethering

Visual Dual Tethering

SN Large Frame Series

2001_10142_20200221 O&M_SN15_10030_20200619 - 5

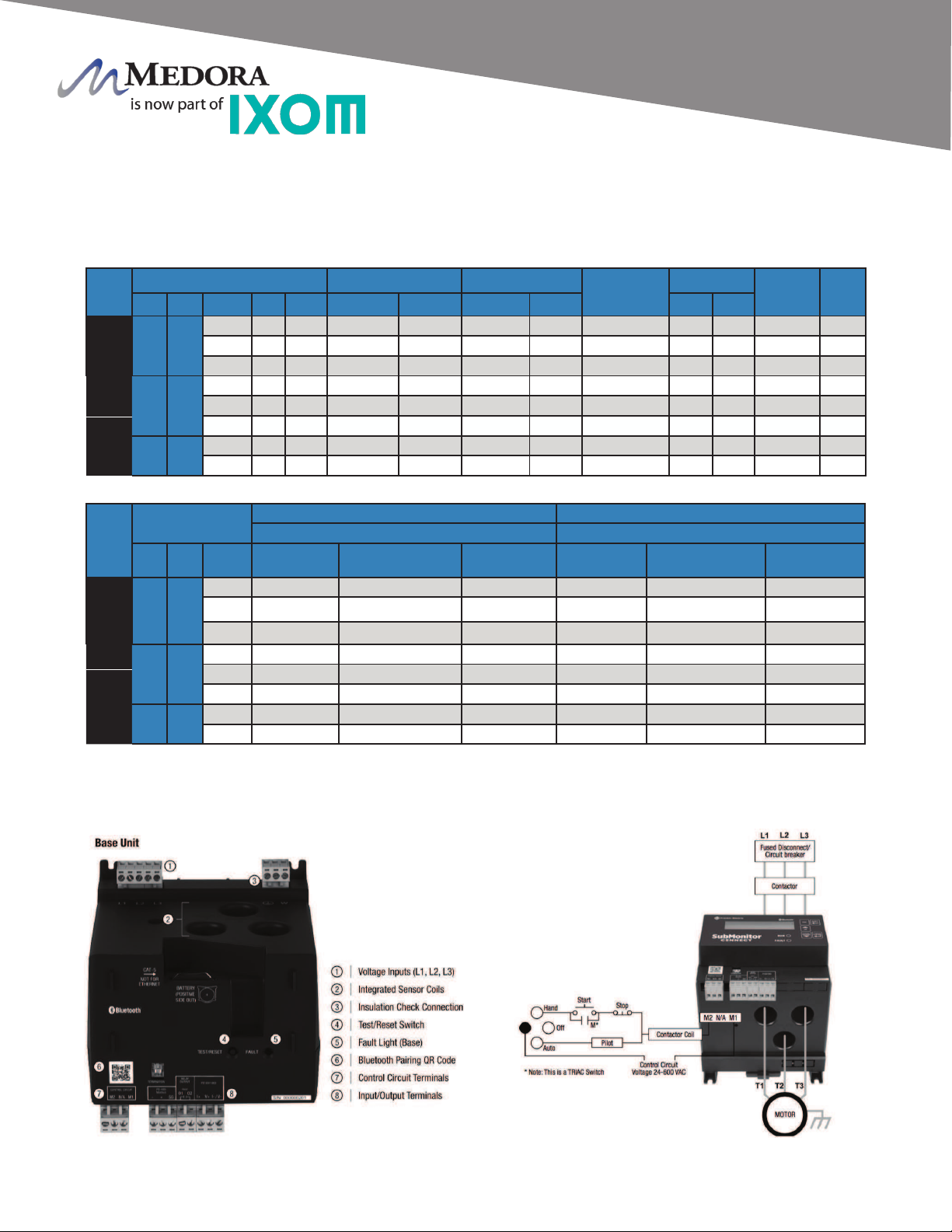

Three Phase Motor Specications (60 Hz) 3450 RPM:

TYPE

RATING FULL LOAD MAXIMUM LOAD LINE TO LINE

RESISTANCE

OHMS

EFFICIENCY LOCKED

ROTOR

AMPS

KVA

CODE

HP KW VOLTS HZ S.F. AMPS WATTS AMPS WATTS S.F. F.L.

4” STD

5 3.7

200 60 1.15 18.3 4800 20.5 5500 .68-.83 78 78 116 K

230 60 1.15 15.9 4800 17.8 5500 .91-1.1 78 78 102 K

460 60 1.15 8.0 4800 8.9 5500 3.6-4.4 78 78 53.7 K

6 ” STD.

10 7.5

230 60 1.15 28.4 9400 32.2 10800 .47-.57 79 79 172 H

380 60 1.15 17.6 9400 19.6 10800 1.2-1.5 79 79 104 H

460 60 1.15 14.2 9400 16.1 10800 1.9-2.4 79 79 86 H

15 11 380 60 1.15 25.8 13700 28.9 15800 .77-.95 81 81 161 H

460 60 1.15 20.8 13700 23.7 15800 1.1-1.4 81 81 133 H

TYPE

RATING CIRCUIT BREAKERS OR FUSE AMPS CIRCUIT BREAKERS OR FUSE AMPS

(MAXIMUM PER NEC) (TYPICAL SUBMERSIBLE)

HP KW VOLTS STANDARD

FUSE

DUAL ELEMENT

TIME DELAY FUSE

CIRCUIT

BREAKER

STANDARD

FUSE

DUAL ELEMENT

TIME DELAY FUSE

CIRCUIT

BREAKER

4” STD &

HI-TEMP

5 3.7

200 60 35 50 60 25 50

230 50 30 40 45 20 40

460 25 15 20 25 10 20

6 ” STD.

10 7.5

230 90 50 80 90 40 80

380 60 35 45 50 25 45

460 45 25 40 45 20 40

15 11 380 80 50 70 80 35 70

460 70 40 60 60 30 60

Three Phase Submersible Motor and Pump Protection Wiring

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Electrical

Three Phase Wiring for THM SN Spray Units

1584_10037_20200619 O&M_SN15_10030_20200619 - 6

TANK PENETRATION IS SEALED WITH

HDPE WASHERS ACCOMPANIED BY

LEXEL® CO-POLYMER RUBBER-BASED SEALANT

CROSS-SECTIONAL VIEW

METAL TANK ROOF

INSIDE TANK

OUTSIDE TANK

ELECTRIC CABLE

1 CORD BOLT PER GRIDBEE:

NUT/GASKET OD: 2.250”

THREADED FIXTURE OD: 1.250”

BORE REQUIRED: 1.3125”

WASHER SEAL, HDPE

STRAIN RELIEF

WASHER

BRASS NUT

316SS UNIVERSAL

FIXTURE

(3/4” NPT FEMALE

THREADS FOR CONDUIT

CONNECTION POINT)

BRASS NUT

T316SS 3/4” MNPT

GLAND SEAL

316SS QUICK LINK

MESH STRAIN RELIEF

INSIDE

TANK

OUTSIDE

TANK

WASHER SEAL, HDPE

MAXIMUM BEARING

THICKNESS: 3.125 INCHES

NOT DESIGNED AS A

SUBMERSIBLE PENETRATION.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Electrical

Universal Fixture Assembly

Tank Penetration

1988_10121_20200221 O&M_SN15_10030_20200619 - 7

Placement Checks

Before starting the SN Spray Unit a few checks need to be done to conrm the placement is correct.

Placement Check Check

Is the SN Spray Unit properly tethered? (Assembly)

Is the cord ran through the cord seal and cord seal tightened at the interior of the cord xture? (Assembly)

Is the top splice between submersible cable conductors and exterior electric conductors insulated from each

other and individually sealed to protect from corrosion? (Assembly)

Is the control panel wired correctly? (Control Panel Diagram)

Is the SN Spray Unit submerged within the minimum water depth required? (Technical Specications)

Is the Motor rotating the correct direction? (See Rotation Check below)

Check Reading

Single Phase Three Phase

Continuity Check (Motor Windings + Splice + Wire)

Reference Wiring for Line to Line Ohms

L1:L2 L1:L2 L2:L3 L1:L3

Discontinuity Check (Power to Ground)

Should be Open to Ground

L1: GND L1: GND L2:GND L3:GND

Source Voltage Reading (while unit is running) L1:2 L1:2 L2:L3 L1:L3

Amperage Reading (while unit is running)

Reference Wiring Full Load / Max Load

L1 L1 L2 L3

Flow Check Auditory

Flow Check Visual

Final Checks

Now that the install checks have been completed. Now to conrm the continuity and discontinuity and then

start the SN Spray Unit.

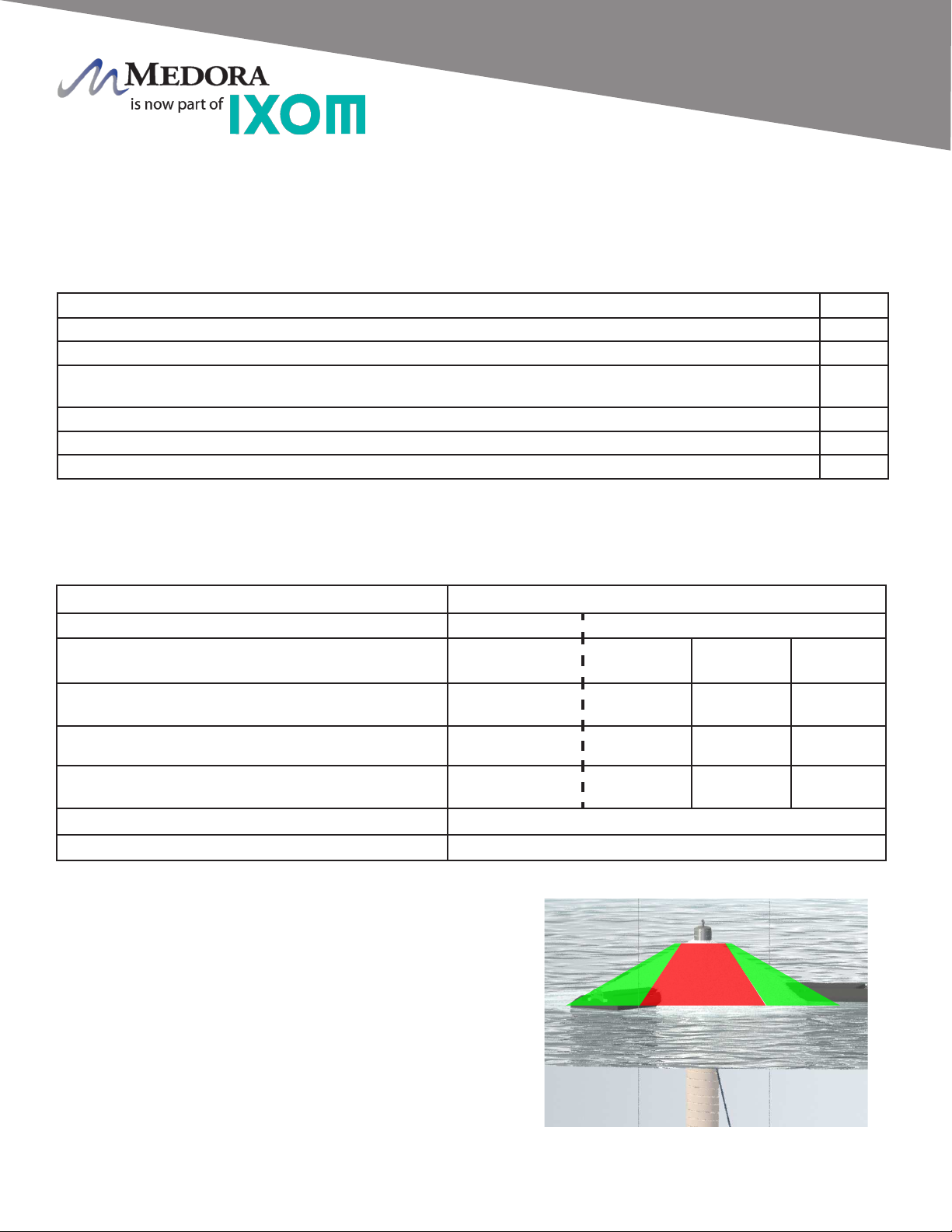

Rotation Check - (Three Phase Only)

Before nalizing the placement, the motor rotation needs to

be checked. With someone observing the SN Spray Unit,

briey turn the unit on for several seconds and observe the

ow pattern, look for how far out the spray reaches. Turn unit

off, isolate power, and have a qualied person switch 2 of the

3 motor leads of outgoing power. Repeat operation again for

several seconds and observe the SN Spray Unit ow pattern

again. Determine which wiring conguration produced the

ow pattern that reaches out the furthest and nalize with that

wiring of the outgoing power leads. See Figure 1 for proper

ow direction. Figure 1: Flow Check

REVERSEFWD FWD

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Startup and Operation

SN Startup and Operation

Wiring

10103_20200221 O&M_SN15_10030_20200619 - 8

Operation

For suspected issues regarding SN Spray Unit operation, observing and recording motor current and voltage

during operation is a good starting point. The normal operating values can be referenced from initial Startup &

Operation records and/or from the Wiring document. In addition to motor voltage and current measurements,

with power isolated, continuity (ohm) value measurements are helpful in pinpointing issues.

Check Reading

Flow Check Visual

Flow Check Auditory

Electric measurements should only be performed

by qualied personnel

Single Phase Three Phase Only

Source Voltage Reading (while unit is running) L1:L2 L1:L2 L2:L3 L3:L1

Amperage Reading (while unit is running)

Reference Wiring Full Load / Max Load

L1 L1 L2 L3

Continuity Check (Motor Windings + Splice + Wire)

Reference Wiring for Line to Line Ohms

L1:L2 L1:L2 L2:L3 L3:L1

Discontinuity Check (Power to Ground)

Should be Open to Ground

L1: GND L1: GND L2:GND L3:GND

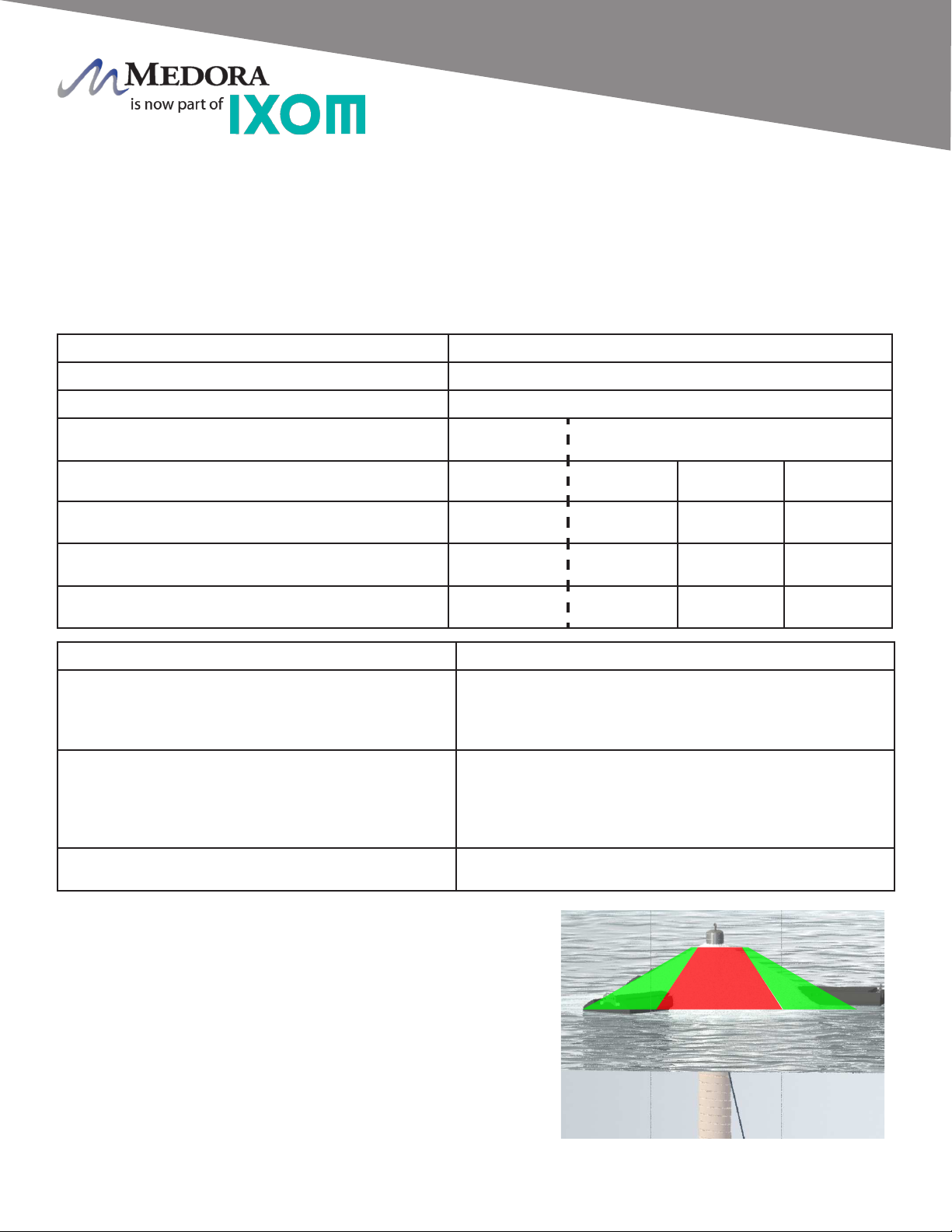

Figure 1: Flow Check

REVERSEFWD FWD

Symptom Possible Issue / Remediation

Motor Amperage is low Blocked pump inlet screen, clean debris from inlet

Blocked spray nozzle(s), clean spray nozzle(s)

Broken, severely worn coupling between pump and motor,

pump and/or motor replacement

Motor Amperage is high Low / Unbalanced line voltage, check source power

Phase loss, check source power

Short to ground, check continuity to ground leads, bad electric

cord, splice, or motor failure, replace faulty component(s)

Motor or pump failure, replace motor and/or pump

Fault Message from Three-Phase Motor

Protection device

Reference motor protection device manual for detailed

problems/conditions resulting in fault message.

Rotation Check - (Three Phase Only)

If wiring was disconnected during troubleshooting steps, the

motor rotation needs to be checked. With someone observing

the SN Spray Unit, briey turn the unit on for several seconds

and observe the ow pattern, look for how far out the spray

reaches. Turn unit off, isolate power, and have a qualied

person switch 2 of the 3 motor leads of outgoing power.

Repeat operation again for several seconds and observe the

SN Spray Unit ow pattern again. Determine which wiring

conguration produced the ow pattern that reaches out the

furthest and nalize with that wiring of the outgoing power

leads. See Figure 1 for proper ow direction.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Troubleshooting

SN Troubleshooting

1981_10044_20200527 O&M_SN15_10030_20200619 - 9

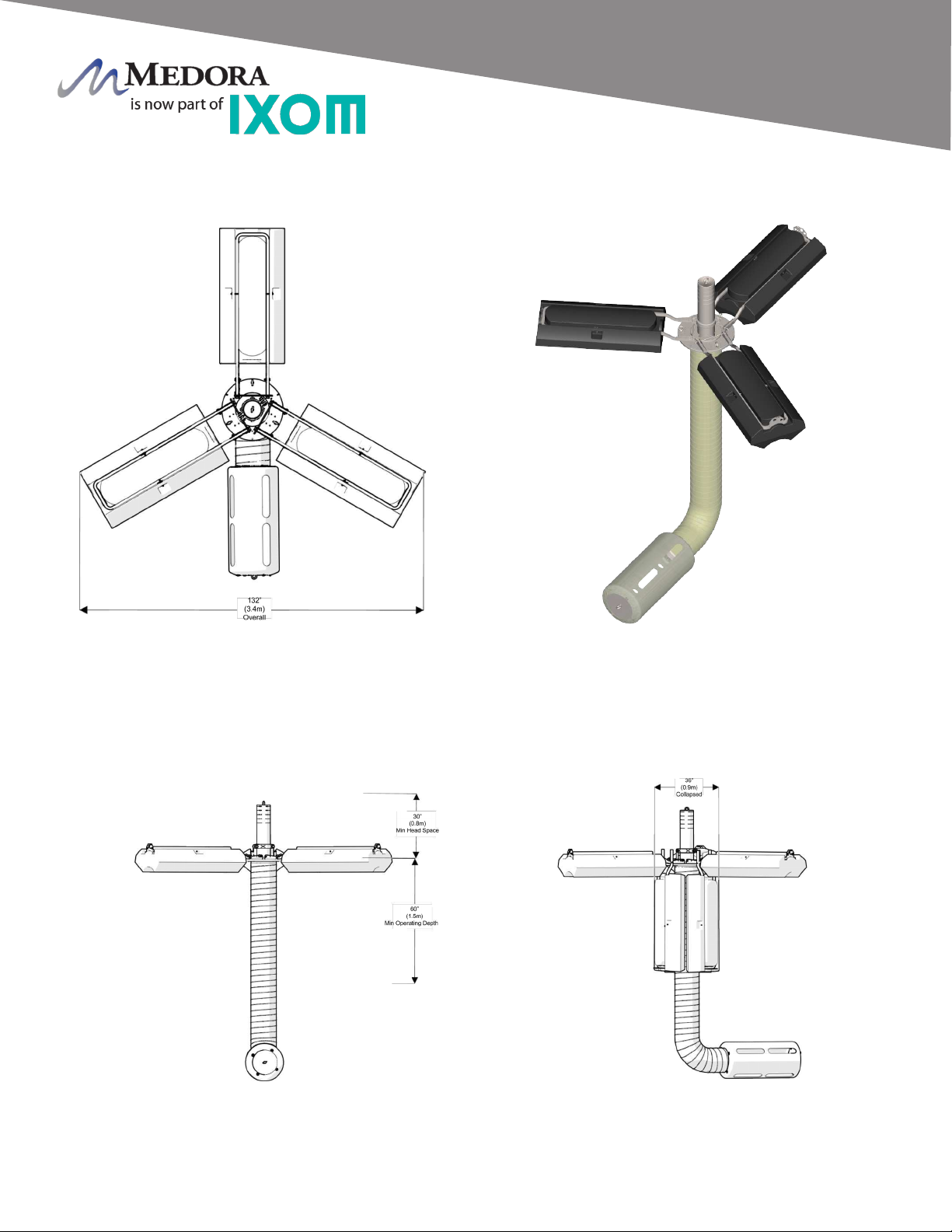

Technology Description- Floating, electric powered, circulation and Trihalomethane (THM) removal equipment for

potable water tanks and reservoirs. Designed for continuous operation and Factory installed through 24-inch diameter,

clear and unobstructed hatch opening.

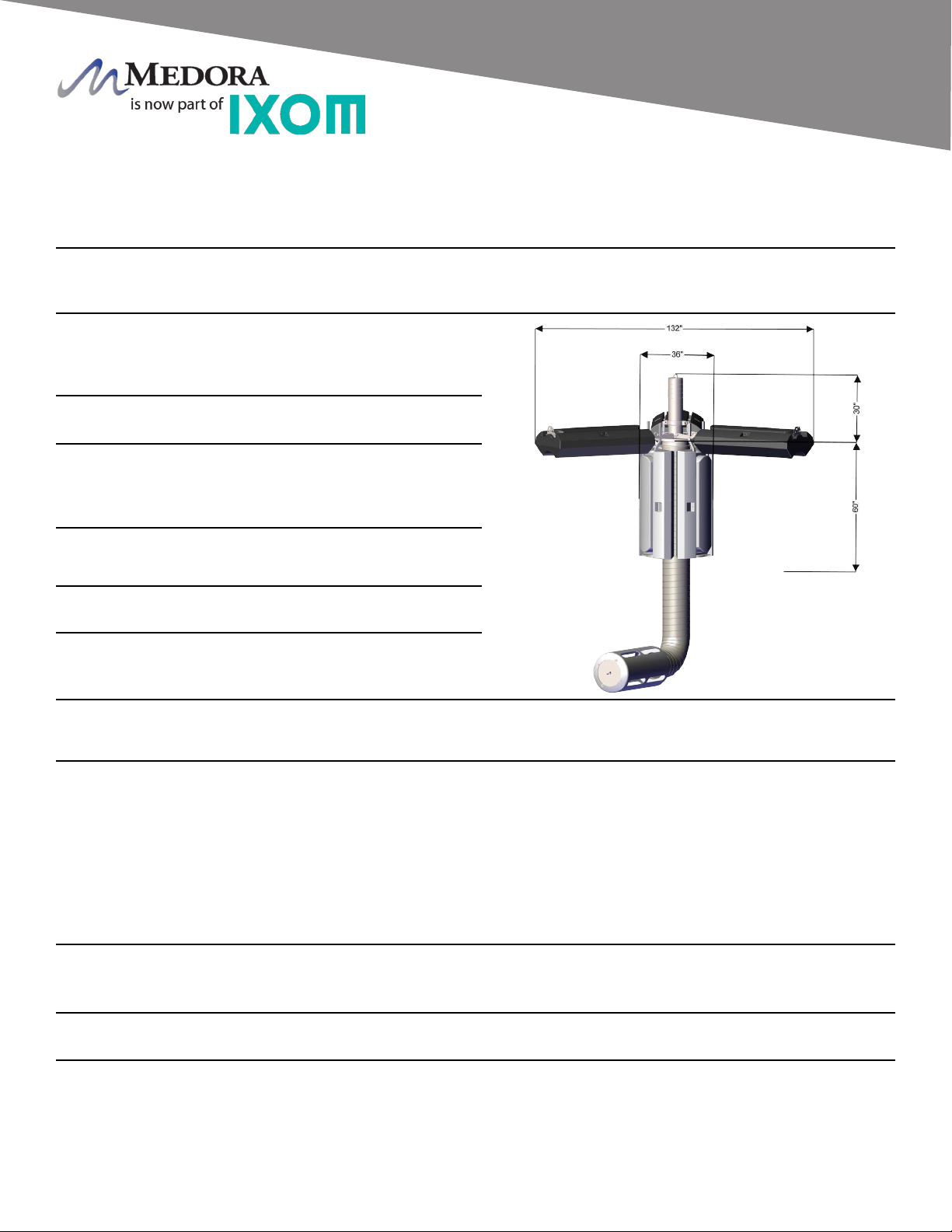

Figure 1: SN15

Electrical Requirements - Requires 480VAC/3PH, 60Hz power. Ixom recommends secondary disconnect to be

located near equipment access hatch. Optional Franklin SubMonitor Connect three-phase motor protection unit highly

recommended and available from Ixom. All switches, breakers, emergency stop buttons, control panels and other controls

shall be installed in accordance to all NEC, State, and local regulations. (Not supplied by Ixom)

Patent Pending Subject to change without notice.

Certications - Ixom’s potable water products are certied to ANSI/NSF Standard 61, and 372 for lead-free content.

Learn more at: www.medoraco.com/std61

Maintenance / Warranty - Limited maintenance. Limited 2-year parts and labor warranty. See Warranty Statement for

details.

Spray Unit Direct Flow Rate - 1.1 Million Gallons Per Day,

MGD. Ixom application engineering evaluations often require

sizing systems based on site specic conditions and NOT

the spray aeration direct ow rate.

Minimum Water Depth - Minimum of 5ft (1.5m) operating

depth required, do not operate out of water.

Minimum Head Space - Minimum of 30in (76cm) head space

between water level and reservoir/tank ceiling required.

(Contact Ixom for exceptions that can be made.)

Sealed Penetration Fitting - T316 stainless steel tank tting with a 3/4” NPT female connection. Not designed

as a submersible penetration.

Wiring - 4-conductor, submersible power cable for submersible motor wiring terminated exterior at top of tank.

Motor - 15HP stainless steel submersible, designed for continuous operation, low power requirement, direct drive,

no gearbox and no lubrication schedule required. See certications section below.

Materials of Construction - T316 stainless steel,

thermoplastic rubber, High Density Polyethylene construction.

GridBee® Machines are constructed using safe materials for

contact with potable water. See certications section below.

TTHM Reduction Range - Dependant on THM Species,

Daily Inow and other variables, see Ixom for proposal.

Minimum Access Opening - Machine can be placed

through 24-inch (61 cm) diameter, clear and unobstructed

hatch opening.

Intake - 20 to 100+ feet (6 to 30+ m) available in 12-inch (30.5 cm) diameter X 20 feet (6 m) sections, thermoplastic

rubber, NSF/ANSI 61 approved. Includes low elevation intake that draws water in a horizontal layer within 18 inches

(45 cm) of the tank or reservoir oor. Includes intake retrieval chain constructed of 316 stainless steel.

Shipping Size / Weight

• Crate - 72in x 48in x 59in (1.85m x 1.22m x 1.5m) / 1200lbs (550kg) Exact weight and dimensions varies dependent

on machine conguration.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Technical Data Sheet

SN15

1555_10015_20200422 O&M_SN15_10030_20200619 - 10

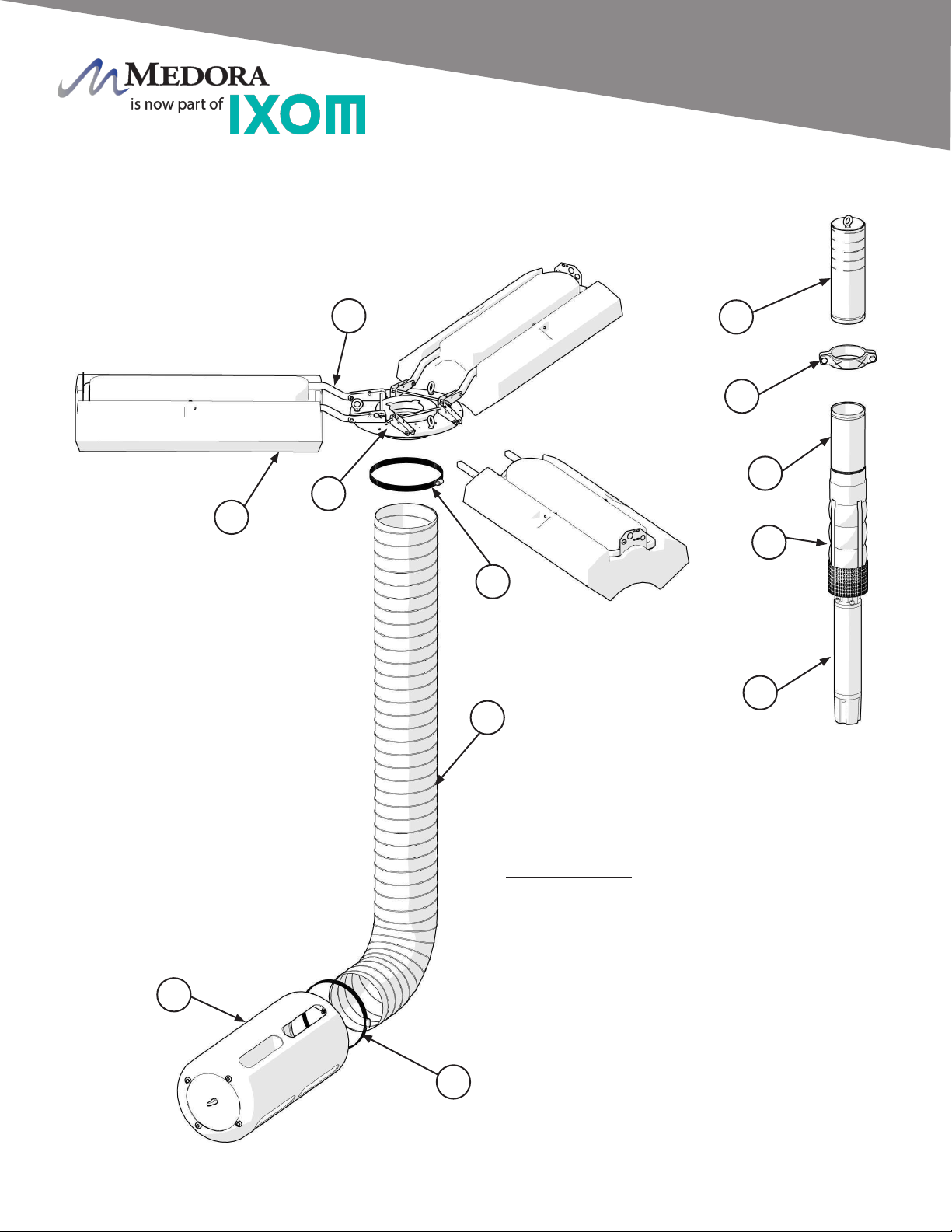

General Notes:

1. PN: 100688 - 3DX Spray Nozzle Assembly

2. PN: 16013206 - Groove Coupling 6”

3. PN: 100211 - Discharge Pipe 6”

4. PN: 20013017 - SN15 Pump

5. PN: 20013019 - SN15 Motor (460vAC/3-Phase)

6. PN: 100541 - Platform Assembly

7. PN: 100284 - Collapsible Float

8. PN: 100395 - Float Arm

9. PN: 26061220 - NSF Hose 12” x 20’

10. PN: 16013107 - Hose Clamp 12” (2 - 6” Clamps)

11. PN: 101464 - Intake Assembly

08 01

06

10

09

07

05

04

02

03

10

11

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Exploded Parts Diagram

SN15

Exploded Parts Diagram

1581_10039_20200221 O&M_SN15_10030_20200619 - 11

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Dimension Drawing

SN15

Dimension Drawing

1552_10034_20200221 O&M_SN15_10030_20200619 - 12

GridBee SN Spray Units. GridBee SN Spray Units and blowers are warranted to be free of defective

parts, materials, and workmanship for a period of two years from the date of purchase. The optional

control panels, by other manufactures, are covered by a manufacturer’s warranty of one year from

date of purchase. This warranty is valid only for use of the GridBee THM Removal System in

accordance with the owner’s manual and any initial and ongoing factory recommendations. This

warranty is limited to the repair or replacement of defective components only and does not apply to

normal wear and tear. If the factory’s service crews performed the original on-site placement and

startup, then this warranty also includes labor. Where labor is included, in lieu of sending a factory

service crew to the site for minor repairs, Ixom may choose to send the replacement parts to the

owner postage-paid and may pay the owner a reasonable labor allowance, as determined solely by

Ixom, to install the parts. There is no liability for consequential damages of any type. The warranty

that is submitted and provided with the purchased equipment is the valid warranty.

GridBee control panels, and any optional accessories. These items are considered “buyout”

items for Ixom, and as such include a warranty against defects in material and workmanship for one

year from the date of purchase. This warranty covers parts only, not labor. Parts that are determined

by Ixom to be defective in material or workmanship under normal use during the one year warranty

period will be repaired or replaced. Shipping charges are the responsibility of the customer.

Terms applicable to all equipment. This Limited Replacement Warranty is subject to the terms of

Ixom’s General Terms and Conditions of Sale. In the event of any inconsistency between the terms

of this Limited Replacement Warranty and Ixom’s General Terms and Conditions of Sale, the terms of

this Limited Replacement Warranty shall prevail to the extent of that inconsistency.

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Warranty

GridBee THM Removal Systems Limited Replacement Warranty

1683_10035_20200420 O&M_SN15_10030_20200619 - 13

Ixom employs qualied highly trained Service and Placement Technicians certied to perform the

necessary tasks required to install or remove SolarBee and GridBee circulation equipment

Ixom's specialized Service and Placement Technicians are trained in Conned Space, Fall Protection,

and other related subjects as required by OSHA to perform the necessary work to install or remove

SolarBee and GridBee equipment, and are knowlegeable in the regulations and standards of OSHA.

If you feel the need to service your SolarBee or GridBee circulation equipment, please contact Ixom's

Customer Service Department at:

+1 866 437 8076

Ixom Service & Support

© 2020 Ixom | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Service & Support

1928_10001_20200420 O&M_SN15_10030_20200619 - 14

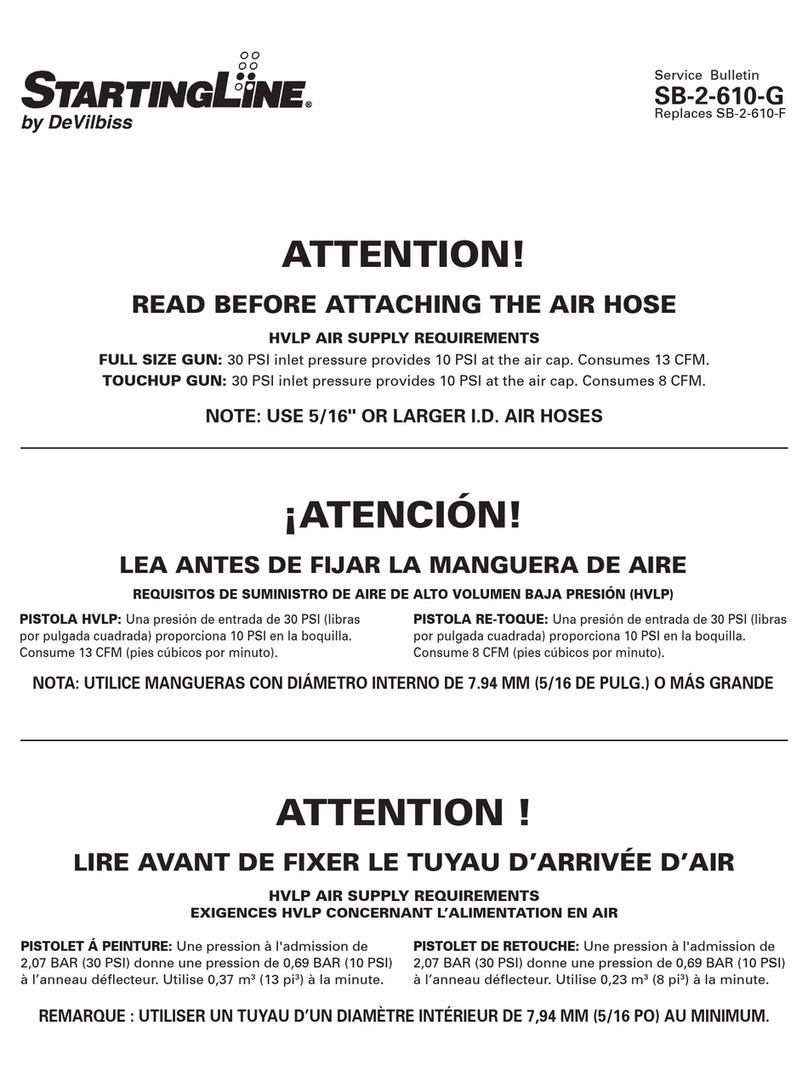

Table of contents

Popular Paint Sprayer manuals by other brands

StartingLine

StartingLine SB-2-610-G instruction manual

3M

3M Scotchkote HSS-450 User instructions

Electro Spray

Electro Spray 3WBJ-8M11 operating instructions

Graymills

Graymills Tempest T-10 Operation and maintenance instructions

WAGNER

WAGNER Super Finish 21 operating manual

Parkside

Parkside 87779 Operation and safety notes

C.A. Technologies

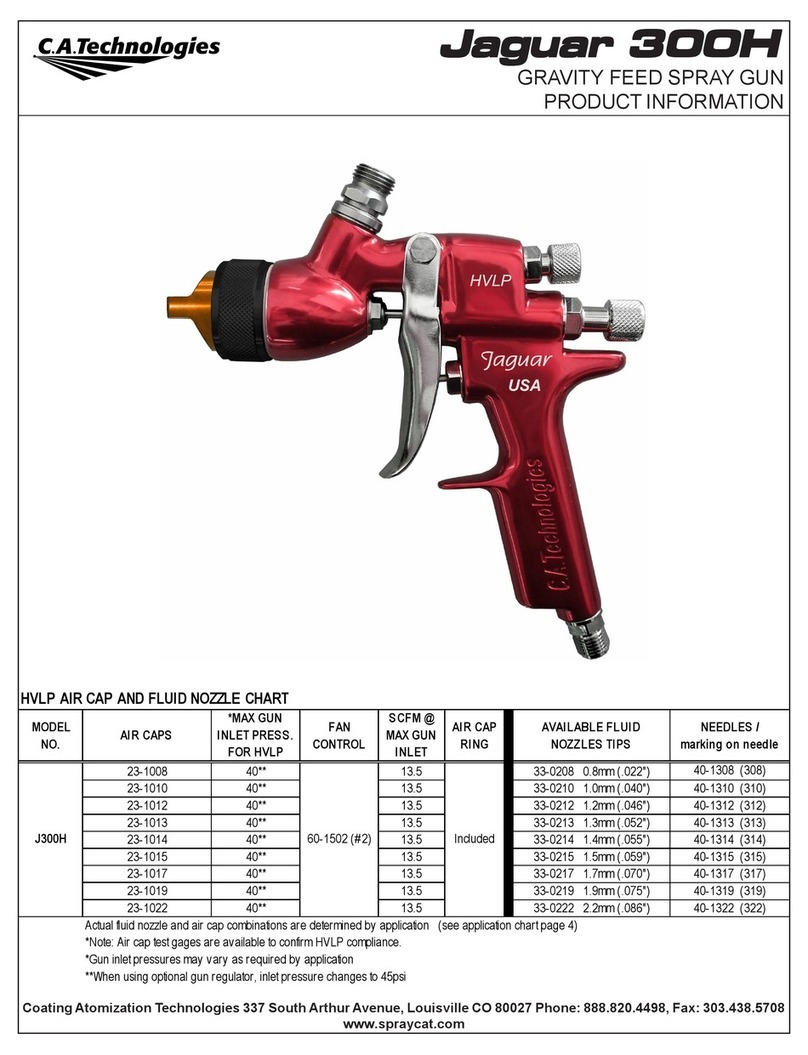

C.A. Technologies Jaguar 300H Product information

Graco

Graco Finex 24C308 instructions

KIRKLAND

KIRKLAND Orvin Mounted Single Sprayer Use and maintenance manual

Hyundai

Hyundai HSPA800-AC Original instructions

IMC

IMC IMCNL-HD-PY02 Series Operation manual

Titan

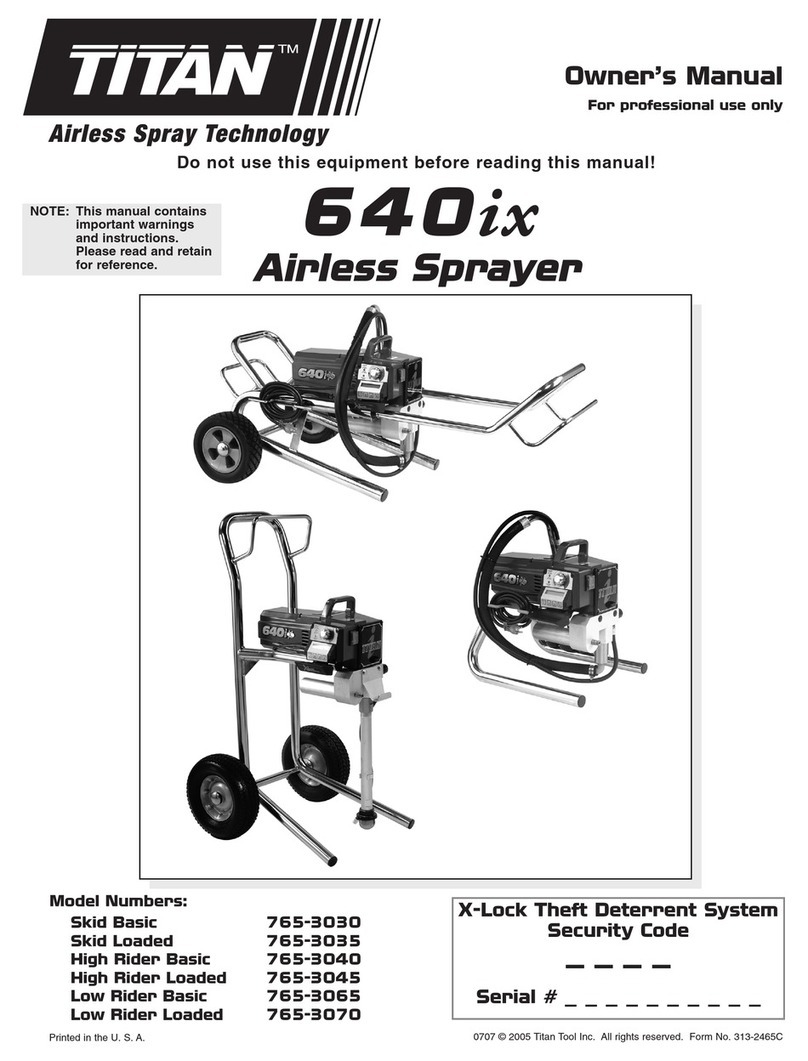

Titan Skid Basic owner's manual