IMC IMCNL-HD-PY02 Series User manual

1

IMCNL-HD-PY02 Series of Oil Spraying

Machinery

INTERNATIONAL MACHINE CONCEPTS WELCOMES YOU TO YOUR NEW

MACHINE

Operation Manual: Date 2015.

2

CONTENTS

Chapter 1

Machine Description 1.1

Uncrating Instructions 1.2

Installation 1.3

Electrical and Pneumatic connections 1.4

Chapter 2

Technical Parameters and Description 2.1

Chapter 3

Operation Instruction

Machine general assembly drawing 3.1

Oil tank subassembly drawing 3.2

Oil spraying machine subassembly drawing 3.3

Chapter 4

Equipment main material list

Table of material list 4.1

Chapter 5

Transportation of the equipment and adjustment of instalation 5.1

Chapter 6

Attention and safety 6.1

Chapter 7

Cleaning and maintenance 7.1

3

Chapter 1

1.1 Machine Description

The machine contain the oil tank components (with the pump), oil conveying pipe, spraying oil

pipe, oil collecting pan, reflow pipe and liquid level control. With compact and briefness

structure, easy dismounting and replace the parts. Easy control, easy operate, low power

consumption, good effect etc.

1.2 Un-crating Instructions

During un-crating make sure that no physical damage to the outside of the crate has taken

place. Carefully break open the exterior panels to reveal the machine and its working parts.

The machine will be covered in a plastic protective cover. This is to be removed. Make sure

that no parts have been damaged during transport, or fallen off the machine. The machine will

arrive with certain parts dis-assembled. These need to be fitted to the machine to resemble

the photos above the machine. The machine is fixed to the wooden palett by four metal

brackets. Remove these brackets and discard or keep for future use. The doors and covers

have been taped closed for safety reasons, these taped parts can now be opened. Surface rust

can take place due to the excessive sea sir during shipping. This will only be surface rust and a

dry cloth should be used to remove this rust residue. The entire machine has bee shipped with

an oil coating on the surface to safeguard the machine from corrosion. This can now be

removed with a very light detergent. The non-stainless steel parts should be re-oiled to

prevent rusting taking place after cleaning. Do not leave the machine wet.

The machine is top-heavy and as such, care should be taken when handling the machine and

removing it from its wooden pallet.

NOTE: DO NOT HANDLE THE MACHINE ON THE FILM BRACKETS OR ROLLERS. These parts are

critically aligned and should they be bent out of position the film may run off.

1.3 Installation

Only a qualified technician should perform the machine installation or a suitably trained

person.

Note: it is dangerous to work on a moving machine and the machine should be off and

isolated before any form of work is performed.

Machine should be placed in a well-ventilated room, free from dust and excessively

corrosive materials.

4

There should be at least 1,5m space around each side of the machine for convenient

operation and maintenance.

Prepare the power supply 380V or 220V/50HZ. Three/Single Phase and neutral, and

connect to an appropriate earth wire.

Pneumatic connections should take place as the designated connection. The air should

not be less than 6Bar while the machine is operational. Air should be free of water and

contaminants.

The machine should be placed on level ground. After installing the machine, check if the

machine is level by Level Instrument. If not, please adjust the four legs.

Check every part of the machine carefully for damage during shipping. Tighten any loose

parts, screws and moving parts.

All gearboxes should be checked for sufficient oil.

Check all electrical connections for loose wires.

Make a test of the machines electrical power and confirm the voltage and earth

continuity. All safety connections relative to your own country should be adhered to.

Before operating the machine, please lubricate the following parts: across sealing bearing

and its bearing holes, longitudinal where sealing the parts needs oil.

1.4Electrical and Pneumatic connections

This machine requires only a single phase connection and earth wire

DISCLAIMER

IMC will not be held responsible fir incorrect installation and subsequent failure of the

machine due to any installation procedure not being followed.

5

Chapter 2

2.1 Technical Parameters and Description

Oil consumption

Be determined by the can number

Topping up of oil way

Manual

Oil supply pipeline

ɸ25.4

Reflow pipeline

ɸ38.1

Total power

0.37Kw

Oil tank parameter

400x400x400mm (L*W*H) ≤64L

Suitable can size

ɸ73H113mm, ɸ65H103mm

Production

Be determined by the production line

Oil spray machine dimension

900x550x1950mm

Oil tank component

890x600x680mm

Oil collecting pan

1600x500x50mm attach the supporting legs

6

Chapter 3

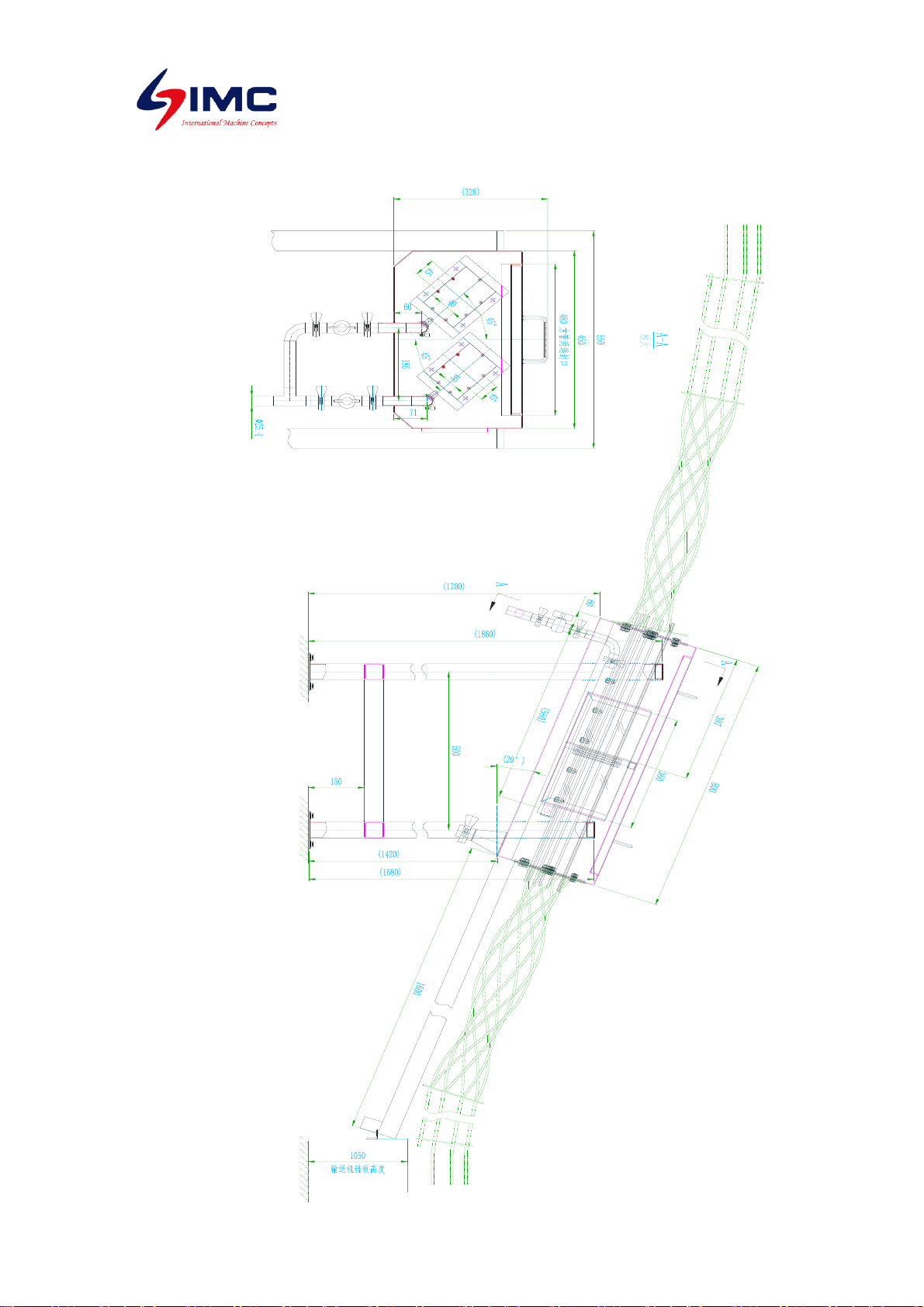

3.1 Machine general assembly drawing

7

3.2 Oil tank subassembly drawing

8

3.3 Oil spraying machine subassembly drawing

9

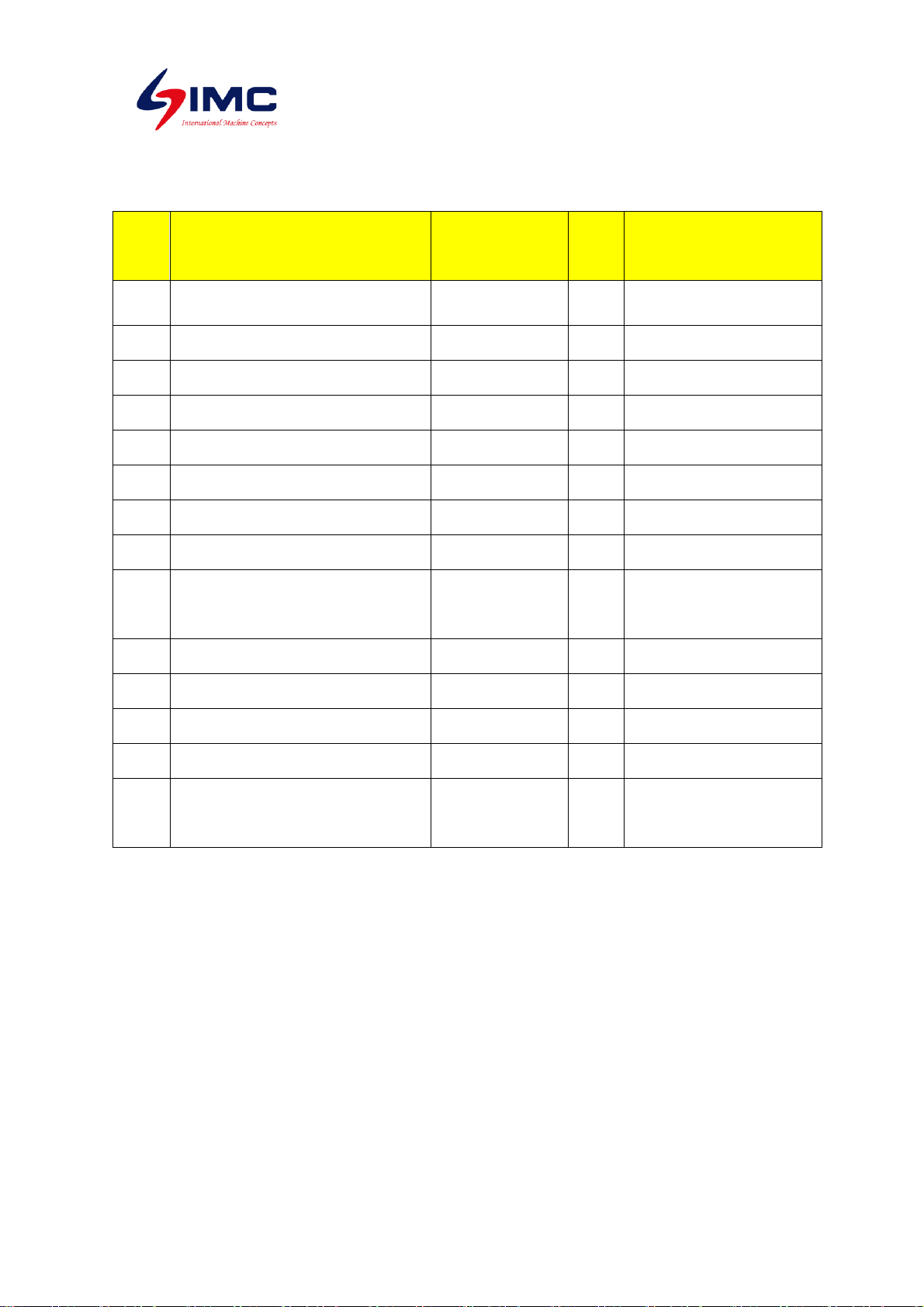

Chapter 4

4.1 Equipment main material list

Item

Name

Specification &

model

Qty

Remark

1

Multi-grade pump P=0.37KW

CH2-30

1

2

3/4″ball valve

304

2

3

1″ball valve

304

1

4

1 1/4″ ball valve

304

1

5

Clamp loose jointФ25.4

304

6

6

Clamp loose jointФ31.8

304

3

7

Clamp loose jointФ38.1

304

5

8

Screw thread loose jointФ25.4

304

1

9

Single-point ball float

valveФ38.1

304

1

10

Oil tank subassembly

304

1

11

Oil spraying machine

304

1

12

Oil conveying pipeline

304

1set

13

Reflow pipeline

304

1set

14

Water collecting pan

304

1

With 304 supporting

legs

10

Chapter 5

Transportation of equipment and adjustment of installation

Packaging:

The machine uses wooden cases or briefness packaging. And the machine has some place

connecting with the packing for fastening, and all the pieces are tied up with transparent

plastic film.

Transportation:

The wooden boxes which contained equipment can't be hit so hard, and it cannot be

dumped and reversed.

There are lifting point and gravity center on the packing box, please comply with them.

When using the forklift to derive must even packing base line.

Equipment installation:

The equipment installation is simple. In general, the main machine can be directly placed on

level ground. If the ground is not level, you can regulate the bolt at the bottom of the

equipment until the body is level up.

After the whole machine position is confirmed, you can connect the external line. The way of

connecting with the external equipment and the circuit can according to the scene situation,

during the period, need to add equipment , when installation, you should notice the location,

direction, etc installing, and make sure operation is convenient. Finally you can connect the

equipment with external power supply and control circuit, and pay attention to the installation

of the power supply circuit and control circuit to avoid the pipeline route, in case that the wire

is heated and affects the normal operation of the equipment. After checked, clean up the

environment around, and get ready to running.

11

Chapter 6

6.1 Attentions and safety

Attentions:

When the machine break down, should immediately notify the special maintenance

personnel

When the equipment is running, you must ensure that no personnel in the danger area

Checks before running:

Every time before start the equipment, should check the fastener screw down or not, at the

same time, to be insure if the tank and the multi-grade pump damage, specific needs

according to the production requirement.

Before start the equipment, pay attention, only under the voltage normal, can start the

machine, don’t start the machine when the voltage too high or too low. At the same time,

should pay attention to the voltage stability, the voltage fluctuation too large will influence

the equipment normal operation.

Every time, before the equipment start, looking over the equipment operate, to insure the

working normal or not.

After the equipment operating for a period, need to screw up the fastener, to avoid be

loose.

Pay attention before maintenance and check the equipment

Cleaning the equipment

Emptying residual water inner the tank, pipeline and the multi- grade pump.

Cutting up the general power

To be ensure the equipment stop already.

To be ensure the next working content.

Put up the maintenance warning brand in the eye appeal.

Pay attention during the equipment operate:

The non-specialized people shall not be arbitrarily remove the electrical component,

control button. At last, when the filled can washing machine in running, cannot to cut up

the multi-grade pump, if you insure to maintenance, must be stop the can feeding before

stopping the equipment.

When the filled can washing machine stop, press the stop button till the system stop

12

operate, can cut off the general power.

Before the equipment maintenance, all the field force need to pay attention:

Before the maintenance and repair because of the leak, please to clean the equipment.

Before maintenance and repairing must emptying the equipment residue liquid.

Safety instruction:

To be ensure the operator’s own life safety, when operating and adjusting the equipment,

please reading carefully the safety instruction section and safety rule, and the usage

regulations of dangerous signal.

The dangerous signal appears in the operate manual contain the follow

meaning: Dangerous: Neglect this signal will lead to damage the life

directly.

Warning: Neglect the signal will lead to the personnel damage and hurt

the life.

Attention: Neglect the signal will lead to personnel damage or break

down the equipment.

Chapter 7

7.1 Cleaning and maintenance

1. After equipment installation, commissioning, equipment and all materials must be pipe for

a thorough cleaning and disinfection, the equipment can be put into production.

2. Pay attention to all parts of the machine normal working or not.

3. Pay attention to check the attrition rate of the wear-out parts, pay attention to replace the

attrition parts at any moment.

4. During the production, should pay attention to the surrounding, to prevent the sundries fall

into the tank, then lead to the pipeline jam or damage the multi-grade pump, to avoid damage

the machine.

Table of contents