MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

Page 3

+617 3283 4536

Free AU 1800 669 006

1. General Safety Guidelines

Before Using This Power Tool

• Always wear hand protecon.

• Keep bystanders out of the work area while operang the tool.

• Wheel guards and eye shields must be properly adjusted and ghtened.

• Always make sure wheels are properly mounted and tension is properly applied.

• Stand to the side of the bandsaw during start-up. Switch it on and let the band operate at full speed for approximately one

minute so that any undetected aws or cracks will become apparent.

• Keep guides in place and working properly.

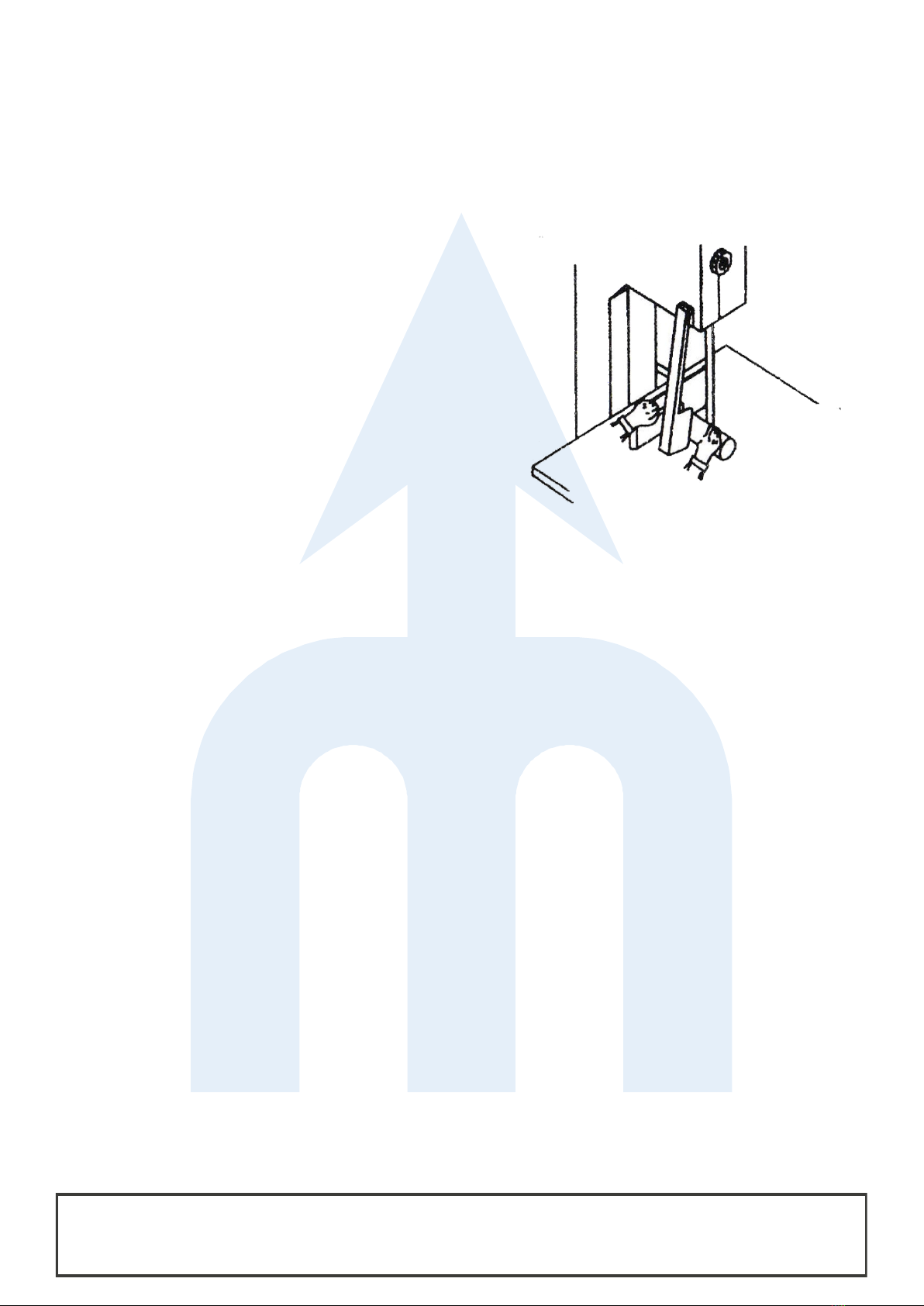

• Keep hands clear of blade wheels.

• Never reach behind or beneath the saw—never reach into or over the table.

• Disconnect power before changing blade or performing any cleaning. Always allow wheels to stop before adjusng or ser-

vicing. Do not stop the wheels with your hands or work piece.

• To avoid electric shock, DO NOT spray direct into motor or submerge machine in water.

• Use only accessories that are recommended by the manufacturer of your model.

• Always check blade is tensioned correctly.

• Grounded tools must be plugged into an outlet that has been properly installed and grounded in accordance with all local

codes and standards. Never remove the grounding prong from the plug or modify it in any way.

• Do not use adapter plugs. If in doubt as to whether the outlet is properly grounded, consult a qualied electrician.

• Do not use the tool when red or under the inuence of drugs, alcohol or medicaon.

• Do not wear loose clothing, gloves or jewellery; e up long hair and buon all long sleeve shirts.

• Ensure the power switch is o prior to plugging in the tool.

• Do not over ghten spindle nuts.

• Service on these tools should only be performed by an authorized, qualied technician.

1.1 Addional Specic Safety Rules

1. DO NOT operate this machine unl it is completely assembled and installed according to the instrucons. A machine

incorrectly assembled can cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or another qualied person if you are not thoroughly familiar with the

operaon of this machine. Knowledge is safety.

3. FOLLOW ALL WIRING CODES and recommended electrical connecons to prevent shock or electrocuon.

4. USE ONLY blades suitable for the product being cut and for the speed of the machine. Unsuitable blades can cause damage

5. DO NOT over ghten wheel nut.