9

4.2 OPERATING PREPARATION

There are several steps will be taken before start the machine.

(1) CHOOSE PROPER SAW BLADE :

Select the saw blade best suited to the workpiece to be cut, Size and shape of the workpiece , and

type of material should all be considered when selecting the saw blade to be used . There is a

reference chart in chapter 7 which can help you to select the right saw blade and cutting conditions .

(2) UNPACK THE SAW BLADE :

Usually the saw blade is packed in 3 circle ,unpack it one circle first grip the part to release another 2

circles gradually , tear off the saw-cap protective shield , inspect the blade teeth , make sure that the

cutting edge of the blade teeth point to the right . If they point to the left the blade should be turned

over.

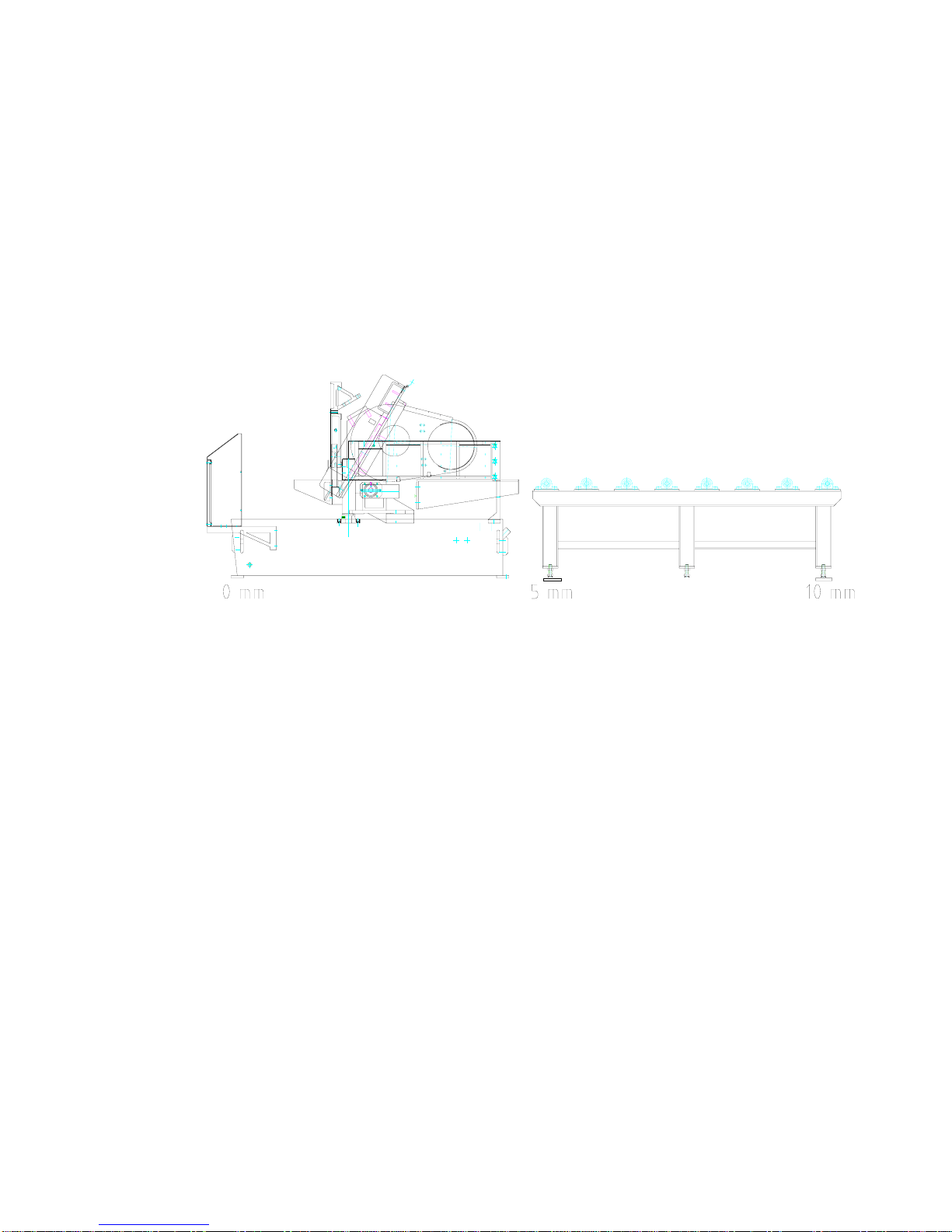

(3) PLACE THE SAW BLADE ONTO BOTH THE DRIVEAND DRIVEN WHEELS ----

a. Turn the hydraulic blade tension handle clockwise , to fully loosen the driven wheel .

b. Open both the drive and driven wheel covers , place the saw blade onto both the drive and driven

wheels. Check the cutting edge of the saw blade , to ensure that it point to the right.

c. Insert the saw blade into both the left and right blade guides so that the back edge of the saw blade

touches the back-up roller of each guide .

d. The back edge of the saw blade should make contact with the flange of the drive and driven wheel ,

turn count -clockwise the hydraulic blade tension handle to tighten the saw blade , Then the blade

is properly tensioned .

e. Don't forget to tighten the insert adjusting screw .

(4) WORKPIECE CLAMPING :

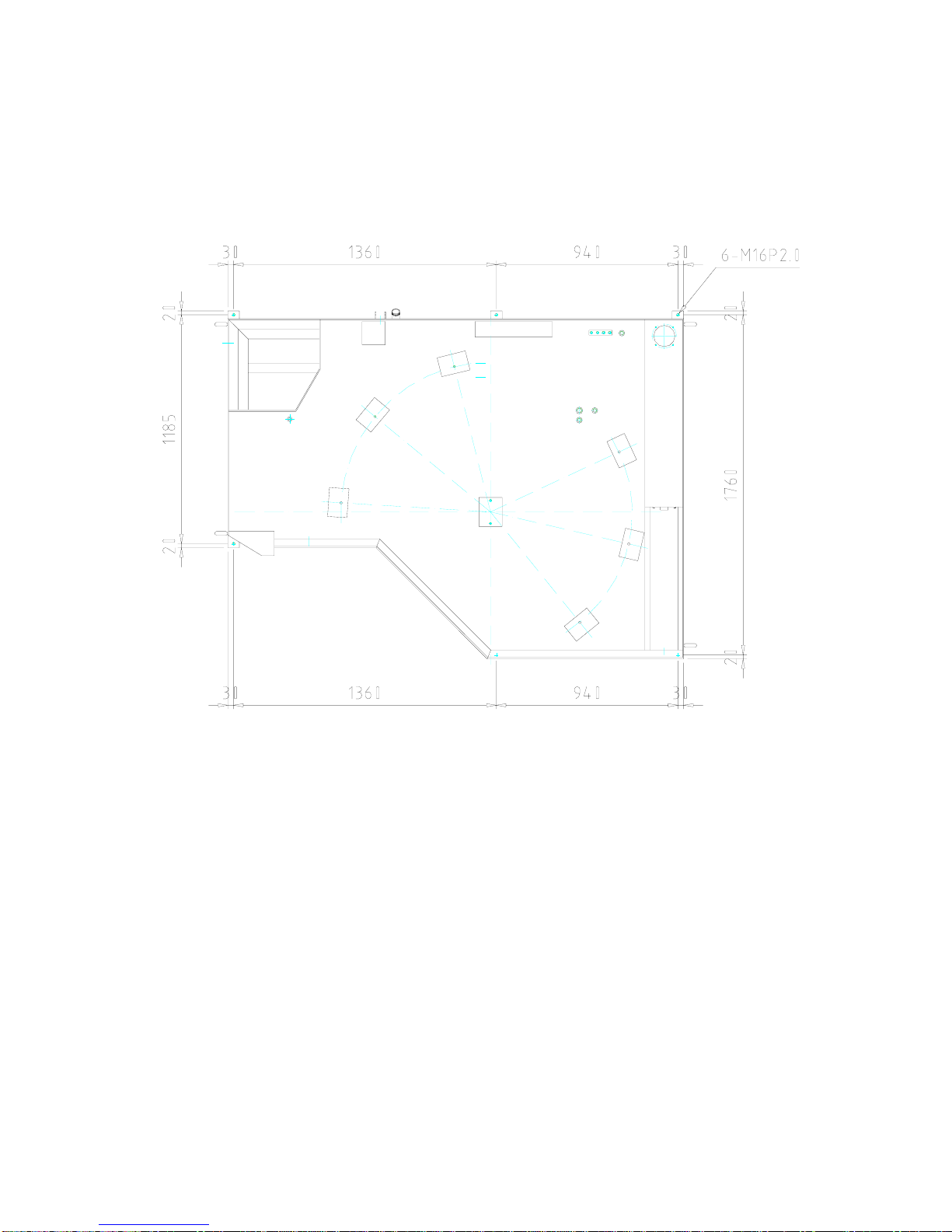

a. Raise the saw frame , open the vise , place the workpiece on the roller table .

b. Gently push the workpiece into the roller-feed vise, taking care not hit the feed rollers.

c. Clamp the workpiece in vise.

(5) ADJUST THE BLADE GUIDEARM :

Properly position the blade guide arms according to the diameter (or the width) of the workpiece to be

cut.

a. loosen the insert adjusting screw.

b. loosen the lock lever of the blade guide arm, and manually move the blade guide arm to suit the width

of material using the scale provided.

c. After adjusting the blade guide arm position ,tighten the lock lever.

d. Finger tighten the insert adjusting screw.

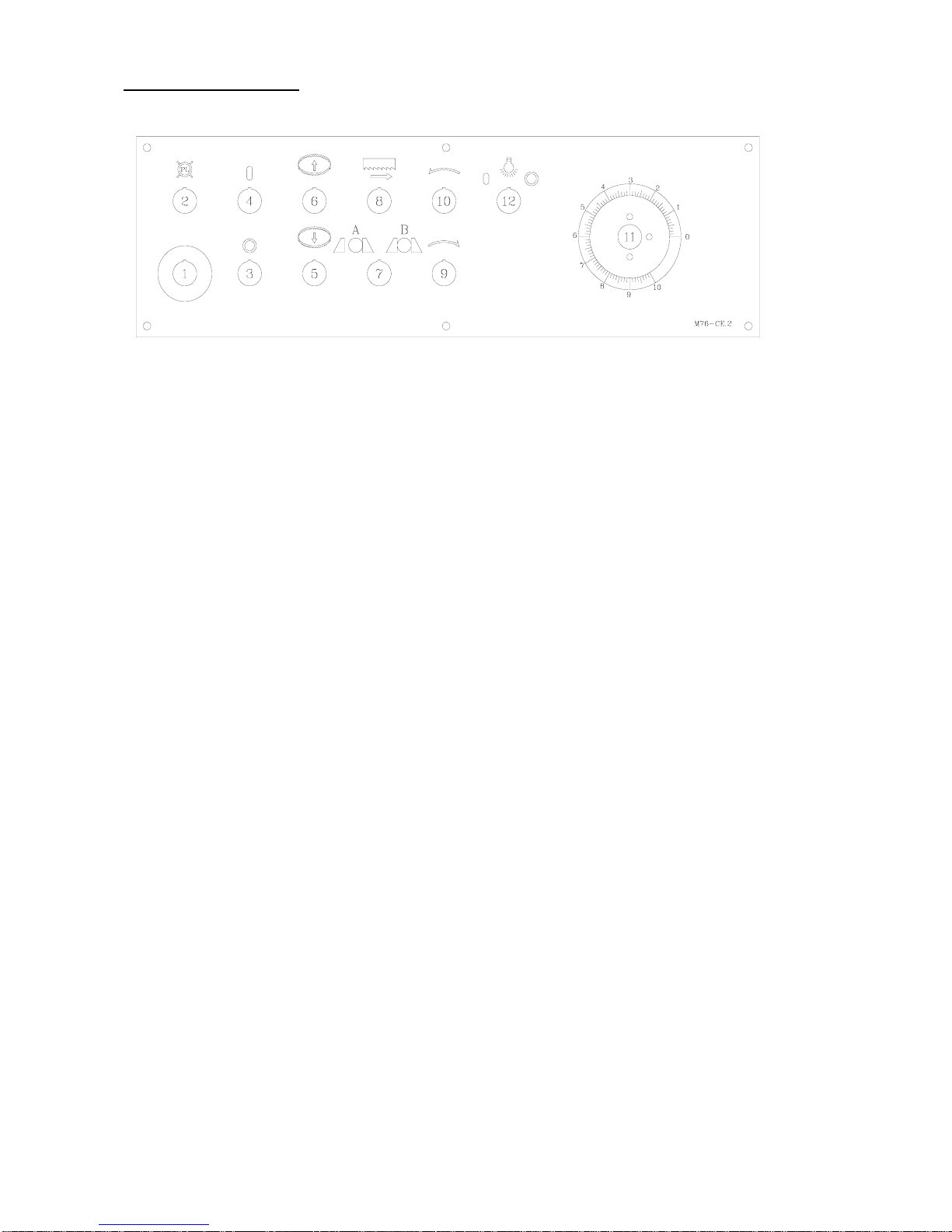

(6) ADJUST THE POSITION OFTHE WIRE BRUSH :

a. loosen the lock lever of the wire brush case.

b. Manually move the wire brush case so that wire brush just contacts the cutting edge of the saw

blade.

c. Tighten the lock lever.

(7) ADJUST THE FEED RATE :

Select suitable feed rate for the workpiece to be cut. This varies according to the size and shape of the

workpiece, type of material , and what type of saw blade is being used. As a guide hard materials, wide

workpiece or structural sections and tubing have to be cut at a slower rate that mild steel bar.

As concerns the saw blade , high speed steel is better than carbon steel, and bi-metal alloy is better than

high speed steel. Roughly the ratio of feed speeds could be 1:2:3